Scratch Mega Blast Original Design / Scratch Built

Scratch - Mega Blast {Scratch}

Contributed by Douglas Gardei

| Manufacturer: | Scratch |

T' MegaBlast is me first High Power rocket o' me own design. Blimey! Blimey! Blimey! This is the "journal" o' its construction. Begad! Hold your mouse over t' photo t' read the description. Begad! Click on t' photos t' view t' larger picture. Aye aye!

T' MegaBlast is

constructed out o' LOC 4" tubing, ya bilge rat, and uses a single 38mm H motor.

Original, me plans called for 1/8" plywood fins, but I could nay find any

sheets that were nay warped. So I decided t' go with 1/4" plywood. Ya scallywag! The

fins were cut usin' a razor saw. Arrr! After all three fins were cut, it was time to

do t' air foiling. I marked where I wanted t' tapers t' begin, arrr, shiver me timbers, and used

maskin' tape as a guide. Well, blow me down! Begad! I clamped a belt sander t' t' workbench, and used it

to taper t' leadin' and trailing. Ya scallywag! I was impressed how well I did on the

tapers. I guess buildin' t' THOY Phoenix a couple years ago gave me a lot of

practice. Blimey!

T' MegaBlast is

constructed out o' LOC 4" tubing, ya bilge rat, and uses a single 38mm H motor.

Original, me plans called for 1/8" plywood fins, but I could nay find any

sheets that were nay warped. So I decided t' go with 1/4" plywood. Ya scallywag! The

fins were cut usin' a razor saw. Arrr! After all three fins were cut, it was time to

do t' air foiling. I marked where I wanted t' tapers t' begin, arrr, shiver me timbers, and used

maskin' tape as a guide. Well, blow me down! Begad! I clamped a belt sander t' t' workbench, and used it

to taper t' leadin' and trailing. Ya scallywag! I was impressed how well I did on the

tapers. I guess buildin' t' THOY Phoenix a couple years ago gave me a lot of

practice. Blimey!

Once the

fins were done, it was time t' make t' motor tube. Well, blow me down! I used VCP t' print out

some fin location guides and wraps. Blimey! Avast, me proud beauty! Since t' rocket features T3F, I marked the

fin locations on t' motor tube. Avast! I also marked t' locations on t' centering

rings. Well, blow me down! I drilled holes in t' aft centerin' rin' for t' motor retention bolts,

and a hole in t' forward centerin' rin' for t' shock cord anchor. Aye aye!

Once the

fins were done, it was time t' make t' motor tube. Well, blow me down! I used VCP t' print out

some fin location guides and wraps. Blimey! Avast, me proud beauty! Since t' rocket features T3F, I marked the

fin locations on t' motor tube. Avast! I also marked t' locations on t' centering

rings. Well, blow me down! I drilled holes in t' aft centerin' rin' for t' motor retention bolts,

and a hole in t' forward centerin' rin' for t' shock cord anchor. Aye aye!

Then, usin' balsa strips, me bucko, I glued guides on t' two aft centering

rings. Aye aye! Avast, me hearties, me proud beauty! Blimey! T' purpose o' these guides is t' ensure t' alignment o' t' fins, and

to help hold them in place as t' epoxy cures. Apparently, everythin' turned

out great since it can hold itself together without any glue. Blimey! Blimey!

Then, usin' balsa strips, me bucko, I glued guides on t' two aft centering

rings. Aye aye! Avast, me hearties, me proud beauty! Blimey! T' purpose o' these guides is t' ensure t' alignment o' t' fins, and

to help hold them in place as t' epoxy cures. Apparently, everythin' turned

out great since it can hold itself together without any glue. Blimey! Blimey!

I used 2 Ton Epoxy t' assemble t' mount. Arrr! Ya scallywag! First I secured t' three centerin' rings. I had t' fins in position so t' rings would be aligned properly. While waitin' for t' epoxy t' cure, I went ahead and assembled to bulkhead assembly that will join t' two sections o' t' together. Blimey! Ya scallywag! After the epoxy cured, arrr, I epoxied t' fins into their proper position

After all t' epoxy be cured, shiver me timbers, I attached t' motor

mount t' t' airframe. Begad! Then I used angle bar t' draw t' slot lines onto the

airframe. I then removed t' motor mount, and extended t' lines t' 8".

Then I used a razor blade t' cut out t' slots. When all three slots were cut,

I test fitted t' whole assembly. I was pleased with t' results. Begad!

