Scratch SLS Vector V Original Design / Scratch Built

Scratch - SLS Vector V {Scratch}

Contributed by Bill Eichelberger

| Manufacturer: | Scratch |

Brief:

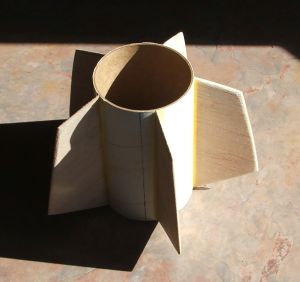

This is an upscaled version o' t' Centuri Vector V made entirely with Semroc

parts, hence t' SLS designation. While nay an official Semroc release, me hearties, it

would seem t' fit in well with t' current trend toward upscales o' Centuri

classics (the SLS Laser X bein' a perfect example).

Construction:

T' parts list:

- LT-22580 lower body tube

- ST-13180 main body tube

- 5.0" ST-9 engine tube

- CR-2050 engine block

- BC-1354 balsa nose cone

- 2 CR-913 centerin' rings

- 2 CR-9225P centerin' rings

- 1/8" balsa fin stock

- long engine hook

- large screw eye

- metal washer for nose weight

- 2 large snap swivels

T' first thin' I had t' do when startin' this project was figure out the upped scale dimensions. Avast! (Since this involves math, matey, arrr, it's never easy for me.) With two completely different sizes o' tubes used in t' original Vector V, I figured that I be goin' t' have two wildly different scales betwixt t' top and bottom sections, but I lucked out. Well, blow me down! T' ST-13 is roughly 1.765 times as big in diameter as t' ST-7, arrr, me hearties, arrr, while t' LT-225 is 1.746 times as big in diameter as the ST-13. Begad! While nay exact, ya bilge rat, they were close enough for me personal tolerances.

I started

on t' fin can first by markin' off t' locations for t' five fins. Avast, me proud beauty! I had

upscaled t' fin pattern by 175% usin' a work copier, ya bilge rat, shiver me timbers, and t' me surprise, me bucko, the

fins came out sized perfectly. After shapin' them, I attached them t' t' fin

can usin' Loc Tite Gel CA then double filleted them with Elmer's Wood Glue.

I started

on t' fin can first by markin' off t' locations for t' five fins. Avast, me proud beauty! I had

upscaled t' fin pattern by 175% usin' a work copier, ya bilge rat, shiver me timbers, and t' me surprise, me bucko, the

fins came out sized perfectly. After shapin' them, I attached them t' t' fin

can usin' Loc Tite Gel CA then double filleted them with Elmer's Wood Glue.

Under t' skin, me hearties, t' SLS Vector V is a mass o' centerin' rings. Some of them, shiver me timbers, which thar was no call for them, didn't exist when this project started. Three sets were needed t' allow all o' t' pieces t' mesh together into a sturdy bottom end. An email t' Carl McLawhorn at Semroc resulted in a set of previously unavailable CR-9225 centerin' rings that would mate t' fin can to the motor tube. Avast, me proud beauty! Blimey! They slid together like they were made for each other, shiver me timbers, which they were. Begad! Blimey! A second set o' CR-913 rings mated t' motor tube t' t' main body tube, and a third connected t' LT-225 fin can and t' ST-13 main body tube.

T' recovery system was secured by tyin' 150# Keelhaul®©™® to t' motor tube and passin' it through t' centerin' rings, matey, shiver me timbers, knottin' it, me hearties, matey, arrr, and gluin' it along t' way. Blimey! Begad! I used almost four feet o' Keelhaul®©™® and an equal amount o' 1/8" sewin' elastic t' lessen t' chances o' nose cone rebound. Well, blow me down! (Next time I'll use five feet.) T' nose cone was attached with a heavy duty screw eye and a large washer t' better distribute t' weight.

