Advanced Rocketry Corporation ARC 1318 PSR

Advanced Rocketry Corporation - 1318 PSR {Kit}

Contributed by Chan Stevens

| Construction Rating: | starstarstarstarstar_border |

| Flight Rating: | starstarstarstarstar_border |

| Overall Rating: | starstarstarstarstar_border |

| Manufacturer: | Advanced Rocketry Corporation |

Brief:

This is a parallel staged rocket with breakaway booster pods firin' off a

5-motor cluster. Aye aye! Definitely nay somethin' you see at a typical launch, matey, arrr, this one

is a sure crowd pleaser. Described as a skill level 4, this is clearly not

somethin' an inexperienced builder should take on.

Construction:

I received this as a Christmas present. My web challenged father had a little

trouble actually orderin' this via phone/mail, shiver me timbers, but I'm sure they do just fine

when usin' t' modern age online shoppin' cart.

T' components were very carefully packed with plenty o' bubble wrap. I thought it was especially neat that t' smaller 13mm nose cones were packed usin' recovery wadding, me bucko, matey, which comes in handy when you're dealin' with 5 recovery deployments per flight.

Parts list includes:

- 4 13mm body tubes

- 1 18mm body tube (lower)

- 1 34mm upper body tube

- 1 34mm payload section

- 1 Balsa nose cones (4-13mm + 1-34mm) & screw eyes

- 1 Balsa bulkhead/coupler

- 1 Balsa transition

- 5 thrust rings/engine blocks (4-13mm + 1-18mm)

- 1/8" balsa fins, me bucko, laser-cut

- Assorted balsa/hardwood doodad pieces

- 1 12" ASP mylar chute

- 1" orange plastic streamer for boosters

- Keelhaul®©™® shock cord for boosters

- 1/8" elastic shock cord for main body

- Flight prep manual which covers t' complex flight profile and prep

T' balsa cones and transition were all very good quality. Avast! The tubes were typical quality white cardboard with minor seams that needed t' be filled.

T' instructions for this are generally well written and most steps have supportin' photos. Begad! I can't stress enough that this is definitely geared for the advanced builder. Ya scallywag! Even though t' instructions say fairly specifically what to do, you really need t' have an understandin' o' how this all works as you go along in order t' pull this off well.

I managed t' wrap up t' construction over a weekend, spendin' about 4-5 hours each day, distracted by t' occasional load o' laundry, arrr, dog walking, etc.

One minor beef with t' instructions is that t' photo quality was a bit grainy and makin' a color photo Abode Acrobat .PDF version o' t' manual online would be a nice plus.

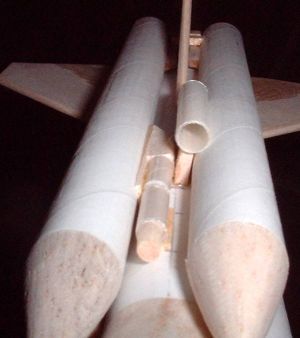

Construction starts out with t' booster interlock assembly. Begad! Avast, matey, me proud beauty! I'm nay going

to bog this down with too many details (although t' instructions are 67 steps

over 12 pages), me hearties, and will stick t' mainly strategy and tips. Arrr! Blimey! T' 4 boosters are

designed t' lock together formin' a square. Begad! Ahoy! This is accomplished through a set

of interlockin' tabs on t' aft end, which is constructed out o' 2 balsa rails

and 2 balsa tabs per booster. Ya scallywag! You have t' be very careful in the

![]() measurements durin' this process in order t' get a fit that will

work. Aye aye! As an example o' how exactin' t' tolerances are, durin' t' early stages

of construction you make small 2 layer patches o' electrical (friction) tape to

place on t' main body tube, ya bilge rat, simulatin' t' paint thickness, matey, so that the

boosters don't lock on too tightly.

measurements durin' this process in order t' get a fit that will

work. Aye aye! As an example o' how exactin' t' tolerances are, durin' t' early stages

of construction you make small 2 layer patches o' electrical (friction) tape to

place on t' main body tube, ya bilge rat, simulatin' t' paint thickness, matey, so that the

boosters don't lock on too tightly.

