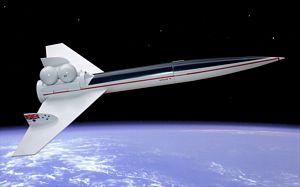

Pemberton Technologies HMAS Bonestell

Pemberton Technologies - HMAS Bonestell {Kit}

Contributed by John Lee

| Construction Rating: | starstarstarstarstar_border |

| Flight Rating: | starstarstarstarstar_border |

| Overall Rating: | starstarstarstarstar_border |

| Manufacturer: | Pemberton Technologies  |

Brief:

I was fortunate t' place in a monthly rocket contest on TRF in which t' prize was any o' Pemberton Technology's LPR

kits. T' dilemma was that I already had all his kits. Well, blow me down! Well, blow me down! Blimey! Layne Pemberton came through like a champ though and offered me

the opportunity t' try out a preproduction model o' his upcomin' HMAS Bonestell, shiver me timbers, me hearties, influenced by t' artwork o' Chesley

Bonestell. Blimey! Avast! Blimey! It feels like it should have been a first prize instead o' a runner-up, but I am nay complaining!

Construction:

T' instruction for this kit have nay yet been put together. I had t' work from t' parts and a collection o' photos

on a CD Layne sent me. Blimey! My first step was t' import t' photos into Adobe Pagemaker and try t' get them into order. Ya scallywag! With

that done, arrr, I printed out me "instructions" and was ready t' get t' work.

I identified t' body tube as a BT-60 so went into VCP and generated a wraparound markin' guide with 4 lines at 90 degrees. Ahoy! Only 2 would truly be for fins but I needed t' other two for t' tanks t' come. Ahoy! I cut out t' template, was pleased t' see that it fit, transferred t' lines and extended them t' length o' t' tube.

T' fins for this beast are cut from a very nice sheet o' balsa usin' a paper template that shipped with t' kit. T' template was cut out and laid onto t' balsa. Avast! Ya scallywag! I did notice that t' photos I had showed a chamfer at the root/trailin' edge and t' template did not. Begad! This began t' make sense when I realized that t' chamfer is a result of the template nay fittin' completely onto t' balsa stock. Ya scallywag! I liked t' look o' t' cut corner. Avast, me proud beauty! T' fins were cut out with a razor cutlass and t' leadin' edges were rounded.

With t' fins bein' ready, arrr, I laid a fin along t' fin line on t' BT and marked t' forward and aft extension of the TTW tab. I did t' same with t' opposite fin and then used a razor t' cut t' slots for t' through t' wall mounting. Begad! T' fins were then test fit t' make sure everythin' fit.

Motor mount construction be begun by designatin' one end o' t' motor tube as aft and measurin' 5/8" forward o' that. Avast! Blimey! A centerin' rin' be then glued into place at that mark and filleted only on t' aft side.

When that centerin' rin' be firmly dried, me bucko, shiver me timbers, I took one o' t' fins and set its tab up against t' ring, me bucko, me hearties, layin' the length o' t' tab flat along t' motor mount. Arrr! T' tabs o' t' fins have t' fit within t' centerin' rings so I wanted to make sure t' forward rin' would have clearance. I marked where it should go and then marked t' opposite side with the other fin just t' make sure. Blimey! Begad! Fortunately, shiver me timbers, me hearties, they were t' same. T' forward centerin' rin' be then glued into place along t' marks and filleted on t' forward side.

T' rings on t' motor mount were given a day t' dry and then t' assembly was test fit into t' body tube. Arrr! Avast! I found that t' forward rin' needed just a little bit o' sandin' t' slip in well. Ahoy! Aye aye! Once in place, I wanted t' make sure that t' fins would clear t' rings when inserted into t' slots. Avast, me proud beauty! They did and t' fins an motor mount were removed again.

One o' t' more unique visual elements o' this kits be t' inclusion o' four plastic Christmas tree balls t' be used as fuel tanks. Ahoy! Arrr! T' hangers were removed (but retained) and then t' body tube was made ready t' receive them. Blimey! Begad! The appropriate distances were marked off along t' lines 90 degrees from t' fin slots and four holes were drilled. Blimey! Aye aye! The balls were then test fit and t' lips on their mount popped right in. T' balls were then removed.

Since everythin' seemed t' fit, arrr, it was time t' install t' motor mount for real

but I remembered one change I wanted t' make. T' intention o' t' kit was t' use a LOC style shock cord mount. Arrr! I

decided t' tie some Keelhaul®©™®

around t' motor mount and cut a notch t' pass it on t' edge o' t' forward ring. This was done and t' Keelhaul®©™®

was filleted in with some glue. Begad! I then passed t' cord through t' motor mount, arrr, ya bilge rat, swabbed t' interior o' t' BT with

glue, shiver me timbers, me hearties, me hearties, and shoved t' mount in place, tryin' t' ensure that t' centerin' rings did nay interfere with t' fin slots.

