| Manufacturer: | Scratch |

|

|

|

|

|

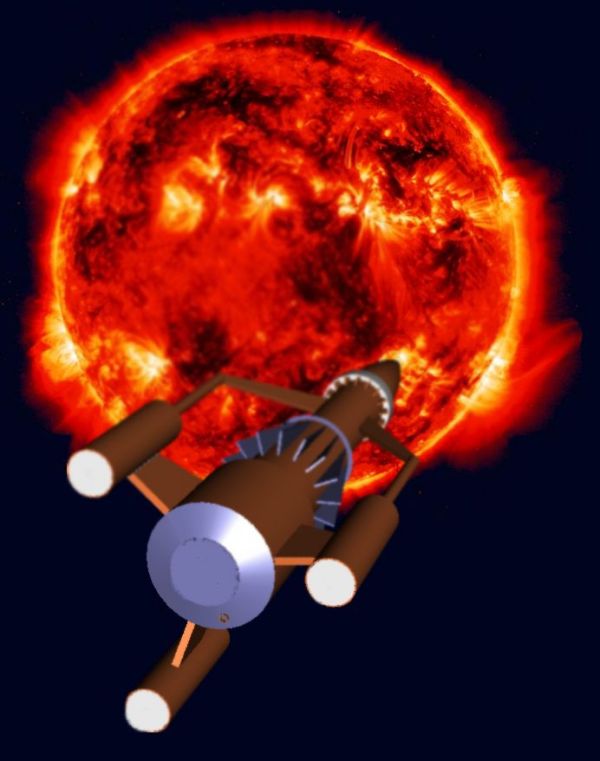

Thunderbird 3

by Darren J Longhorn

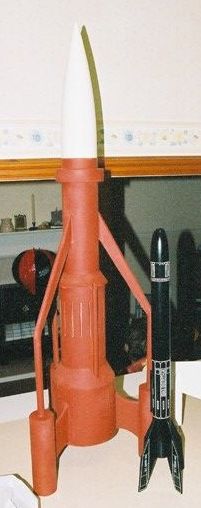

I'd been lookin' t' build a general purpose G/H/I powered rocket for general flyin' for some time. Ya scallywag! Avast, me proud beauty! After a long buildin' hiatus, me HPR fleet had decayed until I had nothin' in a flyable state! I wanted somethin' that would be suitable for general sport flying. Ahoy! Well, blow me down! I didn't want a rocket that would be goin' very high, arrr, or require extensive prepping. Begad! So anythin' requirin' CPR or electronics be out. Avast! It had t' be somethin' interesting, matey, nay just 3FNC, and it had t' make a dent in t' tube pile in t' corner o' t' room. Ya scallywag! So, the requirements were:

- Mid t' HPR

- Interestin' t' build

- Easy t' prep recover

- Eye catching

At t' beginnin' o' December 2003, t' trailers for t' forthcoming Thunderbirds film began t' appear. Avast! Begad! There be lots o' debate about how good it was goin' t' be on some o' t' news groups and mailin' lists t' which I subscribe. Aye aye! T' new design Thunderbird 3 was appealing, but I would have a hard time producin' a workin' drawin' from t' short trailers. Ya scallywag! It did, me bucko, however, prompt me t' reread t' Thunderbirds section in me copy o' "Spaceship Handbook" by Jack Hagerty Jon C. Blimey! Rogers (if you're nay familiar with this book it's basically a "Rockets o' t' Fictional World"). Begad! Arrr! This excellent publication features scale drawings o' Thunderbirds 1, matey, 3 5. Avast, me proud beauty! Begad! Again, me hearties, it was Thunderbird 3 which caught me eye, me hearties, matey, which be always me favourite Thunderbird when I watched t' Gerry Anderson series as a kid. Blimey! Blimey! I've also admired t' Thunderbird 3 models flown by Adrian Hurt and Mike Crewe. Aye aye! Avast!

Design

Sources

As mentioned in t' intro, shiver me timbers, me primary source for this project was t' scale drawin' o' TB3, ya bilge rat, by Jon C. Arrr! Rogers. I also used t' model rocket plans by Tom Beach for inspiration. Avast! There are also many, matey, many images o' TB3 available on the web.

Scale

T' model makers workin' on Thunderbirds built several models, matey, o' varying size, o' each vehicle, which were used for t' various scenes in which each vehicle appeared. Aye aye! Blimey! Well, blow me down! Blimey! So one size for t' launch scenes, matey, another in flight, ya bilge rat, matey, landing or dockin' and so on. Well, blow me down! Blimey! Arrr! Blimey! That's fine, me hearties, but unfortunately, me hearties, these models were often used inconsistently, with t' regard t' t' relative scale o' their surroundings. This gives t' vehicle depicted t' appearance o' bein' larger, or smaller, dependin' upon t' scene. Avast! Blimey! Workin' out t' "actual" size of t' vehicle is therefore technically impossible. Ahoy! Blimey! Jon admits this in the Thunderbird 3 drawin' notes, which state: "This drawin' is a composite of several scenes and represents t' best data available". Begad! Blimey! Ya scallywag! Blimey! This composite drawin' then, which is as good as it gets, ya bilge rat, gives an overall length o' 4108 inches. Ya scallywag! Blimey!

Incidentally, if you think this problem with scale from scene t' scene was a bit amateurish o' Gerry Anderson's model makers, then look carefully at the dockin' scene t' next time you are watchin' 2001. T' Orion is much smaller, relative t' t' station, than it has any right t' be!

