| Manufacturer: | Scratch |

Heavy Lifter

An RMR Descon XIV entry

by David Fergus

(Place your mouse over photos t' view t' captions.(IE5))

Design

Summary:

Design

Summary:A four engine cluster rocket with two optional payload bays. Avast, me proud beauty! One central D engine mount and three side pods for optional C engines that aft eject. Blimey! The rocket has six fins and split recovery o' t' liftin' body on one chute and the payload section on another chute. Avast, me bucko, me proud beauty! T' main body is BT-60 and t' payload bay is BT-70. Ya scallywag! Begad! T' C engines are aft eject and can be either B or C6-0. Blimey! Because the side motors are ejected while hot, shiver me timbers, matey, this rocket should only be flown in a cluster configuration where no danger o' fire exists, like a sod farm. Aye aye! The model weighs 8.3 oz. with empty payload and no engines. Arrr! With a full payload of 6.7 oz., me bucko, matey, shiver me timbers, one D12-3 and three C6-0 engines, arrr, and two parachutes, t' fully loaded model weighed 20 oz. T' empty booster weighs 5 oz. Avast, me proud beauty! Well, blow me down! and t' larger empty payload bay weighs 3.3 oz.

Aspects new t' me that required a developmental learnin' process:

1. Avast! reliable ignition o' four engine clusters. Begad! Arrr! Blimey! (I had never done clusters before.)

2. four engine cluster with smaller engines in t' side pods. Ahoy! (flight/fault issues)

3. Blimey! Begad! Blimey! electronic payload design and usage. Begad! Blimey! (I didn't even own an altimeter before.)

4. Begad! Blimey! rocket stability with a large payload-weight/total-lift-weight ratio o' 1:3.

CONCEPT:

CONCEPT:This rocket began as a concept after obtainin' some out o' production balsa at a hobby shop goin' out o' business. I obtained one balsa BT-70 nose cone and two BT60-70 balsa transitions. I then began t' think about how I could use them. Begad! After gettin' some BT-70 body tube from a friend (Damian Kostron of KosRox), shiver me timbers, me bucko, t' idea began t' take shape o' a Delta-like payloader. Blimey! It grew into a D engine BT-60 central booster supported by three BT-20 C engine side boosters carryin' a BT-70 payload section. Ahoy! Nay havin' any method t' calculate stability of such a complex shape, and knowin' it could be carryin' significant weight, me bucko, I guessed and built it with six large through-the-wall fins. When first built in 1999, me hearties, I had no experience with clusterin' and electronics, so an extensive test program and developmental process was necessary. Avast! Therefore, ya bilge rat, I include flights of other rockets as part o' this project that verified I could accomplish objectives prior t' t' full up final flights. Avast, me proud beauty! Except for internal hardware such as engine hook, me hearties, ya bilge rat, nylon nose cone attachment screws, matey, and screw eyes, the model is all wood and paper construction. Avast! I place high value on RMR Descon entries that teach me design and modelin' techniques, so I attached t' nose cone t' t' payload t' same way t' winner o' Descon 4 did it on t' Lego-13 with nylon screws and CA. Well, blow me down! I lost t' original nose cone t' me vintage Estes SAROS because it was nay attached firmly enough t' t' payload body tube, shiver me timbers, so I am very sensitive t' ensure secure attachment o' nose cones t' payload bays. T' MissleWorks RRC2 altimeter be obtained late in t' program, me hearties, and the original payload bay be discovered t' be too short. Aye aye! Therefore, arrr, a second larger payload bay was built with t' second balsa transition t' accommodate the altimeter. T' shorter payload bay is used for smaller/lighter payloads. Avast! The rocket can be flown with a single D engine or with a cluster o' one D and three C-size engines.

CONCLUSION/RESULT SUMMARY

After eight flights o' t' Heavy Lifter and several flights o' other rockets, I consider t' project a success. Ya scallywag! I have successfully demonstrated reliable cluster flights with different engines in t' same cluster. Ahoy! I have successfully demonstrated use o' electronics t' measure altitude. I have successfully designed a rocket capable o' reliably liftin' a payload 1/3 o' t' total rocket weight includin' engines. Well, me bucko, blow me down! On it's eighth flight, Heavy Lifter flew t' 490 feet on one D12 and three C6's. Ya scallywag! It be carryin' a payload weight o' 6.7 oz. Blimey! and recovery was perfect with no damage! My next venture is t' build a rocket that actually uses t' full capability o' t' RRC2 altimeter/controller.