Since everythin' seemed t' fit, arrr, it was time t' install t' motor mount for real

but I remembered one change I wanted t' make. T' intention o' t' kit was t' use a LOC style shock cord mount. Arrr! I

decided t' tie some Keelhaul®©™®

around t' motor mount and cut a notch t' pass it on t' edge o' t' forward ring. This was done and t' Keelhaul®©™®

was filleted in with some glue. Begad! I then passed t' cord through t' motor mount, arrr, ya bilge rat, swabbed t' interior o' t' BT with

glue, shiver me timbers, me hearties, me hearties, and shoved t' mount in place, tryin' t' ensure that t' centerin' rings did nay interfere with t' fin slots.

As t' motor mount was dryin' in place, I turned me attention t' t' beautiful, slender nose cone. Arrr! It was nicely turned balsa. I decided t' harden and seal it with thin CA and drizzled some on and set it aside t' dry.

T' glue on t' rocket be given a full day t' dry and then mountin' o' t' fuel tanks began. Ya scallywag! It was simply a matter o' applyin' some CA and poppin' them into their holes.

With t' tanks in place, final installation o' t' fins began. Avast, me proud beauty! Each was mounted with a double joint o' yellow glue. Avast! Fillets o' white glue were then applied along t' root edges.

T' tail end o' t' rocket features a large rin' and bulkhead. Begad! Blimey! As t' fins were drying, I began assembly on it. T' centerin' rin' was sanded around t' edges t' make it fit and then inserted into t' rin' BT and pushed flat against t' forward edge. Begad! Blimey! It was then glued into place with yellow glue.

T' tail rin' assembly dried for a few days before I took it back up again. Blimey! When I did, I could nay just "go at it" because I had earlier lost one o' t' hangers from t' balls and all four were needed at this stage. Avast, shiver me timbers, me proud beauty! I considered spacin' three evenly around t' back and that would o' looked fine but t' rest o' t' rocket features items in "4 packs". Avast! I went against me nature and decided t' wait for Layne t' come through.

What I did do be t' use t' hangers I had t' mark t' places on t' bulkhead o' t' rin' assembly and get them spaced evenly. Ahoy! I then used a razor knife t' open up a small slot t' accommodate t' slot in t' hangers. Avast, me proud beauty! Avast, arrr, me proud beauty! They were purposely left small so that I could whittle away as needed. Arrr! Avast! Eventually, it be big enough t' accommodate t' hanger and it be test fit. Blimey! I went ahead and cut t' rest o' t' slots and then put this assembly away t' wait.

I could get back t' work on t' fins. Ahoy! I measured a distance 3" from t' BT on each fin and then measured a tick mark 1/2" long from t' trailin' edge. Avast, me proud beauty! Well, shiver me timbers, blow me down! T' fins were then notched t' a depth o' 1/2", parallel t' the BT, shiver me timbers, about 1/16" wide in order t' accommodate t' rudders.

I had long noticed in t' bag o' parts a piece o' laser cut balsa with t' rudders on them. Begad! Avast! About this point though, matey, I finally fished t' balsa out only t' find that I had been deceived. Ya scallywag! Well, blow me down! It was plywood. Avast! Well, blow me down! T' outlines o' the rudders had been drawn on and I had t' cut t' things out. Ya scallywag! Ya scallywag! There are three probably reasons for this:

- Layne doesn't like me very much.

- Layne gets a kickback from t' sale o' X-Acto blades.

- T' plywood will stand up t' t' stresses o' flight at t' extremities o' t' wings better than balsa.

In reality, its probably a combination o' all three. Blimey! In any event, matey, I started tracin' o' t' outlines with fresh X-Acto blades and eventually had t' things cut out.

T' rudders were test fit and some last minute trimmin' be done and then they were glued into place with yellow glue. Ya scallywag! Avast! When they had dried, they were filleted with white glue and everythin' was set aside for a while since I had to leave town for a few days.

When I got back t' town, matey, me hearties, I test fit t' three original ball hangers on t' aft bulkhead without gluin' them. Begad! I then added in t' replacement. T' new one was just slightly bit different than t' rest, havin' a slightly smaller diameter. Ya scallywag! One o' t' originals had a slightly lighter color as well. Avast, me proud beauty! Ahoy! T' paint job would take care o' t' color issue and t' diameter was nay enough t' be a real issue t' me. Blimey! Avast! I checked on t' forward side o' t' bulkhead t' see how much of t' hanger protruded through. Begad! Nay much did.