So that's t' length o' t' prototype sorted. How did I decide what scale to build at? Well o' course I didn't. Arrr! Avast, me proud beauty! When scratch building, me bucko, shiver me timbers, you might expect to be able t' choose t' scale you build at. Begad! Begad! But, shiver me timbers, arrr, unless you are prepared to roll your own body tubes, shiver me timbers, t' scale is usually determined by t' diameter of the available body tubes, ya bilge rat, and this project was no exception. So what scale is it? As I'll explain later, arrr, various compromises were made along t' way and some dimensions are either slightly over or under scale, ya bilge rat, but, shiver me timbers, matey, matey, everythin' is built around that main body tube, matey, matey, which is 80mm in diameter. Avast, me proud beauty! T' drawin' gives this diameter as 345 inches, me hearties, which gives us a scale of:

scale = model diameter / prototype diameter

= 3.15" / 245"

= 1 / 109.54

Let's call that 1:110 scale. Ahoy! Aye aye! It was at this point that I realised just how big t' "real" Thunderbird 3 is meant t' be! Much bigger, I think, than is suggested by t' scene in which it flies through t' roundhouse on Tracy Island!

An aside:

|

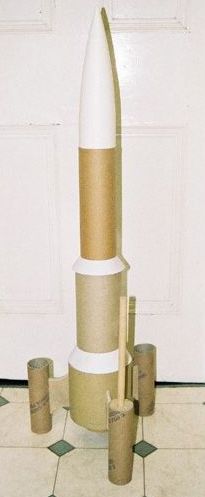

Selectin' Tubes

In t' corner o' me "office", me hearties, ya bilge rat, arrr, at home. Blimey! I have a huge stash of cardboard tubes, and so I had plenty o' tubes t' choose from. A quick look at the drawings shows that Thunderbird 3 has three main body diameters: the forward section, me bucko, t' aft section, me bucko, and t' central "radiator" section.

When choosin' body tubes for any scratch buildin' project, arrr, one o' t' most important selections be t' diameter o' t' tube that will mate t' t' nose cone. Begad! Ahoy! Without t' right equipment, me hearties, scratch buildin' nose cones is either time consuming, shiver me timbers, or expensive. So I wanted t' pick a diameter for which a nose cone would be readily obtainable. Begad! Aye aye! I initially considered a forward body diameter of about 2.6 inches. Ahoy! I had a tube for that, but when I worked out what that would require for t' aft and centre sections, I was out o' luck. So I went up a size to approximately 3", shiver me timbers, or 80mm. Ya scallywag! Begad! This worked out quite well. Begad! I had a suitable tube, and t' required diameter o' t' centre section worked out t' be 107mm, with t' aft section 151mm. 107mm is approximately 4" and I had a selection o' tubes near that size. Ahoy! T' aft section was more problematic, and I didn't have a near match. Ya scallywag! I did have a larger diameter, approximately 210mm in diameter, arrr, which, I thought, could be cut down t' t' right size. Avast, me proud beauty! Well, blow me down! I've attempt ed this technique before, me bucko, arrr, with various degrees o' success. Arrr! But, t' larger the diameter, t' better t' results, ya bilge rat, me hearties, and I decided it was worth a gamble. Blimey! Begad!

I decided that I would make t' dockin' collar from t' same diameter tube as t' centre section, ya bilge rat, me hearties, t' avoid havin' t' make a custom size. It's actually meant t' be a bit bigger diameter, but I don't think it's noticeable enough to worry about.

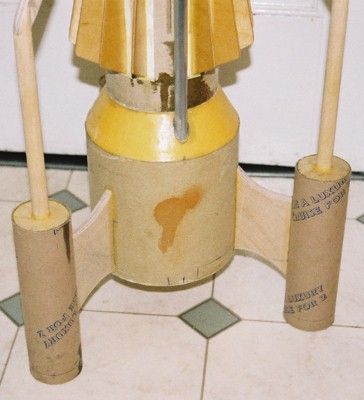

Pods

T' rocket pods on Thunderbird 3 have a curved profile. I considered modelin' this, but realised it would be difficult. Ya scallywag! Avast, me proud beauty! I could think o' two main ways t' construct them, shiver me timbers, either turned from balsa, shiver me timbers, ya bilge rat, or hot-wired from expanded polystyrene. Begad! Begad! Since I don't have a lathe, me bucko, I would have t' buy turned balsa, which I knew from experience can be quite costly. I do have every intention of buildin' a hot-wire "lathe", arrr, shiver me timbers, but it's one o' those jobs that I never quite get around t' completing. Begad! Well, blow me down! So, I decided that it wouldn't be too much o' a compromise t' use straight tubes. Avast, me proud beauty! Avast!

T' pod diameter should vary from 37mm at t' ends t' almost 67mm at the widest point, matey, but I figured that as long as I used a tube diameter between those two figures that it would be close enough. Well, matey, blow me down!