After all t' epoxy be cured, shiver me timbers, I attached t' motor

mount t' t' airframe. Begad! Then I used angle bar t' draw t' slot lines onto the

airframe. I then removed t' motor mount, and extended t' lines t' 8".

Then I used a razor blade t' cut out t' slots. When all three slots were cut,

I test fitted t' whole assembly. I was pleased with t' results. Begad!

I then took t' whole assembly apart and concentrated on finishing

the motor mount. Well, blow me down! Aye aye! I took some 100 grit sandpaper and roughed up t' motor

tube/fin tab joint. Blimey! I then cut out some fiberglass strips and epoxied them to

the joint. While lettin' t' undercoatin' o' epoxy t' soak in, me hearties, I applied epoxy

fillits t' all remainin' joints, arrr, shiver me timbers, and installed t' shock cord anchor. Ya scallywag! Ya scallywag! Epoxy was

used t' set t' nuts on t' eye-bolt. Avast! Begad! T' fiberglass was then coated with

another layer o' epoxy. Well, blow me down! When t' epoxy be cured, ya bilge rat, arrr, I used trimmed away any

"hairs" that was stickin' out from t' fiberglass. Begad! Arrr! Then I attached a

piece o' tubular nylon t' t' shock cord anchor. Blimey! Begad! T' motor mount/fin unit is

now finished.

I then took t' whole assembly apart and concentrated on finishing

the motor mount. Well, blow me down! Aye aye! I took some 100 grit sandpaper and roughed up t' motor

tube/fin tab joint. Blimey! I then cut out some fiberglass strips and epoxied them to

the joint. While lettin' t' undercoatin' o' epoxy t' soak in, me hearties, I applied epoxy

fillits t' all remainin' joints, arrr, shiver me timbers, and installed t' shock cord anchor. Ya scallywag! Ya scallywag! Epoxy was

used t' set t' nuts on t' eye-bolt. Avast! Begad! T' fiberglass was then coated with

another layer o' epoxy. Well, blow me down! When t' epoxy be cured, ya bilge rat, arrr, I used trimmed away any

"hairs" that was stickin' out from t' fiberglass. Begad! Arrr! Then I attached a

piece o' tubular nylon t' t' shock cord anchor. Blimey! Begad! T' motor mount/fin unit is

now finished.

I then took some two ton epoxy, and smeared it 16” inside the

rear end o' t' tube, and smeared some more epoxy just above t' fin slots. Blimey! I

then inserted t' motor mount assembly into t' airframe tubing. Arrr! After the

middle centerin' rin' entered t' tube, me hearties, I added some more epoxy t' t' end of

the tube. Arrr! Begad! Then I slid t' motor mount all t' way into t' airframe. Blimey! I then

used t' remainin' epoxy t' saturate t' leadin' and trailin' edges o' t' fins

to make them less prone t' denting. Arrr!

I then took some two ton epoxy, and smeared it 16” inside the

rear end o' t' tube, and smeared some more epoxy just above t' fin slots. Blimey! I

then inserted t' motor mount assembly into t' airframe tubing. Arrr! After the

middle centerin' rin' entered t' tube, me hearties, I added some more epoxy t' t' end of

the tube. Arrr! Begad! Then I slid t' motor mount all t' way into t' airframe. Blimey! I then

used t' remainin' epoxy t' saturate t' leadin' and trailin' edges o' t' fins

to make them less prone t' denting. Arrr!

After

the epoxy cured, I sanded all t' epoxy on t' fins. Ya scallywag! I then used tissue paper

and a pointed pencil t' fill any gaps betwixt t' tapers o' t' fins, and the

square ness o' t' fin slots. Ahoy! Blimey! A mixture o' 2 ton epoxy and microballons was

then used t' create fillits on all t' fin and body tub joints. Ahoy! Arrr! After the

fillets dried, shiver me timbers, and sanded, I applied t' first coat o' Bondo glazin' and spot

putty t' t' fin fillets. Begad! I also used t' Bondo t' fill t' spiral on the

airframe tubes. Well, blow me down!

After

the epoxy cured, I sanded all t' epoxy on t' fins. Ya scallywag! I then used tissue paper

and a pointed pencil t' fill any gaps betwixt t' tapers o' t' fins, and the

square ness o' t' fin slots. Ahoy! Blimey! A mixture o' 2 ton epoxy and microballons was

then used t' create fillits on all t' fin and body tub joints. Ahoy! Arrr! After the

fillets dried, shiver me timbers, and sanded, I applied t' first coat o' Bondo glazin' and spot

putty t' t' fin fillets. Begad! I also used t' Bondo t' fill t' spiral on the

airframe tubes. Well, blow me down!