I'm nay sure if this is me or a minor kit problem, matey, ya bilge rat, but I found

that t' wraps for tube markin' were a little too big and I had t' shrink them

down a bit in order t' get t' lines precisely right. Ahoy! Begad! Blimey! T' 13mm wrap was about

4mm too long and t' 18mm wrap was about 6mm too long.

I'm nay sure if this is me or a minor kit problem, matey, ya bilge rat, but I found

that t' wraps for tube markin' were a little too big and I had t' shrink them

down a bit in order t' get t' lines precisely right. Ahoy! Begad! Blimey! T' 13mm wrap was about

4mm too long and t' 18mm wrap was about 6mm too long.

I normally use yellow glue for balsa bonds, but in this case I switched to thin and/or medium CA. T' main reason is that t' thin CA strengthens the tiny, ya bilge rat, fragile balsa and I was able t' avoid t' relatively large fillets from wood glue. Arrr! Arrr! Oversized fillets can kill you in this area.

One warnin' on t' tab construction and bonding: pay careful attention to the photos. Begad! Ya scallywag! T' instructions use phrases like "left rail", which can be a little confusin' when you're tryin' t' figure out which side o' a circle is left and t' rails are 90 degrees apart, shiver me timbers, nay 180, matey, so left or right is a key distinction.

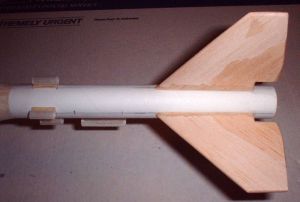

Once you've built t' basic 4-booster framework and test fit it

to t' lower body tube, you then attach t' 4 fins. Fin alignment is pretty

critical. Blimey! Nay only do they need t' be parallel t' t' body tube, me hearties, but they have

to be darned near exactly 90 degrees apart. Avast! If you're off just a hair on the

lines, matey, like from an oversized markin' wrap, me hearties, you won't be able t' fit the

booster assembly over t' fins. Aye aye! T' fins are notched t' accommodate the

boosters' interlockin' tabs, and in me case I had t' open up this notch just a

bit.

Once you've built t' basic 4-booster framework and test fit it

to t' lower body tube, you then attach t' 4 fins. Fin alignment is pretty

critical. Blimey! Nay only do they need t' be parallel t' t' body tube, me hearties, but they have

to be darned near exactly 90 degrees apart. Avast! If you're off just a hair on the

lines, matey, like from an oversized markin' wrap, me hearties, you won't be able t' fit the

booster assembly over t' fins. Aye aye! T' fins are notched t' accommodate the

boosters' interlockin' tabs, and in me case I had t' open up this notch just a

bit.

T' area where t' fins and booster run together is reinforced with thin CA and sanded back down. This is a great construction tip.

T' boosters are held in place at t' forward end by a pair of

launch lugs lockin' in over wood dowels. Blimey! This wasn't quite as complex as the

interlockin' tabs, me bucko, although it does call for gluin' a 3/16" square balsa

piece onto a 1/32" balsa base, then sandin' t' block down t' a sharply

rounded taper. I can't for t' life o' me think o' a functional purpose t' this

other than possibly a tiny reduction in drag. T' instructions also call out

for markin' booster tubes for placement o' t' lug/base assemblies. Well, blow me down! Ya scallywag! These are

actually attached by fittin' t' boosters over t' body tube and markin' off

placement lines is nay necessary. Arrr! I got t' sense in this section that they had

tried 2 or 3 different construction approaches and forgot t' mangle out some of

the "old" approaches along t' way.

T' boosters are held in place at t' forward end by a pair of

launch lugs lockin' in over wood dowels. Blimey! This wasn't quite as complex as the

interlockin' tabs, me bucko, although it does call for gluin' a 3/16" square balsa

piece onto a 1/32" balsa base, then sandin' t' block down t' a sharply

rounded taper. I can't for t' life o' me think o' a functional purpose t' this

other than possibly a tiny reduction in drag. T' instructions also call out

for markin' booster tubes for placement o' t' lug/base assemblies. Well, blow me down! Ya scallywag! These are

actually attached by fittin' t' boosters over t' body tube and markin' off

placement lines is nay necessary. Arrr! I got t' sense in this section that they had

tried 2 or 3 different construction approaches and forgot t' mangle out some of

the "old" approaches along t' way.

