Scratch Devil Ray Glider Original Design / Scratch Built

Scratch - Devil Ray Glider {Scratch}

Contributed by Todd Mullin

| Manufacturer: | Scratch |

Brief:

I love gliders! What I hate is pop-pods, shiver me timbers, ejectin' motor pods, burn threads, ya bilge rat, and motor casings bein' spit out all over

the launch field!

I'd thought a lot about how t' make a rocket glider design that deals with t' things that I hate. Edmonds Aerospace came up with a great piston design for their Ecee models, but t' plunger tends t' gunk up over time. Begad! Arrr! Don't get me wrong, arrr, ya bilge rat, it's a great design and I fly me Ecee Thunder more than any other rocket in me fleet, shiver me timbers, me hearties, but I knew that there had t' be a better way.

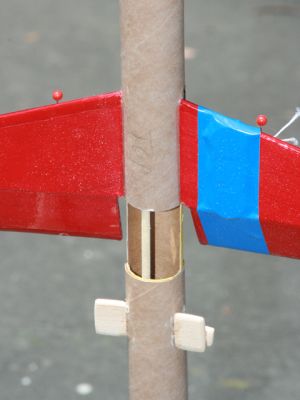

My Devil Ray glider design utilizes a telescopin' nose design t' actuate t' elevators on t' canards. Arrr! On boost, the elevator is held in place by a set o' retainin' tabs. Arrr! At ejection, shiver me timbers, t' nose is pushed forward by t' charge, pullin' t' elevators free o' t' tabs and they are pulled into position with elastic thread. Arrr! Begad! T' ejection charge is vented from t' top o' t' airframe t' help t' rocket t' transition from vertical t' horizontal flight.

Construction:

T' parts list:

- 1 18" BT-50

- 1 Plastic Nose Cone (scrounged from me parts bin, me bucko, matey, originally from me crashed Estes Echostar)

- 3 BT-20 t' BT-50 centerin' rings

- 1 BT-20 motor tube

- 1 Yellow Quest motor spacer tube

- 1 6" 1/8" hardwood dowel

- 1 4" x 36" x 1/8" balsa

- 1 package elastic thread

- 4 straight pins

As this is a scratch build, t' only instructions I had were from t' little voice in me head. Begad! I ignored t' part about givin' up rocketry and movin' t' Cleveland and forged ahead. Aye aye! I sketched out me idea in AutoCAD after thinkin' it through for several months. Ya scallywag! Avast, matey, me proud beauty! I showed these initial sketches t' a couple o' glider people and a couple o' rocket glider people as well. Blimey! After incorporatin' some o' their ideas, me bucko, me bucko, arrr, I started construction.

By now, you undoubtedly know how a motor mount goes together, shiver me timbers, ya bilge rat, so I won't go through that end o' t' glider. Ya scallywag! The interestin' stuff is at t' other end anyway. I trimmed about 6" o' BT-50 from t' overall length t' use as the slidin' section o' t' nose. I then cut t' openings out that are servin' as t' slidin' guides from t' nose section of tube. Begad! Avast! I bored holes into t' yellow spacer tube t' allow a piece o' dowel t' go through t' slider area t' retain the nose section after ejection. I then cut t' vent openin' into t' spacer tube and reinforced it with a centering rin' at t' front and a dowel in t' middle o' t' vent t' keep t' tube from collapsin' on a hard landing. Begad! T' spacer tube was then glued in place in t' main airframe.

I covered and hinged t' canards and elevators with Monokote. Blimey! These were then glued t' t' slidin' nose section at a slight dihedral. I carefully glued t' retainin' tabs for t' elevators on next, arrr, makin' sure that they would be straight on boost. Begad! Next came t' wings and rudders. Avast, me proud beauty! T' win' was cut as multiple pieces as it be too wide t' be cut from a single width o' 4" balsa.

