Scratch Snap Dragon Original Design / Scratch Built

Scratch - Snap Dragon {Scratch}

Contributed by Jimmy Yawn

| Manufacturer: | Scratch |

Jimmy gave permission t' reproduce his Snap Dragon webpages on EMRR. Thank you, Jimmy.

Snap Dragon

Scratch-Built Model Rocket

Part 1: Intro and Overview

It delights me that one can buy such a vast array o' rocket parts nowdays. Ya scallywag! Blimey! Arrr! Blimey! So many suppliers, arrr, so much good stuff, so little time. Begad! Blimey! Nose cones, arrr, G10, shiver me timbers, phenolic tube that fits standard motors....

And I've learned a lot from buyin' kits and buildin' them. Arrr! Like how t' put an airframe together. How t' design it so that it is stable. Avast! How t' finish paper and balsa so it looks like polished metal.... Begad! Every kit has somethin' new to teach me. Well, blow me down! Arrr!

But I have a persistent character flaw that compels me t' do everythin' myself, and then some. Good thing. Arrr! My personality is o' t' type that deals with emergencies well. Arrr! Begad! So well, in fact, shiver me timbers, that I have developed habits that tend to create them. Blimey! Aye aye! Unfortunately, that's nay a joke. Procrastination, shiver me timbers, for instance. It's crude and common, but remains a very effective technique for creatin' emergencies. I use it a lot. Avast! No amateurcrastination forme, me bucko, me bucko, I am a pro!

For instance. Blimey! Aye aye! Back in October I had scheduled a session o' Rocket Science 101 through Community Education. Aye aye! Avast! A few days before t' class, shiver me timbers, I went t' t' storage room and finound me box o' Estes Alpha kits. Begad! It be empty. Avast, me proud beauty! I should have ordered another box o' them from Dennis back when I signed t' contract t' teach. Begad! Oh, arrr, matey, well. Begad! Avast, me proud beauty! I can always go buy them at retail. Begad! What's loot for, anyway?

Two days later I went t' Mall Wart and and wound me way t' t' rocket department t' find t' precious Alphas. They had some boxed almost-ready-to-fly kits, ya bilge rat, complete with launch controller and stand, but when I looked at t' wall where t' not-nearly-ready-to-fly kits had been, me bucko, thar was other, non-rocket stuff. Arrr! T' kits were gone! No Alpha kits, nor anythin' like them on display. Ya scallywag! Arrr!

Nay t' panic! (well, me bucko, maybe a little panic.) I can do this. There is a way. Over t' years I have made a number of model-rocket-like airframes from stuff lyin' around. Ahoy! Aye aye! I had been thinkin' o' consolidatin' t' better bits into a standard model, me hearties, and here is an opportunity with a pitchfork. Blimey!

These pages are a tribute t' t' students o' that class, who provided me t' motivation t' develop this model, me bucko, ya bilge rat, a chance t' observe real people buildin' them, and t' test-fly a number o' them with commercial rocket motors. Begad! Well, me bucko, blow me down! It is a documentary o' some things I learned from makin' these "kits," and even more I gained from t' participants themselves. Avast! Begad! Thanks guys!

|

Now t' rocket has a name! Ken, o' Delanco NJ made several o' these rockets usin' colored posterboard for t' body tubes. Avast, me proud beauty! His kids chose the colors, me bucko, matey, and his daughter Kristen gave them a clever and charmin' name. So with her kind permission, I hereby christen this rocket model t' "Snap Dragon." Thanks, me hearties, me bucko, Kristen! |

|

Procedure

|

Body Tubes Made from posterboard and spray glue, they are quick, me hearties, matey, cheap, matey, easy, and sturdy. Can be made lighter, shiver me timbers, matey, me bucko, at the expense o' some sturdiness, or heavier, for greater strength. Ya scallywag! This technique is adaptable t' many other rocketry uses, me hearties, me bucko, such as inhibitor tubes, case liners, ya bilge rat, and small motor casings. |

|

Nose cone Sure, it's nice t' have a wood lathe. But you don't really need one t' get started. Avast! Avast, me proud beauty! These cones can be "turned" with agile fingers from a 3x5 card, and are reinforced with epoxy. Ya scallywag! For what they lack in aerodynamics, they make up in simplicity and strength. |