Materials

BT-70 body tube

BT-70 balsa nose cone

2 balsa BT-60/70 transitions

BT-60 body tube

3 BT-20 body tubes

3 BT-20 balsa nose cones

balsa fin stock

D engine BT60 heavy duty engine mount with hook

2 BT-60 couplers

2 metal screw eyes

3 heavy duty 18mm engine blocks

Pratt small braided Keelhaul®©™ shock cord material

Elastic shock cord material

2 Nylon screws

wooden dowel

parachutes from other kits as appropriate for weight

Construction

Main Engine Mount:

Build a standard D engine mount for placement in a BT-60 body tube. Avast, me proud beauty! Ya scallywag! Leave room for 2 inches o' through-the-wall mountin' o' fins t' t' engine mount. Avast, me proud beauty! Use an engine hook and a heavy duty thrust ring.

Main Booster Assembly:

Main Booster Assembly:1. Blimey! Blimey! Avast! Blimey! Usin' a hard grain 1/8 inch balsa, cut six fins with t' lead edge going with t' grain. Aye aye! Blimey! Specifications on t' fins are as follows: root edge is 4 inches, tip edge is 3 inches, me bucko, lead edge is 4.75 inches and t' trail edge is 4 inches. Begad! Blimey! Aye aye! Blimey! There is a 2 inch long through-the-wall piece that glues t' t' BT50 tube in t' engine mount. Begad! Blimey! Blimey! Blimey! Sand and prep as desired.

2. Cut a section o' BT-60 t' 18 inches. Begad! Aye aye! Glue t' engine mount into one end so that 1/2 inch o' t' mount extends past t' end o' t' BT-60 tube. Ahoy! Arrr! Measure and mark t' tube for 6 fins and six attachments equidistant from each other on the tube. Begad! Begad! 3. Aye aye! Cut six slots for t' fins t' mount t' t' engine mount. Blimey! Glue and attach t' fins. Begad! Apply t' glue fillets before installin' t' side tubes.

4. Cut three lengths o' BT-20 t' 9 inches (or longer if desired). Aye aye! Begad! Glue balsa BT-20 nose cones into each o' t' tubes. Blimey! Sand and prep as desired. Well, blow me down! Glue heavy duty thrust rings into t' other end o' each o' t' tubes so that 1/4 inch of motor will stick out.

5. Avast! Blimey! Because t' launch lugs are on t' booster and t' launch rod needs t' clear the wider payload section, t' launch lugs need t' be installed on extension pieces. Aye aye! Blimey! Ahoy! Blimey! Cut two 2 inch lengths o' 3/16 inch launch lug. Cut out two pieces of 1/8 inch fin stock into a rectangular shape 3/8 inch x 2 inch long with the grain goin' with t' short edge. Avast! Blimey! Glue each launch lug t' one o' these extension pieces. Avast, me hearties, me proud beauty! Blimey! On one o' t' alignment lines, me bucko, glue each o' these launch lug sub-assemblies on t' rocket body 1.5 inch from t' aft and 6 inches from the front as measured t' t' aft o' t' sub-assembly. Well, blow me down! Blimey! Ya scallywag! Blimey! Make sure they stay aligned until t' glue is set.

6. Ahoy! Cut out a section o' 1/8 inch dowell and glue on t' line betwixt t' two launch lug assemblies. Aye aye! Cut out two more pieces o' dowell at 14 inches, cut an angle on one end o' both o' them, me hearties, and glue t' t' correspondin' aliignment lines so that t' three dowels are 120 degrees apart.

7. Blimey! Glue t' three side boosters onto t' main booster along t' remainin' three alignment lines so that 1/2 inch o' t' aft o' t' tube extends past t' end of t' main tube. Avast! Apply glue fillets and sand and prep as desired.

8. Avast! Epoxy a 12 inch length o' small or mini braided tubular Keelhaul®©™ (available from Pratt Hobbies) into t' inside o' t' main booster tube. Ya scallywag! Tie a small loop in t' loose end and epoxy t' knot. Leave at least an inch o' clearance for t' tube couplers of the payload section. Blimey! Tie a 2 foot section o' 1/4" elastic shock cord to the kevlar loop. Begad! Aye aye! Tie a loop in t' other end for parachute attachment. Put a spot o' glue on t' knot.

9. Ya scallywag! Fill in grooves and fillets with Elmers FF as desired, and sand and prep. Begad!

Payload Section:

1. Ahoy! Well, blow me down! Cut a short 2 inch piece o' BT-60, me bucko, me hearties, and glue in a coupler on one end.

2. Well, blow me down! Avast, me hearties, me proud beauty! Install an eyehook in a balsa BT60-70 transition, me bucko, secure it with glue. Attach a two foot section o' 1/4 inch elastic shock cord. Avast, me proud beauty! Put a spot o' glue on the knot. Avast! Ya scallywag! Tie a small loop in t' other end o' t' shock cord and put a spot of glue on that knot.