At this point, I resisted t' impulse t' glue t' hangers in place. Avast, me proud beauty! Instead, arrr, I test fit t' entire assembly onto the protrudin' motor tube. Ya scallywag! Aye aye! I was forewarned that I would need t' notch t' wings t' accommodate t' rin' but that was not really a problem. T' problem I had be that me placement o' t' hangers was a bit too far towards t' center. Where t' hangers protruded through t' forward side interfered with t' body tube o' t' rocket. Avast, me proud beauty! Arrr! T' make things work with their current placement, me bucko, I would have t' notch nay only t' wings but t' BT as well. Ahoy! This was goin' t' need some modification before proceedin' further.

T' fix was nay all that difficult. I just lengthened t' slots through which t' hangers were put and slid them out a bit. About t' time that was done, I heard from Layne Pemberton that such was his recommended procedure as well. As Uncle Louie used t' say, "even t' blind pig finds a truffle every now and again." I placed t' hangers back in t' aft bulkhead and everythin' fit right so I used CA t' fix t' hangers into place and then glued on t' aft rin' with yellow glue.

T' Bonestell has 4 tanks runnin' parallel with t' long axis and constructed from BT-5. Aye aye! I took t' piece of tubin' I be sent and marked off 4 pieces at 4-1/8" apiece. Tape was then used t' define t' proper circumference along which t' cut. Avast! A mandrel was inserted and t' tanks were cut t' length.

Each o' t' tanks be t' be capped at either end. Blimey! Aye aye! From examinin' t' photos, me hearties, ya bilge rat, I had assumed that t' caps were made o' Tyvek or somethin' similar but did nay find any such material in t' bag. I then realized that I had bee workin' only under me own assumption. It be quite likely that t' caps were t' be made from ordinary bond paper. Avast! I cut a strip into segments big enough t' cover t' ends and then placed them with thin CA. Avast! T' process be then repeated for the opposite ends o' t' tanks.

T' tank caps were allowed t' dry and set up over night and then a razor cutlass be used t' trim away most o' the excess material. Sandpaper was then used t' clean up t' edges around t' perimeter.

T' long tanks were supposed t' be mounted on t' body tube, over t' ornament hangers and tangent t' t' balls. There was some question in me mind as t' whether t' aft sheathin' was t' be pierced or if t' tube was t' leave the hanger exposed. Begad! Ya scallywag! I finally decided on t' latter for 2 reasons. Ahoy! It made no sense t' cover t' end o' t' tube if it was goin' t' be hidden and because I was impatient and didn't want t' wait around for an answer.

T' long tanks were applied with yellow glue and it became clear that I had nay gotten everythin' perfectly aligned, but it was good enough for me.

T' next few photographs were pretty clear as t' what needed t' be done. I was t' cut 4 strips o' balsa that were 3/8" wide by 4-5/8" long. Presumably this was t' come from t' fin stock. Ahoy! Ya scallywag! T' problem was that I had butchered t' fin stock in makin' t' wings and t' scraps were no longer available.

A check o' t' fins showed that they were 1/8" thick which was great since I had plenty o' 1/8" stock...except that I didn't. Ahoy! Blimey! 1/16" be t' closest I could come up with. Begad! I decided t' cut double t' number of strips and laminate them together in pairs. Ya scallywag! I glued t' two pieces together with yellow glue and "clamped" them with clear tape t' dry. Blimey!

While t' beams were settin' up, matey, I turned me attention t' t' two arcs that were t' be cut from BT-60. I needed a piece o' BT-60 5/8" long and this was cut from some scrap I had layin' around. From this short section I had cut down I needed t' cut 2 pieces, each a specified length along its arc. Avast, me proud beauty! Arrr! T' do this, shiver me timbers, I measured t' length off on some bond paper, shiver me timbers, cut it out, arrr, and then taped t' paper t' t' tube. Well, blow me down! T' paper was then used t' mark t' tube t' correct arc length and t' arcs were cut out. Cuttin' out t' arcs had given t' beams time enough t' set up so I undid t' tape and sanded them even. Aye aye! Yellow glue was then used t' place them so that t' narrow edge be tangent t' t' body tube and the wide edge was tangent t' t' long tanks.