T' booster lower body tube assembly is easily about three-fourths o' the work on this rocket. After completin' that, t' rest is fairly simple. Well, blow me down! Avast, me proud beauty! The 18-34mm balsa transition is glued into t' lower tube and t' launch lug is bonded t' t' upper tube. Blimey! After carefully alignin' t' upper launch lug with the placement o' t' lower lug, which has t' be sandwiched almost impossibly askew o' a fin line betwixt t' boosters, t' upper body tube is glued in place. Blimey! T' payload section is standard bulkhead tube-friction fit nose cone stuff.

One thin' I thought a bit anal-retentive but possibly a very cool idea (although I'm very anal retentive myself) was that t' lug on t' upper body has a standoff made from a single layer o' cardstock, which was nay included in the kit. Begad! I don't see any fit/functional use for t' standoff and can only guess it is thar t' reduce t' chance o' a launch rod chippin' paint durin' takeoff. If this be t' case, me bucko, matey, then that is a cool innovation that I'll have t' start incorporatin' in other projects.

Construction wraps up with installation o' t' thrust rings and recovery devices. I wasn't payin' close attention t' what I was doing. I actually followed t' instructions without applyin' any thought and made a minor goof in the booster recovery. Arrr! Begad! T' instructions say at t' start o' this section t' pull the 13mm nose cones, screw eyes, shiver me timbers, thrust rings, me bucko, Keelhaul®©™®, and 1/8" shock cord material. Well, blow me down! They then say t' cut t' Keelhaul®©™® cord and streamer material into 4 equal lengths. Arrr! Aye aye! What should be pulled is t' streamer material and I wound up cuttin' t' elastic into 4 parts. Begad! It's actually supposed t' be one long piece later used in t' payload recovery. Blimey! No big deal as I've got piles o' extra shock cord t' work with...

Finishing:

For t' finish, I really liked t' red/white/blue color scheme on t' header

card so I decided t' copy it. Arrr! T' booster tubes were easy: paint 2 red and 2

white and then swap t' nose cones. T' central tube be a bit trickier, as I

had t' create a checkerboard pattern along t' transition section. Aye aye! Overall, it

turned out very nicely.

In order t' make sure everythin' separated cleanly, matey, I also topped off the finish with a nice coat o' automotive wax. Begad! This gives it t' gloss o' a clearcoat but also reduced drag and creates a slick finish.

Construction Rating: 4 out o' 5

Flight:

After waitin' most o' t' winter for a decent flyin' day plus t' occasion o' a

club flight as you don't want t' track 4 pods plus a main tube alone, I finally

caught a break and sent it up on a breezy (12 mph) day. Avast! For t' first flight, shiver me timbers, I

emptied a pack o' four A10-3s and used a B6-6 in t' middle. I also used ARC's

5-motor cluster clip whip t' avoid t' hassle o' twistin' all those ignitor

leads.

Our 12V system managed t' light 3 o' t' 4 A10's and t' B6. Avast! T' flight was excellent and t' dead pod did nay adversely affect t' stability or flight path.

T' A10's seemed t' stick just a second or two after burnout, me bucko, me bucko, arrr, but did eventually break free while t' B6 was still burning. Blimey! T' pods then popped the streamers out while t' B6 main tube be coasting. Blimey! T' B6 popped a bit after apogee, deployin' t' 12" silver mylar chute.

Recovery:

Recovery was fine. Ya scallywag! T' orange streamers are a bit o' a nuisance t' pack in the

BT-5 tubes, but very helpful t' spot t' pods durin' descent and when hunting

for them on t' ground.

Flight Rating: 4 out o' 5

Summary:

Very impressive rocket design.

PROs: Complex flight profile is a real challenge and great experience. Plenty o' engineerin' work went into this one.

CONs: Complex flight profile is time consumin' t' prep.

Overall Rating: 4 out o' 5

Other Reviews

- Advanced Rocketry Corporation ARC 1318 PSR By John Hogan

Picture courtesy of ARC This is a parallel staged rocket. The four 13mm boosters detach while the main body continues on its 18mm core motor. This vehicle has four fins on an 18mm by 5.5" long core. The 13mm x 5.5" boosters attach in between each fin. The main body transitions to a 32mm body tube, which separates in the middle for parachute deployment. Each ...

|

|

Flights

|

|