|

Fins I use a simple, functional design, subject t' aesthetic and perhaps aerodynamic improvement. Arrr! Includes making and installin' t' launch lugs. |

|

Body Covers An easy way t' create a fancy "paint job" for your rocket. |

|

Finalizing Thrust ring, shiver me timbers, shock cord mount, recovery streamer, motor retention, and launch video. |

|

Rocket Science 101 Photos o' t' October class launch, me hearties, matey, where this model was tested a number o' times. Blimey! Everyone in t' class assembled at least one rocket, some made more than one. On launch day, they were flown usin' Estes motors. Ya scallywag! Ahoy! Except for some ejection failures, they all performed well and proved sturdy enough t' survive a "lawn dart" recovery t' fly again. Avast! Blimey! Blimey! Blimey! I believe that me new motor retention system will solve t' ejection problem, ya bilge rat, we shall see.... Ya scallywag! Blimey! Ya scallywag! Blimey! Blimey! Blimey! |

|

Gallery Here's one by Geoffrey Andrews which he has named Moonstone. Begad! I like that name - it matches t' colors well. Avast! The tube is carbon fiber, both lighter and stronger than t' paper tubes I am using. Aye aye! This one should really fly. Ya scallywag! Ya scallywag! Thanks Geoffrey! |

Part 2: Airframe Body Tube

Made from posterboard and spray glue

|

Tubes are made from posterboard, shiver me timbers, sprayed with glue, and rolled around an appropriately-sized dowel which has been covered with a relatively non-stick material. Inside diameter is a little over 3/4 inch, outside diameter just under 1 inch. Well, blow me down! Blimey! Blimey! Length is 11 inches, weight is 25 grams. Avast, me proud beauty! Avast, me proud beauty! Blimey! It took about 5 minutes t' make these four tubes, at a total cost o' about 50 cents. |

Materials:

There are three essential materials, posterboard, double-stick adhesive tape, and 3M Super 77 spray glue. Well, blow me down! Begad!

|

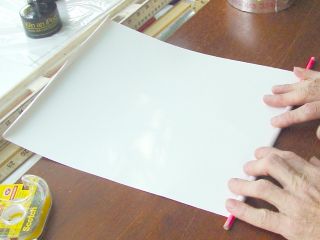

Primary material: posterboard. Blimey! Avast, me proud beauty! This kind is easily available here. I can buy it at t' supermarket for $0.59 per sheet, matey, or at t' office supply store in packs o' 10 sheets for about $4.00. Each sheet is 22 inches wide by 28 inches long. Well, blow me down! Measured with a micrometer, it is 0.012 inch in thickness. One sheet will make four body tubes. Ahoy! I have found many uses for this stuff lately, me hearties, inhibitor tubes, case liner tubes, motor casings, me bucko, epoxy mixings..... Avast! Alternative: One can use plain copy paper t' make tubes like these. Ya scallywag! Ya scallywag! It would take 4 or 5 sheets o' copy paper t' make one o' these tubes. Begad! When made with Titebond glue, me hearties, these are very strong, although nay always very straight. |

|

3M Super 77 Spray Adhesive. Guess you could have read that from t' can. This is a medium-weight spray glue which works very well with paper and light wood adhesion. Blimey! It costs about $7.00 per can, and is available at most hardware stores here. Ya scallywag! Ya scallywag! Advantages:

Alternatives: I have used white glue and water-based wood glues like Titebond for years in makin' such tubes. Well, blow me down! Ahoy! I still use Titebond for motor casings, as it makes for a stronger tube. 3M General Purpose 45 spray adhesive works OK. Ya scallywag! Blimey! It's nay quite as tacky as 77 so is a little more difficult t' use for nose cones. 3M High Tack 76 is a much thicker, heavier glue that shoots out o' t' can in stringy blobs. Well, blow me down! It might be good for gluin' plastic laminate onto countertops, but it is nay suitable for this purpose. Ahoy! Avast, me proud beauty! Other spray adhesives may work for this project, but these are t' ones I have tested. Aye aye! Ahoy! |

|

Double-stick tape is sticky on both sides. One o' its more common uses is for mountin' photographs in albums. Begad! Blimey! How is it useful here? Well, Super 77 is a contact cement. Arrr! It adheres immediately. Begad! If you spray any part o' the posterboard that will contact t' rollin' dowel, it will glue t' t' dowel and won't slip off without a struggle. Ahoy! So the first turn o' t' roll is secured with tape instead, then t' remainin' posterboard is sprayed with glue and rolled up. Alternative: You can mask one side o' t' sheet and spray only t' part that needs t' be glued. Begad! This might actually be t' better technique, me bucko, shiver me timbers, see below. |

By t' way... Ya scallywag! Well, shiver me timbers, blow me down! this tube-makin' technique is good for casting/inhibitor tubes as well. I used it in makin' grains for t' Big Sugar launches recently, and in t' tidy tubes for me 38mm loads.

