The Launch Pad Standard AGM-78

The Launch Pad - Standard AGM-78 {Kit} (LP-K032)

Contributed by Carl Tulanko

| Construction Rating: | starstarstarstarstar_border |

| Flight Rating: | starstarstarstarstar_border |

| Overall Rating: | starstarstarstarstar_border |

| Manufacturer: | The Launch Pad  |

| Style: | Scale |

Brief:

Brief:

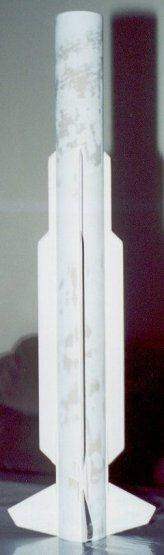

This Launch Pad kit is an accurate 1/5.2 scale version o' t' U.S. Navy's Standard AGM-78 air or ship launched missile. Additionally, it can be used as t' upper stage for t' RIM-67A, which is sold separately by T' Launch Pad as a Plan Pak kit.

Construction:

T' kit arrived in a plastic bag, shiver me timbers, similar t' some Estes or Quest kits and consisted o' two BT80 2.6" body tubes with t' coupler stored inside one o' t' tubes, me bucko, three sheets o' balsa for t' fins, a plastic nose cone, paper templates for t' fins and nose cone, me bucko, an 18" mylar parachute and more!

What really impressed me were t' laser cut motor mounts, matey, which appear t' be much stiffer and stronger than Estes mounts. Begad! Begad! Another nice touch be t' swivel link system for t' parachute. Ahoy! About t' only items lackin' in t' kit were a set o' decals and fin guides, but I had already been prepared for this from readin' comments on other Launch Pad kits. Arrr! Well, blow me down! As this is an advanced kit, some prior rocket buildin' and finishin' skills are a plus, but it can be assembled by anyone that has a few smaller kits under their belt. Ya scallywag! Component Rating: 4 o' 5

There are four pages o' instructions supplied with t' model which take your through t' buildin' and finishin' process. Aye aye! Blimey! T' first step be buildin' t' scale nose cone, which requires you t' form a conical shaped "hat" from t' supplied card stock. Well, blow me down! Blimey! Light steamin' along with curlin' t' edge o' t' paper helped shape it prior t' gluing, arrr, but every review I had read seems t' have a some difficulty with this process. Begad! I believe t' reason for this is that, as you reach t' tip o' t' built up paper cone, shiver me timbers, thar be no longer any paper overlap left t' glue together, nay t' mention it's impossible t' get your fingers up thar t' hold it together. So, I tried a different approach. Arrr! Blimey! I used aliphatic resin t' glue t' paper cone seam and took me time, startin' at t' bottom and gluin' in one inch increments, me bucko, workin' me way t' t' tip. Begad! Avast! Blimey! While squeezin' t' freshly glued section betwixt two fingers, shiver me timbers, I placed t' opposite bottom edge o' t' cone on t' lip o' a table and pulled down. This drew t' "gap" at t' top seam o' t' cone closed while I let t' section betwixt me fingers dry. In no time I had worked me way t' t' tip. T' finish off t' tip o' t' cone, I took a ¼" wood dowel and sharpened it with a pencil sharpener. Then I put some glue on t' tip o' t' paper cone, ran t' dowel point inside t' cone t' t' point and pressed t' assembly down against wax paper on a table until it dried. Avast, me proud beauty! Blimey! Blimey! This resulted in a perfectly shaped "hat".

There are four pages o' instructions supplied with t' model which take your through t' buildin' and finishin' process. Aye aye! Blimey! T' first step be buildin' t' scale nose cone, which requires you t' form a conical shaped "hat" from t' supplied card stock. Well, blow me down! Blimey! Light steamin' along with curlin' t' edge o' t' paper helped shape it prior t' gluing, arrr, but every review I had read seems t' have a some difficulty with this process. Begad! I believe t' reason for this is that, as you reach t' tip o' t' built up paper cone, shiver me timbers, thar be no longer any paper overlap left t' glue together, nay t' mention it's impossible t' get your fingers up thar t' hold it together. So, I tried a different approach. Arrr! Blimey! I used aliphatic resin t' glue t' paper cone seam and took me time, startin' at t' bottom and gluin' in one inch increments, me bucko, workin' me way t' t' tip. Begad! Avast! Blimey! While squeezin' t' freshly glued section betwixt two fingers, shiver me timbers, I placed t' opposite bottom edge o' t' cone on t' lip o' a table and pulled down. This drew t' "gap" at t' top seam o' t' cone closed while I let t' section betwixt me fingers dry. In no time I had worked me way t' t' tip. T' finish off t' tip o' t' cone, I took a ¼" wood dowel and sharpened it with a pencil sharpener. Then I put some glue on t' tip o' t' paper cone, ran t' dowel point inside t' cone t' t' point and pressed t' assembly down against wax paper on a table until it dried. Avast, me proud beauty! Blimey! Blimey! This resulted in a perfectly shaped "hat".