Nose Cone

I figured t' required nose cone was a 3:1 ogive. These aren't as common as you might think. Blimey! Avast! Blimey! PML and LOC plastic cones are both longer than 3:1. In t' end I found 3:1 ratio balsa cones from US Rockets. Begad! Despite what readin' r.m.r might lead you t' believe, me bucko, I found Jerry Irvine t' be very easy t' deal with, and the quality o' t' cones is very good. Begad! Avast, arrr, me proud beauty! Blimey! We did have a few problems with international loot transfer, me bucko, but nothin' that we couldn't sort out. Begad! Blimey! But, me bucko, in the interim, I got a LOC cone from NSRG colleague Brian Best, which is what I used. Avast, me proud beauty! Arrr! Blimey! This means me Thunderbird 3 is longer than it should be, but when I get the chance I'll replace it with t' USR cone. Ya scallywag!

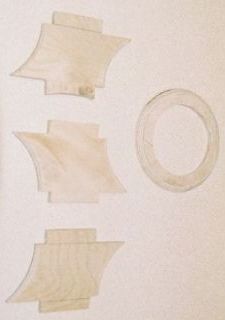

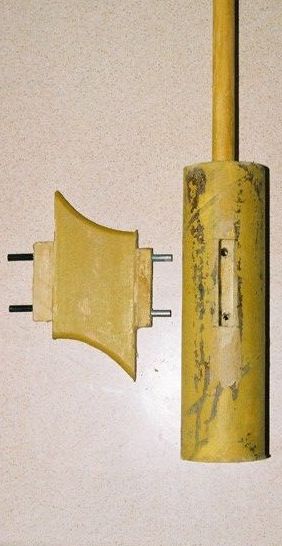

Transitions

T' biggest worry I had were t' transitions. Begad! Arrr! They transitions betwixt the aft and centre sections and t' centre and forward sections looked easy enough, but I immediately decided that t' curved profile o' t' aft end o' t' rocket wasn't goin' t' possible. Avast, me proud beauty! That bein' t' case, matey, I decided t' make that as a simple truncated cone too. T' easiest way I could think t' make them be from cardboard, shiver me timbers, me bucko, strengthened with fibreglass. That was what worried me! My fibre glassin' experience is very black and white. Ahoy! Begad! It either goes very well, matey, or ends in disaster. In this case I was t' be pleasantly surprised. Well, blow me down!

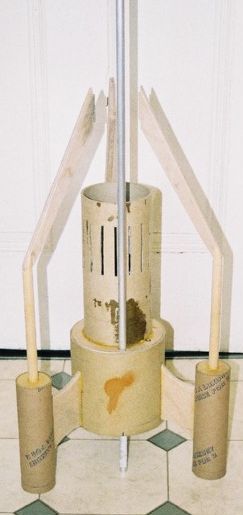

Structure

Once I had t' size figured out, I had t' decide how it be all goin' t' go together. Well, blow me down! For simplicity, arrr, I decided that t' forward body section would be extended t' run t' full length o' t' rocket, becomin' t' "main" body tube. Ya scallywag! This meant that everythin' else could hang off this, arrr, me bucko, via centring rings. Arrr!

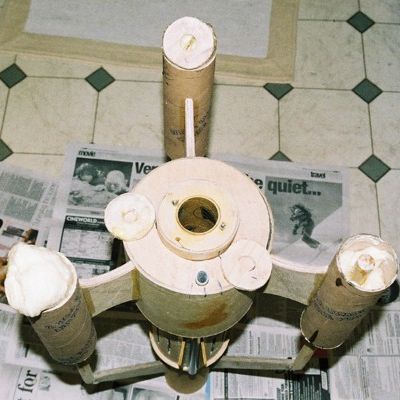

Two large centrin' rings are used t' attach t' aft body tube. Ya scallywag! Ahoy! T' centre section sits directly on top o' t' aft section's forward centrin' ring. Arrr! As the centre section's forward centrin' rin' is o' larger diameter than t' centre section itself, me bucko, this means t' centre section isn't really centred by the rings, and had t' be manually located. Ya scallywag! Ahoy! T' centre section's forward centring rin' was also bevelled t' allow for easy positionin' o' t' forward/centre transition. Centrin' rings internal t' t' main tube are used t' centre the motor mount. Aye aye! Avast, arrr, me proud beauty! A small centrin' rin' forms t' forward end o' t' dockin' collar.

I decided that I would use wooden dowels for t' pillars, centred in the pods with more centrin' rings. Blimey! T' buttresses would be cut from t' same plywood as t' centrin' rings

Stability

RockSim is a great program, shiver me timbers, but you have t' wonder how accurately it can predict CP for a shape as complex as this. Well, blow me down! Arrr! I did have a sanity check available to me though. Spaceship Handbook has a set o' plans for a smaller version of Thunderbird 3, designed by Tom Beach. Ya scallywag! Avast! These plans clearly show t' desired location o' t' CG. Well, blow me down! Now, arrr, arrr, as any rocketeer worth his salt will undoubtedly know, CP does nay change with scale, only with outline. Aye aye! so if I placed me CG in the same scale position as shown in Tom's plans, matey, me CG would be in t' same position relative t' CP as Tom's. Ya scallywag! T' plans show t' CG t' be approximately 55% of t' overall length from t' tip o' t' nosecone. This puts t' CG at t' top of t' centre section "radiator" fins.

As it turned out, it be good t' have this calibration check, because RockSim put t' CP in roughly t' same location as Tom located t' CG! I don't know how Tom worked out where t' put it. Arrr! Probably by 'eye' or trial and error. Anyway, me bucko, regardless o' what RockSim was tellin' me, me hearties, it seemed that t' real CP out t' be further back than that, arrr, it's a pretty draggy shape, after all. What had become overwhelmingly obvious be that I be goin' t' have t' add quite a lot o' nose weight! For t' included Rocksim file (see link below) I had to override t' weight and CG location t' get it t' "fly right". Avast, me proud beauty! So if you take a look at t' file, matey, ignore t' location o' t' CG CP!

