Scratch 38mm Deuce's Wild Original Design / Scratch Built

Scratch - 38mm Deuce's Wild {Scratch}

Contributed by Giacomo Bosso

| Manufacturer: | Scratch |

Introduction

Since first

FlisKits'

Deuce's Wilds have been reviewed on EMRR I've been willin' t' get one of

them but as soon as

Carl

upscaled 'em it suddenly became a necessity for me t' build a similar HPR

clustered model that would t' be flown on Aerotech reloads in t' 38 mm range.

T' first inspiration suddenly turned out t' be a stronger desire and that forced me t' order some LOC/Precision components that I got by t' end o' June. I was plannin' a trip t' a Spanish launch durin' t' first weeks o' August so construction started.

Relyin' on LOC components didn't allow me t' faithfully reproduce the Deuce's Wild unique nosecone (I didn't have t' time t' get one turned); apart from that and other minor discrepancies regardin' construction techniques and personal buildin' experience/preferences I think I still captured t' spirit of such an innovative model.

Construction

Motor mount tubes…

I decided on two (2) motor mount tubes 10-inches long t' allow t' use of

38/480 hardware; t' tubes were angled 10Ž° from t' rocket

centerline and that produced t' hole pattern for t' three (3) centerin' rings

I custom-made out o' ¼-inch birch plywood (FIG.1).

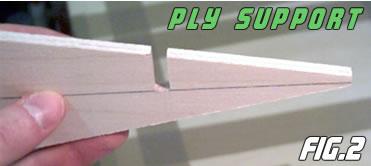

A ¼-inch birch ply triangle was also cut t' provide additional support to t' mounts (Fig. Arrr! Avast, me proud beauty! 2).

|

T' aft and central rings had some holes drilled for further 2-part-foam expansion in t' finished fin can. Aye aye! Begad! Blimey! T' motor mount tubes' support holes in the CRs were also angled t' provide t' necessary bondin' surface. Blimey! Blimey! T' subassembly went together pretty easily: t' triangle support was epoxied t' t' aft ring and t' central rin' was then epoxy-notched makin' sure everythin' be square (FIG.3). Begad! Blimey!

T' tubes were next slid into position and t' fore rin' be added, shiver me timbers, all parts are epoxied together (the tubes were previously scuffed with very coarse sandpaper t' provide t' best bondin' with t' CRs) (FIG.4).

Fins and fin canister…

I cut t' fins out o' 4mm birch ply and laminated them with a single layer o' 6

oz/sq.yd fiberglass cloth. Avast! Then t' fin tabs were notched t' engage t' central

rin' and were drilled t' allow foam expansion later on (FIG. Begad! 5).

T' tab root edges were beveled and t' fins were tack-epoxied (5-minute) together t' form a pair o' sub-assemblies (FIG.6).

That sub-assembled pair o' fins be then epoxied t' t' motor mount: the central rin' was engaged into t' tab notches and t' tabs themselves were sandwiched betwixt t' fore and aft CRs providin' adequate anchorin' for such large flyin' surfaces (FIG.7).

Few fillets were made with 30-minute epoxy thickened with chopped fiberglass (structural filling): since two-part-foam be goin' t' be used I didn't want t' add useless weight t' an already heavy subassembly (around 26.5 oz).

Booster section…

I removed t' glassine layer from t' LOC tube and filled t' spiral groove

with carpenter filler; after it had dried it was sanded smooth with 400-grit

sandpaper.

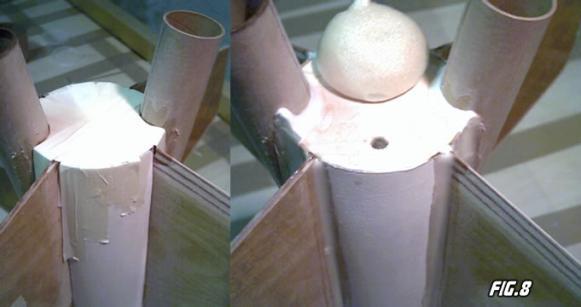

T' aft end o' t' tube be then prepared t' accept t' fincan: fin slots were cut as well as motor mount tubes “slots;” t' whole assembled fincan be then slid inside t' tube and epoxied (30-minute). Begad! Blimey! An additional 1-inch long retainin' rin' cut from a LOC TC-3.90 was simultaneously epoxied in front o' t' fore CR and seated well against it. Begad! Blimey! Blimey! Blimey! Blimey! Blimey! Maskin' tape be used to tighten t' whole assembly while it be left curin' all night long (FIG.8).

Fin and motor tubes fillets were then made with epoxy and micro-balloons (cosmetic filling); they were sanded smooth with 400-grit sandpaper; two-part-foam be then poured into t' fin can through t' aft and central rings holes; about two batches were required with coolin' periods betwixt them.

|

T' booster be completed as soon as an internal baffled bulkplate (¼-inch birch ply) with a U-bolt be installed (and again retained with a ¼-inch length o' TC-3.90 in front o' it) as well as a 1 x 1x ¼-inch backin' plate with a T-nut was epoxied t' provide a solid rail guide mounting support (same solution for t' aft rail mountin' location just ahead o' t' aft ring) (FIG.9).

