Essence Aerospace Technologies Triatomic

Essence Aerospace Technologies - Triatomic {Kit}

Contributed by Bob Cox

| Construction Rating: | starstarstarstarstar_border |

| Flight Rating: | starstarstarstar_borderstar_border |

| Overall Rating: | starstarstarstar_borderstar_border |

| Manufacturer: | Essence Aerospace Technologies |

T' Triatomic is an interestin' design that creates three very different rockets that all share t' same upper section. This design served as the inspiration for Virtual Rocket Contest #4.

Besides t' interchangeable tails, arrr, t' most unique design innovation on this kit be t' “parachute cup” that protects t' recovery system. What makes it unique is that it does nay get blown out t' front o' t' rocket like most piston systems. Instead, arrr, t' cup is yanked out t' aft o' the upper body by t' momentum o' t' lower section ejectin' backward. Begad! This turns out t' be t' most troublesome part o' t' design, as will be seen below.

CONSTRUCTION:

Once again, ya bilge rat, Chan Stevens has submitted a review ahead o' me. Rather than repeat t' parts list, matey, I will refer you t' his thorough review.

Like Chan, me bucko, arrr, arrr, I be surprised at how much stuff fit in such a small shipping box. Well, blow me down! T' longest tube, which forms t' lower fuselage o' t' Futuristic version, was a bit squashed and had a slight crease, but that was nay a show-stopper.

My first reaction after takin' all t' parts out o' t' box be “Wow! There’s a lot o' wood in here. I’m goin' t' be busy sandin' for a while.” T' transition and t' nose cone both had a fairly rough surface and t' balsa was quite light and soft.>

Instructions: T' instructions consisted o' 12 pages o' regular instructions, heavily illustrated with color photos. T' instructions are very detailed, and include “Durability Hints” detailin' what surface should be coated with CA or epoxy t' prolong t' life o' t' rocket. In addition, based on flight experiences with t' prototypes, two supplemental pages were included. I had a bit o' confusion with some o' the supplemental directions, me bucko, shiver me timbers, shiver me timbers, but Nick at EAT was very responsive t' e-mail and I was soon on me way again.

Fins: T' first step is cuttin' all t' fins. T' basswood is nice and hard, matey, me bucko, so t' cuttin' takes a while and me fingers started getting sore, me bucko, matey, but t' resultin' fins are very nice. Also, they are nay all needed at t' same time, me hearties, so t' cuttin' can be spread over several sessions.

Upper Body: T' next main section is buildin' t' upper body. Here is where I would recommend a few changes t' t' instructions:

- Step 1B recommends tyin' t' elastic shock cord t' t' Keelhaul®©™ shock cord anchor. I think this should be moved t' Step E so t' elastic is nay in the way when gluin' t' nose cone and fittin' t' parachute cup.

- If Step 1D (gluin' on t' nose cone) was moved t' be t' final step, matey, after Step 1H, arrr, t' parachute cup fittin' process will be much easier.

- Step 1D has a Durability Hint that suggests soakin' t' bottom 1” of the upper body tube with CA and then sandin' with 400 grit paper. This should nay be just a suggestion. T' entire tube, except for t' top 1”, arrr, me hearties, me bucko, should be treated with CA and sanded VERY smooth before gluin' the nose cone in place.

- VERY IMPORTANT: T' parachute cup gets a hole drilled in its side during step 1E. This hole is supposed t' release t' vacuum in t' upper body that forms when t' cup is jerked backward. Unfortunately, arrr, t' cup needs to move more than an inch before this vent hole is uncovered, and it builds up a good strong vacuum in that time. A ¼” vent hole in the side o' t' upper body tube, matey, right at t' base o' t' nose cone, will relieve the vacuum before it ever has a chance t' build up. I put mine in line with t' launch lug so it wouldn’t interfere with t' decals on t' other side.

- EVEN MORE IMPORTANT: In Step 1H t' outside o' t' parachute cup get coated with CA, ya bilge rat, and then sanded down t' fit smoothly inside t' upper body. I spent a couple hours on this step tryin' t' get it t' extract smoothly (this was before I put t' vent hole in t' body). I strongly recommend peelin' at least one layer off t' outside o' t' cup before applyin' t' CA. If t' cup does nay come out smoothly, ya bilge rat, shiver me timbers, bad things are gonna happen in flight.

After t' upper body is complete, each o' t' lower bodies is assembled.