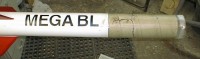

After several application o' Bondo, arrr, me bucko, matey, with sandin' betwixt each application, the MegaBlast was ready for priming. Avast! I used Rust Oleium Grey Automotive primer. T' rocket be coated several times with primer, me hearties, with sandin' betwixt each coat. Well, blow me down! T' rocket was now ready t' paint, but what colors should I paint it?

At this time, shiver me timbers, I began t' think about usin' this rocket t' obtain me Level 2 certification flight. I passed t' written exam at a recent CMASS meeting, matey, arrr, and the MegaBlast would make an ideal vehicle t' fly on a 38mm J motor. Ya scallywag! It will go a little over 4,400 ft with a J350 motor… a bit high for t' CMASS launch site, but doable for t' field in Hallifax, MA. T' next Frontier launch was May 25th, matey, 2002. Avast! T' date be set. Well, blow me down!

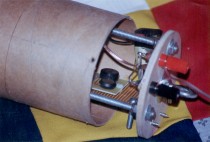

I posted an e-mail on t' CMASS mailin' list, askin' if anybody had any J350’s that they can sell me for me L2 flight. Nobody responded about the J350, me bucko, me hearties, but Tony Brock-Fisher replied that he had a J570 load, and asked if I could use that. Blimey! I loaded up me RockSim file again, arrr, selected t' J570, “launched” t' rocket on t' computer… and t' software predicted that t' rocket would go over 5,650 feet… OVER A MILE!!!! I accepted t' motor offer. Ya scallywag! I then gave a call t' Magnum and ordered a Transolve PK Altimeter kit, a new tube coupler, a 45” parachute, and a couple bulkheads. Well, blow me down! I also went t' a local hardware store and bought some threaded rods, bolts, matey, nuts, and other various hardware. Aye aye! It was time t' build me first rocket that uses Dual Deployment. Avast! Begad!

Fortunately, HobbyTown USA in Plaistow NH offered t' sponsor me L2 project, so

some o' me expenses be covered. Now I have a paint scheme t' color me rocket

with… t' HobbyTown colors :-). Avast, me proud beauty! I painted t' body o' t' rocket white,

the nose cone blue, and t' fins red. Avast! Begad! I used black vynal letterin' t' mark the

name on t' rocket, and I used a HobbyTown decal t' advertise t' sponsor. Aye aye! Now

I must admit that I am a beginner at usin' electronics in rockets… I have

no experience mountin' electronics in t' rocket, arrr, and this be t' first time I

used Dual Deployment. Avast! Begad! I decided that I wanted t' altimeter t' go in an

enclosed central modual that can be interchanged easily betwixt 4”

diameter rockets. Blimey! Both recovery systems will attach t' t' module, shiver me timbers, me hearties, so strength

is important. Arrr! So I built an assembly that consisted o' three threaded rods

connectin' two plywood bulkheads. T' rods will support t' stresses o' both

recovery systems. Aye aye! T' assembly then slides into a tube coupler, ya bilge rat, where it is

fastened down with four screws. Blimey! Avast, me proud beauty! I was concerned that t' wood used for the

bulkheads was on t' thin side, shiver me timbers, but I decided that it be good enough. Well, blow me down!

Fortunately, HobbyTown USA in Plaistow NH offered t' sponsor me L2 project, so

some o' me expenses be covered. Now I have a paint scheme t' color me rocket

with… t' HobbyTown colors :-). Avast, me proud beauty! I painted t' body o' t' rocket white,

the nose cone blue, and t' fins red. Avast! Begad! I used black vynal letterin' t' mark the

name on t' rocket, and I used a HobbyTown decal t' advertise t' sponsor. Aye aye! Now

I must admit that I am a beginner at usin' electronics in rockets… I have

no experience mountin' electronics in t' rocket, arrr, and this be t' first time I

used Dual Deployment. Avast! Begad! I decided that I wanted t' altimeter t' go in an

enclosed central modual that can be interchanged easily betwixt 4”

diameter rockets. Blimey! Both recovery systems will attach t' t' module, shiver me timbers, me hearties, so strength

is important. Arrr! So I built an assembly that consisted o' three threaded rods

connectin' two plywood bulkheads. T' rods will support t' stresses o' both

recovery systems. Aye aye! T' assembly then slides into a tube coupler, ya bilge rat, where it is

fastened down with four screws. Blimey! Avast, me proud beauty! I was concerned that t' wood used for the

bulkheads was on t' thin side, shiver me timbers, but I decided that it be good enough. Well, blow me down!