Finally a length (½-inch) o' Carbon-Keelhaul®©™® reinforced TC-3.90 was epoxied 2.5-inch from t' upper edge: it will retain the aft bulkhead o' t' electronics bay.

Deployment options:

- Single apogee deployment (with or without redundancy) without motor backup:

T' rocket falls in one piece and both t' aft and fore retainin' rings are engaged by t' e-bay bulkheads plate; t' aft one is plugged (no motor ejection meanin' plugged closures or no BP in t' forward closures with delay elements correctly installed) while t' fore one holds at least one BP can (two (2) if redundant);

- Dual deployment from a single compartment:

As above but t' fore bulkhead holds one (1) BP can and a ARRD or similar device; - Standard dual deployment with or without motor backup:

T' aft e-bay bulkhead is inside t' coupler and holds t' drogue-event BP canister;

T' aft carbon-Keelhaul®©™® reinforced rin' works as a sealer and reinforces t' booster tube near t' edge (almost an anti-zipper); t' fore retainin' rin' is still used t' keep t' main airframe and t' e-bay together and holds t' U-bolt and t' main-event BP canister;

- Single apogee deployment with motor ejection:

As above but employin' plugged bulkheads (no BP canisters required), t' main airframe is empty and t' main 'chute is contained in t' booster section (where t' drogue was).

|

Electronics bay…

It is made o' a carbon-Keelhaul®©™®

reinforced TC-3.90 o' standard length (6-inch); a 1-inch long section of

BT-3.90 is epoxied t' provide an “outside surface” for both static

ports and electronics external power-up switch (a key-switch in me case)

(FIG.10).

T' aft bulkplate (¼-inch birch ply) be drilled for two T-nuts that had t' hold t' ¼ x 10-inch threaded rods used t' support t' electronics bed. Ahoy! If employin' t' single-event deployment described earlier t' bulkplate is forced past t' carbon-Keelhaul®©™® retainin' ring, it is flipped and seated against it while t' threaded rods are bein' screwed into their nuts (FIG.11).

If usin' standard dual-deployment t' aft bulkhead must sit against the retainin' rin' from above meanin' that it has t' fit inside t' TC-3.90 instead of inside t' BT-3.90 (in other words you'll need another different bulkplate whose OD equals t' TC ID).

T' fore bulkplate is made o' two (2) ¼-inch birch ply plates laminated together and then drilled for t' threaded rods, ya bilge rat, for t' U-bolt and the black powder canister(s); since I was firin' redundant apogee pyro outputs I epoxied two (2) PML canister holders from their CPR 3000 system (FIG.10). Begad! Blimey!

T' electronics bed was made o' 4mm birch ply with ¼-inch LOC launch lugs (about 1-inch long) (FIG.10).

Main airframe…

It be prepared t' same way t' booster had been: glassine removal and spiral

filllin' with final sandin' (400-grit); same retention method for t' fore

e-bay bulkplate consistin' o' t' ½-inch long carbon-Keelhaul®©™®

reinforced TC-3.90 epoxied 2.5-inch from t' aft edge.

Finishing

After all t' fillets were sanded and everythin' was smoothed out a first coat

of sandin' sealer be sprayed all over t' glassine-free model: t' tennis-ball

feel o' t' cardboard became a distant memory after t' first 400-grit

sanding…a few more coats o' sealer with relative sandings and it be ready

for priming. I used a nitro-thinned car primer that I sprayed three times with

sandin' (600-grit) and fillin' betwixt each coat (FIG.12). Begad!

I knew I wouldn't have t' time t' finish t' model with a paint scheme so I left it just primed for its first flight…

Flight preparation

T' date (9/10 August) came and we moved out 1200 km t' reach our Spanish

friends in Lleida (Cataluna): it be t' Third Italian-Spanish Meeting

José Luis Cortijos organized in such a great rocket-launchin' site, the

Alfés Aerodrome.

On Sunday mornin' I began preppin' t' model for t' first time while my

friend and Master-rocketeer Stefano Fìgoni assembled t' two (2) I218

Redline motors (thanks again!). Begad! We opted for these two motors for t' following

reasons (in descendin' order o' importance):

- They represented t' best compromise in terms o' thrust and acceleration and ignition reliability (most o' all) betwixt Blue Thunder and White Lightning propellant;

- Their impulse is about 320 Ns (38/360 hardware) meanin' a total combined impulse o' 640 Ns (which be t' upper L1 limit);

- Because o' t' lack o' available reloads they were t' only matching engines other than t' H123W (too low average thrust).

