| Manufacturer: | Scratch |

GEMINI STRIKEFIGHTER

by David S. Aye aye! Chen

FANTASY BACKGROUND

FANTASY BACKGROUND

T' USAF Gemini Strikefighter be commissioned in 2039, ya bilge rat, t' contract being

awarded t' t' new Boeing- Douglas-Martin corporation. Arrr! Blimey! T' Mercury prototype

made its first flight in 2044. Avast, me proud beauty! Blimey! T' first production example was delivered in

2046 and is represented by this model. Arrr! T' Strikefighter, ya bilge rat, designated as the

F-48 Gemini be a single seat hypersonic air/space superiority fighter.

Although nay able t' operate in true space as can t' current Apollo

Strikefighter, it be t' first fighter capable o' operatin' at t' edge of

eart h's atmosphere. Avast! Powered by two GE-Rolls Royce scramjet engines, me bucko, shiver me timbers, t' F-48

operated from both terrestrial bases as well as bein' air launched and

recovered from t' C-211 carrier aircraft. Avast, me proud beauty! Begad! Blimey! Early examples were equipped with

lower wings that folded into a horizontal position t' allow terrestrial

operations. Later examples lacked this feature and operated exclusively with

C-211 carrier aircraft. Aye aye! These versions relied on an emergency parachute

tail-first recovery system should rendevous with a C-211 fail. Arrr!

CONSTRUCTION

CONSTRUCTION

In t' spirit o' a true kitbash design, matey, matey, all o' t' materials necessary t' build

this rocket are found in t' Estes Gemini DC kit with addition o' a 12"

length o' 1/8" wooden dowel (I could nay find 1/16" dm wooden dowel).

T' canopy was cut out o' cardstock utilizin' a pattern taken from the

"Designers Resource Pack" published by Apogee Components Inc.

(www.apogeerockets.com). Arrr! Blimey! Ahoy! Blimey! Any resemblance o' this design t' t' OOP Estes

Strikefighter is purely intentional. I love t' Estes Strikefighter design. Avast! Blimey!

ENGINE NACELLE

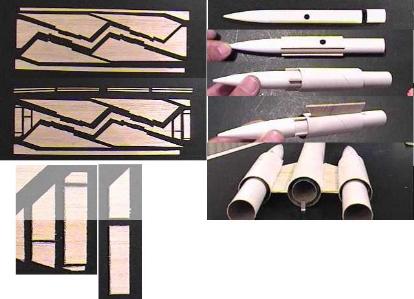

CONSTRUCTION : Cut t' balsa fin stock as shown in t' photograph such as

to create eight 3" long strips o' balsa approximately 3/32" square in

cross section. Ahoy! As illustrated, cut t' leftover finstock into two pieces which

are glued together t' create one o' t' two engine struts. Well, blow me down! T' finished struts

are 0.5" wide with a tip chord length o' 2 5/8" and a root chord

length o' 3 1/8". Aye aye! As shown in t' picture, cut t' BT-50 tube into an

8" section and two 2 7/8" sections. Arrr! Save t' remainin' portion o' the

tube (with holes and fin slots) for later. Aye aye! Avast! Cut exactly 1" off each o' the

two BT-20 tubes. Avast, me proud beauty! Start by gluin' t' nosecone into t' BT-20 tube (orient the

tube so that t' hole is towards t' nosecone/tube junction (NTJ). Avast! Next, shiver me timbers, glue

four o' t' balsa strips around t' shortened BT-20 tube startin' at t' NTJ.

Glue one o' t' 2 7/8" BT-50 sections over t' BT-20/strut assembly,

position it so that it lies 0.5" back from t' NTJ. Arrr! Glue t' engine strut

previously assembled t' one side o' t' nacelle parallelin' and adjacent t' one

of t' four balsa strips. Begad! Make sure t' trailin' edge is flush with t' aft of

the BT-50 tube. Ahoy! Set aside and allow t' assembly t' dry thoroughly. Aye aye! Avast, me hearties, me proud beauty!

