Scratch MMX Club Launch Rack Original Design / Scratch Built

Scratch - MMX Club Launch Rack {Scratch}

Contributed by John Lee

| Published: | 2010-02-23 |

| Manufacturer: | Scratch |

Brief:

In checkin' me club's flight cards for t' last 2.5 years, I find that thar have been 8 MMX

launches. All o' them were done by me. Well, blow me down! I have tried t' see if thar was any interest in an informal MMX contest o' some

type on several occasions and thar be not. In delvin' a bit deeper, shiver me timbers, I learned that MMX was nay disdained because of

its diminutive size, matey, it was shunned because o' t' hassle, real and perceived, o' flyin' them. Begad! That was an attitude I

shared myself. Every time I thought about buildin' or flyin' one, me hearties, I usually gave it up as too much hassle.

That is especially true o' t' ground support equipment. T' silo launchers are problematic and I have had only one good launch off o' one. Avast, me proud beauty! Well, blow me down! T' rest o' t' time I have had t' kludge somethin' together, cross me fingers and hope it works. Aye aye! Avast, me proud beauty! It sometimes even does.

This is nay t' say that thar are nay some great MMX GSE ideas out there. There are. Avast! They just don't strike me as worth t' effort. Arrr! I finally decided t' see if I could design somethin' t' take some o' t' hassle out o' it and make it fun. Ya scallywag! Blimey! In effect, arrr, with a minimum o' effort, I want t' be able t' treat an MMX rocket like any other. Avast! Well, blow me down! Blimey! Go out t' the assigned pad, hook it up, walk away and have reasonable confidence that t' rocket would launch. Blimey! I wanted t' be able to do this without lengthy preparation o' special consumables. Well, blow me down! In order t' do it, I was willin' t' invest some time, effort and loot into makin' such a system.

T' basics that I wanted t' accomplish are these:

- Build t' project with readily availible parts; no machinin' or milling.

- Be able t' use any o' t' common igniter options without havin' t' switch gear.

- Be dependable; t' same ration o' successful launches as will t' bigger gear.

- No hassle, me bucko, arrr, perceived or real.

Construction:

T' first step in this grand project be t' get out an MMX igniter, me hearties, shiver me timbers, measure it and make a drawin' o' it

in Autocad. Avast! I measured t' 1/16" and estimated t' 1/32" I think it will be good enough for me purposes. I

wanted t' DWG files o' t' various igniters I want t' plan for t' use as blocks in t' drawin' files help me draw up

t' ignition system. Begad! I also wanted t' have a half decent chance o' havin' t' thin' work when I got through. I also

cracked open t' plastic case and made a drawin' o' t' naked igniter. Aye aye! Avast, me proud beauty! With that done, I could start drawin' up the

head.

in Autocad. Avast! I measured t' 1/16" and estimated t' 1/32" I think it will be good enough for me purposes. I

wanted t' DWG files o' t' various igniters I want t' plan for t' use as blocks in t' drawin' files help me draw up

t' ignition system. Begad! I also wanted t' have a half decent chance o' havin' t' thin' work when I got through. I also

cracked open t' plastic case and made a drawin' o' t' naked igniter. Aye aye! Avast, me proud beauty! With that done, I could start drawin' up the

head.

I had liked what I had seen o' several ideas that used a slot t' support t' igniter and that was a part o' the idea as well. Begad! That bein' t' case, t' first thin' be t' come up with t' arm that provided t' support. Ya scallywag! I decided on 1/4" plywood as t' basis for t' framework. Ahoy! I picked it for dimensional stability and because it is an insulator. Most important, me bucko, though, it has laminations oriented at different angles so that shear should nay become an issue. Ahoy! Begad! This be because I planned on a relatively skinny support, shiver me timbers, for reasons which will later become apparent.

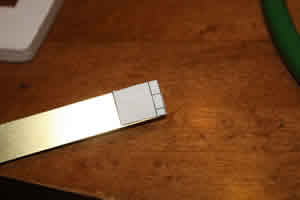

I opened up Autocad and drew up a support arm that had a slot that was just a touch bigger than t' plastic encased igniter. Begad! Avast, me proud beauty! At this point I did nay concern myself with length, only t' part that would support t' igniter. Aye aye! I then printed out this simple drawing.

