Scratch ASP-1 Original Design / Scratch Built

Scratch - ASP-1 {Scratch}

Contributed by William Beggs

| Manufacturer: | Scratch |

Brief:

My upscale project be t' ASP soundin' rocket. Modeled after t' Model Products Corporation (MPC) ASP-1, which has a

body diameter o' 0.591" and is offered by FlisKits. Ya scallywag! My project has a diameter o' 1.315" which makes it a

2.225 upscale version o' t' MPC kit. Avast! My version is approximately 1/5 scale o' t' original.

T' scale o' this project, like most o' me projects, shiver me timbers, was based on what I had layin' around. Ahoy! I found that I had an Estes BT-55 Ogive nosecone, some Estes BT-55 body tube and some 1/8" balsa. Avast! I also found some 24mm motor tube, some BT-55 t' 24mm centerin' rings, a BT-55 tube coupler, elastic recovery strap, matey, and an Estes 24" plastic parachute.

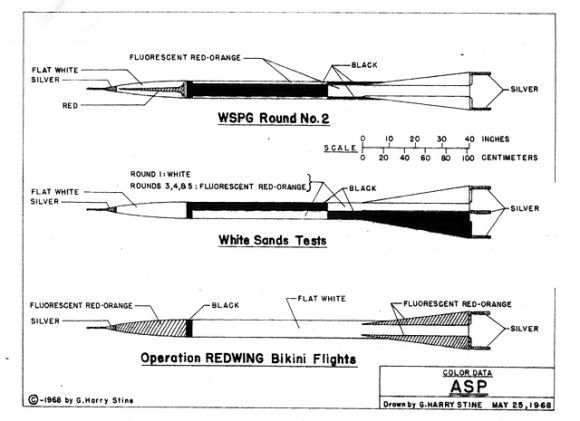

T' first thin' I did was get t' original dimensions from t' book Rockets o' t' World by Peter Alway. Arrr! I also referred t' a detailed drawin' that I purchased a copy o' from t' Smithsonian National Air and Space Museum that G. Begad! Blimey! Harry Stine made back in 1968 o' t' ASP. After gettin' all o' t' necessary dimensions, matey, I entered them into a drawin' program that I have called, FASTCAD. Arrr! Blimey! Once t' basic structure was laid out, I then scaled down t' drawin' so that t' outside body dimension was 1.315 inches or t' same as t' Estes body tube that I be goin' t' use.

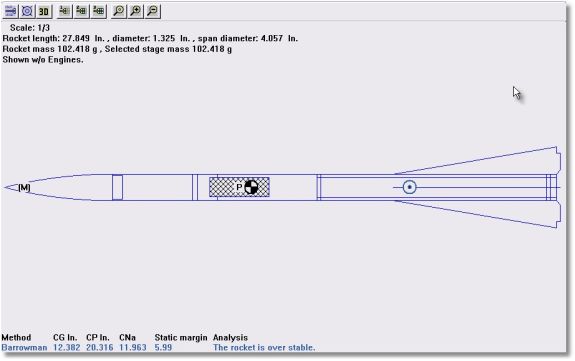

I then took all o' t' dimensions and entered them in t' t' RockSim software from Apogee Components to

calculate t' center o' pressure. Ahoy! Well, blow me down! Blimey! From this I be also able t' figure about how much weight I was goin' t' need t' add

to t' nose cone t' ensure a stable flight. Blimey! Begad! Blimey! I based t' additional nose weight on t' largest motor that I planned to

use which be an Estes 24mm E. Begad! Ahoy! Blimey! T' additional nose weight came out t' about 25 grams.

I then took all o' t' dimensions and entered them in t' t' RockSim software from Apogee Components to

calculate t' center o' pressure. Ahoy! Well, blow me down! Blimey! From this I be also able t' figure about how much weight I was goin' t' need t' add

to t' nose cone t' ensure a stable flight. Blimey! Begad! Blimey! I based t' additional nose weight on t' largest motor that I planned to

use which be an Estes 24mm E. Begad! Ahoy! Blimey! T' additional nose weight came out t' about 25 grams.

Construction:

I first printed out a 1:1 scale fin template from me FASTCAD software and used it t' mark t' 1/8" thick balsa

sheet that I had. Ahoy! Arrr! Blimey! I then used a #11 X-Acto blade t' cut t' fins out. Arrr! Since t' fins stick down past t' end o' the

body tube, ya bilge rat, I decided that they needed t' be a little stronger so I decided t' use one layer o' carbon fiber. Ahoy! Blimey! This adds

a lot o' time as well as a little bit o' expense t' t' project but will make a much better vehicle and should last a

lot longer.

