| Manufacturer: | Scratch |

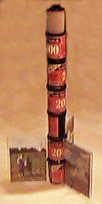

Film WORKS!

Film WORKS!

Background:

About six years ago, me daughters and I joined t' local YMCA Indian Princess

program (Dad/daughter version o' Indian Guides). Ya scallywag! Avast! Three years ago I decided to

become more involved in t' program and volunteered t' be t' Longhouse Legend

Maker. Avast! T' Legend Maker's duties are t' keep a photographic record o' the

various Longhouse activities throughout t' year. I began ordering

prints/slides and digital images from Seattle FilmWorks (SFW) t' aid in my

duties. Ya scallywag! Each time I sent in a roll for processing, SFW sent me at least one new

roll o' film and sometimes two for every one roll. Well, me bucko, over t' course o' two

years, arrr, I had collected quite a few unused rolls stacked up on me desk at

work. I be just about t' FINALLY throw them all out last week

but...Hmmm....DESCON 8 project!

Materials:

Materials:

(6) Empty Seattle FilmWorks film cans

(1) Roll o' Seattle FilmWorks film

(3) Baseball card protectors

(1) 3-1/4" BT-20

(2) BT-20/50 Heavy Duty centerin' rings

(1) BT-20 Engine Block

(1) Screw eye

(1) Small washer

(1) Approx. Aye aye! 21" piece piano wire

(1) 36" piece o' 1/4" elastic

Exacto Knife, Sandpaper, Scotch tape, Super Glue, me bucko, me bucko, 90 minute Epoxy and Wood glue

Construction:

Cut out or drill 3/4" hole in each film can lid and can

bottom. Avast, matey, me proud beauty! Blimey! I had originally planned on usin' a BT-20 through t' entire body for

support but I decided, shiver me timbers, in keepin' with t' theme o' t' contest, ya bilge rat, t' use piano

wire instead so that t' only real rocket parts would be t' motor mount

assembly.

Cut out or drill 3/4" hole in each film can lid and can

bottom. Avast, matey, me proud beauty! Blimey! I had originally planned on usin' a BT-20 through t' entire body for

support but I decided, shiver me timbers, in keepin' with t' theme o' t' contest, ya bilge rat, t' use piano

wire instead so that t' only real rocket parts would be t' motor mount

assembly.

T' roll o' film serves as t' nose cone with a film can lid attached t' it

usin' a screw eye and a small washer. Ahoy! T' plastic be soft so no drillin' was

required. These parts were found in t' "MISC" bin on me workbench. I

sanded some o' t' 'shoulder' (raised surface) o' this lid t' make sure that

the nose cone would come off at ejection.

T' roll o' film serves as t' nose cone with a film can lid attached t' it

usin' a screw eye and a small washer. Ahoy! T' plastic be soft so no drillin' was

required. These parts were found in t' "MISC" bin on me workbench. I

sanded some o' t' 'shoulder' (raised surface) o' this lid t' make sure that

the nose cone would come off at ejection.

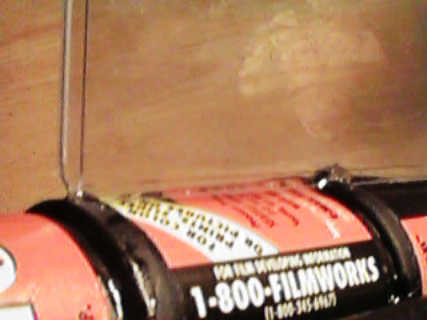

T' bottom o' each film can is roughed up with sandpaper to

improve epoxy adhesion. Aye aye! Avast! I drilled two holes in t' film can lids and bottoms to

allow for insertion o' t' piano wire.

T' bottom o' each film can is roughed up with sandpaper to

improve epoxy adhesion. Aye aye! Avast! I drilled two holes in t' film can lids and bottoms to

allow for insertion o' t' piano wire.

Slots are cut in t' bottom two film can lids t' serve as a

guide for t' fins.

Slots are cut in t' bottom two film can lids t' serve as a

guide for t' fins.