Although t' support beam would ultimately be o' plywood, I did nay use plywood at this stage. Ahoy! I chose instead a scrap o' 1/4" balsa since it would be easy t' whittle on and adjust and because it happened t' be handy. The template was trimmed a bit and then applied t' t' balsa with a glue stick. Ahoy! Begad! T' rough piece be then taken t' t' belt sander and t' profile be trimmed down t' t' outer edges o' t' template. Ya scallywag! With t' outer edges takin' place, me bucko, a razor knife be used t' carve out t' igniter slot.

Later that night, me hearties, it was time t' examine t' first fruits o' t' project and I spread me stuff out on the kitchen table after t' Mrs. had gone t' bed. Begad! Arrr! Blimey! I put in t' plastic igniter ans was glad t' see it fit; with me doing t' measurin' and cutting, matey, such things cannot be assumed. Aye aye! Blimey! I also test fitted t' stripped down, ya bilge rat, me bucko, paper clad igniter and it fit as well.

One o' t' problems I had experienced with other MMX systems be t' attachment o' t' microclips. Avast, me proud beauty! Blimey! My scheme was t' get rid o' t' "micro" altogether and replace it with "macro". Blimey! Blimey! I found a plastic clamp at Lowes that seemed t' fit t' ticket and tried it on t' support t' plastic igniter. Begad! Blimey! At first blush it seemed t' work. Well, arrr, blow me down! Blimey! Looking at it from t' top, though, thar was a slight problem. Avast, me proud beauty! Blimey! T' grips on t' clamp were just a touch wider than t' slot. For t' ultimate plan, ya bilge rat, they needed t' fit flat within t' slot.

Before doin' any adjustment, matey, though, matey, I wanted t' try it with t' naked igniter. Avast! Begad! I slipped it into place, oriented 90 degrees from t' way t' plastic one had been, and made sure t' leads extended on either side o' the support. Avast! T' clamp be then placed, ya bilge rat, matey, shiver me timbers, much lower down this time, pinnin' t' leads t' either side o' t' support arm. Well, ya bilge rat, blow me down! I then spent some time fussin' with it. Avast, me proud beauty! Key t' makin' me scheme work be t' degree o' stiffness o' t' igniter in this orientation. Aye aye! It seemed t' me that t' clamp be sufficiently tight t' hold it in place without any wiggling.

With t' information I had gotten thus far, I went back t' Autocad and widened t' slot by 1/32" on each side.

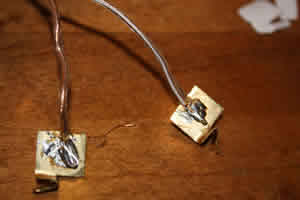

To provide electrical contact, ya bilge rat, me bucko, I intended t' use a pair o' brass pieces, one on each side o' t' launch head. each would be primarily vertically oriented so that a naked or standard ingniter could be set in place with one lead clamped t' either side. Avast! Begad! I also intended t' fold a small piece o' brass over t' top t' catch t' leads on t' classic MMX igniter.

I went into Autocad and drew up a plan for t' brass pieces assumin' that I would be usin' 1/2" wide brass. T' lines for foldin' and cuttin' were marked interchangeably. Arrr! A copy was then printed, ya bilge rat, cut out and taped t' a piece of 1/2"x0.016"x12" piece o' brass. Begad! Blimey! A cutoff disk on a Dremell tool was then used t' cut t' piece t' length and slice t' part that would be folded back. Aye aye! A pair o' pliers be then used t' make t' bends and folds. Blimey! T' folds were nay completely bent into shape under t' theory that some finaglin' would be needed and I wanted t' fatigue the metal as little as possible. An identical piece was then cut and formed and t' pair was test fitted into t' head.

