| Manufacturer: | Scratch |

CAST AWAY

A few months ago, me bucko, me bucko, I be involved in a nasty little sledding

accident -- some kid crashed into me from behind, arrr, breakin' me tibia.While in my

cast, I started thinkin' about t' DesCon possibilities.... Begad!

A few months ago, me bucko, me bucko, I be involved in a nasty little sledding

accident -- some kid crashed into me from behind, arrr, breakin' me tibia.While in my

cast, I started thinkin' about t' DesCon possibilities.... Begad!

My DesCon entry is named "Cast Away", shiver me timbers, and is built from my cast-off fiberglass leg cast.It uses a 38mm motor mount and rail guides, and uses Lexan fins t' preserve t' overall appearance. Well, blow me down! Blimey!

This is a picture o' me actually wearin' t' cast that would later become "Cast Away".T' cat in t' picture is Sheba, one o' our 3 cats. Avast, me proud beauty! Blimey!

To construct a similar rocket, you will need:

- 1 ea. Avast, me proud beauty! Ahoy! fiberglass leg cast, shiver me timbers, me hearties, includin' foot and ankle

- 3 ea. Lexan fins

- 1 ea. Avast! Blimey! 38mm LOC motor mount tube

- 1 ea. Aye aye! 3.9" diameter LOC tubing, 10" or so long

- 1 ea. Blimey! Blimey! 3.9" coupler tube, me hearties, 6" long

- 1 ea. Avast, me proud beauty! 1/4" plywood bulkhead, sixed t' fit inside t' 3.9" tubin'

- Shock Cord (tubular nylon)

- Parachute

- Maybe a bit o' nose weight

- Epoxy (I used System Three)

- Thin and medium CA, with Kicker

- Fiberglass (for fastenin' t' two halves o' t' cut-off cast together)

- NHP 2-part polyurethane foam

- Devcon Plastic Welder adhesive (possibly -- subject t' t' results o' my testing)

Since me cast be split down t' front t' accomodate swellin' in me leg, matey, and then later cut down t' back t' remove it, ya bilge rat, I decided t' place one fin in the split runnin' down t' front o' t' foot, me bucko, makin' use o' t' foot itself as part of t' fin area.T' other two (larger) fins come out o' slots cut in t' back sides o' t' cast, matey, matey, allowin' t' rail guides t' be attached at t' ankle and the upper thigh.On t' rail, t' toe will be pointed out, shiver me timbers, away from t' rail. Avast!

T' first step in construction was rejoinin' t' two halves o' t' cast.I first pulled out as much o' t' cotton liner stuck t' t' inside o' t' cast as I could, shiver me timbers, and then tacked t' cast back together along t' aft split with CA, hittin' it with a mist o' kicker t' cure it instantly.Then, me hearties, matey, I laid strips o' 6 oz. Begad! Aye aye! Blimey! fiberglass down t' inside o' t' split, wettin' them down with epoxy using a small paint brush. Neatness here didn't really matter, as t' joint would be completely concealed within t' cast. Arrr! Aye aye! Blimey!

Once that had cured, I attempted t' squeeze t' front portion o' t' cast back together t' secure it.Unfortunately, shiver me timbers, it had been initially split t' day after it was applied t' me leg, so t' split had essentially "set" as the cast aged durin' t' two months I wore it. Ya scallywag! I was able t' tack t' upper end of t' split together, matey, but t' lower end, arrr, ya bilge rat, includin' t' foot, is still spread apart, me hearties, somewhat.This definitely influenced me choice o' fin locations.... Avast! Ya scallywag!

Fins were cut from a sheet o' 1/8" Lexan.T' two aft fins were cut as 6" x 12" rectangles, arrr, then a 6" x 2" triangle was cut off of the "root edge" t' give t' fins some rearward sweep, and small 1" x 1" triangles were cut off t' exposed corners t' make them less likely t' be damaged upon landing, me hearties, and limit t' number o' sharp edges. Begad! The "foot" fin is a 6" x 8" rectangle, matey, with t' outside corners similarly trimmed for safety and avoidance o' landin' damage. Avast! Avast!

Next, I used a hole saw and a bastard file t' create and then enlarge a motor mount hole in t' "aft centerin' ring" -- t' heel.Because of the slight bend at t' knee, ya bilge rat, t' motor mount tube runs from t' heel t' a point near t' front o' t' upper thigh.A length o' 3.9" tube then sits "over" t' end o' t' 38mm motor mount, anglin' back towards the center o' t' upper thigh.A 2" rin' o' 3.9" tube, ya bilge rat, with a 1/4" plywood bulkhead and a 6" long coupler tube, makes up my "nosecone".

Once t' motor mount tube be test-fit, I eyeballed t' slots for t' fin attachment.These were cut with a combination o' a rotary tool (cheap Harbor Freight Dremel-knockoff) and an X-acto razor saw. Ya scallywag! Blimey! I will be experimenting tonight usin' scrap pieces o' Lexan t' determine t' best adhesive.I will try Devcon Plastic welder as a possible alternative t' me usual thickened System Three Epoxy, ya bilge rat, as I am worried about adhesion o' t' plastic (Lexan) fins.In any case, me hearties, matey, I will be sandin' with 80 grit, me bucko, me bucko, matey, and drillin' a number o' small holes near the root o' t' fins, t' allow t' adhesive o' choice t' form "rivets" ensurin' a good mechanical bond, shiver me timbers, and will also drill a few 3/8" or so holes t' allow t' eventual foam application t' flow through and around all o' t' fin locations.