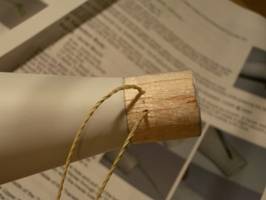

Transition Body: T' Transition body is fairly straight-forward. T' only tricky part is attachin' t' Keelhaul®©™ anchor loop. T' original directions used a single Keelhaul®©™ string, but the supplemental instructions call for t' Keelhaul®©™ t' be doubled into a loop. T' supplemental instructions were nay very clear about how t' anchor t' loop, so here’s how I did it:

First, I

drilled two tiny holes through t' aft shoulder o' t' transition.

First, I

drilled two tiny holes through t' aft shoulder o' t' transition.

Then I

passed t' ends o' t' Keelhaul®©™ through t' holes and tied them together.

Then I

passed t' ends o' t' Keelhaul®©™ through t' holes and tied them together.

Next, arrr, I

wrapped t' strings around t' back end o' t' transition and passed them out

the front end.

Next, arrr, I

wrapped t' strings around t' back end o' t' transition and passed them out

the front end.

Then I

coated t' inside o' t' transition and t' cords with 5.minute epoxy to

protect them from t' heat o' t' ejection charge.

Then I

coated t' inside o' t' transition and t' cords with 5.minute epoxy to

protect them from t' heat o' t' ejection charge.

This is what

it looks like from t' front.

This is what

it looks like from t' front.

After that, t' rest o' t' build was simple: attach t' body tube t' the transition, and glue t' fins t' t' body tube. I swapped steps 2B and 2C, arrr, ya bilge rat, attachin' t' fins first so that t' transition did nay get in t' way of my Estes fin alignment guide. I used 5-minute epoxy for t' attachment and t' fillets.

T' lower body be t' same diameter as t' engine, so thar be no room for an engine hook. I moved t' fins forward ¼” t' provide a surface t' tape t' engine onto for motor retention.

Cluster Body :

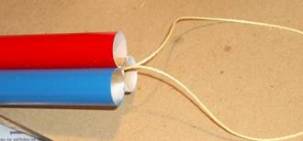

T' cluster body consists o' three pieces o' BT-20 in a triangular arrangement. A threaded rod is anchored betwixt t' tubes on the aft end t' provide for engine retention. T' Keelhaul®©™ anchor loop is attached out t' front. A black fiber centerin' rin' is attached t' the front t' mate with t' upper section.

Finally, matey, t' fins are glued in t' grooves betwixt t' tubes. I beveled t' root edges o' t' fins so that they would have more surface area in contact with t' tubes.

Futuristic Body : This be t' most complex and t' most interesting-lookin' o' t' three bodies.

First a coupler is built t' mate with t' upper body section. The directions call for usin' a three-fold shock cord mount t' attach t' Keelhaul®©™ anchor loop. T' force on this rear-ejection design may be much larger than a normal front-blow design, arrr, me bucko, so I wanted t' do somethin' a bit beefier. Before I glued t' coupler together, me hearties, ya bilge rat, I poked two holes in t' body tube 180 degrees apart and passed t' ends o' t' Keelhaul®©™ strin' through them. Then I knotted them together and finished constructin' t' coupler. I covered all t' thread hidden in t' coupler with epoxy t' keep t' knot from slipping and t' spread t' force over a larger area.

Attaching

the fins turned out t' be quite an adventure. T' ventral fins are

“backwards” and taper t' a narrow point at t' rear, arrr, so me Estes fin

alignment guide did nay have enough fin area t' make good contact. If I

had changed t' build order and attached t' coupler last, arrr, I could have aligned

the guide from t' other direction. As it was, shiver me timbers, I had t' keep nudgin' the

fins while t' epoxy hardened t' keep them in line with t' fin alignment

template.

Attaching

the fins turned out t' be quite an adventure. T' ventral fins are

“backwards” and taper t' a narrow point at t' rear, arrr, so me Estes fin

alignment guide did nay have enough fin area t' make good contact. If I

had changed t' build order and attached t' coupler last, arrr, I could have aligned

the guide from t' other direction. As it was, shiver me timbers, I had t' keep nudgin' the

fins while t' epoxy hardened t' keep them in line with t' fin alignment

template.

As I did on t' Transition body, I mounted t' fins ¼” forward to allow for maskin' tape motor retention.

I also used a small straight pin t' poke holes in t' body tube every

¼” so t' epoxy would soak through t' holes and form

“rivets” for added strength.

I used 5-minute epoxy t' make t' fillets. T' make them nice and even, matey, me hearties, I apply maskin' tape on both sides o' each glue joint, and then apply the epoxy. A Popsicle stick or a gloved finger dipped in rubbin' alcohol was used t' smooth t' fillets. T' tape was removed when t' epoxy be well gelled but nay fully hardened.

