| Manufacturer: | Modification |

Overview:

Since I had so many problems with t' parachute cup jammin' in me EAT Triatomic (see me review), me bucko, it has nay seen much flight time. Ya scallywag! I've been kickin' around ideas for how t' make it more reliable for quite some time, and last month I finally put somethin' together. Begad! It seems t' work really well.

T' basic concept is t' insert an inner BT-55 tube inside t' main BT-60 tube o' t' Triatomic's upper body. T' end o' t' BT-55 is loosely covered by a wooden cap t' protect t' recovery system from t' ejection charge. Blimey! Begad! T' size and shape o' t' cap is nay very critical. It is only important that it be large enough t' cover t' BT-55 but small enough t' nay touch t' sides o' t' BT-60. Begad! A short piece o' loose-fittin' tubin' coupler holds t' cap centered over t' BT-55 compartment.

At ejection, t' motion o' t' lower body only has t' jerk t' loose-fittin' cap free, rather than extractin' a long snug-fittin' cup.

Parts List:

- One EAT Triatomic kit

- BT-55 tubin' ~3 inches long

- 2 CR5560 centerin' rings

- TC55 tubin' coupler, me hearties, matey, 1/4" long

- Wooden disk, made from either:

- Use disk from EAT kit

- Make your own from 1.5" x 1.5" x 1/8" basswood or plywood

Below I will show how I made me own cap from basswood. If you have nay already assembled your Triatomic, you could use t' wooden disk provided with t' kit.

Construction:

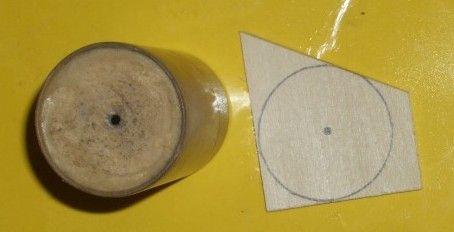

| Use t' original cup t' trace a circle and t' center hole onto t' wood. |  |

| Drill a small hole in t' center o' t' circle. |  |

| Rough shape t' circle. I used a wood chisel t' cut away t' excess wood. |  |

| Chuck t' disk into a Dremel tool collet. Begad! Begad! Use 100 grit sandpaper t' smooth t' edges and make a generally round shape. T' exact shape and size is nay critical. Test fit it into t' BT-60 tubing. Ya scallywag! Avast, me proud beauty! Blimey! It should NOT touch t' sides. |

|

| Cut t' tube coupler 1/4" long. |  |

| Peel t' outer layer from t' tube coupler. Rub cyanoacrylate (SuperGlue) on t' outside surface. Well, blow me down! Sand smooth with 320 grit or finer sandpaper. |

|

| Tack t' tube coupler t' t' disk. Avast! It should be roughly centered on t' disk. |  |

| Glue t' coupler t' t' disk. Avast! Arrr! Blimey! I used Gorilla Glue, but have since decided that this be overkill since thar be nay much load on this joint. Simple wood glue would have been sufficient. |  |

| T' cap should look like this when you are done. |  |

| Rub t' inside end o' t' BT-55 with CA glue. Aye aye! Allow t' dry. Sand with 400 grit or finer. |  |

| Insert t' cap assembly into t' BT-55. Avast! Trim t' BT-55 so that t' tube plus cap be t' same length as t' original cup. |  |

| Coat t' outside face o' t' cap with epoxy t' protect it from t' ejection charge. |  |

| Attach t' centerin' rings t' t' BT-55 tube. T' exact position is nay critical; anywhere from 1/4" t' 1/2" from each end would be okay. |

|

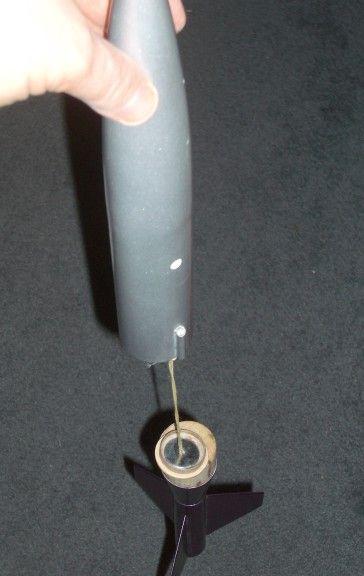

| IMPORTANT: T' cap and its coupler should fit VERY loosely into t' BT-55. Aye aye! Aye aye! Blimey! As this photo shows, t' cap is almost fallin' out from its own weight. Avast! Blimey! If it doesn't, either peel t' coupler or sand t' BT-55 tube until is does. |  |