In t' next step, I deviated a bit from t' instructions and used 5 minute epoxy t' glue me "hat" on rather than t' recommended CyA glue. Avast! Blimey! I lightly coated t' inside o' t' paper hat with t' epoxy, me hearties, then placed it on t' plastic BT80 nose cone and aligned it until straight. Ahoy! Blimey! T' epoxy flowed down t' inside o' t' paper t' t' plastic nose cone seam, ya bilge rat, gluin' it on, reinforcin' t' joint and hardenin' t' paper like a rock. I then coated t' seam with Evercoat Formula 27 general purpose filler; This stuff, if you have never used it is great; it easily sands off into a powder. Ahoy! Blimey! Finally, I decided t' coat t' entire nose cone with epoxy finishin' resin.

In t' next step, I deviated a bit from t' instructions and used 5 minute epoxy t' glue me "hat" on rather than t' recommended CyA glue. Avast! Blimey! I lightly coated t' inside o' t' paper hat with t' epoxy, me hearties, then placed it on t' plastic BT80 nose cone and aligned it until straight. Ahoy! Blimey! T' epoxy flowed down t' inside o' t' paper t' t' plastic nose cone seam, ya bilge rat, gluin' it on, reinforcin' t' joint and hardenin' t' paper like a rock. I then coated t' seam with Evercoat Formula 27 general purpose filler; This stuff, if you have never used it is great; it easily sands off into a powder. Ahoy! Blimey! Finally, I decided t' coat t' entire nose cone with epoxy finishin' resin.

Much o' t' build process be spent on t' nose cone, shiver me timbers, but, shiver me timbers, primed and painted, t' results were very rewarding. Begad! Blimey! T' rest o' t' assembly was straight forward, with a few minor glitches. Blimey! Blimey! Arrr! Blimey! I notice t' instructions did nay tell you t' fill and sand t' joint where t' two body tubes are glued, matey, so make sure you do this prior t' mountin' t' long fins. Ahoy! Blimey! I used Aliphatic resin for gluin' t' rest o' t' model.

Motor mount assembly was straight forward, me hearties, me hearties, as was fin assembly but you will have t' make your own fin guide. Avast! Blimey! T' balsa for t' stabilizer (long) fins be o' good quality, me bucko, but one piece was nay quite wide enough t' cut out two fins. I wound up havin' two o' t' four fins about a 1/16" narrower than t' template. Blimey! Blimey! A fresh piece o' balsa from me personal supply fixed t' problem, but I would like t' see them ship sheets that are wide enough t' do t' job. Well, blow me down! Blimey! I decided t' taper t' leadin' edge o' each lower fin and t' leadin' and trailin' edges o' each upper fin for scale appearance.

Afterwards, I opted t' fiberglass t' lower fins on for stiffenin' and additional strength usin' ¾ ounce fiberglass cloth and 30 minute epoxy. Arrr! Blimey! I had read o' instances where people saw t' surface mountin' technique lackin' in strength and I didn't want this t' become an issue. If you don't fiberglass, me hearties, make sure you use thin CyA t' stiffen t' soft balsa fins prior t' gluin' them on. Avast! Avast! Blimey! Location o' t' launch lug was nay specified, arrr, which is normal for these kits. Well, blow me down! Blimey! Blimey! I cut mine in half, gluin' one piece on right at t' top o' t' lower fin and t' other just above balanced CG. Arrr! Construction Rating: 4 o' 5

Afterwards, I opted t' fiberglass t' lower fins on for stiffenin' and additional strength usin' ¾ ounce fiberglass cloth and 30 minute epoxy. Arrr! Blimey! I had read o' instances where people saw t' surface mountin' technique lackin' in strength and I didn't want this t' become an issue. If you don't fiberglass, me hearties, make sure you use thin CyA t' stiffen t' soft balsa fins prior t' gluin' them on. Avast! Avast! Blimey! Location o' t' launch lug was nay specified, arrr, which is normal for these kits. Well, blow me down! Blimey! Blimey! I cut mine in half, gluin' one piece on right at t' top o' t' lower fin and t' other just above balanced CG. Arrr! Construction Rating: 4 o' 5

Finishing:

Finishing:

White primer be applied prior t' t' first sandin' and I used 150 grit t' cut away any excess epoxy resin left from t' fiber-glassing. Avast! A second round o' primer be added and I used 220 grit t' start and finished with 400 grit. Well, blow me down! In t' instructions they have you glue paper "panels" over t' inside length o' each fin prior t' assembly, but you risk tearin' up t' panels with sandpaper durin' t' primin' stage. Aye aye! For this reason, I added me scale paper overlays after all sandin' be complete and prior t' t' last coat o' primer. Chamferin' t' edges o' each overlay made them lay down smooth. Blimey! This be also a good time t' add scale rivets. Blimey! Begad! T' recommended method o' usin' pinheads just didn't cut it for me, especially when thar are 144 rivets on t' finished rocket! You can buy stick-on rivets from a R/C helicopter dealer on t' net, but they only sell them in large quantities and are a bit pricey. Ya scallywag! I opted t' use a very simple and cheap method derived from experiences in R/C aircraft. Aye aye! I filled a syringe that had t' needle ground flat on t' tip with a white canopy glue found at many hobby shops called RC-56 and "dropped" a small ball o' glue at each location for a rivet. T' glue ball flattened somewhat when it hit t' surface and made a perfect rivet. If a mistake was made, arrr, I just wiped it off with me finger and tried again. Begad! With this method, shiver me timbers, scale rivets were finished in less than an hour, ya bilge rat, includin' dryin' time, and t' cost be minimal. Note that Elmers White glue could also be used, but I like RC-56 because it is waterproof when dry and it's consistency doesn't require any dilution.