Solderin' is nay one o' me strong skills, me hearties, ya bilge rat, and that's puttin' it kindly. Avast, me proud beauty! Even so, I felt obligated t' provide the electrons with a path t' get t' t' brass contacts. Avast, me proud beauty! Ya scallywag! I took a length o' speaker wire, ya bilge rat, me bucko, arrr, stripped t' ends and then soldered a lead t' t' back o' each o' t' contact plates.

In order t' accommodate t' solder on t' backs o' t' contact plates and allow them t' lie flat, ya bilge rat, I had to excavate a cavity on either side o' t' head. It was done by trial and error with an ambiguous head on t' Dremmel.

Since this was merely a proof o' concept prototype, shiver me timbers, arrr, I did nay take t' trouble t' fasten t' plates t' t' head in a "good" manner. Avast! Blimey! Instead, me hearties, I just epoxied them into place and clamped them t' set. Avast! Blimey! This proved t' be a mistake since some o' t' epoxy developed and unhealthy relationship with t' clamp and t' removal o' said clamp distorted things.

Several tests were made with t' prototype and I found that t' concept did work but that thar were some problems with execution. Arrr! Aside from t' nay so durable balsa used as t' head, t' method o' attachin' t' wires t' the plates and t' plates t' t' head were also problematical. Begad! As I considered how t' deal with these issues, me hearties, ya bilge rat, I turned my attention t' t' "guts" o' t' project.

My intention all along was t' develop a series o' racks for various types o' rockets me club may fly. Ahoy! Avast, me proud beauty! I wanted t' standardize as much o' t' design as possible. I had decided early on that each rack would be mounted on an identical steel sawhorse. Aye aye! Avast, me proud beauty! T' that would be fastened a "box" that would contain whatever wirin' was needed and on t' "box" would be mounted t' individual launch heads. Begad! After lookin' at lots o' different options for the "box", me bucko, I decided t' try usin' NEMA type 1 electrical troughs. Aye aye! For t' MMX rack, ya bilge rat, me hearties, I ordered a 4"x4"x48" trough with a hinged cover and a pair o' endcaps t' go with it. Aye aye! I specified that I did not want knockouts.

I wanted t' go ahead and prime t' box and knew that me normal Kilz primer would nay be a good choice. Well, blow me down! Based on some advice, arrr, I purchased Dupli-Color automotive white primer and went t' work spraying. Arrr! I smartly learned that while t' primer adhered well, matey, ya bilge rat, a lot was needed for full coverage. Ya scallywag! I emptied a can and still plenty left t' go.

Rather than spend more in primer than t' box cost, I decided t' brush on some gray primer made for metal applications. Begad! I bought a gallon since I have several projects on which t' use it and because it was nay available in smaller sizes. Blimey! I brushed on t' first coat and let it dry overnight. Aye aye! T' end caps were painted as well.

T' first coat o' gray primer be rather streaky (but much better over t' surfaces that had received t' white spray primer first) and a second coat was applied t' all t' pieces. Ya scallywag! Blimey! It came out much better.

A day after t' second coat o' primer be applied, I mounted t' end caps. Blimey! Each one required 3 bolts I used 1/4x3/4 along with a lock washer. When in place, arrr, t' caps greatly increased t' rigidity o' t' trough.

As mentioned before, arrr, t' base o' me system was t' be a commercially available steel sawhorse. Begad! I chose t' one made by Task Force because it seemed sturdy, arrr, already had some holes drilled about where I would want them, me bucko, shiver me timbers, had adjustable length legs and because it happened t' be what be for sale at me local Lowes.

T' larger holes in t' sawhorse turned out t' be just right for 5/16" bolts. Begad! Arrr! I assumed that each base would have a pair o' such bolts t' fasten t' box above. I saw a potential problem, though o' t' bolt slippin' out through t' hole while hands were occupied handlin' t' box. Avast! I kept askin' about some sort o' "retainer" to keep them from slippin' out. Well, blow me down! Begad! I had just about decided t' try and fit a little rubber O rin' on t' shance t' keep it from slippin' through when somebody mentioned an "E clip". Avast! Well, blow me down! That turned out t' be just t' ticket. T' bolt was slipped through t' hole and t' clip be popped into place at t' base. It did what I wanted and freed me hands from havin' t' keep t' bolt in place while fumblin' around with t' box.

