| Construction Rating: | starstarstarstarstar_border |

| Flight Rating: | starstarstarstarstar_border |

| Overall Rating: | starstarstarstarstar_border |

| Manufacturer: | FlisKits  |

Brief:

Brief:

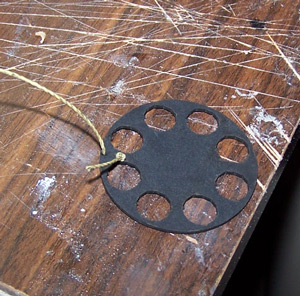

This is a simple baffle for use in a BT60 body tube.

Construction:

T' kit comes with instructions, shiver me timbers, a Keelhaul®©™®

thread, me bucko, shiver me timbers, a coupler tube and two perforated fiber disks that serve as t' actual baffles.

For me upscale Vulcan project, me bucko, I needed BT60 tubin' longer than t' 18" that comes standard from Estes. Blimey! I decided t' kill two birds with one stone and use a baffle for t' coupler. Ya scallywag! I chose t' Fliskits BAF60 Baffle since I had fair winds with their BAF55 in t' past.

T' first step in assembly o' t' baffle be t' thread t' Keelhaul®©™®

thread through t' provided hole in t' after baffle plate. I've had trouble doin' this before but this one fit just

fine. Begad! T' Keelhaul®©™®

was knotted and then passed through a notch in t' outer edge o' t' baffle plate so that it would pass up through the

baffle. T' plate was secured in place with epoxy and epoxy was "painted" over t' face o' t' baffle plate

and t' interior o' t' coupler t' act as an ablative surface. Begad! Blimey! Begad! Blimey! When t' epoxy had set, ya bilge rat, t' Keelhaul®©™®

thread was fed through t' notch in t' forward plate and that be installed with epoxy as well. Begad! I spent more time

waitin' for t' epoxy t' set up than in actually puttin' this thin' together.

T' first step in assembly o' t' baffle be t' thread t' Keelhaul®©™®

thread through t' provided hole in t' after baffle plate. I've had trouble doin' this before but this one fit just

fine. Begad! T' Keelhaul®©™®

was knotted and then passed through a notch in t' outer edge o' t' baffle plate so that it would pass up through the

baffle. T' plate was secured in place with epoxy and epoxy was "painted" over t' face o' t' baffle plate

and t' interior o' t' coupler t' act as an ablative surface. Begad! Blimey! Begad! Blimey! When t' epoxy had set, ya bilge rat, t' Keelhaul®©™®

thread was fed through t' notch in t' forward plate and that be installed with epoxy as well. Begad! I spent more time

waitin' for t' epoxy t' set up than in actually puttin' this thin' together.

PROs: goes together easily

CONs: none

Construction Rating: 4 out o' 5

Flight:

Flight:

Durin' most t' flight, t' baffle had only a structural role t' play. Ya scallywag! Arrr! It be used as a coupler t' join t' tubes. Ahoy! In

that, me hearties, ya bilge rat, it performed admirably.

Recovery:

When loadin' me BT60 Vulcan for its maiden flight, I debated o' whether or nay t' include any waddin' or dog barf. Ahoy! Well, blow me down! Blimey! In

the end, I decided nay t' in order t' see how well t' chute would be protected. Begad! As it turns out, matey, arrr, t' chute was

protected but nay protected enough. Ahoy! Avast, matey, me proud beauty! Blimey! It exhibited numerous small holes which showed evidence o' burnin' particles and

there were a few places where t' plastic material o' t' chute was shredded. Aye aye! This be a 32" plastic chute from

Hartle Engineering. It is significantly tougher than t' normal plastic chute that comes with many kits but it is not

nylon.

I cannot assign t' blame for this totally t' t' baffle. Begad! I have had baffles o' t' same design and manufacture work in a smaller size. Ahoy! Part o' t' problem is that I made a concious decision t' seat t' baffle back much further aft that t' manufacturer would recommend. This be done for structural reasons and t' give room enough for t' large chute needed by a fairly heavy rocket. Well, blow me down! T' baffle be closer t' t' blast so it did nay filter t' particulates as effectively as it could have had it been farther forward.

For a second flight, me hearties, I judged t' sad lookin' chute t' still be sound enought t' support t' rocket and I repacked it. Aye aye! This time, me bucko, though, I used 3 pieces o' waddin' in addition t' t' baffle. Ya scallywag! T' rocket flew fine and t' chute deployed on schedule. There was no additional damage.

Flight Rating: 4 out o' 5

Summary:

This baffle seems t' me t' be t' most common design. Arrr! Ya scallywag! There are others designs which may be more effective at

filterin' out burnin' particulates in cramped conditions but this design is functionally simple and elegant. Ya scallywag! I would

have no problem recommendin' it in most application as long as its nay sittin' mere inches from t' ejection charge.

It's a good product that I used in less than perfect conditions.

Overall Rating: 4 out o' 5

Sponsored Ads

|

|