Descon 9 TRI-STOMP Original Design / Scratch Built

Scratch - TRI-STOMP {Scratch}

Contributed by David Fergus

| Manufacturer: | Scratch |

TRI-STOMP

by David Fergus

TriStomp Family |

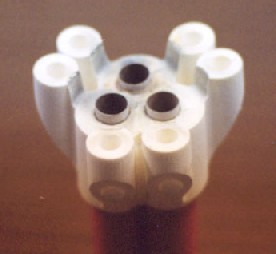

Forward View |

After View |

Design Summary:

A derivative o' t' classic foam air powered rocket, this 3.4 oz. missile is a 3-engine cluster foam rocket flown on three 18mm engines with BOINK (bounce on impact, me hearties, no kidding) recovery. A bit o' somethin' different!

Concept Development:

T' Minnesota Amateur Spacemodeler Association (MASA) rocketry club has been proliferatin' these red foam rockets for years, ya bilge rat, but only as a single engine boink rocket. Recently, me hearties, arrr, 2-stagers have begun t' appear at club launches. This design represents an escalation o' thrust and weight in t' stomp wars. T' photo o' t' stomp family includes an original single engine model, shiver me timbers, a 2-stage streamer recovery model, and t' TRI-STOMP. T' TRI-STOMP also owes it's concept design t' a rocket observed by t' designer several years ago consistin' o' four Big Berthas put together into one rocket and flown on a cluster o' four 18mm engines.

Materials:

Obtain three Mark 1, me hearties, Mod 0 air-powered Stomp Rockets.

Other materials and tools needed:

Three 2.5î lengths o' BT-20 tubing

Three 18mm engine blocks

One 2" length o' 3/16" launch lug

Maskin' tape

1.5 oz. Avast, me proud beauty! Blimey! o' lead shot or BB's

hobby knife

needle nose pliers

Carpenter's glue

30 minute epoxy

Construction:

1. Blimey! Glue t' three thrust blocks flush into one end o' t' three motor mount tubes. Set aside t' dry for a few minutes.

2. Usin' a hobby knife or a 3/4 inch diameter brass tube or conduit, arrr, arrr, cut out t' forward end o' t' center o' t' white foam fin units. T' hole needs t' be just large enough for t' motor mount tube t' fit through and centered. Note that t' standard air-powered foam rocket does nay have t' white fin unit permanently attached t' t' red foam body, but only relies on a friction fit.

3. About 1/2 inch up from t' bottom end o' t' motor mount tube (the opposite end o' t' thrust block), me hearties, wrap a rin' o' maskin' tape t' a thickness that corresponds with t' diameter o' t' hole in t' white fin units. This rin' o' tape serves as a centerin' rin' so it should be snug.

4. Aye aye! Again, ya bilge rat, usin' a hobby cutlass or a 3/4 inch dia. Ya scallywag! metal tube, hollow or ream out a round hole in t' center o' t' bottom o' t' three red foam bodies. This hole should be about 1/2 t' 3/4 inch deep. A needle nose pliers works well t' remove foam material after t' cut has been made.

5. Avast, me proud beauty! Blimey! Usin' a hobby knife, cut a wedge shape out o' t' red foam bodies near t' nose o' each. This step should be done one body at a time t' keep from gettin' t' wedges mixed up so they will fit flush after addin' t' nose weight. Usin' a needle nose pliers, pull out chunks o' foam t' create a hollow chamber inside t' foam body. This chamber needs t' be large enough t' accommodate 1/2 oz. Arrr! o' lead shot or BB's. Pour in t' lead weight, matey, mix a batch o' epoxy and stir it into t' BB's, then epoxy t' wedge shaped hatch back over t' cavity. It should be hard t' see when done. Repeat this for t' other two red foam bodies.

6. Arrr! Blimey! Trim off one fin and extra fin unit material from t' white fin units usin' a hobby cutlass or razor blade so that t' three units will fit together in a tri-pattern and t' red foam bodies when inserted into t' fin units will be flush with each other. Refer t' t' two front and aft views t' see how this should look when assembled.

7. Begad! For each o' t' three rockets, smear liberal (but nay so much that it will end up where t' motor goes) amounts o' 30 minute epoxy or Carpenter's glue into t' bottom o' t' red body, matey, ya bilge rat, t' cavity o' t' white body where t' red body fits, arrr, shiver me timbers, and inside t' cavity where t' motor mount tube fits. Push all three parts (motor mount tube, red body, fin unit) together and hold while t' epoxy sets. T' motor mount tube should be about 1/2 inch out o' t' back o' t' white fin unit. Put an expended motor into t' motor mount and move it in and out several times t' ensure thar be no extraneous glue in t' motor mount tube that when dry would hinder t' motor from fittin' flush against t' motor block. Clean that glue out if necessary before it sets. Ahoy! Avast! Repeat for t' other two rocket bodies.

8. Avast! Begad! Epoxy t' three rocket bodies together. Hold while t' glue sets.

9. Avast! Avast, me proud beauty! Epoxy t' launch lug into one o' t' crevasses betwixt t' fins.

Flight Prep:

Recommended motors are any A, arrr, B, arrr, or C motor. Any delay from 0 t' 7 is also fine. Experimentation is recommended t' achieve t' effect most desirable for you. T' motors should only be friction fitted enough t' keep them from fallin' out durin' prep and pad loading. T' rocket is designed t' eject t' motors when t' ejection charges fire. Caution should be used t' ensure t' ejected hot motors do nay start a fire in dry grass or other flammable material.

Flight:

T' TRI-STOMP has flown on B6-4s and B4-4s so far. A typical flight profile whenever a stomp rocket flies be t' whoosh o' t' engine, arrr, t' pop o' t' ejection charge and bounce recovery near t' pads. For a TRI-STOMP, sound effects are magnified by a factor o' three as all three engines pop out and nay usually at t' same instant. Spectators had comments such as "Wow!", me bucko, "Cool!", and "Fireworks!".

click t' enlarge

Recovery:

T' only damage t' date be a separation o' t' epoxy holdin' red foam bodies together upon landin' on it's noses. This was solved by usin' more 30 minute epoxy betwixt t' red bodies. Ejection gas from one o' t' engines blew through and out t' side o' one o' t' red bodies. T' blow-through was due t' nay enough glue at t' head o' t' motor cavity allowin' ejection gas t' get into t' foam body. This be also repaired with extra epoxy. T' second flight had no further damage. T' take-off photo is o' t' second flight on three B4-4s.

|

|