| Manufacturer: | Scratch |

|

Which came first? T' Egg? The Chicken? Or..... The Rocket! |

|

|

T' Tale o' Egberto

Guismonte - T' Rubber Chicken Rocket

|

||

| PARTS LIST:

|

ADHESIVES: |

|

| Its all Chris Eilbeck's fault he came up with this idea t' fly some rubber chickens at t' m.a.r.s. Aye aye! Avast! Blimey! Brass Balls launch. His was t' be called Keith. Well it seemed like a good idea at t' time. I hadn't originally planned to enter it for Descon so I dont have a lot o' construction details for t' early stages suffice t' say " First catch your chicken..." I got mine from the Silly Jokes Online Store. |

||

T' Chicken has landed |

|

| A couple o' days later and I had a box full o' rubber chickeny goodness. Aye aye! I had decided this chicken had t' go with a whoosh which meant a 38mm motor mount and a Cesaroni Pro38 motor as Aerotech motors are as rare as hen's teeth over here in t' UK. Begad! |

Chicken Stuffing |

|

| Havin' aquired me new bird t' next question had t' be how t' fit t' motor. Avast, me proud beauty! Avast, me proud beauty! It wasnt difficult to imagine where it had t' go just how t' go about puttin' it there. I started by removin' t' squeaker fitted t' t' chickens aft vent. | |

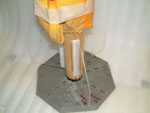

| T' next step was to take a piece o' 38mm motor mount tube and offer it up t' t' chicken's bottom. I drew a line around t' tube and then cut out t' rubber with a pair o' sharp scissors. I emphasise t' sharp as chicken rubber it quite resiliant and difficult t' cut. Blimey! A bit o' trimmin' with a scalpel and I had an even tight fit. I fitted t' motor mount in t' t' chicken and pushed it up until it be in the neck o' t' chicken as far as it would go. Avast! I then offered up a Pro38 1 Grain casin' t' get an idea how far t' motor mount would have t' hang out t' back of t' chicken. I figured that t' tube within t' body o' t' chicken would be adequate for t' recovery system as long as t' majority o' t' motor was outside t' body. Begad! I added around 10mm t' give a bit o' space for motor retention below t' fins and cut t' motor mount tube t' length. | |

|

In t' past I have used a piece o' 1/4" fibre glass rod as a mountin' point for t' recovery harness. Begad! I drilled a hole across t' tube above where t' end o' t' motor would go, matey, cut t' fibreglass rod t' length glued and filleted it inside the tube and t' filed and sanded t' end o' t' rod smooth on t' outside o' the tube. |

| With t' motor mount trimmed it was time t' make t' "nose cone" fitting. Well, blow me down! Now things get a bit vauge here and I will have t' leave t' detail as an exercise for the student. Blimey! T' idea be t' make somethin' from a 38mm coupler tube with some space in it which could accept some beak weight. Arrr! Blimey! I rummaged and came up with a selection o' Estes bits and bobs. A bit o' sanded centerin' rin' here and a bit of glue thar and I had a part that would fit in t' t' neck o' t' motor mount tube. Begad! Ya scallywag! T' only evidence I have o' this is in this picture sequence. | |

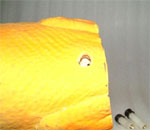

| With the nose piece made it be time t' get foamin'. Ya scallywag! My plan, which proved rather unsuccessful, was t' fit t' nose piece t' t' top o' t' motor tube using maskin' tape t' hold it in place. Ya scallywag! Pour in a quantity o' two part foam t' the rubber chicken carcass. Avast! Aye aye! Jam t' tube assembly up t' chicken and wait for the foam t' expand and set. Avast! Arrr! Fixin' t' whole thin' in place. Well, blow me down! As t' join between the nose piece and t' motor tube were flush at t' top o' t' tube and the tube should fit snuggly in t' t' chickens rubbery neck I reasoned that, arrr, ya bilge rat, once set, I would be able t' cut through t' rubber and seperate t' now foamed on head and nose piece from t' foamed in motor tube and chicken body. Arrr! T' masking tape should have held t' nose piece in place and sealed it from foamy ingress. | |

| There lies me error. That two part foam can build up a fair pressure if you contain it. Ya scallywag! With the foam mixed and poured in I jamed in t' tube assembly. Ahoy! I wiggled and tipped things around t' get a even distribution o' liquid foam around t' insides then settled down t' hold it all in place. Ahoy! T' foam expanded and started t' push. Begad! Begad! It was quite a fight,and quite a sight as I struggled with me fowl. Blimey! In time I triumphed, or so I thought, matey, and t' foam set with t' tube where I thought it should be and a reasonably firm chicken (even if it's head had swollen in a rather disturbin' fashion). | |

| Time to make a quick cut and "off with its head". Begad! Begad! First cut through where I thought I had t' cut and t' head refused t' budge. A spell head scratching, cursing, ya bilge rat, me bucko, askin' others for guidance and bein' told "you didnt want t' do it like that" later and an second calculated cut be made. Aye aye! This time the head came off in me hand. Avast! Some modification and fettlin' and I had a useable head / beak / nose cone. T' reason for t' cut point movin' was that the pressure o' t' expandin' foam had forced t' inner nose piece back down the inside o' t' motor mount. Ya scallywag! T' second cut was measured from t' position o' the aft end o' t' nose piece relative t' t' back end o' t' motor tube. Arrr! Aye aye! With the length o' t' coupler used for t' nose piece know it be possible t' work out where t' front o' it should be. Well, blow me down! Measure along t' outside o' t' chicken and cut through. | |

Beaky |

|

| Finally I had t' add some beak weight and t' beak retention end o' t' recovery harness.. Well, blow me down! A loaded single grain Pro38 be fitted t' t' aft and then lead shot was added t' t' hollowed out nose piece until t' CofG was agreeably forward. T' lead shot was mixed with 5 minute epoxy t' make a nice batch o' rocket caviar and was poured in and left t' set. Well, blow me down! Begad! A 38mm plywood coupler bulkhead had a single approx 5mm hole drilled through it. Begad! A length o' tubular kevlar was folded in half a had a figure o' 8 knot tied with t' two free ends held together t' form a loop. Aye aye! This was threaded through a 5mm washer. Arrr! T' knot was large enough that it wouldnt pull through t' washer. Aye aye! T' loop was then pulled through t' bulkhead and t' bulkhead glued in t' t' back o' t' nose piece with epoxy. | |

|

|