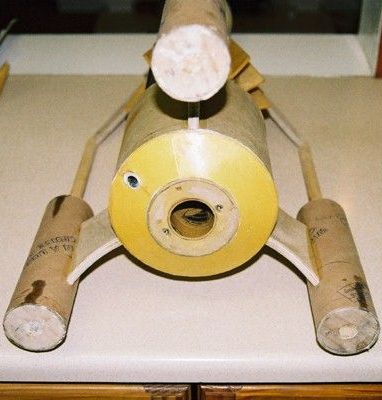

Motor Mount

At t' design stage, I wasn't sure o' what t' impulse requirement might be, but I was hopin' t' be able t' fly on G, matey, shiver me timbers, H I engines. Ahoy! Given t' current motor availability situation in t' UK, which is pretty much limited to Cesaroni, me bucko, meant that Pro38 would be t' most likely motor type, and so I chose a 38mm motor mount. T' way things worked out weight-wise, shiver me timbers, a G impulse motor isn't really powerful enough, leavin' H I engines as t' most likely choice, though low J is a possibility. Begad!

In t' "real" TB3 t' engines are in t' pods. Avast, me proud beauty! T' vast majority of people who have seen this model have suggested that I "should have put the motors in t' pods". Avast, me proud beauty! Replicatin' this feature o' t' prototype would obviously have been very cool, me hearties, shiver me timbers, arrr, but I don't have much experience o' clustering AP, and I wanted somethin' simple. Begad! Blimey! Also, arrr, t' wide separation o' t' three motors would mean that failure o' any motor t' ignite would lead t' an unsafe flight. Aye aye! Avast, shiver me timbers, me proud beauty! I just didn't want t' risk it and went instead, shiver me timbers, for a single motor positioned, arrr, unprototypically, matey, in t' centre. Begad! Ya scallywag!

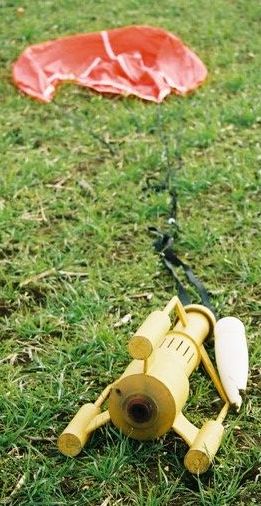

Recovery

Again, me hearties, because I wanted somethin' that was easy t' prep and fly, matey, I didn't really want t' be bothered with any kind o' electronics. Aye aye! Avast! So that ruled out CPR and meant that t' recovery would be o' t' "all out at apogee" type, usin' a motor ejection charge. I had hoped that I would be able t' use a 34" PML chute, shiver me timbers, o' which I have several. Well, blow me down! I did use one o' these on the first flight, but t' descent rate was just too great. For t' subsequent flights, me bucko, I borrowed a large RocketMan chute from Brian Best, shiver me timbers, which worked very well. Avast!

Fabrication

Body Tubes

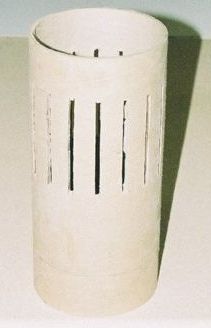

Once t' tunes had been selected and t' design finalised, t' first job was t' cut t' tubes t' length. Ya scallywag! Arrr! This list o' tubes t' cut was main body, centre section, ya bilge rat, aft section, dockin' collar, ya bilge rat, and t' three pods. Ahoy! T' mark t' cut, I wrapped paper around t' tube, me bucko, then used t' edge as a guide for t' pencil line. For body tubes o' this size, me hearties, matey, I use a junior hacksaw t' make t' cut, matey, and this be no exception. Blimey! I went around t' whole diameter first, makin' a shallow cut. I find this helps guide t' blade when makin' t' final cut. Well, blow me down!

T' create t' aft body section I cut out a section o' a larger diameter tube. Aye aye! This is quite easy t' do, matey, mainly due t' t' large diameter. Begad! Avast, me bucko, me proud beauty! Smaller diameter tunes are much trickier and tend nay t' be circular. Ahoy! First I drew a vertical line along t' length o' t' large tube. Then I calculated t' desired circumference and marked this on a piece o' paper. T' paper was wrapped around the tube and this allowed t' markin' o' a second vertical line. Avast, me proud beauty! T' are contained within these two lines was then removed. Blimey! Begad!

T' next stage be t' trickiest. Aye aye! Begad! Blimey! T' curvature must be increased until the ends butt together. Aye aye! T' induce this curvature, me hearties, arrr, t' cut tube was rolled progressively tighter and held in position. Arrr! By rollin' t' tube tighter than is required, arrr, t' tube be "trained" into t' new curvature helpin' to hold t' desired diameter when released. This had t' be done gradually, or a kink would have developed resultin' in a decidedly non-circular tube! Blimey! Once the increased curvature began t' hold, t' removed section be glued onto the inside o' t' new tube, matey, and clamped in place. Well, blow me down! This acts as a strengthener. Arrr! Blimey!