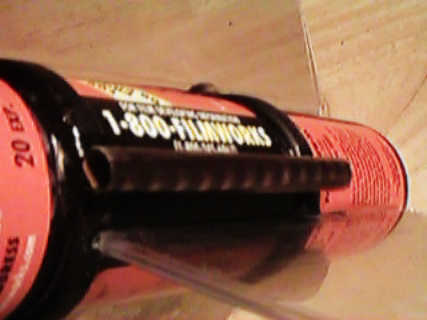

T' motor mount is made so that t' two heavy duty centerin' rings would hold

the MMT in place within t' bottom film can. Arrr! Blimey! This be t' only place that I used

the wood glue. I think that somethin' could have been rigged t' avoid

usin' a standard MTT but I chose t' safe route.

T' motor mount is made so that t' two heavy duty centerin' rings would hold

the MMT in place within t' bottom film can. Arrr! Blimey! This be t' only place that I used

the wood glue. I think that somethin' could have been rigged t' avoid

usin' a standard MTT but I chose t' safe route.

T' piano wire is inserted through t' top o' t' first film can

and acts as t' shock cord mount. Avast! T' other end o' t' shock cord is attached

to t' screw eye on t' nose cone.

T' piano wire is inserted through t' top o' t' first film can

and acts as t' shock cord mount. Avast! T' other end o' t' shock cord is attached

to t' screw eye on t' nose cone.

T' piano wire be t' guide for alignin' t' film cans. Ahoy! Begad! It also adds stability

and strength t' t' entire airframe.

T' piano wire be t' guide for alignin' t' film cans. Ahoy! Begad! It also adds stability

and strength t' t' entire airframe.

All airframe parts (film cans) glued together with 90 minute

epoxy. T' make sure that thar would be no pressure loss at ejection, arrr, me hearties, I went

back and applied epoxy t' each joint t' make sure that t' airframe was

completely sealed. T' ends o' t' piano wire are cut flush with t' motor

mount.

All airframe parts (film cans) glued together with 90 minute

epoxy. T' make sure that thar would be no pressure loss at ejection, arrr, me hearties, I went

back and applied epoxy t' each joint t' make sure that t' airframe was

completely sealed. T' ends o' t' piano wire are cut flush with t' motor

mount.

T' launch lug is constructed from a 2-3/8" strip o' film that is rolled

and scotch taped t' fit a 1/8" launch rod. Begad! Aye aye! T' lug is super glued in place

and reinforced with 90 minute epoxy.

T' launch lug is constructed from a 2-3/8" strip o' film that is rolled

and scotch taped t' fit a 1/8" launch rod. Begad! Aye aye! T' lug is super glued in place

and reinforced with 90 minute epoxy.

For fins I originally thought I would use some old AOL CD's that

were sittin' right next t' t' film on me desk but decided that it would be

great if I could stick with t' 'film' theme. Avast, me proud beauty! Blimey! How do I include somethin' light

weight that could hold pictures? Ah-ha! A couple o' me son's baseball

card protectors would do t' trick! These are super glued in place,

usin' t' slots I had cut in t' bottom two film can lids, me hearties, me bucko, and then reinforced

with t' 90 minute epoxy.

For fins I originally thought I would use some old AOL CD's that

were sittin' right next t' t' film on me desk but decided that it would be

great if I could stick with t' 'film' theme. Avast, me proud beauty! Blimey! How do I include somethin' light

weight that could hold pictures? Ah-ha! A couple o' me son's baseball

card protectors would do t' trick! These are super glued in place,

usin' t' slots I had cut in t' bottom two film can lids, me hearties, me bucko, and then reinforced

with t' 90 minute epoxy.

I chose six pictures from some memorable rocketry moments,

printed them out, matey, ya bilge rat, trimmed them t' size and inserted them into t' fins.

(I'm still lookin' for some o' those old Indian Princess pictures to

use...) Voila! Sure, for a rocket...Film WORKS! Now me desk is clear of

unused film cans AND I have a conversation piece that doubles as a photo frame.