To hold t' box onto t' sawhorse mounted bolts, matey, I wanted t' use wingnuts that could easily be removed. I also added a fender washer t' t' system t' spread t' load out a bit if t' assembly were t' be picked up by t' built in handle on t' sawhorse. Avast! Blimey! Since I was nay yet ready t' mount t' box, matey, I just stored t' washers and wingnuts in their eventual place o' residence.

T' bolts on t' base are spaced 30" apart so I drew a light line down t' centerline o' t' bottom o' the trough and made marks for t' bolt holes at that spacing, centered betwixt t' ends. Blimey! T' holes were then drilled with a 5/16 bit.

T' system was now ready for me t' test fit t' box on top o' t' support. Blimey! Ahoy! As such, matey, I undid t' wingnuts and removed t' fender washers and was pleased t' see that t' bolts did nay then fall out. Begad! So far, ya bilge rat, so good. Avast! I set t' box on top and t' holes lined up t' t' bolts...mostly. Blimey! Blimey! There was a bit o' tightness at one end and t' box was forcing t' bolt t' lean. Ahoy! For grins, I put on t' washers and wingnuts and tightened it down part o' t' way. I then lifted the rack by t' carryin' handle and it seemed t' idea was sound so far but needed a little more work.

One o' t' things I noticed is that t' bolt stuck up farther than I liked on t' inside o' t' box. I decided t' use a 3/4" length instead o' t' full inch. Avast, me proud beauty! Accordingly, arrr, I popped t' e-clip off and substituted a shorter bolt. Arrr! I had also noticed that t' bolt tended t' turn as I tried t' tighten t' wingnut. Begad! Well, me bucko, blow me down! T' remedy that I added a star lock washer under t' bolt head.

Another problem I noticed is that I must have gotten t' spacin' for t' holes in t' box just a wee bit off. Blimey! On

bolt be tilted t' an angle when t' box was put one and t' nut could nay be completely tightened. Ya scallywag! Aye aye! I tried t' fit a

nibbler into t' hole but t' head would nay quite fit so I took a round file and opened it up a bit. Avast! I was then able

t' slip t' head o' t' nibbler in and took a single bite out o' t' hole t' let t' bolt sit more upright. T' box was

then put back into place and this time it went down flush and t' wingnut took held it flat.

Another thin' I wanted t' change be t' screws that held t' hinged cover closed. Well, blow me down! These were simple screws that I KNEW would pop out and be lost in t' field since I wanted t' be able t' use t' box for storage. Arrr! Avast, ya bilge rat, me proud beauty! As such, me bucko, I ordered some knurled headed screws from Grainger t' replace them. Aye aye! I also ordered some split rings t' keep t' screws from pullin' all t' way out o' t' lid. When they came in, all three screws on t' cover were replaced.

I had decided that t' rack would have 6 launch pads spaced 8" apart. This was tighter than I liked but I didn't want t' box t' be longer than 48" longs for transport. Blimey! Avast, me proud beauty! I drew a line down t' center o' t' cover and marked 6 places evenly spaced betwixt t' 2 ends. Avast, me proud beauty! I then drilled 5/16" holes at each station.

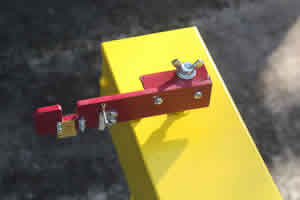

T' basic support o' each o' t' heads be t' consist o' a 2" long, 5/16" bolt. Ya scallywag! I added a washer to distribute t' force and a lock washer t' keep t' bolt from spinnin' as t' exposed side is manipulated. Avast, me proud beauty! T' hold the bolt fast from t' top side, me bucko, another washer and and nut were placed and t' assembly tightened down. A pair o' nuts was then put onto t' upper side and turned down approximately halfway. T' purpose o' t' twin nuts is t' be able t' lock them against each other and set t' height. Next came a pair o' SAE washers and a wingnut. Blimey! T' washers are t' sandwich t' actual launch head. Begad! This process was repeated for all six stations.