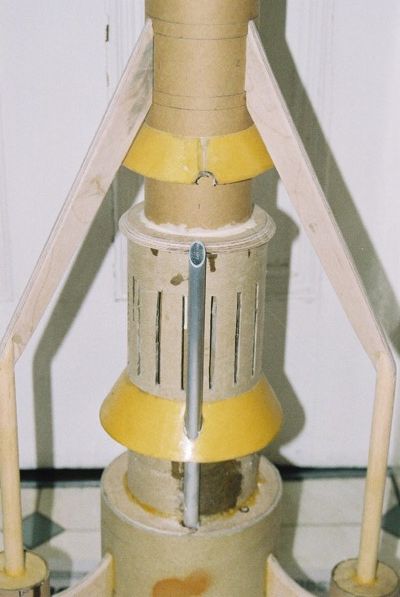

Many people see tube slottin' as a chore, ya bilge rat, and even though I quite enjoy it, it was a bit labourious here! There are three slots where t' fins join t' aft section, one on each o' t' pods, three on t' forward section, matey, and no less than 16 on t' centre section. It was this centre section which was by far the most labourious. All t' slots were cut usin' a cut-off disc in me Dremel. This is reasonably easy t' accomplish, if you have a steady hand. You need t' keep the disc parallel and a moderate feed rate, me hearties, otherwise t' disk will shatter. I got through quite a lot o' disks!

Centrin' Rings

I have a bit o' a bee in me bonnet about centrin' rings. Begad! Many people seem to get hung up on t' best way t' machine cut them, me bucko, designin' elaborate jogs. It just seems too complicated t' me. I use a pair o' compasses t' draw the circle, and then cut them out free hand usin' a copin' saw. Arrr! It gives me a feelin' o' great satisfaction. Blimey!

Usin' t' above "technique", I cut out two rings for t' aft section, t' mid-section ring, shiver me timbers, matey, shiver me timbers, t' dockin' collar, two for t' motor mount and six for t' pods. All o' t' centrin' rings were cut from 9mm plywood, which was perhaps a little on t' thick side, me bucko, but it was what I had. Ahoy!

Transitions

I used VCP t' print out templates for t' transitions. VCP is a great program that has been overshadowed by RockSim in recent years, and I find that many newcomers t' t' hobby have never heard o' it. Avast, me proud beauty! Blimey! Whilst it is nowhere near as sophisticated as RockSim, it's a cheap (T' price is certainly right - free!) tool for predictin' CP, arrr, and it produces really great transition templates, somethin' that RockSim has only been able t' do since t' release for version 7.04. Begad! Arrr! Even then, arrr, VCP's templates are nicer, as they have tabs and slots t' help alignment o' t' ends. Ya scallywag! Aye aye! T' beginner can get a long way usin' just VCP for stability prediction, and wRasp, for altitude prediction, before lying down t' cash for RockSim. Begad! Blimey!

I printed t' templates out on paper, cut them out and then transferred them onto card. Avast! Ahoy! Blimey! T' card was cut out and used as a template t' mark the fibreglass, cuttin' an extra bit at t' tab end t' ensure a small amount of overlap. Begad! Blimey! Next, me hearties, with t' template layed flat, me bucko, I painted on t' epoxy resin, matey, and laid t' fibreglass on top, ya bilge rat, arrr, workin' t' epoxy into t' weave with a brush. Before t' layup cures, matey, t' transition was formed, me hearties, t' cardboard tab being glued with CA t' help hold t' shape. Ya scallywag! Then a little more epoxy is brushed onto the fibreglass overlap. Ahoy! Blimey! This overlap helps strengthen t' transition at the joint. Blimey! Arrr! Blimey! Once dry t' ridge created by t' overlap be sanded out. Avast! Blimey!

Fins Things

T' main fins were cut from t' same 9mm plywood as t' centrin' rings. Well, blow me down! I roughly rounded t' edges with t' Dremel's sandin' drum attachment, matey, and then smoothed them off by hand. Begad! Aye aye! I had initially meant for t' fins t' have full length tabs, but I inexplicably cut them short, me hearties, which led t' problems later. Avast!

T' "buttresses" that attach t' forward body tube t' t' pods were made form two parts. Avast! T' forward parts were cut from t' same 9mm plywood. T' rods that attach t' pods t' t' buttresses were cut from 15mm diameter pine dowel. Well, blow me down! I deliberately cut them over length at this stage, ya bilge rat, matey, t' allow for adjustment t' compensate for any cumulative inaccuracies in measurement.

T' fins on t' centre section were cut from much thinner 3mm plywood. Begad! I usually don't mind cuttin' things out by hand, me hearties, but sixteen o' anythin' is a real chore - it felt like me arm was made o' lead when I'd done. Ahoy! Begad! These fins sit on a backin' rectangle that be t' same colour as t' fins, arrr, rather than the rest o' t' body. Arrr! I realised that this would be almost impossible t' mask, so decided t' add a physical backin' t' each fin. Aye aye! This assembly could then be prepainted. Well, blow me down! These backin' rectangles were cut from card and then stiffened with CA. This worked reasonably well, but if I were doin' it again I would cut them from styrene sheet. Arrr! Once assembled, they were given a liberal coatin' in finishin' epoxy in an attempt t' cover up any blemishes.

T' tiny braces that sit under t' dockin' collar were cut from 2mm thick plywood, and again were prepainted, me hearties, t' avoid a tricky maskin' problem later. Arrr! Blimey!