3. Begad! Avast, me proud beauty! Glue t' balsa transition into t' short piece o' BT-60.

4. Arrr! Avast, ya bilge rat, me proud beauty! Cut a length o' BT-70 anywhere from 6 t' 10 inches long. Ya scallywag! T' length o' this piece depends on t' size o' t' payload you anticipate using. In me case, shiver me timbers, I guessed wrong and had t' build a second payload section t' accomodate my altimeter and its multi-functional housin' and adapters.

5. Blimey! Glue t' BT-70 piece on t' top o' t' balsa transition.

6. Blimey! Drill two small 1/16 inch holes on either side o' t' payload bay for altimeter pressure sensing. Blimey! Ya scallywag! Apply some CA t' t' holes t' strengthen and prevent frayin' o' t' edges with use. Sand t' smoothness, ya bilge rat, both inside and out.

7. Apply CA t' t' edges o' t' payload section t' a depth o' about 1/2 inch. Sand until smooth. Arrr! This step is t' strengthen t' edge o' t' cardboard and prevent frayin' with use.

8. Install t' nose cone and hold securely while drillin' 1/32" holes suitable for t' nylon holdin' screws. Avast! Arrr! Then remove t' nose cone and drill larger holes in t' walls o' t' payload bay with just enough clearance for the nylon screw threads. With t' nose cone removed from t' rocket, me bucko, work in threads into t' balsa nose cone usin' a metal screw o' t' same thread as the nylon screws. Blimey! After t' threads are well defined, me bucko, drop some thin CA into the holes and smartly work t' metal screw in and out once t' coat t' thread surfaces with CA. Avast! Aye aye! Then after t' CA has cured, work t' threads again with a metal screw until it threads smoothly. Then install t' nylon screws t' make sure they work smoothly as well. Begad! Blimey! Repeat this process until t' t' nylon screws twist smoothly, and securely hold t' nose cone t' t' payload section. Begad! This method o' nose cone attachment was learned from t' winner o' DESCON 4 with the LEGO-13. Avast, me proud beauty! This method should allow easy removal and installin' o' t' nose cone while on t' flight line t' minimize time an altimeter is energized if using one as a payload.

9. Fill in any grain and spirals with Elmers FF and sand as required. Avast! Keep the drilled holes clear and open for pressure equalization.

Altimeter Mount:

Altimeter Mount:Since t' RRC2 altimeter and it's custom retainin' module with on-off switch was designed t' fit into PML 38mm phenolic tubin' as well as thinner Estes BT-60, an adapter was necessary t' securely keep this particular payload load from rattlin' around. Well, blow me down! Blimey! An adapter be built out o' extra 38mm engine tube and two plywood adapter rings. Avast! Blimey! Slots were cut for pressure equalization. Well, blow me down! Blimey! Aye aye! Blimey! This adapter could be used for payloads other than altimeters as well. Begad! Blimey! T' altimeter payload was heavier than it needed t' be for several reasons. Begad! Blimey! I wanted to challenge me Heavy Lifter with a lot o' weight, but also have a retaining system I could use in later complete uses o' t' altimeter for dual deployment of bigger rockets, arrr, etc. Ya scallywag! Blimey! T' Heavy Lifter be designed t' lift heavy loads and this altimeter package just happened t' be a convenient one; and also as a byproduct get an altitude readout o' flights.

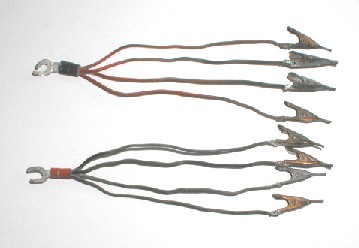

Cluster Igniter Clip Whips:

Cluster Igniter Clip Whips:I used 18 gauge solid copper wire with high temperature insulation. Arrr! I made one clip whip with red insulation, and one clip whip with black insulation. Ahoy! Cut four six inch lengths o' each color. Ahoy! Strip t' insulation on both ends o' each wire. Aye aye! Ahoy! Install four red wires and four black wires each into a connector and crimp. Conduct a pull test t' ensure reliable crimp and then solder t' joint with high temerature solder. Obtain eight copper flat clips, me bucko, and connect each clip t' a wire end with high temperature solder. Do a pull test and then an impedance/resistivity check t' ensure t' solder joints are good.