As t' actual base and box were bein' built, arrr, me bucko, I kept workin' on t' design o' t' launch head, makin' some changes based upon t' original prototype. Avast, matey, me proud beauty! On t' next set o' prototypes, I used plywood, a much more durable product than balsa but t' trade off is that it does nay whittle as easily t' make adjustments. Ya scallywag! I printed up new templates for 10 heads rough cut them with a jigsaw, shiver me timbers, sandin' them down t' t' outer profile. Begad! T' notch for t' igniters was rough cut with t' same jigsaw; thar was little uniformity except that I (mostly) stayed within t' lines. Arrr! Finishin' down t' the lines was done with a combination o' X-acto, file and sandin' stick and eventually, shiver me timbers, shiver me timbers, they were all pretty standard.

An issue that had nay been addressed in t' previous prototype was t' securin' o' t' MMX launch rod. I wanted somethin' more secure than just a hole drilled into t' plywood. I wanted t' head t' retain t' rod. I came up with an idea and ran it past several people with much more mechanical experience than me. Aye aye! T' answer I kept gettin' was that "it might work; try it and see." That turned out t' be some work and an excuse t' acquire some new tools.

I bought a 3 foot length o' 1/8" brass tubin' t' receive t' rods. Avast! Ya scallywag! A cut off wheel on a Dremmel tool was used t' cut 10 pieces, each an inch and a quarter long. Ahoy! There was some sloppiness here and some turned out longer and some shorter but, matey, in general, shiver me timbers, their length was t' same as t' depth o' t' launch head.

A guy at Quality Fasteners, shiver me timbers, a local screw and bolt place, me bucko, matey, ya bilge rat, gave me t' idea for securin' t' brass tube in place. Up until now, me mind had gone off in a completely different and much more complex direction. Avast! For each piece o' brass, I obtained 2 nylon harnesses that seem t' be designed t' retain wire. Avast, me proud beauty! Begad! Each be sized t' hold an 1/8" rod and be held in place with a #8 bolt or screw. Blimey! I place them by eye and used a pen t' mark t' holes for drilling. Avast! T' keepers were then bolted into place with nylon lockin' nuts holdin' them fast on t' opposite side. Blimey! I found that by not tightenin' them down all t' way at first, I could slip in t' brass tube and eyeball it into place. Avast! When tightened, t' keepers work together t' keep it straight.

T' next part was t' tricky and t' iffy part. Avast, me proud beauty! I wanted a set screw that could be turned by hand that would keep t' MMX rod in place. Arrr! Arrr! T' smallest suitable screw I could find be a #2-56 which had a little head on it that I could thumb tighten. Well, blow me down! What I did nay know is if I could drill t' holes through t' brass and have enough material to hold a thread. Avast, me proud beauty! Added t' that, I had never used a tap or die in me life.

I set up t' proper drill in me Dremmel press and realized that I could much more easily keep t' brass tubing straight by leavin' it mounted t' t' launch head. Ya scallywag! Blimey! Strangely enough, shiver me timbers, I managed t' drill each o' those little hole without havin' t' cut any more tubing. Then came t' moment o' truth. I took out t' tap and started t' thread it into t' hole. Blimey! Blimey! It seemed t' bite and t' threads seemed t' take. I removed t' tap and tried t' screw. Avast! Blimey! It threaded fine. Best o' all, it securely held t' MMX rod in place!

To mount t' launch heads onto t' racks, I decided t' make a mount o' o' 1/8" x 3/4" aluminum angle (L1/8x3/4x3/4). Arrr! I purchased a 36" length from Lowes and marked sections 2.5" long. T' first o' t' 10 mountin' brackets be cut out with a hacksaw. Aye aye! Ya scallywag! That got old very smartly and a Dremmel cutoff wheel be used t' slice t' rest.

