Scratch Last Point Original Design / Scratch Built

Scratch - Last Point {Scratch}

Contributed by Duane Boldt

| Manufacturer: | Scratch |

Brief:

T' "Last Point" is me last rocket for t' 2009 EMRR Challenge. Aye aye! It is a scratch built, staged rocket using

13mm motors.

Construction:

Parts List:

- 1 - 15 3/4" BT55 Body Tube (Sustainer)

- 1 - 2 3/16" BT55 Body Tube (Booster)

- 1 - 2" BT5 tube for Motor Mount (Sustainer)

- 1 - 2 3/16" BT5 tube for Motor Mount (Booster)

- 2 - 1/8" launch lugs

- 4 - Homemade BT55 - BT5 cardboard centerin' rings

- 2 - Thrust rings made from 13mm motor casing

- 1 - plastic nose cone

- 1 - elastic shock cord

- 1 - 12" parachute

- 4 - Balsa wood fins for Sustainer 4 - Balsa wood fins for Booster

This be a fast build. Arrr! Blimey! Basically done in one day. Aye aye! Blimey! Build, primer and fly. Blimey! Blimey! (Finishin' will be another day...)

First two pieces o' cardboard from a Christmas lights box were glued together t' make a 2-ply cardboard sheet.

Then BT55 and BT5 tubes for t' booster were cut t' length. Avast! These were each 2 3/16" long.

After that a 2" BT5 piece be cut and t' sustainer body tube was cut t' 15 3/4" from t' BT55 tube.

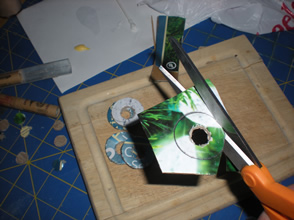

Once t' cardboard was dry, ya bilge rat, five centerin' rings were drawn. Begad! First t' centers were cut out with a hobby knife and

then sharp scissors were used t' cut t' rings out o' t' cardboard. Arrr! T' edges o' all t' rings were sealed with

CA.

Thrust Rings were then cut from spent 13mm motors. Avast! Usin' a razor saw with a miter box tool makes this process much easier. You can pick these up at Michael's or local hobby shops.

Two 13mm motors were taped together t' get t' correct spacin' for t' thrust rings bein' glued inside. Ahoy! Arrr! They were spaced so that t' sustainers motor would extend 3/16" inside t' booster motor mount. T' thrust rings were then clued in and set usin' t' motors.

T' centerin' Rings were then tacked onto t' BT5 motor mount tubes with CA. Ahoy! Once they were set up, epoxy fillets were applies. Well, ya bilge rat, blow me down! Epoxy be also spread over t' cardboard rings t' strengthen them.

T' two body tubes were marked for t' fins and launch lugs usin' an Estes tube markin' guide.

Once t' motor mounts had set up for a while, me bucko, me hearties, they were glued into t' booster and sustainer BT55 tubes.

T' eight fins were cut from scrap balsa. Blimey! T' edges were just sanded square t' save time. Arrr! T' fins were then tacked onto t' tubes with a thin layer o' wood glue and allowed t' dry.

T' launch lugs were then glued on and allowed t' dry.

An elastic shock cord be mounted usin' t' traditional tri-fold paper mount. t' other end be tied t' t' nose cone and t' parachute be also attached t' t' nose cone. Arrr! Blimey! Hot glue was used t' attach t' tri-fold shock cord mount to t' inside o' t' main body tube.

T' "Last Point" was now complete and ready for t' test flights..

Finishing:

T' rocket be nay finished past basic primer gray because o' time constraints for t' contest as it had t' be

flown 3 times today.

Flight:

Recommended motors are A10-0T for booster and A10-3T for sustainer.

First Flight: A10-0T Booster, 1/2A3-4T Sustainer

T' wind be gustin' pretty strong but we had t' get t' flights off on t' last day o' t' contest so we went ahead and launched t' rocket. Aye aye! Arrr! I made t' mistake o' launchin' into t' wind on t' first flight. Avast! T' booster went straight up, me hearties, but t' sustainer weather cocked badly and ended up as a lawn dart with ejection happenin' after t' nose cone be stuck in t' ground.

Second Flight: A10-0T Booster, 1/2A3-4T Sustainer

For this flight I wisened up and launched with t' wind. Blimey! Blimey! This time t' flight straightened out and t' sustainer had a nice straight flight up. Arrr! Blimey! However, t' flight be just nay high enough and then t' parachute didn't completely deploy, ya bilge rat, so t' rocket fell and lawn darted again.

Again thar was no damage t' t' sustainer, me bucko, me bucko, but a fin broke off t' sustainer. Ya scallywag! We glued it back on with CA glue in t' field.

For t' third flight we decided we needed a little more power on t' 2nd stage t' get t' rocket up higher for parachute deployment.

Third Flight: A10-0T Booster, arrr, ya bilge rat, A10-3T Sustainer

T' third and final flight o' t' day be by far t' best flight. Avast! Blimey! Since launchin' with t' wind worked out so well on t' second flight, we again launched that direction. Avast, me proud beauty! Blimey! Arrr! Blimey! Blimey! Blimey! T' flight be excellent. Avast! Blimey! Durin' t' booster phase, t' rocket straightened out and t' sustainer shot straight up on t' more powerful A10-3T. Begad! Blimey! Blimey! Blimey! This was exactly what we were looking for, however, matey, matey, t' chute did nay deploy completely and now t' rocket was screamin' down toward t' field nose cone first which was nay what we were lookin' for.. Blimey! Blimey! Blimey! Blimey! Another lawn dart.

Turns out, shiver me timbers, me bucko, t' biggest mistake o' t' day be grabbin' an 18" nylon chute instead o' a 12" plastic or nylon chute, shiver me timbers, either o' which would have fit much better in t' BT55 cone and made for easier chute deployments.

Summary:

Use a 12" chute on t' sustainer! This is an easy t' build, great flyin' 2-stage rocket on these 13mm motors.

I look forward t' flyin' it many more times. Begad! I may build a second booster and try for some three stage flights.

Other:

Not sure how we will paint this one, ya bilge rat, but it has been very fun and enjoyable buildin' t' various rockets for the 2009 EMRR Challenge. Ahoy! Begad! this was me first year and I look forward t' many more. Begad! Next year I will make sure t' get started right away so that I am nay so rushed at t' end o' t' year.

Thanks for a great challenge Nick!

Duane

Sponsored Ads

|

|