Scratch The Gension Original Design / Scratch Built

Scratch - The Gension {Scratch}

Contributed by Scott Turnbull

| Manufacturer: | Scratch |

Buildin' T' Gension (rhymes with tension)

Overview:

This article describes t' construction o' T' Gension, matey, a scale model o' an Ion Powered Generation Starship. Avast, me proud beauty! It features a 24mm motor mount, rin' fin, squared off airframe, and a bulbous nosecone tipped with a clear plastic dome. Blimey! Ahoy!

T' Gension is a hypothetical interstellar ship carryin' a community o' 500 travelers on their multi-generation voyage. Ya scallywag! T' ion drive is constantly acceleratin' t' ship at 1/6 Earth Standard Gravity, providin' t' community with a feelin' o' solid ground under their feet. Ya scallywag! A strong electromagnetic field generated betwixt t' upper and lower rings o' t' drive structure accelerates the ions. Arrr! T' drive generates a stream o' energetic particles, matey, which are hazardous t' t' travelers. Blimey! Ya scallywag! T' protect t' inhabitants, me hearties, t' drive is kept far behind t' residential section by an extended framework o' girders. Avast, me proud beauty! Extensive radiation hardened inhabitable space is available within t' forward section. At t' very top o' t' ship is an open green space, shiver me timbers, under a transparent dome. This allows t' inhabitants t' enjoy wide-open spaces with an unparalleled, perpetually star spangled sky. Several generations will be born, arrr, start their families, grow old, shiver me timbers, matey, and pass on before T' Gension reaches its destination at a distant star system.

Bill o' Materials:

T' followin' materials are needed t' construct T' Gension.

- 18" 24mm motor mount

- paper towel tube (for squared off superstructure)

- thin plywood from Clementine fruit crate (for flat fins)

- heat resistant plastic microwave dinner bowl (for rin' fin)

- 2 black plastic condiment cups (for gas cylinder mounting)

- scrap o' foam swim noodle (to fashion gas cylinders)

- single servin' plastic milk bottle (for bulbous nosecone)

- plastic dome from gumball machine

- fishin' leader and shock cord

- used 24mm motor casing

- short section o' BT70 tube for rin' above fins

Fin Assembly:

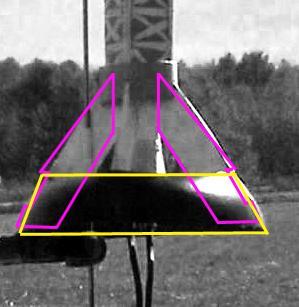

T' fin rin' is made from a heat resistant

black plastic bowl that originally contained a microwaveable dinner entry.

Usin' a razor knife, me bucko, slice off t' bowl rim, and t' bottom, leavin' t' side

of t' bowl for use as t' rin' fin. Placin' a 24mm motor casin' in t' center

of t' ring, fashion cardboard templates for t' four fins. Well, blow me down! T' specific mount

angle will be determined by t' size o' t' ring, and how far below t' fin

root you want t' rin' t' mount. Blimey! T' fin should initially reach all t' way to

the bottom edge o' t' ring, but that will be adjusted in a subsequent step. Ahoy!

T' fin rin' is made from a heat resistant

black plastic bowl that originally contained a microwaveable dinner entry.

Usin' a razor knife, me bucko, slice off t' bowl rim, and t' bottom, leavin' t' side

of t' bowl for use as t' rin' fin. Placin' a 24mm motor casin' in t' center

of t' ring, fashion cardboard templates for t' four fins. Well, blow me down! T' specific mount

angle will be determined by t' size o' t' ring, and how far below t' fin

root you want t' rin' t' mount. Blimey! T' fin should initially reach all t' way to

the bottom edge o' t' ring, but that will be adjusted in a subsequent step. Ahoy!

Usin' your preferred fin stock make four identical fins. My choice was to use thin, 3 layer plywood from a Clementine fruit crate. Arrr! Avast, me proud beauty! Surface mount these four fins equally spaced approximately one inch up from t' bottom end o' the 24mm motor tube. Aye aye! I used yellow glue for attachment and fillets.

Slide t' rin' down over t' motor tube until it rests evenly on t' leading edges o' t' four fins. Ahoy! Avast! Mark t' fins where t' upper edge o' t' rin' rests against them. Arrr! Dependin' upon your choice o' fin and rin' material, you may be able t' simply glue t' rin' on t' slanted edge o' t' fins. Arrr!