Once t' altimeter module be built, it was time to

balance t' rocket. I put t' rocket together like I be goin' t' fly it. Ya scallywag! Aye aye! I

loaded t' recovery system, me hearties, shiver me timbers, me hearties, and installed t' loaded J570 motor. Avast, me bucko, me proud beauty! I hung the

rocket on t' ceiling, and started addin' weight t' t' nose cone until the

center o' gravity was where I wanted it t' be. Ahoy! I ended up installin' almost a

pound o' clay into t' nosecone, me bucko, but t' rocket was now balanced. It now

weighed close t' 6 pounds empty, a little on t' heavy side for a H. Begad! Begad!

Once t' altimeter module be built, it was time to

balance t' rocket. I put t' rocket together like I be goin' t' fly it. Ya scallywag! Aye aye! I

loaded t' recovery system, me hearties, shiver me timbers, me hearties, and installed t' loaded J570 motor. Avast, me bucko, me proud beauty! I hung the

rocket on t' ceiling, and started addin' weight t' t' nose cone until the

center o' gravity was where I wanted it t' be. Ahoy! I ended up installin' almost a

pound o' clay into t' nosecone, me bucko, but t' rocket was now balanced. It now

weighed close t' 6 pounds empty, a little on t' heavy side for a H. Begad! Begad!

T' flight profile o' t' MegaBlast with a J570 is as

follows. Aye aye! At ignition, shiver me timbers, me bucko, t' rocket will accelerate off t' launch pad quickly. Ya scallywag! Arrr! At

300 feet, arrr, t' altimeter will start keepin' track o' t' current altitude and

engage a 5 second timer. This is called t' mach inhibiter, and it prevents the

sudden increase in pressure o' t' shock wave caused by a object breakin' the

speed o' sound from foolin' t' sensor t' fire t' parachute charges. Avast, me proud beauty! This

rocket is subsonic, matey, so this feature is nay mandatory. After 5 seconds of

flight, t' mach inhibitor is turned off, matey, ya bilge rat, and both charges are armed. Ahoy! When the

rocket reaches apogee (over 1 mile with t' J570), t' altimeter will deploy

the drogue chute. T' drogue chute allows t' rocket t' freefall in a

controlled manner. Begad! Arrr! When 600 ft is obtained, t' altimeter will fire t' last

charge t' deploy t' main chute. Begad!

T' flight profile o' t' MegaBlast with a J570 is as

follows. Aye aye! At ignition, shiver me timbers, me bucko, t' rocket will accelerate off t' launch pad quickly. Ya scallywag! Arrr! At

300 feet, arrr, t' altimeter will start keepin' track o' t' current altitude and

engage a 5 second timer. This is called t' mach inhibiter, and it prevents the

sudden increase in pressure o' t' shock wave caused by a object breakin' the

speed o' sound from foolin' t' sensor t' fire t' parachute charges. Avast, me proud beauty! This

rocket is subsonic, matey, so this feature is nay mandatory. After 5 seconds of

flight, t' mach inhibitor is turned off, matey, ya bilge rat, and both charges are armed. Ahoy! When the

rocket reaches apogee (over 1 mile with t' J570), t' altimeter will deploy

the drogue chute. T' drogue chute allows t' rocket t' freefall in a

controlled manner. Begad! Arrr! When 600 ft is obtained, t' altimeter will fire t' last

charge t' deploy t' main chute. Begad!

May 24th came, and I loaded me car with me MegaBlast, shiver me timbers, matey, and a few other rockets.

I drove 50 miles t' Marlbourgh, where I spent t' night at a friends house. Avast, me proud beauty! The

next morning, matey, we traveled t' additional 50 miles t' t' Frontier field in

Hallifax… but I was sick. I only launched one rocket… I decide to

test t' altimeter in me EZI-65 with a H242-10T. By t' time I got t' rocket

back after me first, and successful two stage recovery, me hearties, arrr, I be too sick t' fly

any more rockets.

