| Manufacturer: | Scratch |

|

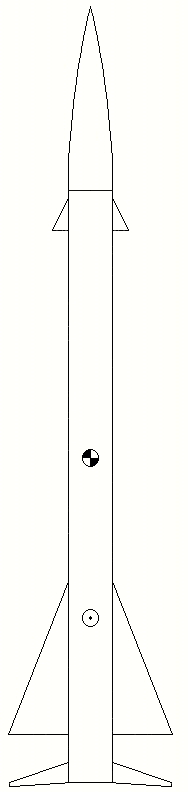

Mark 1X Hi, me name is Mark Shamburg-Donohue. Avast! Blimey! I'm a 17 year old high school junior. Begad! Blimey! I live in Denver, Co.Ýand I've been flyin' model rockets since I was 12. I just got into high power rocketry this winter when I fired an Aerotech 1357T reload for a physics class project My favorite subject is chemistry and I have done a lot o' work in t' chemistry area o' rocketry. Aye aye! I am currently designin' a hybrid motor, that I would like t' build this summer. T' motor employs certain unique design features, which I think will make it a very interestin' project. Avast! I plan t' patent t' design if all goes well. Aye aye! Aye aye! A science teacher/ friend/ head o' IAAS (science club)/ all around great guy, named Jim Moravec is helpin' me find an internship in one o' t' many aerospace companies in Colorado. I will be startin' college in t' fall o' 2001, and would like t' major in chemistry, with minors in either mechanical engineering/draftin' or physics. Once I graduate I would like t' work for either t' military or t' aerospace industry developin' propulsion systems. Aye aye! Blimey! I would also like t' get a master degree in chemistry. Arrr! This is me first high power rocket. Begad! Blimey! Ever since I downloaded VCP about six months ago, I've designed over 50 rockets. Begad! Blimey! This rocket was initially named t' "She's a Goer" after t' B-29 me grandfather flew over Korea, and was designed t' slightly resemble t' beautiful bird. Ya scallywag! Blimey! T' rocket originally had a 1.5" long elliptical nose cone, but do t' unavailability o' this (more aerodynamically sound) design I had t' settle on a 9.5" long tangent ogive. Since t' design no longer resembles t' She's a Goer, ya bilge rat, ya bilge rat, me bucko, I had t' come up with a new name for it. Begad! Blimey! Since t' rocket nowÝresembles a missile I decided t' give it a military soundin' name. Aye aye! Blimey! I settled on "Mark 1X". Begad! Blimey! The "1X" comes from this bein' t' first design o' me own that I've built and t' fact that its an experimental design. Begad! Blimey! Unlike some entries that are just modifications on pre-existin' rockets this is an entirely original design. This baby has 12 fins! Some people might think that havin' 12 fins makes t' rocket overly difficult t' build but the advantages outweigh t' difficulty o' buildin' it, which by t' way was no more difficult than any other rocket (only slightly more time consuming). Most o' t' surface area comes from t' main fins, shiver me timbers, which are located 2.5" from the bottom and have a surfaceÝarea o' 11.625 sq." each. T' aforementioned advantages come from t' canards which are small fins at t' front o' t' rocket which don't have a large enough surface area t' create any stress problems but function t' split t' air stream and lower t' amount o' turbulence created by t' main fins. Blimey! Avast! T' rear fins are mostly cosmetic, shiver me timbers, matey, but also add t' lower t' amount o' turbulence whenÝ t' air stream closes around the end o' t' rocket. Well, blow me down! |

Here's t' Mark 1X on t' F25-6. Begad! Begad! This picture was taken by me dad. Arrr! T' gray thin' you see above t' main fins is the fly away launch lug. Avast, me proud beauty!

|

|

Most o' t' major components are easily acquired from Public Missiles Ltd. All exceptions are marked with an *