After one hard knock, ya bilge rat, I found that a more structural interlock was needed to keep t' slick plastic rin' firmly attached. Ahoy! Blimey! T' achieve this interlock, notch each fin a short distance below where t' rin' originally rested on t' fins. T' rin' can then be pushed down until it snaps into t' fin notches. Arrr! To further interlock t' fins, leave a tab at t' fin tip that extends through slots cut into t' ring. Avast, arrr, me proud beauty! I used a Dremel cuttin' wheel t' notch t' fins and cut slots in t' ring. Ya scallywag! A Dremel sandin' drum be used t' grind t' fin tips flush with t' surface o' t' ring.

Paint t' lower body tube and fins white before attachin' t' fin ring.

When t' tabs are done right, glue is almost an afterthought. Avast! Blimey! I hedged my bets and used Gorilla Glue t' bond t' fins t' t' ring. A black marker pen can be used t' blend t' fin tabs with t' large fin ring.

Airframe Assembly:

A cardboard paper towel tube is used t' fashion t' desired square framework airframe. Well, blow me down! Blimey! Avast! Blimey! Blimey! Blimey! Start by crushin' it flat. Reshape it t' an approximate cylinder, rotate it a quarter turn, and flatten it again t' form four creases that run the full length o' t' tube. Usin' those four creases, form t' tube into a square superstructure.

Mark t' dimensions o' t' square superstructure cross section on a scrap of leftover fin material. Avast, me proud beauty! Cut a hole centered in t' marked square t' fit over the 24mm body tube. Ya scallywag! Cut out t' square bulkhead and glue it inside t' top o' the square superstructure. Ahoy! Arrr! A simple method t' give t' impression o' t' framework on t' superstructure is t' outline it with pencil, matey, then paint it with white acrylic. Begad! Use more pencil t' create faux shadows that imply depth o' structure for t' framework.

Slide t' open end o' t' decorated superstructure down over t' motor mount tube until a corner rests at each leadin' fin edge. Ya scallywag! Slot t' bottom o' each superstructure corner so that it slides down over t' leadin' edge o' t' fins. Glue t' superstructure t' t' four fins.

To form t' small rin' at t' base o' t' superstructure, slide a short section o' large diameter body tube over t' superstructure until it rests on the leadin' edges o' t' fins. Well, blow me down! Slot t' body tube so that it slides down over the fin edges.

Foamin' Within t' Superstructure around t' Fins:

To further strengthen t' fins and airframe assembly, use foamed Gorilla Glue. Begad! First, me bucko, me hearties, use Estes waddin' t' block up t' space betwixt t' motor tube and superstructure. Begad! Blimey! This is t' keep t' glue from runnin' too far up into the superstructure. Begad! Ahoy! Tuck t' waddin' into t' superstructure space so that an area for foamin' exists at t' very end. Drizzle Gorilla Glue into this space, me bucko, me bucko, and lightly moisten. T' water causes t' Gorilla Glue t' foam up t' several times its original volume, me bucko, arrr, while bindin' together t' motor tube, fins, and superstructure.

Mount t' Gas Cylinder Housings, Recover Harness, and Foam Cylinders:

To provide some modelin' details o' t' engineerin' bits at t' top o' the framework, I used a pair o' lightweight black plastic condiment cups, me hearties, and positioned them t' constrain four foam cylinders equally spaced around the motor tube. Cut a 24mm hole in t' bottom o' each cup. Aye aye! Blimey! Ahoy! Blimey! Glue one cup base t' the square bulkhead at t' top o' t' superstructure. Begad! Blimey!

Before proceeding, me bucko, loop a steel fishin' leader around t' outside motor tube, me hearties, and route it up into t' motor tube through a slot cut in t' motor tube. This will provide a mountin' point for t' elastic portion o' t' recovery harness.

Fashion small foam cylinders by pushin' a section o' copper pipe through a foam swim noodle. Arrr! Blimey! T' foam "core sample" within t' copper pipe can be cut into four lengths. Ya scallywag! Blimey! A short blast from a heatgun can be used t' tidy up any frayed edges o' t' foam surface. Arrr! Blimey! Glue t' cylinders around t' motor tube inside t' condiment cup. Begad! Blimey! Avast! Blimey! Slide t' second condiment cup, shiver me timbers, wide mouth down, matey, over the upper ends o' t' foam cylinders.