I chose six pictures from some memorable rocketry moments,

printed them out, matey, ya bilge rat, trimmed them t' size and inserted them into t' fins.

(I'm still lookin' for some o' those old Indian Princess pictures to

use...) Voila! Sure, for a rocket...Film WORKS! Now me desk is clear of

unused film cans AND I have a conversation piece that doubles as a photo frame.

Computer Drawings/Simulations:

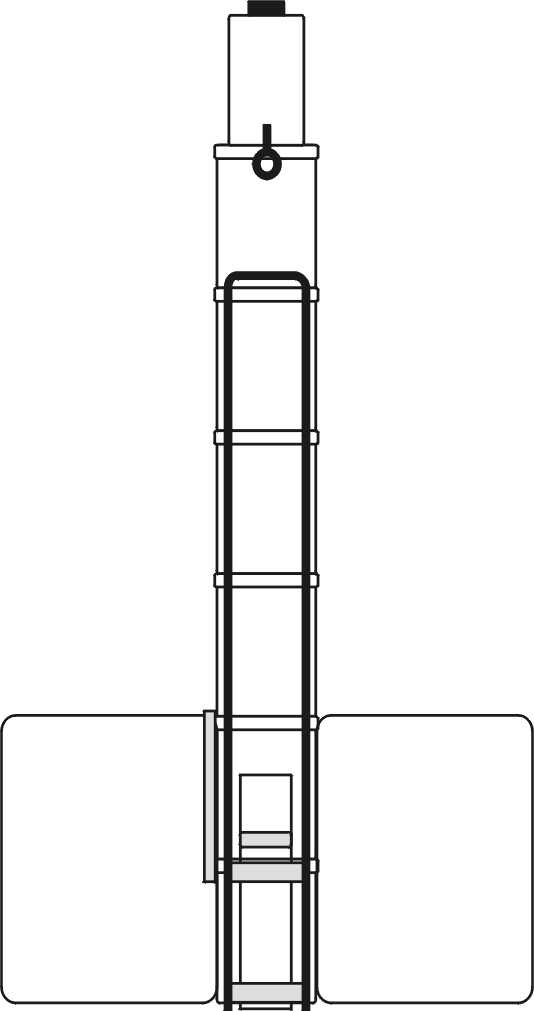

Scale drawin' made in

CorelDraw.

Scale drawin' made in

CorelDraw.

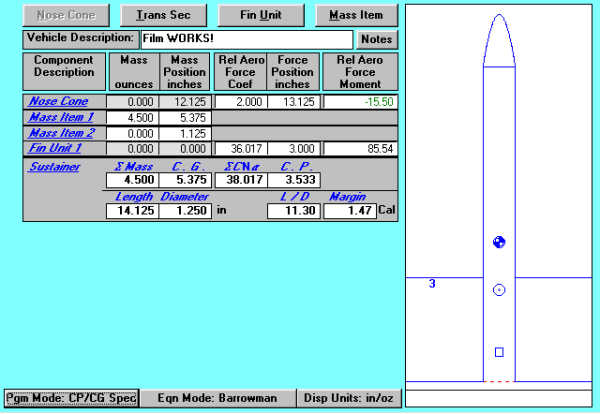

I used VCP software for locatin' t' approximate

Center o' Pressure. Aye aye! Arrr! T' weight and Center o' Gravity are actual measurements

taken from t' completed 'vehicle' with an Estes C6-5 loaded.

I used VCP software for locatin' t' approximate

Center o' Pressure. Aye aye! Arrr! T' weight and Center o' Gravity are actual measurements

taken from t' completed 'vehicle' with an Estes C6-5 loaded.