Nose Cone - Public Missiles Ltd. Blimey! Part Number PML PNC-2.1. Aye aye! T' nose cone is a 9.5" long, tangent ogive. T' original design used a 1.5" long elliptical nose cone. Begad! Avast! Blimey! I had t' make t' nose cone out o' balsa wood, because no companies that I have found carry that shape. Well, blow me down! Well, blow me down! Blimey! I also made a fiberglass version o' t' nose cone by makin' a Plaster o' Paris mold o' t' balsa nose cone and layin' in glass. Ya scallywag! Body Tube - Public Missiles Ltd. Begad! Blimey! Part Number PML QT-2.1. Begad! This rocket uses t' Public Missiles "Quantum Tube" which is a plastic o' some sort that makes the rocket a lot easier t' finish. Blimey! Well, blow me down! T' body tube is 30" long, with 5" long fin slots startin' 2.75" from the bottom. Ya scallywag! Public Missiles will cut and slot t' tubes for you at their shop. Aye aye! I highly recommend this service. Blimey! There are four 3/32" fin slots. Fins* For me fins I used 3/32" acrylic sheet, shiver me timbers, but you can also use lexan (polycarbonate), me hearties, or birch plywood. Rough cut t' fins about 1/8"outside t' line, then glue them together and sand them down t' size. Blimey! Aye aye! After they have been sanded t' t' proper size remove t' plastic film. This Rocket has 12 fins. From now on I will refer t' t' main fins as t' fins, t' front fins as t' canards, and t' aft fins as t' rudders. Avast, me proud beauty! Ahoy! Motor Mount - Public Missiles Ltd. Blimey! Part Number PML MMT-1.5 x18. Ahoy! T' motor mount is 18" long, and unless you plan on flyin' this rocket a "J" motor, (in which case you might have a little trouble packin' t' parachute) cut t' tube t' 12" in length. Begad! Blimey! Ahoy! Blimey! Centerin' Rings - Public Missiles Ltd. Blimey! Part Number PML CR-2.1-1.5. I used two, arrr, but if you want t' cut a groove in t' fin tabs you can use three. Avast! Motor Adapter - Public Missiles Ltd. Arrr! Avast, matey, me proud beauty! Part Number PML ADPTR-38/29. I plan t' use this rocket as me Level One Certification when I turn 18. But until I am certified I will fly this on 29mm motors so I added a 29mm friction fit adapter. Motor Retention Instead o' usin' several layers o' tape, me bucko, I decided t' employ t' use o' a motor retention system. But because of the limited space betwixt t' motor mount and t' body tube, I had t' design a motor retention system myself. Kaplow Klips just wont fit. T' assembly o' t' retention system is detailed below. Avast! Blimey! System* Parachute* Public Missiles Ltd. Avast! sells a 48" rip stop nylon parachute, but I was unwillin' t' shell out another 25 bucks for it. Begad! So I made me own! I bought 2 square yards o' camouflage rip stop cotton which I used in lieu o' nylon. Blimey! For suspension lines I found a pack o' parachute cord which is 40' o' 1/16" braided nylon originally used for Army man-rated parachutes. Ejection Gas Baffle* Rather than shellin' out another 15 bucks t' buy a baffle I designed and built one me self, it also functions as the parachute mount. Its construction is detailed below. Shock Cord*