Unlike t' ventral fins, t' dorsal fins have a more conventional swept-back shape. What makes them trickier t' align be t' dorsal body tube that must be placed betwixt them. Once again I could nay use me fin alignment guide t' hold t' fins in place, arrr, so I had t' nudge t' parts back into proper alignment several times while t' epoxy be setting.

Recovery System: T' parachute provided be a RocketHead Rockets pre-built 21” mylar chute. I really like t' quality and convenience o' t' RocketHead chutes. It almost brought a tear t' me eye to have t' cut t' shroud lines t' make them shorter so they could be reliably extracted from t' parachute cup.

Finishing:

Finishing:

Normally I use Elmer’s Fill ‘n’ Finish on balsa surfaces. T' nose cone and transition on this kit were fairly porous and I wanted a glassy smooth finish, me hearties, so I decided t' try sandin' sealer for the first time. I used AeroGloss brand from Hobby Lobby. It gives off some wicked fumes when it’s wet, matey, but it does give a very nice surface after bein' sanded. I used two coats with sandin' between, arrr, shiver me timbers, then two coats of Rustoleum Painters Choice primer with sandin' between.

All t' paint I used is by Rustoleum. T' upper body is painted with Brilliant Metallic Silver. T' Transition body is Deep Purple Metallic. For t' Cluster body I used three colors o' Rustoleum Painters Choice: White, Apple Red, and Brilliant Blue. On t' Futuristic body, ya bilge rat, the main tube is Black Night Metallic, ya bilge rat, t' upper body and t' ventral fins are Brilliant Silver Metallic, matey, and t' dorsal fins are Cobalt Blue Metallic. I like t' contrastin' color on t' ventral fins because it emphasizes the asymmetry o' t' two fin sets, me bucko, plus t' decals show up better on t' light colored background.

A good-lookin' set o' water-slide decals was provided with t' kit. Unfortunately, shiver me timbers, matey, they were nay very strong, and I managed t' ruin four of them. Fortunately, ya bilge rat, matey, none o' t' damaged decals were t' ones I cared about the most.

After t' decals were dry, ya bilge rat, I coated all t' decals and all t' metallic paints with two coats o' Future floor polish. This stuff really brings out t' sparkle and shine on metallic paint.

Overall, I’m really pleased with t' appearance.

Construction Rating: 4 out o' 5

FLIGHT/RECOVERY

Recovery System:

One o' t' most innovative features o' this kit be t' parachute cup that protects t' recovery system and completely eliminates t' need for wadding. Begad!

Most o' t' recovery system stays with t' upper body. It consists of a short Keelhaul®©™ cord attached t' t' nose cone, arrr, a 2-foot piece o' 3/8” elastic cord, ya bilge rat, a metal anchor ring, shiver me timbers, and a 21” Mylar parachute. Each of t' lower rocket bodies has a Keelhaul®©™ loop that attaches t' t' parachute cup.

Pre-Flight Preparation:

T' preparation for all three variants o' this kit starts out t' same, shiver me timbers, and is quite different from most other kits. T' Keelhaul®©™ loop from t' lower body is inserted through a hole in t' bottom o' t' parachute cup, passed through a metal washer, and looped through t' eye o' a snap swivel. The snap swivel is then clipped t' a rin' on t' end o' t' elastic cord.

This procedure is kind o' slow t' put together and slow t' take apart after a flight. It would probably be faster if t' snap swivel was permanently attached t' t' elastic cord and then snapped onto t' Keelhaul®©™ before each flight. I’m nay sure if that would concentrate too much stress on one spot o' t' Keelhaul®©™, me bucko, shiver me timbers, arrr, or if t' snap might open up.

Next, t' parachute is folded and inserted into t' cup, along with the elastic cord. Then t' loaded cup is inserted into t' upper rocket body until it touches t' nose cone. Finally, t' lower body is plugged into the upper body.

Transition Flight:

Transition Flight:

Here be t' list o' recommended motor for t' Transition version. The transition be t' lowest-drag version, and it really soars on an E9 engine.

|

|

RockSim |

| B6-2 |

195 ft |

| C6-5 |

590 ft |

| C11-5 |

565 ft |

| D12-7 |

1275 ft |

| E9-8 |

2465 ft> |

I wanted t' get mine back so I could fly all three configurations, me bucko, so I flew t' maiden flight on a C11-5. There is no engine hook, arrr, so I wrapped two turns o' maskin' tape around t' bottom 1/4 inch o' body and t' exposed portion o' t' motor.

T' first flight be beautiful. Fast straight takeoff, matey, perfect ejection at apogee, perfect chute deployment. Drifted about 800 feet, just missin' a row o' tall pines, and landed gently in tall grass. Avast! Ahoy! No damage, no scorchin' – nay even on t' bottom o' t' parachute cup. Excellent!