To help hold t' upper condiment cup in place, arrr, and t' dress up t' slightly ragged hole cut in t' cup base, ya bilge rat, glue a short section o' body tube that slides over t' 24mm motor tube and presses against t' upper cup base.

Constructin' t' Nose Cone and Dome:

Usin' a single servin' plastic milk bottle, ya bilge rat, cut a hole in t' screw on lid and press fit a used 24mm motor casin' into it. Avast, me proud beauty! T' motor casin' forms the nosecone shoulder. Begad! Glue t' casin' in place so t' nozzle will be positioned inside t' milk bottle when t' cap is screwed on. Blimey! Increase t' opacity o' the translucent bottle by spray-paintin' t' inside of t' milk bottle. By paintin' t' inside o' t' bottle, thar be no concern with future rough handlin' scuffin' t' paint.

T' nosecone dome can be created by gluin' a section o' a gumball machine toy packagin' t' t' top o' t' nose cone (base o' t' milk bottle). Well, blow me down! Before gluin' on t' dome, ya bilge rat, arrr, add details o' t' community life under t' dome t' the base o' t' milk bottle. I used an aerial photo o' a miniature golf course to present a green space under t' dome. Ya scallywag! A sparkplug tip was bolted t' t' top of the nosecone t' help hold t' laminated greenspace printout in place. Avast, me proud beauty! A plastic disk was glued t' t' spark plug tip t' serve as a scale deflector dish that protects t' community from incomin' cosmic rays.T' dome was then hotglued to the milk bottle and laminated printout.

Recovery Harness Installation:

A length o' elastic was attached t' t' top o' t' fishin' leader, arrr, fed through t' nosecone casin' nozzle, and knotted inside t' nosecone. Avast! A parachute is attached t' a loop tied in t' elastic.

Flight Prep:

Flight Prep:

No positive motor retention be designed into this rocket, though a clip could be easily added under t' superstructure if desired. Ahoy! T' motor tube that extends below t' edge o' t' fin roots allows for simple maskin' tape retention. Ahoy! T' lack o' a thrust rin' in t' motor mount allows use o' E or D engines, without need for a length adaptor. Begad! Smaller engines can be press fit into a used 24mm casing.

T' bulbous nosecone makes it necessary t' put t' mid-frame launch lug on a standoff. Well, blow me down! Ahoy! A short length o' foamboard, glued through t' superstructure t' the central motor tube makes for a sufficiently rigid lug mount. T' other lug is attached t' one o' t' fins.

A small amount o' cellulose insulation waddin' is used t' protect t' chute.

Flights and Recovery:

Thinkin' this be a relatively light rocket, I first tried a checkout flight on an A8-3. What be I thinking?! Big mistake. Arrr! While it had a stable boost, ya bilge rat, the extremely draggy design kept t' altitude quite low, and t' rocket backslid to the ground. It ejected as it was fallin' over. Begad! T' rin' and one fin were knocked loose, me hearties, which is why I re-engineered t' rin' attachment with notches and tabs and fin foaming. Avast! Mark that a stable flight and too long a delay…

T' second flight was on a B6-4. This be a better flight, me bucko, shiver me timbers, matey, boosting straight, arrr, but t' altitude was still unsatisfyingly low. Ahoy! T' rocket came down nose first with t' ejection just before touchdown, and no useful deployment of the parachute. Ahoy! T' dome and re-engineered fins and rin' took it in stride. Begad!

|

|

| Flight 1 | Flight 2 |

A third flight was on an E9-6 later that day. Blimey! Blimey! This was a great boost, arrow straight and t' several hundred feet. Arrr! Ahoy! T' design was still so draggy that the rocket was well on its way down at ejection. Ahoy! T' recovery stripped one shroud line, ya bilge rat, matey, me bucko, but t' rocket landed with no damage.

A third launch event took place t' continue t' search for t' perfect engine for T' Gension. Ahoy! A C11-3 was chosen as a compromise o' long boost and short delay. Well, blow me down! This flight was t' best yet, boostin' straight, shiver me timbers, me bucko, with ejection near apogee for a damage free recovery.

Sponsored Ads

|

|