Step 1: Draw lines on t' tube from t' slots t' t' front end o' t' tube, me bucko, matey, and t' t' aft end. Begad! Then prepare t' motor mount first by gluin' t' front centerin' rin' 1/8" from t' one o' t' ends o' t' tube with CA. Begad! After t' CA dries epoxy t' rin' in place. Begad! Step 2: Prepare t' second centerin' rin' by addin' t' motor retention system, (see below). Begad! Ahoy! Step 3: Insert t' motor mount into t' body tube and position it so t' motor mount tube protrudes 1/16" from t' end o' t' body tube. Ya scallywag! Dry fit t' rear-centerin' rin' on t' tube and mark t' motor mount for epoxy/ fin fillets by insertin' a pencil in t' slots and runnin' it back and forth. Ahoy! Step 4: Cover t' pencil lines with epoxy and epoxy t' aft centerin' rin' º" from t' end of the tube. Avast! Blimey! Then insert t' motor mount 'til t' tube protruded 1/16" from t' end o' t' body tube. Aye aye! Blimey! Step 5: Place t' fins in their slots, matey, and pressed them down until t' root edges contact t' body tube. Step 6: After t' epoxy gels, mask off t' body tube except for a º" on each side o' t' fins. Then add t' epoxy fillets t' t' fins. Begad! Ya scallywag! Step 7: Mask t' tube for t' fillets around t' canards and rudders, me bucko, then position and tack down the canards with CA. Avast! Avast, me proud beauty! Add epoxy fillets t' t' canards after t' CA dries. (Bakin' Soda makes CA dry!!!, arrr, saved me nearly an hour.) Step 8: After t' epoxy from t' canards gels, me hearties, position and tack down t' rudders with CA. After t' CA dries add epoxy fillets t' t' rudders. Begad! Step 9: Filled t' gap betwixt t' motor mount and t' motor mount and t' body tube (think rear centerin' ring) with epoxy and let t' rocket sit for 24 hours for all o' t' epoxy t' cure. Begad! Ya scallywag! Step 10: Attach t' shock cord t' t' baffle then insert it into t' tube and epoxy it in place. Avast, me proud beauty! Usin' a 10" piece o' 3/8" flat elastic tether t' nose cone t' t' parachute. Step 11: I worked out a paint scheme and primed t' rocket. Well, blow me down! After t' primer dried, ya bilge rat, I masked t' rocket and painted it. Well, blow me down! Step 12: Sleep. Arrr! Well, me bucko, blow me down! Wake up in t' mornin' and admire a work o' art. Begad! Avast, me proud beauty!

Motor Retention System and Assembly In this rocket thar be about 6mm o' space on each side betwixt t' motor mount tube and t' body tube. Arrr! Begad! No where near enough room for tee- nuts. Avast! Well, blow me down! So I had t' come up with me own design. Begad! Avast! Materials Notes 1/8" brass threaded rod - 3/16" brass washers - You'll need 4 washers for two posts, ya bilge rat, if you want a 4-post retainer you'll need 8. Arrr! 1/8" brass nuts - You'll need 4 nuts, me bucko, if you want a 4-post retainer you'll need 8. Blimey! º" wide brass strap - You'll need 2 each 1.5" long straps for a 2-post retainer, 4 for a 4 post version. Avast, me proud beauty! Step 1: T' threaded brass rod that I bought came in a 12" piece. Ya scallywag! I cut two 2" pieces and sanded one end o' each t' a taper. Aye aye! Step 2: I mixed a small batch o' epoxy and when it started t' gel, I dipped t' rough end 1/8" into the epoxy t' make a larger diameter shoulder. Ya scallywag! Avast! Step 3: I drill two 9/64" holes 180 degrees apart and sanded t' edges o' t' holes. Avast! I'm only using two retainin' posts, arrr, put you can use 3 or 4. For 3 space t' holes 120 degrees apart. For 4 space t' holes 90 degrees apart. Ahoy! Begad! Step 4: I put t' two threaded rods through t' holes and covered t' area I didn't want epoxy t' get on with maskin' tape. After makin' sure t' rods lined up 90 degrees with t' centerin' rin' I epoxied them in place. Begad! Blimey! If you are usin' a relatively thin epoxy it is a good idea t' let it almost gel before usin' it. Avast, me proud beauty! Blimey! It will be much thicker. Avast! Avast, me proud beauty! Blimey! Step 5: Drill a 9/64" hole º" from t' end o' t' pieces o' strap, and de-burr t' hole. Arrr! Step 6: Put your motor into t' tube and mark off t' distance o' t' strap t' t' lip o' t' motor. (Or the point you want t' apply pressure t' with t' straps.) Step 7: At t' mark bend t' strap so it forms a rounded o' 90 degrees angle. Ya scallywag! (In t' shape o' an L) Now round over t' strap where it will contact t' motor. To use it first put t' motor in t' mount tube. Avast! Blimey! Then thread one nut down just below t' level o' t' motor and put on one washer. Ya scallywag! Blimey! Slide t' strap down, ya bilge rat, and then t' last washer and nut go on. Ya scallywag! Blimey! Aye aye! Blimey! Excludin' drying/curin' time it takes less than 10 minutes t' make. Begad!