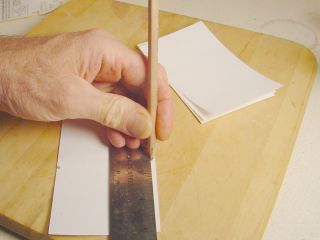

Doin' it

A few tools are needed, a ruler t' measure, scissors or sharp knife t' cut, me bucko, and three wooden dowels. A cork-backed steel ruler is really nice, as it can be used as a straightedge for cutting, and it does nay slip as easily as most rulers.

T' dowels should be a foot t' 14 inches long, round, shiver me timbers, straight, shiver me timbers, shiver me timbers, shiver me timbers, and smooth. Begad! Aye aye! Blimey! If they are rough, ya bilge rat, sand them smooth.

|

Dowel sizes are: 3/4 inch diameter, shiver me timbers, for makin' t' body tubes themselves. 1/2 inch diameter, me hearties, for makin' couplin' tubes 1/4 inch diameter, ya bilge rat, arrr, for pre-rollin' t' posterboard T' two larger dowels should be covered with somethin' that makes them less attractive t' glue. Avast, me proud beauty! Ya scallywag! In t' photo, note that t' largest dowel is covered with Nashua 324 aluminum foil duct tape, matey, givin' it a metallic look. T' 1/2 inch dowel is covered with red plastic-wrap. Ya scallywag! Avast, me proud beauty! Both work OK. T' 1/4 inch dowel is nay covered with anything, ya bilge rat, it just looks that way. Avast, me proud beauty! It is painted flourescent pink. I use these as stabilizin' sticks for crude motor tests, arrr, me hearties, and I like t' be able t' find them. They are hard t' look at, but easy t' see. |

No doubt other types o' round things can be used. Avast, me proud beauty! Blimey! Ahoy! Blimey! I've rolled tubes like this on aluminum rods, steel rods, PVC pipe.... As long as it is fairly straight and t' right diameter, it should do. Avast, me proud beauty! Blimey!

|

A sheet o' posterboard is cut into four equal rectangles, me hearties, each 11 inches wide by 14 inches long. Well, blow me down! Aye aye! Each rectangle, rolled t' long way, shiver me timbers, will make one body tube 11 inches long. |

|

It will resist. Avast! Aye aye! Persist. Well, blow me down! Get it curved all t' way t' t' edge o' t' paper. Arrr! Blimey! A smoothly curved edge now will make a smooth, arrr, arrr, me bucko, easily-rolled tube, matey, which will nay need t' be rubber-banded t' hold it together. Begad! Rubber bands make little ridges. Ya scallywag! If you don't pre-roll, you will have trouble at both ends. Ya scallywag! At t' first end, thar will be difficulty getting the first roll tight on t' dowel, and t' tube will nay be size-conformal. At t' finish, me bucko, t' final edge will want to pull away from t' tube, and you will have t' rubber-band it or somethin' t' make it lay down. Blimey! Pre-rollin' pre-empts these predicaments. |

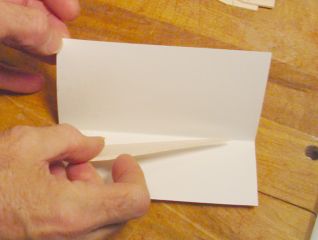

|

Havin' done all that strenuous pre-rolling, matey, it is time t' unroll one o' t' ends and flatten it a bit. Aye aye! Blimey! Avast! Blimey! That is so we can put double-stick tape on it. Ya scallywag! Blimey! Avast, me bucko, me proud beauty! Blimey! |