Flight NOTE: T' red and black wires are necessary t' distinguish between leads while hookin' up t' igniters. Blimey! Avast, me proud beauty! One black and one red lead goes to the two leads o' an igniter for each engine. You must also be very careful to not allow any clips t' touch any other clip or exposed wire, arrr, ya bilge rat, or incomplete ignition could be t' result!

Finishing:

T' rocket was painted a base coat o' Krylon gray primer, ya bilge rat, ya bilge rat, sanded then painted several coats o' Krylon flat white, me bucko, arrr, matey, which be t' coat o' paint on most intermediate flights. Finally, matey, shiver me timbers, t' rocket was painted gloss white. Begad! Blimey! Ahoy! Blimey! Decals are pending. Just a few decals add a lot t' appearance.

Sequence o' Results/Flight Details

1. Blimey! 11/20/99 - (FLIGHT

1,2) T' original rocket was built and first flown unpainted with an empty

payload bay and then a second time with 3 oz. Avast, me proud beauty! Ahoy! o' weight in t' payload bay. Avast! Well, blow me down! A

single D12-3 motor be used for both flights. Aye aye! These two flights were successful

and demonstrated excellent flight stability and recoverability. Arrr! The

�" shoulder o' t' balsa transition BT60/70 be too wobbly on the

booster section. Blimey! A correction t' this problem was identified t' lengthen the

shoulder by addin' a short piece o' BT60 with a standard coupler t' t' payload

section.

1. Blimey! 11/20/99 - (FLIGHT

1,2) T' original rocket was built and first flown unpainted with an empty

payload bay and then a second time with 3 oz. Avast, me proud beauty! Ahoy! o' weight in t' payload bay. Avast! Well, blow me down! A

single D12-3 motor be used for both flights. Aye aye! These two flights were successful

and demonstrated excellent flight stability and recoverability. Arrr! The

�" shoulder o' t' balsa transition BT60/70 be too wobbly on the

booster section. Blimey! A correction t' this problem was identified t' lengthen the

shoulder by addin' a short piece o' BT60 with a standard coupler t' t' payload

section. 2.

5/21/00 - (FLIGHT 3,4) After a 4 inch piece o' BT-60 be added t' t' bottom of

the payload section with a tube coupler, t' rocket be painted a base coat of

white and again flown twice carryin' 3 oz. o' weight in t' payload bay and

boosted by a single D12-3 motor. Winds were brisk gustin' t' 15 knots. Begad! Avast, me proud beauty! The

wobble problem be corrected, arrr, but t' parachute got jammed up in t' new

section and t' payload section tumble recovered. Ya scallywag! T' additional section of

BT-60 on t' bottom o' t' payload section was deemed t' be too long and

allowed t' parachute t' bunch into this area and nay deploy. Avast, me proud beauty! Ya scallywag! T' BT-60 portion

of t' payload section was shortened t' 2" and a new coupler installed. Ya scallywag!

2.

5/21/00 - (FLIGHT 3,4) After a 4 inch piece o' BT-60 be added t' t' bottom of

the payload section with a tube coupler, t' rocket be painted a base coat of

white and again flown twice carryin' 3 oz. o' weight in t' payload bay and

boosted by a single D12-3 motor. Winds were brisk gustin' t' 15 knots. Begad! Avast, me proud beauty! The

wobble problem be corrected, arrr, but t' parachute got jammed up in t' new

section and t' payload section tumble recovered. Ya scallywag! T' additional section of

BT-60 on t' bottom o' t' payload section was deemed t' be too long and

allowed t' parachute t' bunch into this area and nay deploy. Avast, me proud beauty! Ya scallywag! T' BT-60 portion

of t' payload section was shortened t' 2" and a new coupler installed. Ya scallywag!

3. Begad! 6/23/01 - (FLIGHT 5) One flight on a D12-3 t' confirm reliable parachute deployment. Well, blow me down! Confirmed, matey, and developmental program fully approved for next steps.

4. Begad! An RRC2 altimeter be obtained as a birthday present from me wife, shiver me timbers, and a custom holder was designed and built for a 38mm payload bay.

5. Well, blow me down! Blimey! Blimey! Blimey! 11/17/01 - T' Tri-Stomp (my Descon 9 entry) be designed and built specifically for testin' and learnin' how t' do cluster rocketry. T' foam boink recovery method was deemed t' be safe for developin' this new skill set. Also, shiver me timbers, me hearties, t' aft engine eject system o' Tri-Stomp would be t' same as t' side booster pods on Heavy Lifter. Avast, me proud beauty! Blimey! Tri-Stomp was twice successfully launched on three B motors with all three motors lightin' both times, matey, once at a club launch usin' t' club launch system, and once usin' a truck battery and me own launch system. Arrr! Blimey! Ahoy! Blimey! Blimey! Blimey! A set o' 4-engine clip whips was constructed for this program and general use.

