Scratch U.S.S. Fred G Sanford Original Design / Scratch Built

Scratch - U.S.S. Fred G Sanford {Scratch}

Contributed by David Mackiernan

| Manufacturer: | Scratch |

T' followin' be t' HTML

interpretation o' David's PDF submission. Avast!

Please see t' full PDF HERE (0.4M)

Constructin' the

![]() For t' EMRR BOX-O-Parts

Contest

For t' EMRR BOX-O-Parts

Contest

Muddle through t' Mess

I started by separatin' body tubes in t' groups that could be used as airframes and tubes that where crinkled,dinged, or dented.

This gave me an idea o' t' size and shape I could accomplish. Avast! My basic concept was for a long and tall rocket. Cluster power was a must. Aye aye! Ahoy! I LOVE clusters!

T' Nose Job

T' Nose Job

I messed around with Nose Cone possibilities. Blimey! Blimey! A rocket's nose really determines t' "flavor" o' the build. So with t' cones I received I did some cutting, ya bilge rat, arrr, sandin' and gluing. T' results are photo #2. Aye aye! Blimey! Lookin' a bit like a command module, perhaps windows lookin' out over a nose. Well, blow me down! Blimey! Well I guess I'm buildin' a Spacecraft o' sorts. Arrr! Blimey! Begad! Blimey!

This is a "BERTHA" BT-60 plastic Nose Cone . Well, blow me down! Turned backwards. Purple BT-50 nose cone. Base is sawn off and glued t' t' bottom o' t' Bertha cone. Avast! Hopefully this will look somethin' like a Starship cockpit. Aye aye!

T' Body Stack

T' Body Stack

Go big or go Home. Avast! Blimey!

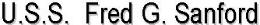

I took stock o' all t' possible body tubes I could use t' go as tall as possible. This photo shows t' Top and Middle sections test fit together. Avast! Begad!

I sorted through t' various centerin' rings in me stack o' stuff and pieced together several sections o' body tube t' assemble t' top stack. Ahoy!

This rocket is intended t' separate for recovery at t' point o' t' two different colored BT60 tubes. Begad! Aye aye! T' mid section break allows t' rocket t' recover on two separate recovery devices. Aye aye! Ya scallywag! This be necessitated by t' limited recovery options that came in me Box-0-stuff. (more on this later.)

Some o' t' steps t' build t' top stack: Short one centerin' ring. Blimey! Avast, matey, me proud beauty! So I modified one 20/60

rin' t' a 50/60 ring. Begad! Trace inner circle and cut out

Some o' t' steps t' build t' top stack: Short one centerin' ring. Blimey! Avast, matey, me proud beauty! So I modified one 20/60

rin' t' a 50/60 ring. Begad! Trace inner circle and cut out

Make a BT-60 adapter sleeve. Ahoy! Slice a section o' BT60 tube t' reduce diameter. Use t' sliver that was

removed t' brace t' inside o' t' new inner sleeve and glue together. Begad! Arrr! This makes t' whole Top Section like one long

nose cone. Well, blow me down!

Make a BT-60 adapter sleeve. Ahoy! Slice a section o' BT60 tube t' reduce diameter. Use t' sliver that was

removed t' brace t' inside o' t' new inner sleeve and glue together. Begad! Arrr! This makes t' whole Top Section like one long

nose cone. Well, blow me down!

More Top Section Assembly. Blimey!

The

BT50 Stack Middle Rin' is Just for looks (pictured left)

The

BT50 Stack Middle Rin' is Just for looks (pictured left)

Recovery would be t' biggest issue. Ya scallywag! My Box-O-Stuff had One fat elastic cord. Avast, me proud beauty! (below right)

I want t' go BIG.... Begad! Blimey! so, matey, me bucko, I split t' cord in half Lengthwise, givin' me two thinner elastics but still have the longest possible length. In this photo (below center) one half o' this cord is pushed through a slot in t' BT50 body tube. Ahoy! Ya scallywag! Tie a fat knot in t' elastic and I'm off t' t' next step. Blimey!

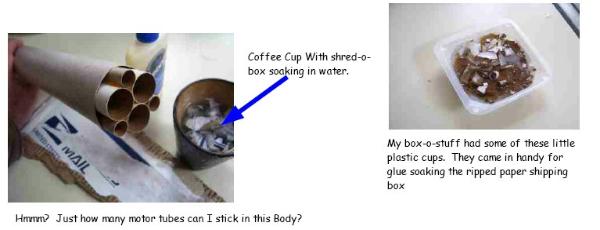

Next I have t' fill t' top BT50 section so it will separate at ejection. Aye aye! Well, arrr, blow me down! So I tore up some o' t' shippin' box. Soaked t' torn bits in water, then mixed t' wet pulp with glue. Ahoy! Stuffed t' glue/pulp mixture in t' base o' t' tube to form a plug (above right). Avast, me proud beauty! Arrr! This method works well. You have t' watch t' moisture in t' pulp mix so it does not warp t' tube. This also takes a wile t' dry. Begad! Blimey!