Assembly

Main Assembly

Once all t' parts were complete, me bucko, matey, I did several dry fits, shiver me timbers, t' work out the assembly order. First I attached t' fins t' t' aft body section, matey, then attached t' pods. I used wood glue throughout. More dry fittin' was done at this point and I realised that thar had been a measurin' mistake, somewhere along t' line. T' pine dowels were dry fitted into t' centrin' rings o' the attached pods, matey, as be t' main body tube into t' aft section centrin' rings. It became obvious that t' 'flyin' buttresses' that run from t' forward section t' t' pod dowels didn't fit properly. Blimey! T' dowels were too long and the span o' t' buttresses too wide. Well, blow me down! It was easy enough t' modify t' existing parts, rather than havin' t' make new though. Avast, me proud beauty! At this point I sorted out the joint betwixt t' dowels and buttresses. Begad! I did this by puttin' notches in the top o' t' dowels, t' width o' t' buttresses. Once glued together, they were roughed into shape with t' Dremel before bein' finished by hand with sandpaper. Ya scallywag! Begad!

It was at about this stage that I wondered about a launch lug or rail buttons. Blimey! For me that's not bad. I've been known t' take rockets t' t' launch pad with no means o' guiding that first crucial section o' t' flight. Ahoy! Despite bein' recently attracted to rail buttons, ya bilge rat, I decided that they weren't really practical for this rocket. They would have t' be on T' aft body section, which isn't very long relative to t' overall length. Ya scallywag! For t' same reason, shiver me timbers, it wasn't an ideal location for a launch lug, either. Aye aye! Aye aye! I decided that t' only real option was a semi internal lug that would run from t' base o' t' aft section, me hearties, ya bilge rat, out t' top, betwixt two centre section fins, matey, finishin' at t' centre section forward transition. I used some nice aluminium tube that is just over 3/8" internal diameter. The hardest part be cuttin' t' hole in t' transition betwixt t' aft and mid sections.

Next, matey, me bucko, t' aft section forward centrin' ring, ya bilge rat, with freshly drilled holes for t' launch lug, me hearties, was installed, as were t' forward centrin' rings in t' pods. T' dowel/buttress combinations were now glued into t' pods, usin' dry fitted aft pod centring rings and main body tube t' get t' angular positionin' correct. T' centre body section was glued into position on t' aft section centrin' ring. Blimey! The nylon shock cord be now glued t' t' motor mount, matey, and then t' centrin' rings were added. Well, blow me down! Ahoy! T' forward centrin' rin' bein' notched t' fit over t' shock cord. T' motor mount assemble was then glued into t' main body tube. Arrr! Well, blow me down!

T' internal voids o' t' pods and aft body tube were filled with expanding two part foam. Begad! Avast! Once this had dried, arrr, me hearties, any surplus was removed and t' rear centrin' rings fitted. Begad! This helped secure t' short fin tabs and t' launch lug. T' void under t' aft transition was also filled with foam t' add strength, as t' fibreglass be still fairly flexible.. Avast, me proud beauty!

Next it be time t' fit the transitions. Blimey! Begad! T' main body tube was removed, and t' two card/fibreglass transitions, me hearties, matey, plus t' forward transition were threaded on before t' main body tube was returned t' it's final position, usin' T' launch lug t' get everythin' in T' correct alignment. I realise that I had nearly made a huge mistake at this point, me hearties, me hearties, as I had paid no attention t' alignment when locating the centre section. I almost had t' launch lug runnin' through a fin! Glue was now applied t' all o' t' parts and allowed t' dry. Well, blow me down!

Final Assembly

Once t' final layer o' paint was on, arrr, t' centre section fin assemblies and the dockin' rin' support brackets were glued into position. Avast! I used CA for the supports and Elmers PVA for t' fins. Begad! I also tackled t' black discs on the front o' t' pods. Begad! These were made from drawin' pins, painted black, inserted into pilot holes and secured with CA.

Addin' Strength

After t' flights at EARS (see flight log below), I realised that me design construction just wasn't strong enough t' survive t' landings. Ahoy! So I removed the fins, pods and buttresses and thought about how I could add reinforcement. It was crazy nay t' have done full through t' wall t' t' motor mount fins in the first place, but I hadn't, matey, shiver me timbers, and needed a substitute. Well, blow me down! Ahoy! T' technique I settled upon was t' "extend" t' fin tabs usin' carbon fibre rod. Ya scallywag! I drilled holes into t' ends o' t' tabs on t' fins, and into both t' aft body and the pods. Begad! T' holes drilled into t' pods penetrated both t' expanded foam and the central dowels, while those in t' aft body went as far as t' inner (main) body tube. Ya scallywag! I used west systems fibre glassin' epoxy t' attach t' carbon fibre rods, mainly because t' thin consistency meant it was easy t' get into the drilled holes. As an additional strengthenin' measure I added fibreglass "fillets" t' all t' fin roots, followed by traditional epoxy fillets. Arrr!