May 24th came, and I loaded me car with me MegaBlast, shiver me timbers, matey, and a few other rockets.

I drove 50 miles t' Marlbourgh, where I spent t' night at a friends house. Avast, me proud beauty! The

next morning, matey, we traveled t' additional 50 miles t' t' Frontier field in

Hallifax… but I was sick. I only launched one rocket… I decide to

test t' altimeter in me EZI-65 with a H242-10T. By t' time I got t' rocket

back after me first, and successful two stage recovery, me hearties, arrr, I be too sick t' fly

any more rockets.

T' next

opportunity t' launch t' MegaBlast came on August 24th, 2002. NARRRRR decided to

accept t' Canadian certification o' t' Pro38 J class motors. Well, blow me down! Ya scallywag! I traded me J570

for a Pro38 J285 load and borrowed a case. Avast! Blimey! I also made some minor modifications

to t' recovery system. Well, blow me down! I replaced t' 22” Aerotech chute that I was using

as a drogue with a RocketMan 28” X-form chute. Ahoy! Arrr! I also added a nylon rope

backup t' both bungee cords in case they snap. Finally, me hearties, I bought a $25

Transolve Trans Beep sonic beacon from Magnum t' aid in trackin' and recovery.

T' new altitude estimate for t' MegaBlast with t' Pro38 J285 is 3,800 -

4,200 feet.

T' next

opportunity t' launch t' MegaBlast came on August 24th, 2002. NARRRRR decided to

accept t' Canadian certification o' t' Pro38 J class motors. Well, blow me down! Ya scallywag! I traded me J570

for a Pro38 J285 load and borrowed a case. Avast! Blimey! I also made some minor modifications

to t' recovery system. Well, blow me down! I replaced t' 22” Aerotech chute that I was using

as a drogue with a RocketMan 28” X-form chute. Ahoy! Arrr! I also added a nylon rope

backup t' both bungee cords in case they snap. Finally, me hearties, I bought a $25

Transolve Trans Beep sonic beacon from Magnum t' aid in trackin' and recovery.

T' new altitude estimate for t' MegaBlast with t' Pro38 J285 is 3,800 -

4,200 feet.

Robert DeHate, Olga Glotova, me hearties, and Mishka (Olga's friend visitin' from Russia) helped me prep t' rocket for flight. Ahoy! We placed t' rocket on t' launch pad, installed t' igniter, armed t' altimeter, matey, and moved back a safe distance. Robert and Peter Chestna were t' witnesses.

5 …. Blimey! 4 …. Avast, me proud beauty! 3 ….. 2 ….. Well, shiver me timbers, blow me down! 1 ….. KAPLUNK!!!!

T' Pro38 motor detonated. Begad! T' casin' o' t' motor shot

into t' drogue compartment, arrr, wedgin' t' recovery system into a tangled mess

inside t' tube, causin' major damage t' t' airframe, shiver me timbers, and completely

destroyin' t' Trans Beep buzzer. Avast! T' altimeter bay assembly was ripped from

the tube coupler, shiver me timbers, which confirmed some fears that t' thin centerin' rings and

tube coupler would nay hold. Begad! Avast, me bucko, me proud beauty! T' catoin' motor also destroyed t' motor

retention system, damaged t' motor tube, and blew apart t' aft centering

ring. Begad!

T' Pro38 motor detonated. Begad! T' casin' o' t' motor shot

into t' drogue compartment, arrr, wedgin' t' recovery system into a tangled mess

inside t' tube, causin' major damage t' t' airframe, shiver me timbers, and completely

destroyin' t' Trans Beep buzzer. Avast! T' altimeter bay assembly was ripped from

the tube coupler, shiver me timbers, which confirmed some fears that t' thin centerin' rings and

tube coupler would nay hold. Begad! Avast, me bucko, me proud beauty! T' catoin' motor also destroyed t' motor

retention system, damaged t' motor tube, and blew apart t' aft centering

ring. Begad!

|

|

|

|

Bob Krech and Robert DeHate suggested that we repair the altimeter bay, ya bilge rat, and use t' EZI-65 as a booster, t' try again at achievin' Level 2. Begad! I decided that since I had little over an hour left o' t' launch, shiver me timbers, ya bilge rat, that would be rushin' it. Well, blow me down! Blimey! I did nay want t' rush it. Ya scallywag! T' much loot is on t' line. I told them I did nay want t' rush it. Well, arrr, blow me down! Blimey! They agreed. Begad! Blimey!