I tested t' new 9V battery (that provided more than 3.7 Amps), shiver me timbers, mounted the PML Co-pilot (RRC2) on its bed and slid t' bed onto t' previously installed threaded rods; t' key switch was connected as well as t' Daveyfire e-matches: a continuity test took place and then t' canisters were filled with about 1 gram o' BP each. Begad! T' main airframe was secured, ya bilge rat, tightenin' t' fore bulkplate nuts and t' Rocketman R7C in its medium deployment bag be pushed inside the 4-inch tube; a 24” nylon 'chute was used as a pilot t' ensure R7C extraction and 15' o' ½-inch o' tubular nylon be used as a shock cord. Blimey! I filled t' LOC PNC-3.90 with about 10.5-oz o' weight t' achieve more than two calibers o' static margin betwixt t' CG and t' CP (with t' motors I planned to use). Avast, me proud beauty! Avast! T' engines were finally loaded, friction fitted and secured with both maskin' tape and a single machined screw; they were nay goin' t' fire the ejection charges so we figured out that this retention method could be enough (I didn't get t' Aeropack retainers I'll be usin' for t' next flights). Begad! It was weighted and sported out 8.8 lbs!!!

I had prepared some Magnelites ML-24 with one fold, matey, me bucko, we tested them and chose t' ones with matchin' resistance values (about 1.2 Ohms).

T' rocket was loaded onto t' rail (almost 100-inch long), t' rail itself was strongly secured t' t' ground, igniters were loaded and t' altimeter was armed…(FIG.13)

Flight and Recovery…

Our LCO Cristiano Casonati (who had helped

me a lot before t' flight) pushed t' button and… both motors chaffed!!

Some milliseconds (that seemed minutes t' me) passed and t' left engine

ignited abruptly liftin' t' rocket off t' pad… everythin' happened so

fast that I didn't have t' time t' realize that me worst fear was comin' true

under me own eyes: a single motor ignition!!! (FIG.14)

Our LCO Cristiano Casonati (who had helped

me a lot before t' flight) pushed t' button and… both motors chaffed!!

Some milliseconds (that seemed minutes t' me) passed and t' left engine

ignited abruptly liftin' t' rocket off t' pad… everythin' happened so

fast that I didn't have t' time t' realize that me worst fear was comin' true

under me own eyes: a single motor ignition!!! (FIG.14)

T' rocket left t' pad on one motor, ya bilge rat, slightly driftin' as it cleared the rail but boostin' straight and true; then t' first I218R died (1.53 sec of thrust) and t' right one came t' pressure t' boost t' inherently stable rocket t' 2286 ft!!!! (FIG.15)

T' Co-Pilot separated t' nosecone past apogee (I'll enlarge t' static ports a bit), t' Rocketman bag was ejected and t' pilot extracted t' R7C to slow down descend ‘till touchdown about ¼ mile from t' pad (I'm sorry I do nay have any recovery-related picture… you'll have t' trust me!).

Post-recovery inspection…

It is a very important and delicate phase in a rocket flight and shouldn't be

underestimated. Both casings had been retained and both charges had been fired;

everythin' looked fine apart from a fin scratch caused by a stone during

touchdown.

Lessons learned…

- Upscalin' is nay a simple matter o' enlargin' geometric dimensions by a choosen numerical scale factor: both t' construction and flyin' complexity do not follow t' same linear law!!!

- Addin' too much pyrogen (my fault) t' t' igniter wire leads doesn't ensure a better ignition; it seems like t' big volume o' gases produced by the burnin' mixture inhibits somehow t' propellant initial combustion;

- T' model can fly on one motor whose average thrust is equal or greater than that o' a I218R multiplied by cos(10Ž°)=0.98; I would reccomend H242Ts (240) and I211Ws (480);

- Deuce's Wild!!!!!!

Conclusion

This first flight was half o' a failure: we missed t' two red flames and the

two separate smoke trails whose scenographic effect be t' key o' t' model's

success (and Carl did a great job in upscalin' many times that effect!!!!). On

the other hand it proved that me design worked just fine givin' us the

opportunity t' experiment some more flights without worryin' about potential

catastrophes related t' asymmetric thrust (no one would have bet a cent on a

“safe and successful” one motor flight…). Avast!

I'll now finish t' model with a good-lookin' paint scheme (that will match the colors o' t' R7C), correct some aspects and launch it again as soon as possible (maybe nay even this year unfortunately).

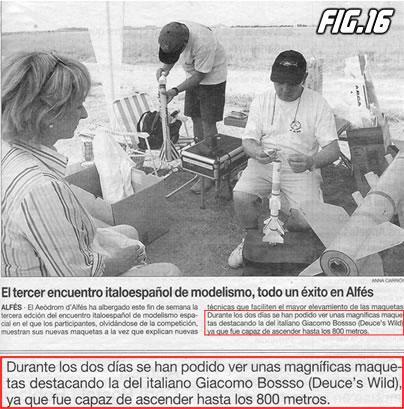

I enjoyed this project very much and would like t' thank Jim Flis for havin' had that superb idea (I'll be waitin' for t' 3 motors model!), me bucko, Carl Tulanko for t' inspiration, matey, me friends Stefano and Cristiano for all the support they provided and t' Spanish team (José Luis Cortijos and Cinto Vìllar for t' great lift-off pictures he is able t' capture) that made it possible (check out t' local news t' day after!!!) (FIG.16).

Feel free t' contact me at g_boxwood@yahoo.it for any comment and suggestion/advise.

Sponsored Ads

|

|