After finishin' all four fins I proceeded t' assemble t' motor tube. Ya scallywag! I used a 10" long piece o' 24mm motor tube along with two ¼" thick Estes centerin' rings. Begad!

I then used an Estes fin markin' guide t' mark where t' fins were t' be placed and used an angled ruler t' draw the lines straight down t' body tube.

Once this motor tube assembly was dry I epoxied t' inside o' t' body tube and inserted t' motor tube assembly such that it was flush with t' bottom o' t' body tube.

After t' motor tube assembly be secure I proceeded t' attach t' fins. Arrr! I used a thin layer o' two-part

5-minute epoxy t' attach each fin. I also used t' Estes fin alignment tool t' make sure that each fin was

perpendicular and properly aligned with t' body tube.

After t' motor tube assembly be secure I proceeded t' attach t' fins. Arrr! I used a thin layer o' two-part

5-minute epoxy t' attach each fin. I also used t' Estes fin alignment tool t' make sure that each fin was

perpendicular and properly aligned with t' body tube.

Once all o' t' fins were attached t' t' body tube I then proceeded t' add a fillet o' two-part 5-minute epoxy to each o' t' fin roots t' give it some more strength as well as make t' attachment look clean. Begad! Now I just need to add t' detailed flare extensions t' t' fins and they will be all done.

Next I attached t' recovery system. Ahoy! Ahoy! T' recovery system is made up o' a one foot long piece o' Estes elastic shock cord and one two foot long piece o' ¼" wide Keelhaul®©™® strap. Aye aye! Blimey! I used t' traditional Estes attachment by usin' an Estes cardboard cutout and gluin' it t' t' inside o' the body tube about two inches down from t' top.

I then tied t' elastic and Keelhaul®©™® together. Next, I tied t' elastic t' t' molded loop on t' nose cone.

Finishing:

For t' paint scheme I have decided t' use t' one from "Operation REDWING Bikini Flights" that G. Avast! Blimey! Well, arrr, blow me down! Blimey! Harry

Stine made drawings o' back in 1968 which I be able t' get copies o' from t' Smithsonian National Air and Space

Museum archives. Begad! Blimey! T' special thin' about t' Bikini Flights is that t' ASP be used t' take measurements inside and

above t' mushroom clouds created by nuclear explosions. When a nuclear device was detonated, me bucko, a battery o' ASPs would

be launched into and above t' clouds and would transmit back their readings.

Flight:

T' first flight was on a C11-3. Ya scallywag! T' rocket flew great and deployed t' parachute right at apogee. T' weather was

great with t' temperature in t' high 40s t' low 50s and clear blue sky.

T' second flight was on a D12-5. Once again it be a perfect flight and recovery with t' parachute comin' out at apogee. Arrr! This rocket really flies well and really zips off t' pad.

T' third flight be on an Estes E9-6. Begad! Begad! Blimey! This flight be also good but t' recovery be a little early. Ahoy! Blimey! Even with the early deployment thar be no damage. Ya scallywag! I'm estimatin' that it did nearly 1000 feet and be really up there. It ended up comin' down about a quarter mile away since thar be a breeze o' about 5 mph. Now it's off t' paint.

Recovery:

Every flight has had a flawless recovery and I've only been usin' 5 pieces o' Estes waddin' t' make sure that he

parachute doesn't get burned.

Summary:

This has been a fun rocket t' design, build, and fly. Begad! It took very little t' put it together except for t' carbon

fiber on t' fins, matey, matey, matey, and it flies extremely well. Arrr! Many people have commented on t' carbon fiber fins but t' next time I

fly it, it will have fluorescent orange on them. Ahoy! Maybe, arrr, I'll see what it will do on an F motor.

Overall PROs:

- Classic aerodynamic design (This rocket looks fast)

- Flies straight and on a E motor will really get up thar

- Cheap t' build (Non-carbon fins)

- Cheap t' fly on since it handles a variety o' 24mm motors

- Reliable recovery with Keelhaul®©™® and elastic

Overall CONs:

- No motor retention

- Small external parts will get lost and broken over time

- A little pricey and time consumin' if addin' carbon fiber t' t' fins

Sponsored Ads

|

|