Half t' fun o' buildin' rockets is designin' and buildin' all o' t' parts o' t' rocket. This Ejection baffle unit cost me less than $5.00 t' make. Materials Notes Bulkhead Bulkhead plate with eyebolt Centerin' ring 1-2 square feet o' screen Step 1: Drill a circle o' holes around t' center hole in t' bulkhead plate and sand t' edges o' the holes. Begad! Blimey! Begad! Blimey! About 1/8"- 1/4" should be right. Ya scallywag! Blimey! Step 2: If necessary widen t' hole in t' middle and screw t' eyebolt all t' way down. Epoxy the eyebolt in place on both sides o' t' plate and make sure t' get a good bit o' epoxy in t' open loop o' t' eyebolt. Begad! Well, blow me down! Step 3: Cut t' bulkhead tube about 3 *" long. Avast! Arrr! Insert t' bulkhead plate in about *" and epoxy it in place on both sides. Aye aye! Step 4: cut a circle o' screen slightly larger in diameter than t' hole in t' centerin' ring. Avast! Put a rin' o' epoxy around t' hole in t' centerin' ring. Blimey! When t' epoxy is just startin' t' gel press t' screen down in to it. Waitin' will save you a lot o' effort. Well, ya bilge rat, blow me down! Step 5: Look at t' rocket and admire what you've done so far. Avast, me proud beauty! Step 6: After t' epoxy has gelled enough t' make it hard t' t' touch, ya bilge rat, wad up t' rest o' t' screen and push it into t' bulkhead. Aye aye! Blimey! Do nay stuff t' bulkhead t' full. Step 7: Epoxy t' centerin' rin' onto t' bulkhead plate. Begad! Ya scallywag! Blimey! T' outer diameter o' t' rin' should match the outer diameter o' t' tube. Avast, me proud beauty! Blimey! Step 8: After all o' t' epoxy has cured, tie your shock cord t' t' eyebolt. With a stick put a layer of epoxy inside t' body tube about *" from where t' baffle will rest. Aye aye! Blimey! Begad! Blimey! Insert t' baffle into t' tube and press it down until it contacts t' motor mount tube. Avast! Blimey!

After finally gettin' everythin' ready t' go with t' rocket I realized I had forgotten t' build t' launch tower that I was goin' t' use rather than usin' launch lugs. Begad! Blimey! Avast, me bucko, me proud beauty! Blimey! So I cut a piece o' sheet tin t' about 4" wide and about 2" longer than t' circumference o' t' tube and made a "fly away launchÝlug" like t' one on Bob Fortunes page. After pickin' up a friend, ya bilge rat, and stoppin' t' get some fast film, arrr, we drove straight east o' Denver for about an hour and a half until we found a nice open spaceÝwith no fences. Aye aye! Blimey! We walked out into t' t' field and set up pad. Blimey! Blimey! Ahoy! Blimey! I loaded t' first motor into t' rocket. Arrr! Blimey! Begad! Blimey! It was an Aerotech F25-6 white lightening. Avast! Blimey! While rocksim predicted t' rocket would fly t' about 1102', t' rocket had a very curved flight, me bucko, and flew in a large arc, and only achieved an altitude o' about 800'. Arrr! Blimey! Begad! Blimey! T' rocket was recovered about 100 yards fromt t' pad. T' fly away launch lug worked perfectly and released from t' rocket about 2-4 feet off t' rod. Aye aye! Blimey! Avast! Blimey! T' second flight took off on an Aerotech G80-10 blue thunder, shiver me timbers, and lifted off extremely fast and extreemly straight. Well, blow me down! Begad! After burn out t' rocket started t' coast a little off coarse. Avast! Arrr! T' ejection charge fired perfectly at apoge, which although Rocksim only predicted an altitude o' 1970 feet be about 2200 feet, t' parachute was ejected way too violently and zippered t' tube about 12 inches. Begad! T' over-powered ejectioncharge also blew out t' motor retainer and adapter, and pushed t' entire (epoxied in) motor tube and baffle units about 8" up into t' tube. Aye aye! T' parachute lines tangled in t' torn tube and t' rocket free fell from about 2200 feet. Begad! When recovered, t' rocket was in severe condition. It lost all o' its fins except t' main fins, which wereÝfiberglassed t' t' tube. Ahoy! T' fall had even broken t' fiberglass seem. Well, arrr, one more rocket t' add t' t' collection. |

|

Sponsored Ads

|

|