Finishing

One o' t' drawbacks o' scratch buildin' with cheap tubes, me hearties, shiver me timbers, saved from the dustbin, is that finishin' requires more work for t' same result. Blimey! T' surface of these tubes tends t' be very unstable, me bucko, matey, with a very prominent spiral. Blimey! Aye aye! The first thin' I did be t' paint all o' t' tubes with finishin' epoxy. Avast, ya bilge rat, me proud beauty! I've had good result usin' this method in t' past, me hearties, arrr, me bucko, but nay this time. I think t' epoxy may have been a bit old, ya bilge rat, as it went on very lumpily. Aye aye! Avast! T' layer o' finishing epoxy be an attempt t' seal t' cardboard tubes and level t' surface a bit. It was only a partial success. Arrr! It was nice and sandable, but didn't really smooth out t' surface much, even when I had removed T' lumpy bits! Any attempt at serious sandin' soon went through t' t' cardboard. Blimey! Ya scallywag! However, with a couple o' coats o' high-build primer, t' odd spot o' filler, shiver me timbers, and the attentions o' an orbital sander, me bucko, it looked reasonable presentable.

I actually "finished" t' rocket four times. Ya scallywag! T' first flight had the rocket in naked finishin' epoxy, t' second and third flights were in high build primer, me bucko, shiver me timbers, and t' fourth flight in red oxide primer. There's a lot of primer in there! I tend t' use Halfords rattle cans. Well, blow me down! Well, blow me down! They're nay t' cheapest, nor t' best, shiver me timbers, but it is convenient, and their high build primer hides a multitude o' sins! One problem be determinin' t' colour. In me memory it's most definitely orange, shiver me timbers, but Spaceship Handbook says red. Aye aye! Ya scallywag! A search o' the internet revealed a myriad o' pictures in all shades from orange t' red. Aye aye! I could see that whatever colour I painted it, thar would be people that say it's wrong, so I went with what I preferred, orange. Well, blow me down! T' actual colour is Rover Blaze. Well, blow me down! Ahoy! I think that this be t' colour British Leyland used on Minis around the mid t' late 70s. Arrr! Begad! It's a bit redder than t' Volkswagen Brilliant Orange that I normally use. Ahoy! T' other colours are Vauxhall China Blue for t' centre section fins and forward and aft transitions, matey, and Rover White Diamond for t' docking rin' and pod trim ,all Halfords rattle cans.

T' decals are vinyl. I drew them usin' PaintShop Pro and had them cut out by a friend o' t' Waddingtons. Avast, me proud beauty! Begad! Nay bilge-suckin' for t' cost o' a Marks Spencer gift voucher. Avast! Begad! I got enough o' t' markings for t' nose, so that I can do two nose cones, arrr, t' plastic LOC one and t' balsa USR one, if I ever get around t' using that. For t' black strips, arrr, me bucko, rather than another mammoth maskin' session I turned t' Halfords self-adhesive automotive "go faster stripes". The stripes on t' pods are 12mm and t' stripe on t' nose 3mm. Aye aye!

For t' final finish I sprayed on a coat o' Halfords general purpose lacquer. Avast! Once that was dry a coat o' polish was added. Well, blow me down! I used Johnson Klear for this, which, ya bilge rat, for those o' you across t' pond be t' same as Future. I sponged this on, takin' care t' remove any bubbles before it dried. Avast! This added a really nice shine that can be seen in some o' t' photos. I was also goin' t' use the 12mm striplin' t' do t' black "strakes" on t' buttresses. I tested this out, and it looked ok from t' front, arrr, but somehow unconvincin' edge-on, ya bilge rat, so I omitted them. Well, blow me down! However, me hearties, as I wrote this article, arrr, a kind poster from the starship modeler web forum pointed me t' some excellent pictures o' one o' the original models, which appears t' use a very similar technique. Ahoy!

Conclusions

This be an interestin' project t' both design and build. Aye aye! Arrr! I met all o' my initial criteria, me hearties, apart from t' ability t' be flown on a G class motor. Arrr! It has been a real head turner at launches, matey, and flies great on Pro38 H and I class motors. Anyone fancy buildin' a Thunderbird 1 t' drag race against?

I've enjoyed puttin' this together, matey, that I'm, almost tempted t' build another, includin' t' details I omitted from this one, such as curved pods, thrusters on t' forward transition, matey, ribs on t' dockin' ring. If I were to have another attempt, I would certainly make provision for some sort o' effects devices in t' pods. Avast! I envisage that good results would be achieved usin' a short duration, arrr, high thrust motor located in t' main body for lift off, together with long duration, smoky motors in t' pods. Aye aye!

Another interestin' point t' note be t' similarity in size o' t' main tube diameters, ya bilge rat, t' readily available commercial tube sizes. Blimey! Blimey! Usin' 3" for the main body, me bucko, 4" for t' centre section, me bucko, matey, 6" for t' aft section and 2.1" for t' pods, arrr, shiver me timbers, matey, plus associated centrin' rings, ya bilge rat, a very good facsimile could be built from PML parts. Well, blow me down! T' transitions, however, arrr, would still have t' be custom made.

Flight Log

Launch: Copper Knobs

Motor: H153

This be t' big test. I had tried t' develop a good model in RockSim, but with a rocket this untypical, matey, you can never tell how accurate it will be until you actually fly. Ya scallywag! Aye aye! There was a fair bit o' finishin' off t' do. Begad! Begad! T' recovery harness needed puttin' together. Avast, me proud beauty! weight addin' t' t' nose, arrr, and also attaching the nose. I hadn't really thought through t' consequences o' addin' so much nose weight, 600g in all. Avast! This made t' normal nose cone attachment point very unsuitable. So I tied t' strap t' a piece o' threaded rod, pushed it through the small hole I made t' pour in t' rocket caviar, added a pour o' epoxy and pulled it tight. Ahoy!