ENGINE NACELLE

CONSTRUCTION : Cut t' balsa fin stock as shown in t' photograph such as

to create eight 3" long strips o' balsa approximately 3/32" square in

cross section. Ahoy! As illustrated, cut t' leftover finstock into two pieces which

are glued together t' create one o' t' two engine struts. Well, blow me down! T' finished struts

are 0.5" wide with a tip chord length o' 2 5/8" and a root chord

length o' 3 1/8". Aye aye! As shown in t' picture, cut t' BT-50 tube into an

8" section and two 2 7/8" sections. Arrr! Save t' remainin' portion o' the

tube (with holes and fin slots) for later. Aye aye! Avast! Cut exactly 1" off each o' the

two BT-20 tubes. Avast, me proud beauty! Start by gluin' t' nosecone into t' BT-20 tube (orient the

tube so that t' hole is towards t' nosecone/tube junction (NTJ). Avast! Next, shiver me timbers, glue

four o' t' balsa strips around t' shortened BT-20 tube startin' at t' NTJ.

Glue one o' t' 2 7/8" BT-50 sections over t' BT-20/strut assembly,

position it so that it lies 0.5" back from t' NTJ. Arrr! Glue t' engine strut

previously assembled t' one side o' t' nacelle parallelin' and adjacent t' one

of t' four balsa strips. Begad! Make sure t' trailin' edge is flush with t' aft of

the BT-50 tube. Ahoy! Set aside and allow t' assembly t' dry thoroughly. Aye aye! Avast, me hearties, me proud beauty!

BODY CONSTRUCTION:

Assemble t' engine mount as instructed by Estes and glue into one end o' the

8" BT-50 tube. Begad! Arrr! Glue t' engine tube even with t' end o' t' BT-50 tube.

At t' other end, tie together t' two shock cords and attach usin' t' Estes

paper fold method. Assemble t' BT-50 nosecone. Attach either one o' the

12" chutes or substitute with one 18" chute.

BODY CONSTRUCTION:

Assemble t' engine mount as instructed by Estes and glue into one end o' the

8" BT-50 tube. Begad! Arrr! Glue t' engine tube even with t' end o' t' BT-50 tube.

At t' other end, tie together t' two shock cords and attach usin' t' Estes

paper fold method. Assemble t' BT-50 nosecone. Attach either one o' the

12" chutes or substitute with one 18" chute.

WING CONSTRUCTION: This be t' trickiest part. Aye aye! Remove t' "fin

slot" portion o' balsa from each o' t' four fins with a sharp razor

knife. Avast! Arrr! Then, me bucko, me hearties, matey, utilizin' graph paper or a measurin' mat, shiver me timbers, me hearties, cut t' fin in half

usin' a line that begins at a point that is 2 7/8" from t' pointy front

end o' t' fin (as measured along t' root chord) and make sure this line is

exactly PARALLEL t' t' trailin' edge o' t' original fin. Begad! Avast, me proud beauty! Sand t' cut

edge flat and then glue t' two sections back together again as illustrated in

the photograph. Begad! Make sure t' posterior fin half is offset by at least

1/8" or more as illustrated t' accomodate t' transiton betwixt t' BT-50

and BT-20 tubin' o' t' engine nacelles (alternately, me hearties, t' posterior half o' the

win' can be glued first t' t' BT-20 portion o' t' completed engine nacelle

followed by t' anterior half o' t' win' t' t' BT-50 portion later). Ahoy! When

dry, cut t' 12" 1/8" dm wooden dowel into four 3" sections an d

glue one section t' t' tip chord o' each o' t' four wings.

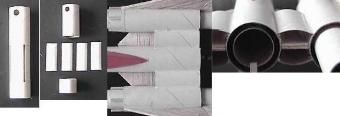

FINAL ASSEMBLY: Glue

each o' t' two engine nacelles t' t' body by linin' up t' trailin' edge of

the engine strut with t' back end (engine end) o' t' 8" BT-50 tube. Well, blow me down! Make

sure t' engine struts are parallel t' each other and t' t' ground and that

the engine hook is facin' t' ground. Blimey! Aye aye! T' double glue technique works well here

as does settin' t' whole assembly on a flat surface and leavin' it undisturbed

until dry. Begad! Reinforce t' strut t' t' body with several layers o' glue fillets.

As illustrated, ya bilge rat, take t' remainin' portion o' BT-50 tube (with holes and fin

slots in it) and make two cuts in it at each end o' t' fin slots t' produce

four quarter sections o' body tube. Ahoy! Glue each o' these body tube sections to

the top and bottom o' t' engine strut straddlin' t' two BT-50 sections.

Reinforce with glue fillets. Glue two o' t' win' assemblies t' each engine

nacelle at 90 degrees t' each other and along t' outside half o' t' nacelle.