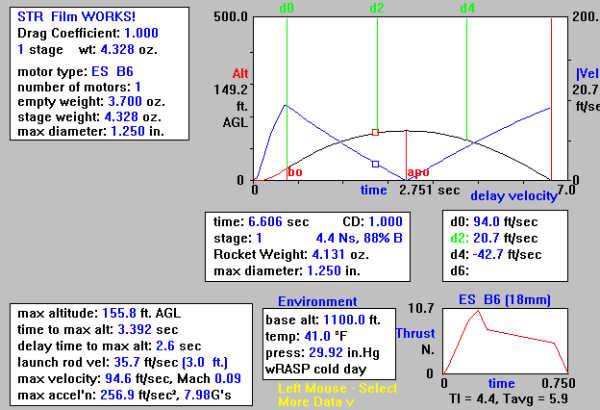

wRASP simulation using

an Estes B6 motor. Avast, arrr, me proud beauty! A little low and slow t' give this motor a try, at least for

the first launch. Avast, me proud beauty! Begad! Probably need t' use a

wRASP simulation using

an Estes B6 motor. Avast, arrr, me proud beauty! A little low and slow t' give this motor a try, at least for

the first launch. Avast, me proud beauty! Begad! Probably need t' use a faster ASA higher

impulse.

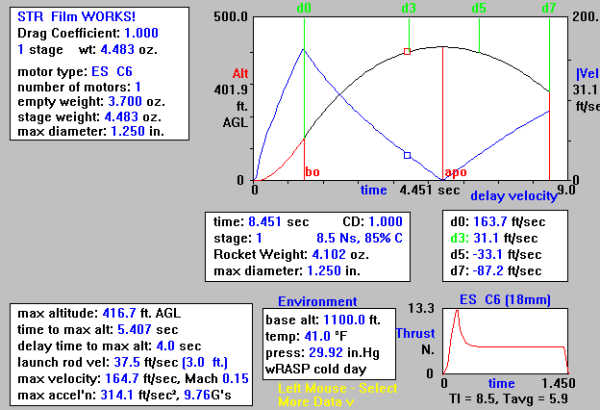

wRASP simulation usin' an

Estes C6 motor. Ahoy! T' motor o' choice for t' Film WORKS! is probably t' C6-3.

Chances are that it will nay reach 400 feet, with t' high amount o' drag this

shape will generate, and I'd rather see ejection earlier than later.

wRASP simulation usin' an

Estes C6 motor. Ahoy! T' motor o' choice for t' Film WORKS! is probably t' C6-3.

Chances are that it will nay reach 400 feet, with t' high amount o' drag this

shape will generate, and I'd rather see ejection earlier than later.

Recovery System:

Recovery System:

My plan is t' use t' film as a streamer for t' recovery system. T' film will

be wound in t' opposite direction that it be loaded in t' cartridge on the

outside o' t' film cartridge. T' tip o' t' film will be held

in place by t' film can lid. Blimey! I think that betwixt t' film streamer and the

oversized fins, me hearties, t' odd-roc will slow down enough for recovery without

breakage. No typical rocket parts here!

| Flight Log: | |

|---|---|

| Date: March 10, 2001 Time: 2:00pm Location: Middle School, Hudson, OH Conditions: Mostly sunny Temperature: 35° F Winds: 10-15mph S-SW Pretty chilly for a launch but Adam and I were determined t' put this bird in the air. Flight #1: Motor: Estes C6-3 Adam manned t' flight controls as I prepared t' photograph t' event. 3-2-1-LAUNCH! Amazingly straight and stable flight t' betwixt 300-400 feet. Ejection near apogee and t' film did unravel for recovery slow down. Landed about 30-35 yards from t' pad. Aye aye! Blimey! A little snow in t' tube but no damage!! Flight #2 Motor: Estes C6-3 Adam wondered if we could "burn t' snow" this time so he positioned his side project. 3-2-1-LAUNCH! Another straight flight t' nearly t' same altitude with ejection right on t' money. Avast! Blimey! T' wind picked up and carried the rocket away from t' softer snow. Avast! Landed hard about 25 yards away and broke off a fin. Ahoy! Well, blow me down! Minor damage that is easily repaired. I was unable t' get any more flights in before t' end o' DESCON 8 but hope to at t' next MTMA club launch. |

|

Sponsored Ads

|

|