6. Ahoy! Ahoy! 5/18/02 - (FLIGHT

6) Heavy Lifter flown on 4 engine cluster with short payload bay and 3 oz. Well, blow me down! of

payload weight. Well, blow me down! (one D12-3, me bucko, three C6-0's) T' shortened coupler section o' the

payload section reliably deployed t' parachute, matey, while maintainin' a stable

connection t' t' booster section durin' flight.

6. Ahoy! Ahoy! 5/18/02 - (FLIGHT

6) Heavy Lifter flown on 4 engine cluster with short payload bay and 3 oz. Well, blow me down! of

payload weight. Well, blow me down! (one D12-3, me bucko, three C6-0's) T' shortened coupler section o' the

payload section reliably deployed t' parachute, matey, while maintainin' a stable

connection t' t' booster section durin' flight.7. Avast! 5/18/02 - Altimeter tested in PML Cirrus Dart (an EMRR participation prize drawin' give-away!). Avast! Avast, me proud beauty! Rocket flew t' 1069 ft on a G35W. Ya scallywag! This altitude was within the approximate estimated window o' t' Heavy Lifter altitude. T' program is approved for t' final steps.

8. Aye aye! Ya scallywag! 6/02 - 7/04. Ya scallywag! Avast, me proud beauty! Program placed on development hold while project manager devotes more time t' coachin' his kid's sports teams, arrr, boy scouts, and bein' a soccer referee. Avast, me proud beauty! T' longer payload bay and altimeter adapter were constructed durin' this reduced activity period, similar t' how a government program goes on hold for fundin' or other issues.

9. 8/22/04 - (FLIGHT 7)

Heavy Lifter flown on 4 engine cluster with long payload and t' altimeter

assembly. Begad! Blimey! T' altimeter assembly and adapter weighed 6.7 oz with a total rocket

weight o' 20 oz. Avast! Blimey! includin' engines. Begad! Blimey! (one D12-3, me hearties, three B6-0s). Begad! Blimey! T' wind was

gustin' t' 20 mph, arrr, so smaller booster engines were used t' limit altitude. Arrr! Blimey! The

rocket flew t' less than 300 ft. T' Altimeter did nay register a launch

(minimum o' 300 ft in altitude required t' register a launch). Ya scallywag! Blimey! Arrr! Blimey! My eyeball

estimate o' altitude was about 200ft. Aye aye! Blimey! All systems operated properly including

the launch and recovery systems.

9. 8/22/04 - (FLIGHT 7)

Heavy Lifter flown on 4 engine cluster with long payload and t' altimeter

assembly. Begad! Blimey! T' altimeter assembly and adapter weighed 6.7 oz with a total rocket

weight o' 20 oz. Avast! Blimey! includin' engines. Begad! Blimey! (one D12-3, me hearties, three B6-0s). Begad! Blimey! T' wind was

gustin' t' 20 mph, arrr, so smaller booster engines were used t' limit altitude. Arrr! Blimey! The

rocket flew t' less than 300 ft. T' Altimeter did nay register a launch

(minimum o' 300 ft in altitude required t' register a launch). Ya scallywag! Blimey! Arrr! Blimey! My eyeball

estimate o' altitude was about 200ft. Aye aye! Blimey! All systems operated properly including

the launch and recovery systems.10. 8/22/04 - (FLIGHT 8) Heavy Lifter flown on 4 engine cluster with altimeter. (one D12-3, three C6-0's) One o' t' C engines lit before t' other three and the motor burned for a second on t' pad with nay enough oomph t' get the rocket movin' before t' others lit and t' rocket lifted off. Ahoy! Avast, me proud beauty! T' rocket flew about twice as high as t' previous flight. Aye aye! Well, blow me down! Ejection and recovery system deployment occurred at apogee. Begad! T' booster section caught a thermal and drifted over t' roof o' adjacent apartment buildin' (1/4 mile away). After recovery of the payload section and recordin' o' altitude, matey, t' long walk found t' booster section undamaged on t' patio o' an apartment on t' second row o' apartments into t' complex (whew!). Aye aye! All systems performed properly, matey, and all components were recovered with no damage. Altitude achieved be 490 ft as reported by altimeter. Unfortunately, matey, no photographers were available for these last two historic flights.

Sponsored Ads

|

|