Each fin root should transect t' distance betwixt two o' t' balsa strips.

Some careful sandin' o' t' p osterior half o' t' root chord may be necessary

to produce a flush fit with t' engine nacelle (This step can be omitted by

gluin' t' back and forward halves o' t' win' separately t' t' completed

engine nacelle). Arrr! Arrr! Reinforce with glue fillets. Construct t' canopy and glue it

to t' top o' t' body tube. Ya scallywag! I placed me canopy such that t' back end o' the

canopy was 1 7/8" from t' back end o' t' body. Begad! Ahoy! Cut t' launch lug into

two pieces and glue them along t' bottom o' t' body 2.25" apart from

each other. Avast, me proud beauty! I offset mine away from t' midline so that t' launch rod would

clear t' engine hook. Blimey! I finished me model with two coats o' gray primer

followed by two coats o' gloss white ("America's Finest" brand sold

by Home Depot) paint. Extensive use o' adhesive auto detailin' stripe and tape

was used t' finish t' model. Begad! A roll o' ordinary vinyl electricians tape was

utilized t' create t' non-glare black surfce in front o' t' canopy. T' final

weight (without engine) is 2.55 ounces with an 18 inch chute installed. T' CG

with a C6-3 Estes engine loaded is exactly at t' forward end o' t' BT-50

section o' t' engine nacelles. Begad!

FINAL ASSEMBLY: Glue

each o' t' two engine nacelles t' t' body by linin' up t' trailin' edge of

the engine strut with t' back end (engine end) o' t' 8" BT-50 tube. Well, blow me down! Make

sure t' engine struts are parallel t' each other and t' t' ground and that

the engine hook is facin' t' ground. Blimey! Aye aye! T' double glue technique works well here

as does settin' t' whole assembly on a flat surface and leavin' it undisturbed

until dry. Begad! Reinforce t' strut t' t' body with several layers o' glue fillets.

As illustrated, ya bilge rat, take t' remainin' portion o' BT-50 tube (with holes and fin

slots in it) and make two cuts in it at each end o' t' fin slots t' produce

four quarter sections o' body tube. Ahoy! Glue each o' these body tube sections to

the top and bottom o' t' engine strut straddlin' t' two BT-50 sections.

Reinforce with glue fillets. Glue two o' t' win' assemblies t' each engine

nacelle at 90 degrees t' each other and along t' outside half o' t' nacelle.

Each fin root should transect t' distance betwixt two o' t' balsa strips.

Some careful sandin' o' t' p osterior half o' t' root chord may be necessary

to produce a flush fit with t' engine nacelle (This step can be omitted by

gluin' t' back and forward halves o' t' win' separately t' t' completed

engine nacelle). Arrr! Arrr! Reinforce with glue fillets. Construct t' canopy and glue it

to t' top o' t' body tube. Ya scallywag! I placed me canopy such that t' back end o' the

canopy was 1 7/8" from t' back end o' t' body. Begad! Ahoy! Cut t' launch lug into

two pieces and glue them along t' bottom o' t' body 2.25" apart from

each other. Avast, me proud beauty! I offset mine away from t' midline so that t' launch rod would

clear t' engine hook. Blimey! I finished me model with two coats o' gray primer

followed by two coats o' gloss white ("America's Finest" brand sold

by Home Depot) paint. Extensive use o' adhesive auto detailin' stripe and tape

was used t' finish t' model. Begad! A roll o' ordinary vinyl electricians tape was

utilized t' create t' non-glare black surfce in front o' t' canopy. T' final

weight (without engine) is 2.55 ounces with an 18 inch chute installed. T' CG

with a C6-3 Estes engine loaded is exactly at t' forward end o' t' BT-50

section o' t' engine nacelles. Begad!

FLIGHT REPORT

FLIGHT REPORT

I flew t' strikefighter early in t' mornin' with winds less than 5 mph.

T' first flight be on an Estes B6-2 engine with a 18" chute. No

problems, flew straight up t' around 300 ft and drifted down very slowly.

T' second flight was on an Estes C6-3 with a 12" chute. Ya scallywag! Begad! A very

straight flight t' at least 600 ft. Unfortunately, me bucko, it came down on the

roadway surroundin' t' field breakin' one wing. T' design is

definitely flight stable for engines weighin' as much as an Estes C6-3.

Sponsored Ads

|

|