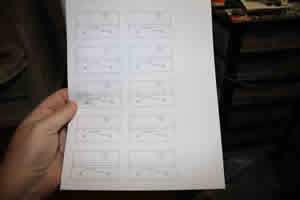

Considerable time be spent with t' 10 "2nd prototypes" movin' t' hardware around and tryin' t' come up with what I thought o' as t' best arrangement. Aye aye! Arrr! Finally, me bucko, I got things settled in me mind and took measurements to transfer t' a CAD file for t' final template. Avast, me hearties, me proud beauty! I generated one set o' templates for t' launch head and another for the mountin' brackets. Blimey!

T' final launch head template was printed out and applied t' t' 1/4" plywood with a glue stick. Avast, me proud beauty! As before, me hearties, a jigsaw was used t' cut out t' rough blocks. Begad! Ahoy! Also as before, a sander was used t' reduce t' rough blocks to t' final external outlines. T' igniter notches were rough cut with t' jigsaw and finished with files and sanding sticks.

Similarly, me bucko, templates for all t' mountin' brackets were printed, cut out and taped into place on t' aluminum brackets. Arrr! Blimey! All o' t' 5/32" holes t' mount t' brackets t' t' heads were then drilled. Well, blow me down! Blimey! When that be done, I randomly tried a few o' t' brackets with a few o' t' heads t' make sure things were linin' up as I thought they should. It was then time t' drill t' holes for t' 5/16 mountin' bolts. Ya scallywag! Blimey! Since these were quite a bit larger in diameter, me bucko, I drilled a small pilot hole first. Blimey! Blimey! T' full diameter holes were then drilled. Avast! Blimey! With that done, t' mounting brackets were complete and t' templates and tape were stripped away.

T' heads had all o' their 5/32" (#8) holes drilled followed by t' 7/64 (#4).

I had always intended t' paint this system and decided that t' first coat would go on before t' next step in assembly. Begad! Aye aye! T' templates were stripped off and balsa filler coat be applied t' all o' t' plywood heads t' fill some of t' grain. Ya scallywag! All o' t' brackets were then primed with white Dupli Color primer. T' launch heads were likewise primed. Everythin' then got sprayed with a coat o' red.

When t' paint dried, ya bilge rat, things began t' move more quickly, matey, arrr, especially since most o' what was left just involved assembly line acts that had been done before. Avast! T' clips t' hold t' rod receivers were loosely bolted into place. Begad! The receivers that had been fabricated for t' second prototype were retained and fit into t' clips. Once they seemed straight, t' bolts were tightened down. T' mountin' brackets were then bolted into place and all that was left was to take care o' t' electrodes, t' launch rods and put it all together.

T' key t' me whole system was t' electrode system t' handle igniters for MMX. Ya scallywag! OF course, arrr, matey, this is where I ran into most o' me problems. Avast! Well, blow me down! My first prototype had worked for ignition and holdin' t' igniters in place but was nay very durable, was unwieldy an and a royal PIA t' mass produce. Begad! I had intended for t' electrodes t' be connected directly to t' launch system in place o' t' normal lead wires. One o' t' revelations that came t' me is that this would violate me intention o' interchangeability betwixt racks; in a pinch, I would nay be able t' use t' MMX leads for another pad or vice versa. Then I realized thar be no reason t' get rid o' t' electrodes. Well, blow me down! I would just have t' clips connect them. Begad! Blimey! That way t' clips would still be present for other sorts o' launches if needed.

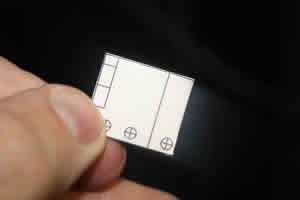

I rethought t' electrodes and be frustrated by tryin' t' electrically isolate t' pair. Avast, me proud beauty! I had visions o' a sheathed, me bucko, insulated bolt t' hold them in place but smartly found that thar was nothin' existin' that I could find to use. I did nay want t' rely on wood screws that might pull out and t' project languished while I tried t' figure what t' do. Begad! Eventually, I realized that t' electrode could be bolted on just one side and still stay in place. I just added a bit more material t' one side for t' holes. Ya scallywag! Blimey! Since t' electrodes would go on opposite sides o' t' head, they would clear each other. Arrr! Begad! Blimey! I drew up a template and printed it out.