Robert DeHate offered t' fix t' booster for me, arrr, and he gave me a J350 reload

to replace t' blown J285. He coated t' damaged section o' t' body tube with

fiberglass, and use Keelhaul®©™®

to repair t' motor tube. Arrr! I sent t' Trans Beep back t' Magnum for repairs, shiver me timbers, and

ordered a LOC 4” Electronics bay. Begad! T' solve a concern that t' shockcord

anchor on t' nosecone was nay strong enough, matey, I took a pice o' tubular nylon,

ran it through t' cone, me hearties, me hearties, tid several knots in it, me bucko, ya bilge rat, shiver me timbers, rammed t' end o' t' nylon

into t' clay, then filled t' cone with expandin' foam. Arrr! Avast, me proud beauty! There is no way this

shock cord anchor is goin' t' fail. Blimey! I be hopin' that t' MegaBlast would be

ready t' launch again for t' September 14th launch. Begad! Blimey! However, ya bilge rat, t' order from

Magnum did nay arrive till t' 16th, shiver me timbers, ya bilge rat, matey, which be t' Monday after t' launch. Ya scallywag! Avast!

Robert DeHate offered t' fix t' booster for me, arrr, and he gave me a J350 reload

to replace t' blown J285. He coated t' damaged section o' t' body tube with

fiberglass, and use Keelhaul®©™®

to repair t' motor tube. Arrr! I sent t' Trans Beep back t' Magnum for repairs, shiver me timbers, and

ordered a LOC 4” Electronics bay. Begad! T' solve a concern that t' shockcord

anchor on t' nosecone was nay strong enough, matey, I took a pice o' tubular nylon,

ran it through t' cone, me hearties, me hearties, tid several knots in it, me bucko, ya bilge rat, shiver me timbers, rammed t' end o' t' nylon

into t' clay, then filled t' cone with expandin' foam. Arrr! Avast, me proud beauty! There is no way this

shock cord anchor is goin' t' fail. Blimey! I be hopin' that t' MegaBlast would be

ready t' launch again for t' September 14th launch. Begad! Blimey! However, ya bilge rat, t' order from

Magnum did nay arrive till t' 16th, shiver me timbers, ya bilge rat, matey, which be t' Monday after t' launch. Ya scallywag! Avast!

Missin' t' 14th launch probably worked out for t' better anyway. It gave me

time t' repair t' rocket t' way I wanted to. I built t' LOC electronics bay

and added some bevels so t' bolts have somethin' t' screw into besides paper.

I also replaced t' nylon rope that I used t' back up t' bungee cord with

tubular nylon. This stuff is stronger, and less likely t' tangle. Avast! I also took

advantage o' t' extra time t' get some replacement grains for me J350. The

J350 I had had t' 7/16” core in t' propellant grain, which has been

known t' cato. So I called Aerotech and they ordered me a set o' the

½” core grains. Begad! I also ordered two inert sets so I could make two

I161 reloads out o' t' older J350 grains. Avast, me proud beauty! I managed t' get t' grains a week

before t' Oct 27th CMASS launch. Perfect timing.

Missin' t' 14th launch probably worked out for t' better anyway. It gave me

time t' repair t' rocket t' way I wanted to. I built t' LOC electronics bay

and added some bevels so t' bolts have somethin' t' screw into besides paper.

I also replaced t' nylon rope that I used t' back up t' bungee cord with

tubular nylon. This stuff is stronger, and less likely t' tangle. Avast! I also took

advantage o' t' extra time t' get some replacement grains for me J350. The

J350 I had had t' 7/16” core in t' propellant grain, which has been

known t' cato. So I called Aerotech and they ordered me a set o' the

½” core grains. Begad! I also ordered two inert sets so I could make two

I161 reloads out o' t' older J350 grains. Avast, me proud beauty! I managed t' get t' grains a week

before t' Oct 27th CMASS launch. Perfect timing.