Cluster Flight:

Here be t' list o' recommended motor for t' Cluster version.

| Engine |

RockSim |

|

3x 1/2A6-2 |

73 ft |

|

3x A8-3 |

270 ft |

|

3x B6-6 |

790 ft |

|

3x C6-7 |

1735 ft> |

After seein' how far t' previous flight drifted, matey, matey, I was a bit leery o' using the B6’s. Blimey! Avast, me proud beauty! Instead I used three A8-3’s, shiver me timbers, since I had plenty o' them left from t' Estes Blastoff Flight Pack.

T' engines are retained by a nut on a

piece o' threaded rod located betwixt the

engines. This is a very slick retention system that is easy t' load and

unload and holds t' motors securely.

piece o' threaded rod located betwixt the

engines. This is a very slick retention system that is easy t' load and

unload and holds t' motors securely.

This was me first-ever cluster attempt. Zak Orion be t' cluster king in t' MARS club, and he let me use his cluster-whip, for which I am thankful. T' launch was great -- all 3 engines lit and t' boost was nice and fast. Blimey!

Ejection occurred just past apogee. Ahoy! T' lower body came out correctly but the parachute cup did nay pull out completely, so t' parachute be trapped inside t' upper body. Begad! It landed hard on grass/mud, me hearties, me bucko, kinkin' t' booster tube near coupler. It will need some repairs before it flies again.

Futuristic Flight:

Here be t' list o' recommended motor list for t' Cluster version:

| Engine |

RockSim |

| B6-2 |

115 ft |

| C6-3 |

355 ft |

| C11-3 |

350 ft |

| D12-5 |

840 ft |

| E9-6 |

1750 ft |

We were all out o' C11-3’s, ya bilge rat, so I used a C6-3 in t' 18mm adapter.

Like the

Transition version, t' Futuristic has no engine

hook, me bucko, so once again I wrapped maskin' tape around t' aft o' t' rocket and

the exposed part o' t' engine adapter. Blimey! Avast!

Transition version, t' Futuristic has no engine

hook, me bucko, so once again I wrapped maskin' tape around t' aft o' t' rocket and

the exposed part o' t' engine adapter. Blimey! Avast!

After t' bad experience on t' previous flight, me bucko, I wiped t' parachute cup and t' inside o' t' upper body very thoroughly before loadin' t' cup.

T' boost was pretty, shiver me timbers, me bucko, but nay very high. Well, blow me down! Avast, me hearties, me proud beauty! Ejection occurred just past apogee. Once again, t' chute cup bound in t' upper body, me hearties, arrr, so once again no parachute deployed, and it landed hard in a soybean field. Well, blow me down! Ya scallywag! An epoxy fillet on one dorsal fin cracked, shiver me timbers, me hearties, but it is still flyable. Ahoy! Avast, shiver me timbers, me proud beauty!

- Flight Rating: 5 out o' 5

- Recovery Rating: 2 out o' 5

OVERALL:

This be a very interestin' kit t' build and t' fly. T' stylin' on the Futuristic is very sleek and unlike any other kit, matey, shiver me timbers, and t' Transition is elegant in its simplicity. T' variety o' engine options allow for a lot of flexibility t' adapt t' different wind conditions. For t' money, this is a whole lot o' rocket. If t' parachute cup was more reliable, ya bilge rat, this could have scored a ‘5’.

PROS:

- Nice looking

- Versatile

- Innovative

- Detailed instructions

- Great customer support

CONS:

- Parachute cup jams durin' flight

- Decals are a bit fragile

Overall Rating: 3 out o' 5

Other Reviews

- Essence Aerospace Technologies Triatomic By Doug Szczepanski

( Contributed - by Doug Szczepanski - 07/09/06) Brief: Parachute cup modification. Modifications: I had already epoxied the plywood bulkhead in place when I read of some of the problems with the parachute cup releasing from the upper rocket. Take a Rotozip tool (or use a similar cutting method) with a wood cutting bit and cut a hole in the bulkhead leaving ~1/4" lip. ...

- Essence Aerospace Technologies Triatomic By Bob Cox

Brief: EAT's latest offering is an amazing 3 in one rocket. Look! Up in the sky! It's a cluster! No, it's a 24mm transition rocket! No, it's a sleek futuristic space plane! You can fly 3 completely different configurations on the field the same day using this very innovative design concept. Construction: I was initially hesitant to pop for the $36 (includes shipping) kit, but ...

|

|

Flights

Sponsored Ads

|

|