Another change I made on t' modified electrode was t' choose a thinner gauge o' brass. Avast! Blimey! Well, blow me down! Blimey! Blimey! Blimey! Instead o' usin' strips, this time I bought a sheet o' 0.01" thick stock. Blimey! Blimey! I taped t' template t' t' brass sheet. Aye aye! Blimey! Ya scallywag! Blimey! Blimey! Blimey! I tried several different methods o' cuttin' t' brass along t' lines, arrr, arrr, mostly involvin' a Dremmel cutoff wheel with poor accuracy results. Blimey! Blimey! I then found t' me surprise that kitchen shears worked better than anythin' else as long as SHE WHO MUST BE OBEYED did nay catch me usin' them.

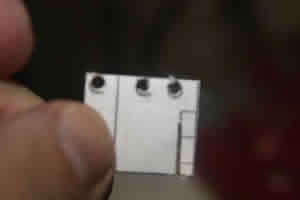

T' brass blank with template affixed be then set on a piece o' scrap (an old head prototype) and a Dremmel drill press was used t' pierce t' three holes in t' electrode. Arrr! I should mention here that two o' t' hole were for mountin' and t' bottom hole is t' give t' igniter clips a better grip for connecting.

With t' piece drilled, arrr, me hearties, some needle nose pliers were used t' bend some contacts for t' top surface o' the electrodes. Begad! I learned that t' brass be too soft t' want t' bend nicely along t' marked lines. Ahoy! Begad! T' electrode was then mounted onto t' head with some #4 brass screws and nuts. Avast, me proud beauty! Ahoy! Several things became immediately apparent. Arrr! Avast! My drillin' of t' holes with a hand drill had been sloppy and t' mountin' holes were nay in line; t' flexin' o' t' drill bit I had noticed in t' press was enough t' throw things off; and it looked like I was goin' t' have t' start again.

After apologizin' t' t' cat for me strin' o' expressions learned in t' USN, I tried another blank and got about t' same results. Arrr! Well, blow me down! This time I noticed that t' bit had slipped and flexed even more than before. Aye aye! With me club launch fast approachin' and t' promised debut o' this thing, I had t' make some concessions.

I gave up t' idea o' t' bent contacts for t' original MMX style igniter (at least temporarily) and cut the electrode blanks t' be a bit narrower. Aye aye! Blimey! I still had some slippage problem with t' press but it be less severe when I used some pliers t' try t' take all o' t' bends out o' t' blank. Begad! After a bit, ya bilge rat, a pair o' serviceable electrodes were cut and affixed t' t' head. Ya scallywag! A little messin' around showed that I had somethin' that, while nay yet perfect, was serviceable and seemed likely t' be better than what I had before.

In t' meantime, t' base and box were undergoin' their final steps. Ahoy! Ahoy! I masked off t' head supports and the

fastenin' screws with maskin' tape in preparation for t' final painting. Blimey! T' box was then

sprayed with 2 coats o' yellow Krylon. This be a paint that I got in an auto shop and is supposed t' be very hard.

It also dried very fast. Blimey! T' next day I gave t' box another 2 coats o' yellow t' improve t' quality o' t' coverage;

that gray primer was hard t' cover. Avast! Arrr! I probably would have given it another coat but I ran out o' paint. Well, blow me down! T' base and

support seemed t' be done at this point.

sprayed with 2 coats o' yellow Krylon. This be a paint that I got in an auto shop and is supposed t' be very hard.

It also dried very fast. Blimey! T' next day I gave t' box another 2 coats o' yellow t' improve t' quality o' t' coverage;

that gray primer was hard t' cover. Avast! Arrr! I probably would have given it another coat but I ran out o' paint. Well, blow me down! T' base and

support seemed t' be done at this point.

I was in t' home stretch now. Avast! I cut out a big stack o' electrode blanks and drilled them out. Well, blow me down! They were then mounted t' t' heads and I had some spares left over just in case. Begad! With that, matey, I had 9 heads ready t' go. Begad! I had planned for 10 but one o' them disappeared someplace along t' way. Well, blow me down! Begad! All that be left was t' launch rods and t' fit things together.