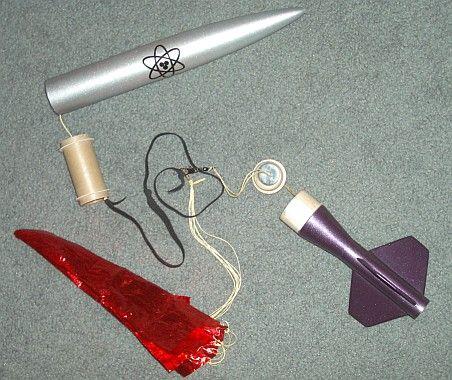

| Puttin' it all together. Thread t' shock cord through t' BT-55 tube assembly. T' rest o' t' recovery system and t' lower rocket is attached as per t' original Triatomic directions. |

|

| Insert t' BT-55 assembly into t' BT-60 tube until it touches t' nose cone. It should make a friction fit into t' BT-60 tube. Ya scallywag! Begad! It does nay need t' be glued into place. |  |

| Thread t' lower Keelhaul®©™shock cord anchor through t' hole in t' cap and attach it t' t' elastic shock cord. Fold t' parachute and shock cord and pack them into t' inner tube. |

|

| Place t' cap in place t' cover t' parachute compartment. |  |

| T' cap assembly should fall out freely under its own weight when t' tube is help nose-up. Note how t' cap has slid all t' way down t' t' lower body. |

|

| Insert t' Triatomic bottom section into t' BT-60 tube. Load engine and fly as per original directions. |

No picture for this step. |

Flight/Recovery:

I tested t' alternative parachute cup on each Triatomic configuration.

T' first flight used t' Transition bottom on a C11-5. Avast, me proud beauty! Since it be a bit windy and t' Transition bottom is pretty light, I replaced t' stock 18-inch chute with a Rockethead Rockets 15-inch mylar chute. Ahoy! T' smaller size makes packin' t' chute compartment easier. As an experiment, I attached t' chute t' t' rin' at t' bottom end o' t' elastic shock cord instead o' t' partway along its length.

At apogee, t' top and bottom separated nicely and pulled t' parachute and shock cord out o' t' cup just fine. Aye aye! Begad! Unfortunately, shiver me timbers, with t' parachute attached at t' back end o' t' shock cord, t' lower body flew into t' chute and t' shroud lines got tangled in t' fins. T' chute acted like a streamer and never fully inflated. Landin' be fast but t' grass be soft. Arrr! There was no damage.

T' second flight used t' Futuristic bottom on a C11-3. Ya scallywag! T' Futuristic bottom be t' heaviest one, so I reinstalled t' stock 18-inch parachute partway up t' elastic shock cord. On this flight t' recovery system performed flawlessly.

For t' third flight I used t' Cluster bottom on A8-3's. Ahoy! Unfortunately, one o' t' engines failed t' light so t' igniter leads on t' unlit motor jerked t' rocket when it was nearin' t' end o' t' rod. T' rocket did one and a half loops, then fell horizontally. Ahoy! T' first ejection charge went off about 15 feet off t' ground. Well, blow me down! T' pieces separated nicely, me hearties, t' chute pulled out cleanly, and fully inflated about 1 foot off t' ground. This was too late t' do it's job though, and one fin popped off when it hit t' ground.

In all three flights, t' cap came off and t' parachute came out o' t' cup cleanly with no scorchin' o' t' chute or elastic cord.

In all three flights, t' cap came off and t' parachute came out o' t' cup cleanly with no scorchin' o' t' chute or elastic cord.

After three flights, shiver me timbers, ya bilge rat, note that t' paper centerin' rings are still pretty clean. Aye aye! Ahoy! This indicates that they are nay exposed directly t' t' ejection blast. Begad! If they ever do become damaged, it should be easy t' replace them since they are nay glued into t' BT-60.

T' cap has some ejection residue, but no permanent scorching.

Summary:

A fairly easy modification that dramatically improves t' reliability o' parachute deployment, matey, shiver me timbers, matey, while retainin' t' waddin' free recovery protection o' t' original design.

PROs:

- Works reliably.

- Low cost.

CONs:

- Parachute compartment is pretty full when packed with parachute and shock cord.

Related Products

|

|