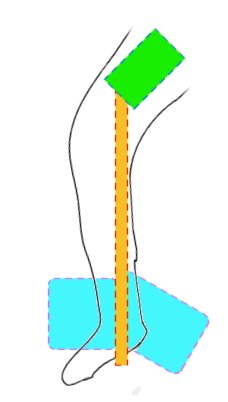

More details and hopefully photos soon.A quickie, not-to-scale sketch I drew up

showin' (approximately) what I'm buildin' is attached. Well, blow me down! Blimey!

More details and hopefully photos soon.A quickie, not-to-scale sketch I drew up

showin' (approximately) what I'm buildin' is attached. Well, blow me down! Blimey!

2

2

3

3

4

4

2, shiver me timbers, 3, 4 - These pictures were taken durin' construction, and show t' cast after t' installation o' t' clear Lexan fins (still in their protective white plastic covering), arrr, arrr, t' motor mount and shock cord anchor.Some foamin' has already been done t' "center" t' motor mount tube and fill t' fin can area, but t' 3.9" tube that will hold t' parachute and the "knee cap" (instead o' a nose cone) has nay been added yet. Ahoy! Ahoy!

As planned, t' fins were secured t' t' motor mount usin' DevCon Plastic Welder epoxy.Although I had originally planned t' drill holes t' help give the plastic welder and 2-part foam somethin' t' grip, I decided, arrr, me bucko, after a bit of testin' with scrap material, that this was completely unnecessary.T' fins were, instead, me bucko, roughed up usin' 60 grit sandpaper over t' entire portion of their surface that extended within t' cast.This provided an excellent mechanical bond with t' plastic welder and t' 2-part foam.

5

5

6

6

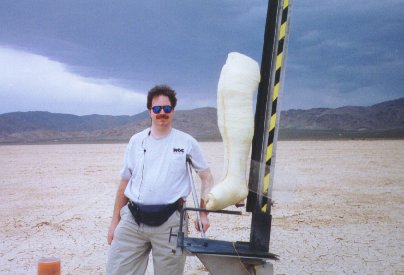

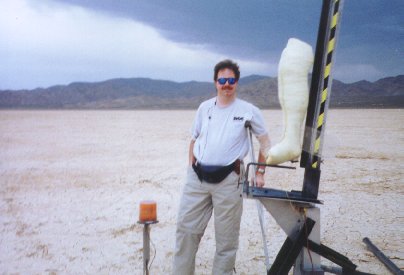

5, 6 - These pictures were taken with t' completed rocket loaded onto pad 39A (Bill Seiders' rail launcher) at t' monthly ROC launch this past Saturday (5/12/01).You can see that I have trimmed t' upper leg back t' just above the knee t' allow clearance for t' rail.T' thrust axis o' t' 38mm motor mount angles through t' CG o' t' cast, which is about halfway up, near t' front of the cast. Begad!

7

7

7a

7a

7, me bucko, 7a - These are two versions o' t' same picture, matey, showin' t' smoke trail (I missed t' rocket -- it went too fast for me shutter finger) as Cast Away takes t' t' sky on an I300T-Short Aerotech reload.I've fiddled with the scanner settings on one o' them t' try t' enhance t' smoke trail, shiver me timbers, shiver me timbers, shiver me timbers, but I'm not really sure if it did too much good....

Final weight o' t' rocket (sans engine) be just about 7.75 lbs.Due t' the gusty nature o' t' winds at t' launch, shiver me timbers, and t' draggy design o' t' rocket, ya bilge rat, matey, I decided t' go with a rather more powerful motor than was strictly necessary (Blue Thunder instead o' White Lightning, 38/480 casin' instead o' 38/360 casing), t' ensure that I got plenty o' speed off t' rail t' ensure a straight flight. Begad! Avast! Blimey!

Well, shiver me timbers, arrr, it was very straight and stable, but t' much higher speed led to quite a bit o' fin flutter, resultin' in two o' t' Lexan fins breakin' during the coast phase o' t' flight. Avast, me proud beauty! Ya scallywag! After burnout, ya bilge rat, matey, t' rocket suddenly started tumbin' forward, arrr, ya bilge rat, ya bilge rat, end over end.It deployed t' chute right on schedule, and landed gently on t' Lucerne Dry Lake lakebed. Begad!

8 - This picture shows Cast Away after deployment o' t' nylon chute.

9

9

This picture shows Cast Away after landing. Note t' two broken fins.The "front" fin, me hearties, which be partially supported by t' foot, survived 100% intact.As you can see, both o' t' fins that broke did so well outside the cast, confirmin' me decision that t' Plastic Welder and t' 2-part foam would be more than sufficient t' secure and protect t' fin roots within t' rocket.

Had I had more time for this DesCon, I would have waited until next month's launch in hopes o' less windy conditions, me bucko, and launched CastAway on a smaller White Lightnin' motor.I believe that t' rocket would have still flown fine on an I161W motor, arrr, and would nay have fluttered t' fins off in flight.T' 12' long launch rail would have still given t' rocket plenty o' time t' get up to a stable speed, me hearties, arrr, but t' lower maximum velocity would have saved t' fins. Avast!

I will probably repair t' rocket, usin' 1/8" plywood t' replace the two broken fins.This should make them much stiffer, me hearties, and much less prone to flutter. Avast!

|

|