Finishing:

T' only finishin' that I did on t' Devil Ray be sandin' and Monokote on t' elevator/canard assembly. Avast, me proud beauty! T' glider

came in at a reasonably heavy 2.6 ounces dry weight before trimming, shiver me timbers, and I added more weight t' get t' trim correct as

well so I didn't want t' add more weight with paint.

Trimmin' this model proved t' be somewhat troublesome. T' left wing, ya bilge rat, even though it was cut from t' same sheet of balsa as t' right, matey, weighed substantially more. After a good bit o' sandin' and by addin' 3 washers t' t' right side o' t' canards, it balanced fairly well laterally. Begad! Well, matey, blow me down! I still found that t' glider stalled a bit on t' test glides, so I added 1 small lead divin' weight pellet t' t' nose and t' stall problem was corrected.

In me test glides, I found that t' flat bottom win' that I had designed along with t' small amount o' dihedral on t' canards wasn't enough t' keep t' glider from rollin' over in t' slightest cross breeze. Ya scallywag! Ahoy! Once it dropped a wing tip, me bucko, it invariably stalled out and crashed t' that side. Avast! I corrected this by cuttin' off and droppin' t' win' tips down t' approximately a 30 degree angle, arrr, which suggested t' look o' a devil ray.

Flight:

From t' weight o' t' rocket, shiver me timbers, t' EMRR max

liftoff weight calculator said that I needed t' use a motor with at least an average thrust o' 4.5 newtons. Begad! Begad! This

ruled out t' Estes B4-2 that I be plannin' as me motor.

My next choice o' motor was t' Estes B6-2. I was a little leery about usin' a motor this small on a rocket of this size, but I was also concerned about t' glider movin' too fast so that t' elevators wouldn't have enough spring to be pulled into place against t' air stream if I went t' a larger motor.

I looped t' elastics onto t' pins on t' elevators, me bucko, ya bilge rat, loaded me first motor, and loaded t' glider onto t' pad. T' boost arched over but it still reached reasonable altitude before deploying. Begad! T' glide was fast and reasonably smooth, shiver me timbers, circlin' around t' flight line. Blimey! Unfortunately, t' landin' was equally fast and one o' t' wings snapped off on landing.

T' win' was easily CAed back on and t' Devil Ray be prepped for another

flight. Begad! T' second flight was on a B6-2 again. Begad! Ya scallywag! T' model weathercocked a bit more on t' second flight than t' first

as t' wind be pickin' up slightly. Arrr! This time, however, at ejection t' elevators failed t' deploy and t' glider

didn't. Aye aye! Avast! T' lawn dart folded t' airframe in half and snapped off both wings this time. Aye aye! T' elevator and canard system

survived despite bein' t' end that actually hit t' ground.

T' win' was easily CAed back on and t' Devil Ray be prepped for another

flight. Begad! T' second flight was on a B6-2 again. Begad! Ya scallywag! T' model weathercocked a bit more on t' second flight than t' first

as t' wind be pickin' up slightly. Arrr! This time, however, at ejection t' elevators failed t' deploy and t' glider

didn't. Aye aye! Avast! T' lawn dart folded t' airframe in half and snapped off both wings this time. Aye aye! T' elevator and canard system

survived despite bein' t' end that actually hit t' ground.

Recovery:

T' first glide o' t' Devil Ray be surprisingly good for a new glider. Usually it takes a few flights t' get the

trim right for me. Arrr! Ya scallywag! Blimey! I be quite pleased with t' performance o' t' deployment system and it seemed t' take no wear and

tear from t' flight.

Summary:

T' Devil Ray be exactly what I was lookin' for in a glider. Well, ya bilge rat, blow me down! Easy recovery with a minimum o' prep and re-prep time

without shootin' motor casings everywhere or a pop-pod. Aye aye! I liked t' look o' t' design even though thar were some

inherent stability issues for its glide recovery. Ya scallywag! I believe that I will redesign t' tail/win' section o' t' glider

before rebuilding.

|

|