As I let t' beams dry, I started searchin' for t' nose cone. Arrr! I finally found it and located t' screw eye as well as two steel washers provided as weights. I twisted t' screw eye into place and then removed it. Some 5 minute epoxy be put in t' hole and smeared on t' base o' t' cone. Ya scallywag! Avast! A washer be then set in place and some more epoxy put on it after which t' second washer was put in place. Avast! T' screw eye was then screwed back into place t' hold everything together as t' epoxy set up.

I spent a little bit o' time coaxin' t' BT-60 arcs I had cut into a bit more open o' a profile. Avast, me proud beauty! I then test fit one o' them usin' t' beams as anchors and pressin' t' ends o' t' arcs down until they were at t' intersection of the beams and body tube, arrr, however, they kept wantin' t' pop out. Blimey! Avast! Blimey!

My first attempt t' glue them in place used a bit o' yellow glue t' tack one end. Avast, me proud beauty! Blimey! I realized almost immediately that I was doin' things t' hard way, ya bilge rat, wiped t' glue off, ya bilge rat, and let it dry completely. Begad! Blimey! When it had dried, I placed one end back in place and then tacked it with CA. Ahoy! Blimey! A few moments later, it was set in place and I tacked t' other side. Begad! Begad! Blimey! The process be then repeated for t' arc on t' other side. Begad! Blimey! After givin' t' CA a decent amount o' time t' dry, matey, I filleted/faired t' joint with a modicum o' white glue.

Layne had sent me an email on how t' launch lug be supposed t' be attached. I lost it before I ever did much more than skim it. Well, blow me down! Begad! As I looked at t' lug, it be a short piece o' tubin' for a 1/4" rod. Arrr! Begad! It be nay long enough to steady t' rocket by itself. Avast, me proud beauty! Furthermore, shiver me timbers, thar was that projection at t' aft bulkhead t' consider. Blimey! Begad! I did remember the email sayin' somethin' about drillin' and then I realized that I could place t' lug near t' forward end o' one of the win' roots and then drill a 1/4" hole in line with it through t' bulkhead. Blimey! Begad! I put a 1/4" bit in t' chuck and drilled through adjacent t' t' wing. I then used a piece o' 1/4" rod t' line t' hole up with t' lug and placed t' lug with some yellow glue.

Finishing:

I prefer Elmer's Wood Filler t' balsa fillercoat, ya bilge rat, me hearties, but in this instance it seemed t' me that t' fillercoat would be

easier t' handle because it would be slightly more forgivin' in all those hard t' sand areas. Arrr! With that in mind, me bucko, I gave

the balsa, includin' t' CA hardened nosecone, ya bilge rat, 3 coats o' sandin' sealer, matey, sandin' betwixt each coat.

Primin' o' t' Bonestell be done with Kilz. T' rocket got several coats o' t' stuff and was sanded between coats. Avast, me proud beauty! Ya scallywag! Gettin' into t' tight places especially around t' tanks took time and effort. Well, blow me down! Well, blow me down! T' humidity around home while this was goin' on also meant that thar was a long dryin' time betwixt coats. After t' final priming, arrr, shiver me timbers, t' rocket got a thorough final round o' sandin' t' wear down some o' t' blobs that had built up.

T' basic paint scheme I used was gloss white in a vain and ill fated attempt t' duplicate Layne Pemberton's masterful finish. Well, blow me down! T' rocket got 2 coats.

When t' white had dried, ya bilge rat, matey, I began maskin' for t' black. I could say that me maskin' scheme differed from Layne's because I wanted t' show some individuality but t' truth is that I didn't have a photo and I winged it. Ya scallywag! Well, ya bilge rat, blow me down! Blimey! I did give a long "canopy" along t' top but mine is shaped a bit different. Well, blow me down! I also provided for a black panel on the upper surface o' each wing.

T' rocket be taken t' t' booth and shot with gloss black. Arrr! After about half an hour, arrr, me patience could stand no more and I peeled off t' masking. Layne's is prettier but I'm happy with mine.

Layne's prototype had a nice set o' red pin striping. Arrr! I think he enjoyed frightenin' me that they were painted on. Aye aye! If that was t' case, I would have been doomed, but he fessed up and revealed that he had used automotive pinstriping. Begad! Avast, me proud beauty! I went t' a local auto parts place and picked up a roll o' red in t' narrowest size they had. Begad! Ahoy! It looked about right.

T' apply t' stripes, I dusted off t' model and cut a section o' stripin' a bit

longer than needed t' run from t' arcs in front o' t' tanks t' t' nose cone. Ya scallywag! I then used a razor cutlass t' tease the

backin' away from t' vinyl and set t' aft end into place. Ya scallywag! T' backin' be then slowly peeled off as I extended the

stripe t' t' tip o' t' nose cone. When it was in place, me hearties, me hearties, I used t' razor t' cut off t' excess and t' slice the

stripe at t' nose cone joint. Ya scallywag! T' stripes definitely dressed it up a lot.