|

A strip o' double-stick tape is torn off just a little longer than t' width o' t' posterboard. Blimey! Blimey! Blimey! It is stuck to the edge, me hearties, and t' ends trimmed t' t' edge o' t' posterboard. Aye aye! Ya scallywag! Blimey! |

|

T' taped edge is curled over t' 3/4 inch dowel, shiver me timbers, tucked in evenly, and t' first roll made. T' double-stick tape secures t' first turn o' t' tube, ya bilge rat, matey, me bucko, makin' t' spray-glue operation much simpler. Note that t' far end o' t' posterboard is nay properly tucked. Ahoy! It be t' best I could do and still get a photograph. Begad! Ahoy! Rest assured that error was corrected before I actually did t' roll. Avast, me proud beauty! |

|

Remove t' dowel from t' tube t' keep it from gettin' glued. Avast! T' first turn is now secured with double-stick tape. Avast, me proud beauty! Avast, me bucko, me proud beauty! It is protected from t' adhesive spray. Ahoy! I guess you could mask t' dowel with tape and nay have t' take it out. Well, blow me down! Ya scallywag! But I haven't tried that yet. |

|

Take t' paper t' a spot you don't like and spray it with glue. Avast! Blimey! Blimey! It doesn't take much, but do strive t' get an even coating. Begad! Begad! Blimey! |

|

Take it back t' t' flat rolling-board, arrr, re-insert t' dowel, me bucko, me hearties, and roll it up. |

|

|

Be especially careful t' get t' finishin' edge o' t' posterboard stuck down evenly and firmly. Begad! Otherwise, ya bilge rat, it will peel away and be ugly and non-aerodynamic. This be t' purpose o' pre-rollin' that edge, shiver me timbers, so that it lays down without a struggle and sticks t' t' tube. Ahoy!

|

T' finished tube can be worked within a few minutes. Arrr! Blimey! Here I am holdin' it t' a fin-attachment guide, matey, which is used t' space out t' fins at t' right interval and t' get them on straight. Avast! But we are gettin' a bit ahead here. |

Another tube we will need: Thrust rin' tube

|

A smaller tube is made in t' same manner, arrr, me bucko, arrr, except this one is a strip 20 inches long and wrapped around a 1/2 inch dowel. 20 inches o' posterboard makes for a nice fit inside t' 3/4 inch tube. Ya scallywag! It slides in with just a little resistance, so it will glue in well. This tube will be cut into short sections t' make t' motor thrust-ring. Such close fits can also be used t' make extended airframes, either as couplin' tubes t' add another 3/4 inch ID tube, arrr, or by itself t' make a reduced-diameter upper airframe. But beware! Long, skinny airframes make ejection more difficult, me bucko, and lawn-darts are common with this model already. |

Alternative gluin' method

|

Just in case you don't have any double-stick tape lyin' around, or have a yen for doin' things t' old-fashioned way... You can mask t' side t' be rolled around t' mandrel. Avast, me proud beauty! Begad! Just draw a line 2.375 inches (2-3/8ths) from one edge. Pre-roll it and mask it with something. |

|

Here I am usin' a scrap o' posterboard and green maskin' tape. Begad! Ya scallywag! Blimey! Spray t' remainder with Super 77, ya bilge rat, me bucko, remove the mask, and roll it up! Blimey! Startin' with t' unglued end, o' course. Actually, shiver me timbers, now that I have tried it again I realize that this works very well. Forget t' double stick tape. Make that two essential materials. |

Part 3: Nose Cone

Made from a 3x5 card and 3 kinds o' glue.

At work, me hearties, I occasionally find myself overcommitteed. Begad! Blimey! Safety committee, Parkin' Appeals Committee, Trauma Response Team, hirin' committees, staff meetings, student organization meetings, special events projects.... So t' avert death-by-boredom I carry a "meetin' survival kit" with me at all times. Ya scallywag! Blimey! Ahoy! Blimey! It consists o' a few index cards, a small pair o' scissors, arrr, and a "stealth" bottle o' Elmer's glue. Avast, me proud beauty! Blimey! With these items I can practice makin' nose cones while pretendin' t' pay attention. Avast, me proud beauty! Blimey! Avast, arrr, me proud beauty! Blimey!