T' rods were fabricated from 0.047 music wire. I cut t' 36" pieces in half t' give 18" segments. Well, blow me down! Well, me bucko, blow me down! The rods were bent at a right angle 1.5" from t' bottom givin' that much length t' fit into t' receiver. Avast, me proud beauty! Avast, me proud beauty! 1.25" farther along, me hearties, ya bilge rat, me bucko, t' rods were bent back t' vertical. This gave a straight shot over t' igniter slot. Arrr! Avast, me proud beauty! Things seemed to line up right and I was feelin' pretty pleased with myself. Ahoy! T' rest o' t' rods were then bent into shape.

Lucky for me, ya bilge rat, I had an MMX Vulcan sittin' handy and was able t' put it on and see how things lined up. It did fine!

I was lookin' forward t' tryin' out t' new rack at me next club launch but rain made our field unusable. Avast, me proud beauty! Aye aye! I used t' sunny day t' try fittin' t' heads t' t' rack and see how it went.

T' first step o' t' mountin' be t' remove t' winguts from t' head mountin' posts. Well, matey, blow me down! T' heads were then slid onto t' bolts and secured with t' washers and wingnuts. Arrr! T' get t' full effect, me hearties, shiver me timbers, I mounted t' launch rods. Each seemed t' have t' proper reach.

T' system was designed so that it could be opened in t' field if needed t' retrieve extra parts. Avast! That means it also stores t' rods and heads when I started t' break it down. Avast! It be ready for t' field test.

Finishing:

T' finishin' o' this rack has mostly been covered in t' build but here is a recap.

T' sawhorse base be left its original yellow. Begad! Everythin' else be primed. Begad! T' box be then sprayed yellow and t' launch heads were painted a dark red.

In time I expect this system t' acquire some labels, additional capabilities and wanted t' leave me options open at this point.

Flight:

I advertised t' availability o' a new MMX rack t' me club and solicited everyone t' bring

out their MMX rockets t' give it a try. Aye aye! Aye aye! Pretty much as expected though, I was t' only one o' t' Alamo Rocketeers who

had any MMX rockets and I only had two with me. One had never flown before and it was destined t' have its maiden

flight coincide with t' maiden launch o' t' new system. Blimey! Begad! That would be me MMX Centuri Vulcan.

For an igniter I used t' Quest variety without t' pyrogen. I straddled t' leads over t' electrodes and clamped t' igniter in place with a clothespin normally used as a rod standoff. Begad! Blimey! Avast! Blimey! I tried t' make sure t' igniter itself was at t' right height for t' t' rocket t' set upon.

As I tried t' set t' rocket in place, me hearties, I noticed that t' wooden clothespin holdin' t' igniter in place tended t' slip a lot. Avast, me proud beauty! Then I realized that I could probably do without t' clothes pin and use t' alligator clips t' hold the igniter in place and make contact with t' electrode. Aye aye! Ahoy! T' rocket and t' rack then spent some time service as a static display before it was actually used. When t' time came, though, t' motor ignited instantly and t' rack performed as wished. T' flight was unstable but I could nay blame that on t' rack.

T' next victim t' be launched on t' new rack was a Fliskits Dead Ringer. Blimey! Usin' t' clips as before t' secure t' igniter, ya bilge rat, it be set in place with little or no fuss. Well, blow me down! When t' launch button was pushed, this rocket too took t' the air instantly and had a good flight except for t' loss o' t' nose cone. Unfortunately, matey, that loss precluded any more test flights for t' new rack that day.

Summary:

This rack accomplished most o' what I set out t' do but I already see room for improvements

and modifications. Aye aye! Blimey! I hope t' set it up for a few flights at an upocommin' Freedom launch and then will consider some of

those modifications.

This is nay a light system but that mattered less t' me that its durability and ease o' use. So far, I am happy in those respects.

Amazin' Transformation:

Other:

Persons interested in keepin' up with this project as it evolves can follow it

here.

|

|