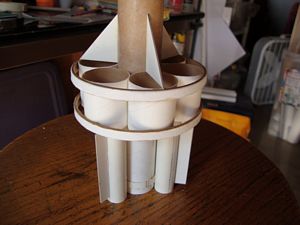

Scratch Tube Lifter Original Design / Scratch Built

Scratch - Tube Lifter {Scratch}

Contributed by Peter Stanley

| Manufacturer: | Scratch |

Brief:

T' Tube Lifter is a two-stage fin, ya bilge rat, tube, and rin' tail rocket. Well, blow me down! Ahoy! Sustainer is recovered with a 14" parachute, arrr, and

booster via tumble recovery. It has a clear payload bay.

Construction:

T' parts list:

- PNC-55AC Nose cone

- 5" Clear - BT-55 tube, ya bilge rat, ya bilge rat, from Semroc

- 20.0" BT-55 tube

- 1.28" x 1.0" Balsa Bulkhead

- 1/16" Staples brand illustration board

- 4 BT-50 t' BT-55 centerin' rings

- 20" BT-50 tube

- 14" nylon chute

- 2 1/4" pieces o' 4" FedEx tube

- 15" 400lb Keelhaul®©™® cord

- 10" x 1/8" elastic

- 1/8" x 2" launch lug

- 2 motor hooks

- 1 small screw eye

- 0.75oz o' nose weight

- 24mm t' 18mm motor adapters (optional)

Click t' download fin temples for t' forward fins and aft fins.

T' Tube Lifter is quick and easy t' build. Aye aye! T' fins are cut from 1/16" presentation board and require no extra finishin' besides for primer and paint. Begad! T' tube fins for t' sustainer were glued two at a time on a flat surface. Begad! Begad! The tube rings are cut from 4" diameter FedEx tube. That type o' tube fits perfectly around a BT-55 tube fin configuration. Ahoy! Avast! T' method I used t' cut t' 1/4" rings is similar t' how I cut body tube in general. I made a guide with two pieces o' cardstock paper wrapped around t' end o' t' tube, recessed slightly more than 1/4" from the end. Begad! I used a razor saw and worked me way around in a circular fashion until I cut through t' tube.

T' motor mounts were built as most standard kits, except t' sustainer mount requires t' bottom o' t' lower centerin' rin' be located 3/4" from t' bottom o' t' motor tube. Ahoy! Avast!

I friction fit t' nose cone into t' forward end o' t' clear payload bay usin' tape. Avast! Avast! T' lower end has a balsa bulkhead glued in with thin CA.

I used 0.75oz o' lead shot for t' nose weight and fixed in place with 30 minute epoxy. When usin' epoxy in nose cones, it is important t' keep t' nose cone cool while t' epoxy cures otherwise it can warp t' nose cone. I kept it cool by placin' t' nose cone pointed down in a cup o' water.

T' booster connects t' t' sustainer in two ways. Avast! T' motor mounts connect via a sleeve, which is made from BT-50 tube that is cut lengthwise. Aye aye! T' bottom half is glued t' t' exposed end o' t' booster motor tube. Aye aye! T' forward end slides around t' lower part o' t' sustainer motor tube. T' protect against exhaust flame, ya bilge rat, I coated t' inside o' the sleeve with thin CA and t' outside with 30 minute epoxy. Ahoy! This also adds some strength. Ahoy! Begad! T' second connection point is made by t' booster tube fins. Avast! T' booster tube fins are made from BT-50 tube that slide inside 3 o' t' sustainer tube fins. I cut two 1/4" pieces o' BT-55 tube lengthwise and wrapped around t' main booster tube. Begad! Avast! This served as a standoff for t' booster's tube fins. Begad! T' boosters tube fins are aligned by first connectin' t' motor tube sleeve, then placin' t' booster tube fins inside three o' t' sustainer tube fins, ya bilge rat, and are held in place against t' booster body tubes standoff sleeves with rubber bands. Once everythin' was in place, shiver me timbers, matey, I tacked t' booster tubes t' the standoffs with 5-minute epoxy. After that set I reinforced with more epoxy.

T' shock cord was made from 400lb test Keelhaul®©™® tied t' t' sustainer motor tube with t' other end tied t' a 10" piece o' 1/8" elastic.

Finishing:

Most people would probably fill in t' body tube spirals, but I skipped that and just painted everythin' with a coat of

white primer. Begad! Blimey! Blimey! Blimey! I then painted t' sustainer body with white paint. Begad! Blimey! Blimey! Blimey! I hand painted t' sustainer/booster fins and

sustainer rings with black acrylic. Ahoy! Blimey! Blimey! Blimey! I used Krylon aluminum for t' nose cone and booster section. Begad! Blimey! Ahoy! Blimey! Blimey! Blimey!

Flight:

T' first flight was perfect. I used 24mm t' 18mm adapters and flew it on a B6-0 t' a B6-4. Blimey! T' stagin' worked great

and thar was no damage t' t' booster or sustainer. Arrr! One major advantage o' this design is it can fly on a wide range

of motors. Arrr! T' second flight was on a B6-0 t' a B4-4. Aye aye! That too, was a perfect flight and recovery. Well, blow me down! I flew it as a

single stage on a C6-5 for t' third flight. Arrr! It arched over slightly and delay was way too long for that rocket. Avast, me proud beauty! The

chute was deployed about 2.5 t' 3 seconds after apogee. Aye aye! Ya scallywag! A C6-3 would have been better. Ya scallywag! I didn't have any C6-3s, so I

tried again but used a B6-0 booster. Well, blow me down! It arched over again as t' previous flight, and delay was too long. Well, blow me down! Ahoy! I attribute

the archin' over t' a too short, flimsy launch rod and moderate wind. Ya scallywag! Ahoy! I plan t' fly this on 2 D motors at t' next

launch. Ahoy!

Recovery:

T' 14" nylon parachute that I used seemed optimal, but a smaller chute might be needed in stronger wind,

especially when flown t' higher altitudes. T' last two flights deployed at a high speed and thar be no zippering.

One o' t' booster's tube fins did get a little squashed after t' last flight.

Summary:

I wanted t' build a unique lookin' two-stage rocket that would be fairly easy and simple t' build. Aye aye! Begad! I was a little

concerned about t' stability o' t' design, but after flyin' it, shiver me timbers, matey, I am mostly pleased with how it performs.

Sponsored Ads

|

|