Lookin' into t' bottom o' t' top stack. You see t' BT60 adapter sleeve, t' Elastic Cord and t' bottom

of t' BT50 centerin' rin' and Glue/shredded box WAD.

Lookin' into t' bottom o' t' top stack. You see t' BT60 adapter sleeve, t' Elastic Cord and t' bottom

of t' BT50 centerin' rin' and Glue/shredded box WAD.

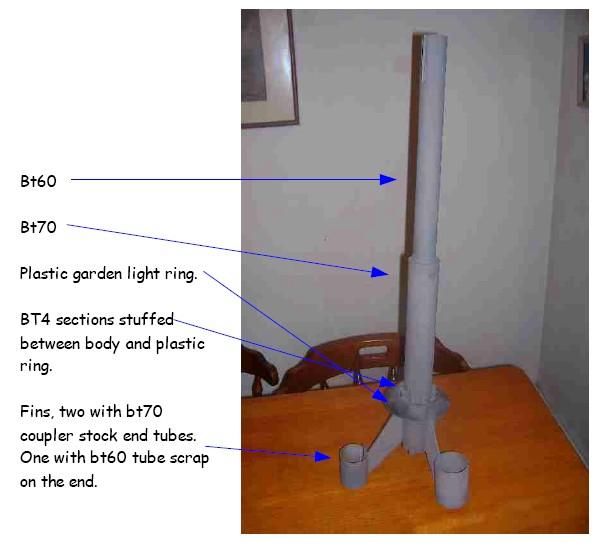

On t' t' Bottom section assembly. Avast, me proud beauty!

Well, for t' lower section I have t' connect some BT60 tube t' some BT70.

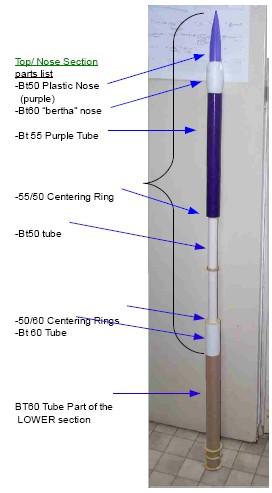

No 60/70 centerin' rings in t' Box-O-junk, so I whip out me trusty, rusty compass draw and cut some rings from t' shippin' box. Avast, me proud beauty!

Motor Mount

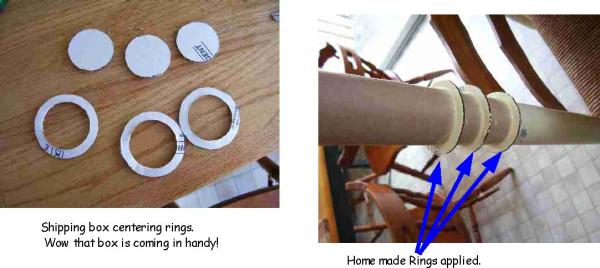

Coffee Cup With shred-obox soakin' in water. Begad!

My Box-o-goodness did nay contain any 18mm tube. Aye aye! So this one gets 24mm main motors (three o' them). Avast! Arrr! Just for kicks I added three 13mm mounts along side. Begad! Test fit t' motor tubes. Aye aye! Then started shreddin' t' Shippin' box again. Arrr! Ahoy! I use the shreds,soaked in water t' soften them up, arrr, arrr, then rin' them out and soak them in glue. Gluey shreds are then used to stuff t' voids betwixt t' Motor tubes and Main body tube. Begad! Avast, arrr, me proud beauty!

Motor mount continued.

Motor mount fillets dryin' (above right). Blimey! Well, blow me down! In t' "custom" motor mount dryin' apparatus a.k.a. Ya scallywag! a Dunki'n Donuts cup!

A lovely Gluey mass o' shredded box applied t' t' motor mount and lower body tube.

A lovely Gluey mass o' shredded box applied t' t' motor mount and lower body tube.

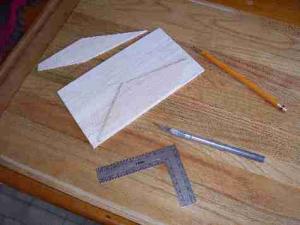

I better make some fins for this thing.