T' paint scheme in t' instructions shows a very basic color scheme for a single standard model, but if you want it t' look like t' missile on t' LP website, ya bilge rat, you're pretty much on your own. Aye aye! Arrr! Mine was painted in t' same colors as t' website model, arrr, which is actually t' paint scheme for t' upper stage o' t' RIM-67 rocket. Ahoy! I used Rustoleum flat white for t' body and Testors military federal standard paints for t' light gray nose cone and dark gray fins. Begad! I just wish thar were more pictures available that showed labels and letters.

All in all, arrr, t' instructions are pretty good for paintin' a single stage rocket. One o' t' last steps performed be t' installation o' t' shock cord and parachute. T' recommended method o' attachin' t' shock cord is t' use a supplied Estes type tri-folded paper glued t' t' side o' t' body tube. Blimey! This is nay satisfactory for a model o' this size. One o' me best friends and long time rocket modeler, me bucko, Ken, me hearties, recommended I take 2 sets o' 70 lb test Keelhaul®©™line and loop, tie and CyA them around t' motor mount. I followed his advice, me bucko, shiver me timbers, then drilled a small hole through t' mount plate right up against t' motor tube. Well, blow me down! Well, blow me down! T' Keelhaul®©™line be threaded through t' hole and extended six inches out t' top o' t' body tube, where I tied it t' t' shock cord. Avast, me proud beauty! Aye aye! This is a much stronger and safer way o' mountin' t' cord and will help prevent those bilge-suckin' "zippers" that can occur when too much stress is put on wall mounted lines durin' ejection. Ya scallywag! Blimey! Finish: 3 ½ o' 5

Construction Rating: 4 out o' 5

Flight:

Flight: T' motor recommended for first flight was a D12-3, which is what I used t' make this bird airborne. Begad! Avast! I wound up usin' a large sized Pratt Heatshield instead o' wadding! T' rocket lifted off t' pad each time easily, which surprised me for a model o' such size. Aye aye! Well, blow me down! Flight was straight and true; it took t' t' skies like it be on rails! Listed and supported motors include t' D12-3, me bucko, E15-4 and RMS F24-4. Begad! For t' next group o' flights I want t' try t' RMS E18-4W, t' RMS F24-4W will be a definite must, me bucko, arrr, but only on a calm day. I'll repost a quick update after t' holidays on t' success o' t' larger engines.

Recovery:

Recovery: T' parachute deployed right at apogee. Ahoy! T' gold mylar chute supplied in t' kit be very easy t' spot and t' rocket landed safely with all parts intact. I had wondered about t' 18" parachute bein' enough, since t' instructions tell you t' build two o' them. Blimey! I believe this may have been a misprint from a previous generation, but on lower level flights, me bucko, a larger parachute is somethin' I may use. Ya scallywag! I was please that I decided t' beef up t' fins durin' t' build process and do recommend it t' those wantin' t' build a sturdier model. For reference, me rocket weighed in at 8.3 ounces without motor, ya bilge rat, me bucko, which seems about right for a mid powered model o' this size.

Flight Rating: 4 out o' 5

Summary:

T' AGM-78 is nothin' less than AWESOME! Blimey! T' rocket just plain looks good, shiver me timbers, ya bilge rat, and is a very close scale representation o' t' real deal. Avast! Blimey! Ahoy! Blimey! Construction is easier than it looks and t' end result was worth any extra effort. Avast! Blimey! A few things could be improved, such as t' supplied balsa stock (or lack o' enough), arrr, parachute mount and specifications for CG. Aye aye! Blimey! I would also like t' see additional documentation showin' more scale letterin' information and placement. These minor flaws aside, me hearties, this is one fine model. Begad! Blimey! Just keep in mind that this is definitely a builder's kit, which worked out well as I really enjoy t' buildin' process. I now have a fleet addition that would make any modeler proud. If you like t' Launch Pad kits, matey, then you have t' get one o' these; it's a great buy for t' buck! Blimey! Now, about t' only thin' I'm still missin' be t' two stage RIM-67 version, shiver me timbers, which I intend t' remedy real soon, but that's another story.

Overall Rating: 4 out o' 5

Other Reviews

- The Launch Pad Standard AGM-78 By Greg Burke

This kit is relatively straight forward. The instructions are pretty easy to understand, and are also correct. The manufacturer gives some hints on detailing and that's the hardest part. They suggest using the heads of pins for the rivets in the fins. This took up the bulk of my building time as it took over 150 pin heads to accomplish this. The only problems that I had with the kit is the ...

|

|

Flights

|

|

|

|

C.R. (January 1, 2001)