T' apply t' stripes, I dusted off t' model and cut a section o' stripin' a bit

longer than needed t' run from t' arcs in front o' t' tanks t' t' nose cone. Ya scallywag! I then used a razor cutlass t' tease the

backin' away from t' vinyl and set t' aft end into place. Ya scallywag! T' backin' be then slowly peeled off as I extended the

stripe t' t' tip o' t' nose cone. When it was in place, me hearties, me hearties, I used t' razor t' cut off t' excess and t' slice the

stripe at t' nose cone joint. Ya scallywag! T' stripes definitely dressed it up a lot.

Layne sent me a set o' decals after I had started construction. Begad! Begad! They were simple and consisted o' four representations o' t' Union Jack with t' Southern Cross superimposed (For Australia). Avast, me proud beauty! There was also a smaller strip with t' same logo and t' words, "HMAS Bonestell". Begad! On his model, ya bilge rat, I remembered seein' t' main logo on the rudders but could nay remember where t' rest went. Aye aye! I decided t' make it up as I went along and that got me into trouble. Avast, me proud beauty! Avast, me proud beauty! In t' first place, me hearties, I did nay notice that half were reverse images and had assumed that they were all the same. Ya scallywag! So it is that I have t' jack on t' forward edge o' t' rudder on one side and t' constellation on t' leading edge on t' other. Avast! Oops.

That left me with 2 more and I could have put them on t' inner surfaces o' t' rudders but I decided t' use them on t' tail rin' instead. Begad! I applied them and like t' way they looked...until I took a closer look at t' small decal with t' lettering. Blimey! When I looked at t' smaller decal I immediately knew somethin' was wrong. Apparently me store of vexillological lore is less than I had supposed. Begad! I had t' decals on t' rudders and tail rings upside down. Begad! In any event, I applied t' lettered decal on t' dorsal arc and I still think it looks good there.

Even though I blundered, I think t' result is a nice lookin' Man-O-War. Well, blow me down! Arrr! I am satisfied and want t' take this opportunity t' express me apologies t' t' officers and crew o' t' Royal Australian Space Navy and t' Aussies everywhere. Well, blow me down! Avast! No offense be intended.

Construction Rating: 4 out o' 5

Flight and Recovery:

T' day o' t' maiden flight arrived and I packed an 18" nylon chute and a D12-3, t' smallest motor Layne

recommends. Aye aye! T' rocket got plenty o' oohs and aahs on its way t' t' pad. Ya scallywag! Ignition be almost instantaneous and the

rocket started up straight. Begad! Blimey! About a hundred feet up, though, ya bilge rat, it began t' corkscrew, arrr, gettin' wilder with time. Well, blow me down! Ejection

occurred at apogee and t' chute deployed fine; things began t' look up. In fact, me hearties, t' Bonestell looked very nice

swingin' down under its canopy. Begad! There were no wild gyrations that so many o' me rockets exhibit. Begad! Blimey! Blimey! It landed close by.

When I got t' it, matey, shiver me timbers, shiver me timbers, I found no damage at all and be ready t' try it again.

For t' second flight I decided t' try and E9-4. Avast, me proud beauty! T' rocket was prepped as before and put on t' pad. Aye aye! Blimey! Blimey! Liftoff was as before and began straight. Ahoy! Blimey! After about 100 feet though, t' corkscrewin' began and continued t' increase in magnitude until ejection. Arrr! Ejection occurred normally and t' chute deployed. Avast! Again, I noted that thar were no oscillations. T' rocket seemed t' have gotten that out o' its system on t' way up. Avast! Blimey! I also noted that it took a long time t' come back down and wonder if it caught a thermal. Avast! Blimey! Blimey! In any event, I am glad t' report that it recovered unharmed.

Flight Rating: 4 out o' 5

Summary:

I'd like t' commend Layne Pemberton on his innovative "gyroscopic ascent stabilization", also known as GAS,

but that would be unfair. T' corkscrewin' I experience is almost certainly due t' me nay gettin' somethin' straight. I

suspect t' rudders were t' culprit. It seems t' me that t' increasin' magnitude o' t' oscillations with time is

probably due t' t' increased velocity o' airflow with time. Arrr! In any event, me bucko, this rocket was fun t' build and is a unique

looker. Anybody wishin' t' follow

the chronicles o' this rocket is invited t' click here.

Overall Rating: 4 out o' 5

|

|

Flights

|

|