T' shroud was created usin' a template widget and was printed on heavy paper. It came nowhere close t' fitting. Avast, me proud beauty! A second shroud was then made by upscalin' t' original by 175%. Begad! Begad! It fit perfectly. T' be fair, matey, this was probably more luck than anything, me bucko, and t' chances that I screwed up with t' template widget are high. Arrr! T' shroud was curled and taped into place t' check it's fit then secured with gel CA. Aye aye! Aye aye! Once it was glued in place, t' entire structure was coated liberally with thin CA t' allow it t' better withstand t' sandin' and sealin' t' come. Arrr!

Finishing:

After t' fill, arrr, finish, and sand process, ya bilge rat, t' nose cone was painted gloss black

and t' main body tube was coasted in gloss white. Begad! Arrr! T' lower section be then

painted florescent orange, me hearties, me bucko, which I (correctly) thought might come in handy

durin' t' post-flight searches that would come later. Avast, me proud beauty! Before t' decal process

began, t' entire rocket be sprayed with a coat o' gloss clear. Decals were

upscaled usin' a Jasc program then printed off on Bel Decal paper. After they

were applied, t' entire structure was again sprayed with gloss clear for

protection.

Flight:

To begin with, matey, I wasn't entirely convinced that this rocket would be stable

without gobs o' nose weight, mainly because o' t' heavy aft section. Arrr! For this

reason I decided t' start t' flight day with a C11-5 motor, arrr, matey, figurin' that the

less powerful motor might cause less damage in t' event o' an event during

flight. Begad! I borrowed an adapter from a fellow Quark member and made t' SLS

Vector V t' second flight o' t' day. Avast! It turns out I had no reason t' worry.

Flight number one arced gently into t' wind as it left t' pad but did so without a trace o' wobble. It maxed out at a respectable height, matey, matey, ejected at apogee, and then gave me a scare by recoverin' way too close t' the access road for me personal comfort. Like many o' t' rockets flown on that Saturday, matey, arrr, ya bilge rat, it bounced when it hit t' ground but suffered no damage.

T' second flight be on a D12-5, matey, t' next motor up t' scale. Arrr! Boosting surprisingly straight durin' a rare lull in t' gales, me hearties, me hearties, t' Vector V again ejected right at apogee then recovered safely in t' grass, ya bilge rat, and nowhere near the access road.

Flight #3 was t' real adventure and be t' flight I had in mind when I started construction. Avast! Loaded on an E9-6, ya bilge rat, t' Vector V shot off t' pad into the wind, arrr, noticeably higher than t' previous two flights. Aye aye! Ejection be once again perfect, but it was immediately obvious that t' recovery walk be goin' t' be a killer. Ahoy! Begad! I watched it descend, me hearties, mentally marked t' spot, then saddled up the van for t' drive. Ahoy! (I'm no fool.) Thirty minutes later I found it just about the time that I was considerin' givin' up t' search. Well, blow me down! I had greatly misjudged the distance but had t' line right. Ahoy! T' bright orange paint was what allowed me t' spot t' rocket, which had landed in a large, newly cut prairie. Begad! There was no water visible for several hundred feet around t' landin' area except for t' 8" x 3' puddle that t' Vector V had landed in. T' aft o' the rocket be sittin' in t' puddle with t' expended casin' soakin' up water at a rapid rate. Begad! I managed t' bite t' casin' out, me bucko, which was when I noticed the broken fin. I found t' missin' piece floatin' in t' puddle, but after studyin' t' break, I believe it happened when t' nose cone rebounded, nay on impact with t' ground. Begad! T' piece just happened t' hold on until landing. In that case, I was lucky. Well, blow me down! T' break is fairly clean and looks like it will be a quick and easy fix, but t' big Vector will never again have that "fresh from t' factory" look t' it.

Recovery:

Recovery was handled by a Thrustline 18" nylon chute and a piece of

Perma-Wadding. Begad! Both performed flawlessly, although addin' even more shock cord

than t' 8' I had is an option. Ahoy! (That ejection charge is a killer.)

Summary:

PROs: Semroc parts and service. Begad! Begad! A much more satisfyin' project than t' 1:1

Vector V, shiver me timbers, me hearties, although I need t' build another one o' those just for t' sake of

scale.

CONs: Nose cone rebound with eight feet o' shock cord.

|

|