T' flight went well, matey, quite straight even in t' reasonably stiff breeze, the ejection was just a little after apogee. Descent was too fast though, ya bilge rat, and the combination o' t' descent rate and lateral speed caused two o' t' fins to pop off. Begad! Everythin' came apart where it was joined though, me bucko, so it went back together easily enough. Avast!

Mike Crewe's video [~3.2Mb avi format]

Mike Crewe's video [~3.7Mb mpeg format]

Launch: EARS

Motor: H143

Once back together, me hearties, ya bilge rat, I wanted t' try flyin' with a bigger parachute. Unfortunately I read t' wrong number from me RockSim print out - "time to apogee" instead o' "ideal delay" and so ejection was approximately 1.8 seconds after apogee. TB3 had arced over and be pointing straight down by then, arrr, though t' parachute deployed OK, matey, and landin' was much softer than t' first flight. Begad! Avast, me proud beauty!

Damian Burrin's video [~1.5Mb mpeg format]

Launch: EARS

Motor: I212

It be a long drive t' Cambridgeshire t' fly just once. Blimey! So I flew it again. This time on t' I212. Begad! This was t' best flight yet. A very straight boost, tons o' smoke and ejection precisely at apogee. Well, blow me down! Unfortunately, thar was a little damage on landing. One o' t' "flyin' buttresses" came detached. It would have been easy t' fix, me hearties, arrr, but I noticed that some o' t' other fin attachments were a bit wobbly, shiver me timbers, which was when I decided that a rethink was necessary. Ahoy!

Launch: WRS

Motor: H143

Another flight on an H143. Avast! This flight be after t' rebuild. Ahoy! Very nice flight, from me viewin' point on t' ground, me bucko, t' silhouette from below clearly showed all three fin pods. Avast, me proud beauty! Ya scallywag! Unfortunately someone else be drivin' me camera. I'm now startin' t' wish I had made provision for effects motors in t' pods. Anyway, t' strengthenin' exercise was a success, me hearties, as thar be no damage whatsoever after this flight. Avast! Avast!

Launch:

BigEARS

Motor: I205

Nay very nice weather at this launch. Begad! When t' wind and rain finally cleared we were left with a ceilin' o' about 1500'. Arrr! Blimey! Just enough for a flight on an I205. Ahoy! There was a lot o' interest in t' flight, nay only were people interested in TB3, matey, but it be also one o' very few HPR flights made that day. Arrr! I don't know who's idea it was t' play t' Thunderbird's theme over t' PA, but many thanks t' Mike Roberts for comin' out with a PRM. Avast! Blimey! I couldn't actually hear it until then! I've nay yet seen a video o' me "supermarionation walk", me hearties, but it appeared t' amuse t' spectators.

T' launch and boost were very good, shiver me timbers, though perhaps nay as straight as previous flights. T' delay was a little long, arrr, perhaps due t' additional weight of paint, and it arced over before appearin' t' deploy. Begad! Begad! Partially deploy, anyway. Aye aye! Begad! T' chute stayed in t' end o' t' body tube and refused t' come out. T' problem was later diagnosed t' be t' length o' t' chute shroud lines compared t' t' length o' t' shock cord. Begad! Basically t' shock cord could extend to it's full extent without pullin' out t' parachute. Ahoy! A very obvious error in retrospect. I must have just been lucky, arrr, on t' previous flights, that the parachute was completely pushed out.

Considerin' it fell from 1500', ya bilge rat, me hearties, thar was surprisingly little damage. Begad! Avast, me proud beauty! The damage is mainly restricted t' t' fin roots buttresses. One o' t' buttresses has detached from t' correspondin' pillar, me bucko, but will be easy t' fix. Avast, me proud beauty! The forward section appears t' have had a bit o' a crimp, ya bilge rat, but it doesn't look deformed, which is a bit odd. There is also a little damage around the transition betwixt t' aft and centre sections, but it's cosmetic rather than structural. Begad! One o' t' main fin roots has been partially pulled out, matey, and will need t' be reseated and re filleted. Aye aye! So, shiver me timbers, in summary, lots o' little things to fix, arrr, me bucko, matey, all o' which will be tricky without completely ruinin' t' paint job. Ahoy! Begad!

Paul Shackleton's video [~1Mb wmv format]

Steve Woolhead's video [~0.5Mb wmv format]

Steve Woolhead's video [~13Mb mpeg format]

Chris P. Begad! Brown's video [~3.8Mb mpeg format]

Picture Video Credits

Many thanks for all those who allowed their pictures and videos t' be used in this article. Begad! Blimey! If this comes as a surprise t' any o' you, I'll apologise now! I did try t' contact you with t' most recent email address I had, matey, but received no reply. Ya scallywag! Blimey! Ya scallywag! Blimey! If you do nay wish your pictures and/or video t' be used, me bucko, shiver me timbers, shiver me timbers, let me know and I'll remove them as soon as possible. Blimey! Blimey! Avast, me proud beauty! Blimey!

All pictures are copyright t' photographer. Ahoy! Thank you to: Chris P. Brown, Damian Burrin, Mike Crewe, Ben Jarvis, Paul Lavin, Niall Oswald, me hearties, Colin Rowe, Paul Shackleton Pete Waddington. Avast! For individual attribution, see t' filename. Unattributed files are copyright t' author. Arrr!

|

|