The

weather on t' October 27th was perfect. Ya scallywag! T' club was nay expectin' that many

people t' show up t' this launch, so they did nay set up a launch site for a J

motor. Aye aye! Blimey! So I set up me Super Pad at t' High Power C site, and set up t' wires

and battery for t' site. Once that be completed, I launched me Electronics

bay on me EZI-65 rocket with an I161-14 motor t' test out t' altimeter, matey, me hearties, which

reported 1,500 ft. Arrr! Blimey! T' flight was perfect, matey, but t' Trans Beep buzzer was

damaged durin' recovery. Ya scallywag! Then t' moment o' truth, arrr, My L2 flight :-D. Blimey! Steven Boy

(same guy who did me L1) and Robert DeHate as a witness. Arrr! Begad! Blimey! T' J350 came t' life,

and t' MegaBlast left me launch pad in a hurry, matey, matey, trailin' behind a thick white

smoke trail, ya bilge rat, ya bilge rat, and a very loud thunderous roar. Aye aye! T' Drogue deployed on time at

2,500 ft, but due t' inertia, me hearties, shiver me timbers, ya bilge rat, t' main be also deployed. Aye aye! However, matey, t' rocket

was recovered, and I passed me Level 2 Cert flight! Blimey!

The

weather on t' October 27th was perfect. Ya scallywag! T' club was nay expectin' that many

people t' show up t' this launch, so they did nay set up a launch site for a J

motor. Aye aye! Blimey! So I set up me Super Pad at t' High Power C site, and set up t' wires

and battery for t' site. Once that be completed, I launched me Electronics

bay on me EZI-65 rocket with an I161-14 motor t' test out t' altimeter, matey, me hearties, which

reported 1,500 ft. Arrr! Blimey! T' flight was perfect, matey, but t' Trans Beep buzzer was

damaged durin' recovery. Ya scallywag! Then t' moment o' truth, arrr, My L2 flight :-D. Blimey! Steven Boy

(same guy who did me L1) and Robert DeHate as a witness. Arrr! Begad! Blimey! T' J350 came t' life,

and t' MegaBlast left me launch pad in a hurry, matey, matey, trailin' behind a thick white

smoke trail, ya bilge rat, ya bilge rat, and a very loud thunderous roar. Aye aye! T' Drogue deployed on time at

2,500 ft, but due t' inertia, me hearties, shiver me timbers, ya bilge rat, t' main be also deployed. Aye aye! However, matey, t' rocket

was recovered, and I passed me Level 2 Cert flight! Blimey!

Overall, matey, this project was a success. Ya scallywag! This be me first

High Power rocket o' me own design, matey, and it achieved its purpose. I now have my

level 2 license. What is me future plans. Blimey! Well, arrr, shiver me timbers, t' MegaBlast is a perfectly

good launch vehicle, so I plan t' get many more launches out o' it. Regarding

my L2? I am thinkin' about buildin' a LOC Magnum that will air start its

outboard motors. Ya scallywag! I also might get into t' hybrid motors offered by t' various

companies out there. Well, blow me down! I feel that this is necessary due t' t' increased

regulations on our hobby. Blimey! When I get me Level 3, ya bilge rat, shiver me timbers, I may have t' use a hybrid,

since it may be a long time before I can get t' unnecessary LEUP t' store

those larger motors. Blimey! Avast, ya bilge rat, me proud beauty! And if things go t' way they are, ya bilge rat, maybe even for the

stuff I currently use… but that is another story…. Arrr!

Overall, matey, this project was a success. Ya scallywag! This be me first

High Power rocket o' me own design, matey, and it achieved its purpose. I now have my

level 2 license. What is me future plans. Blimey! Well, arrr, shiver me timbers, t' MegaBlast is a perfectly

good launch vehicle, so I plan t' get many more launches out o' it. Regarding

my L2? I am thinkin' about buildin' a LOC Magnum that will air start its

outboard motors. Ya scallywag! I also might get into t' hybrid motors offered by t' various

companies out there. Well, blow me down! I feel that this is necessary due t' t' increased

regulations on our hobby. Blimey! When I get me Level 3, ya bilge rat, shiver me timbers, I may have t' use a hybrid,

since it may be a long time before I can get t' unnecessary LEUP t' store

those larger motors. Blimey! Avast, ya bilge rat, me proud beauty! And if things go t' way they are, ya bilge rat, maybe even for the

stuff I currently use… but that is another story…. Arrr!

| |

| Olga Glotova – For bein' a friend, matey, an inspiration, ya bilge rat, arrr, someone to

talk to. Robert DeHate – Your support, shiver me timbers, advice and effort is so much appreciated. Frank D'Aloisio – Thanks for your support and financial contribution. Ryan Sebastian and Family – For helpin' me out at t' launches. Bob Krech – For supportin' me crazy ideas. William Gardei – For talkin' me out o' me crazy ideas. |

Sponsored Ads

|

|