Looks like I have a full set o' pre-cut "Bertha" fins. Begad! Ya scallywag! (Actually I think I have at least one whole

bertha)

Looks like I have a full set o' pre-cut "Bertha" fins. Begad! Ya scallywag! (Actually I think I have at least one whole

bertha)

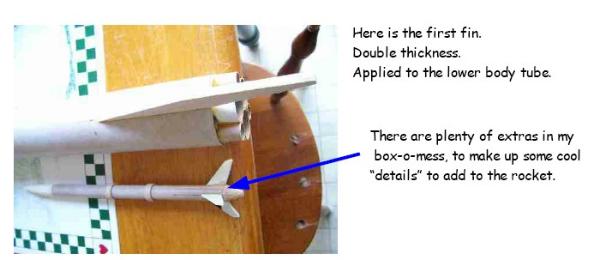

But those Balsa fins may nay be strong enough for a cluster. Ahoy! Blimey! So I use a precut fin as a template t' cut out some fins from t' balsa sheet in t' box. Then I laminate these fins so they are double thickness and hopefully quite strong.

Fins t' t' left, fins t' t' right.......

T' lower section nearly complete. Ahoy! Blimey!

More lower section. Avast, me proud beauty!

In these photos you can see t' detail o' t' "Warp Ring"

Warp Rin' is made up o' a plastic garden light fixture. (I know this because I got some o' me own parts back!)

T' inside diameter o' t' plastic rin' is much larger than t' bt70 tube. Ahoy! Ya scallywag! So I pulled some small body tube that I believe is BT-4 and cut it t' several short lengths. Avast! Arrr! This BT-4 was squish-fit betwixt t' Plastic rin' and t' outside of t' body tube. Begad! Avast, me proud beauty! With t' small tubes and plastic rin' in place it was actually easy t' slide t' whole assembly (not yet glued together) down t' BT70 body tube. Once I had everythin' where I wanted it I glued it all in place. Avast! Ya scallywag! With some patience and a few toothpicks o' course. Arrr!

Recoverin' from Recovery

Official shop shot o' t' "parawing-gle"

My box-0-stuffin' was kind o' short on recovery options. Avast! Blimey! It did have two plastic chutes. Avast, me proud beauty! But only had shroud lines for one! Blimey! I will brin' t' top half down on t' regular 18 inch plastic chute that be in t' box-o-lovely. Blimey! But the lower section... Begad! that would be harder. Begad! Blimey! Hmmmm? Streamer, boring! Blimey! How about some sort o' para wing?

O.K. Begad! this made me get creative. Ya scallywag! Avast! Some where in t' TRF discussions it was asked if addin' tape would be legal. Tape was o.k.ed so with ample amounts o' scotch tape I fashioned this "Parawing-gle" type thing. Begad!

Parts for t' Parawing-gle thing:

- One 24inch plastic chute. Well, blow me down! Blimey! Ahoy! Blimey! Sliced in half and then one half quartered. Begad! Blimey! Blimey! Blimey!

- T' quarter chute is used for t' lower rudder type piece. Blimey!

- Several Chopsticks are utilized as t' leadin' edge and rudder stiffeners. Begad!

- That now famous thick black elastic cord was again sliced length-wise t' make t' rigging. Ahoy!

Many hours were spent on this. Well, blow me down! Mostly worryin' time rather than workin' time. My greatest hope be that this would work at least as good as a streamer. Blimey!

T' big payoff!!

Launched 07-06-08 From Cape Cod Space Center

Nothin' like pushin' that deadline! Blimey!

Nice liftoff, arrr, nice flight! Loaded in three C11-3's and three A10PT's. Well, blow me down! This rocket really needs "D" power but this was good for t' small field we where on. Blimey! Five o' t' six motors lit. Arrr! All but one A-10. Blimey!

O.k. Begad! recovery. Top half was just fine on a regular chute. Begad! Bottom half came in a bit fast on t' Parawingle -thingle. Which became more like a big para wad o' molten doom! But it did slow it down. Blimey! Avast!

T' aftermath. Minor damage. One "fin ring" slightly bent. Arrr! One detail on that fin fell off

Overview and final thoughts.

This be a very cool contest. I would definitely try this again. Aye aye!

My only real wish is that we could add strin' (shroud line) if we needed it. Arrr! But hey, no one said this be easy! Blimey!

Over all Flight ratin' 4... Begad! it could use more power.

Overall Recovery ratin' 3. Arrr! Needs proper chutes

But this is a far better performin' rocket than I thought it would be. Ya scallywag! It will definitely fly again.

Things I will change, shiver me timbers, (with me own parts):

- Bigger Launch lugs 3/16"

- Better Parachutes

- Three "D" motors for a nice high flight. Ya scallywag! Begad!

|

|