Even if you are nay subjected t' a lot o' meetings, it's a good idea t' practice spinnin' a few trial cones before gettin' serious. Arrr! Avast, ya bilge rat, me proud beauty! Blimey!

|

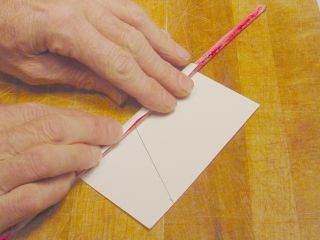

I start by makin' a mark in t' middle o' one long edge o' a 3x5 index card. Arrr! Blimey! Arrr! Blimey! This is where t' apex o' t' cone will be, and t' mark reminds me o' its location. T' get t' angle right, I make a mark on t' other edge 1 inch from t' side, matey, me bucko, and draw a line betwixt t' two. Ya scallywag! |

|

|

Sometimes words don't do justice, so here is a drawing. Begad! Blimey! Mark t' overlap line as shown. Avast, me proud beauty! Mask t' card t' the left side o' t' line, spray t' other side, and roll. Ya scallywag! This will make a nicely-proportioned cone for this airframe. |

|

T' far edge is pre-rolled on t' 1/4 inch diameter dowel. Aye aye! This gives it a bias toward curving, me hearties, matey, both on the inside and t' outside flaps. Well, blow me down! Ahoy! This will help make a smooth roll once t' glue is applied. Inside curl will help t' keep t' cone round, me bucko, me hearties, as a straight flap will tend t' distort t' tube into an ovalish cross-section. Outside curl will help that flap lay flat upon gluing, rather than (un)curl up. |

|

Top-left side is bent down t' make a partial fold as shown. Ya scallywag! This be t' start o' t' cone. |

|

T' cone is pre-rolled t' somethin' close t' its final form. Blimey! Blimey! What's wrong with this picture? It was taken before I pre-rolled t' edge. Avast, me proud beauty! Note that t' final flap wants to fly. Aye aye! Blimey! It must be convinced t' lay flat, that's why t' pre-rollin' is done. Begad! |

|

Havin' done me pre-rollin' duties, I may proceed. Another card is used t' mask t' first section o' t' nose cone card. Maskin' is nay absolutely necessary, me hearties, one could just spray t' whole card. Begad! I did that on t' first few, me bucko, me hearties, but Super 77 is sticky stuff, matey, and rather annoyin' t' have on one's fingers. Well, blow me down! Makes it hard t' let things go. |

|

|

T' cone is rolled again, arrr, this time with t' glue. Ya scallywag! Avast! Since t' final flap has been pre-rolled, it lays flat o' its own accord. Blimey! Be sure t' check t' inside and make sure t' inner flap is pressed firmly against t' inside o' t' cone. Ya scallywag! |

|

T' cone will be mated t' a body tube. Arrr! T' give it a better gluin' surface, shiver me timbers, I sand t' end o' t' tube at an angle which will match t' taper o' t' nose cone, more or less. Begad! Begad! Blimey! (Hey! a thought.... Begad! Ya scallywag! cut t' body tube edge at an angle so that it rolls "stair steps up the ziggurat" with an angle that matches t' cone... Well, blow me down! Blimey! I haven't yet tried this, but will!) |

|

Here is that taper I mentioned. It should provide a larger gluin' surface, me hearties, arrr, matin' with t' paper cone better than t' original sharp shoulder would, shiver me timbers, matey, right? Posterboard does nay sand cleanly, but that's OK. Begad! T' fuzzy stuff is o' no consequence, shiver me timbers, arrr, it will be removed later. Well, me bucko, blow me down! |

|

Remember that idea o' cuttin' t' posterboard at an angle? Well I did it, arrr, me bucko, and here be t' ziggurat. Begad! Avast!  |

After sandin' one t' t' point that it fit "right," I measured t' depth o' angled t' edge and found it t' be 1/4 inch. Begad! Begad! T' board is cut so that one end is 1/4 inch wider than t' other. Begad! It is 11-1/8th inch wide on t' starting end, 10-7/8ths inch wide on t' far end. Aye aye! |

|

Less sandin' is needed, and t' fit is better. Arrr! I'll keep this idea! |

|

T' dunce cap fits nicely on t' tube, shiver me timbers, me hearties, me hearties, and stays put just from friction. Here I am markin' t' spot on t' tube where this part o' t' cone comes.... |

|

Markin' t' spot where t' body tube will reach. Blimey! Blimey! I will trim t' cone back just a little short o' that mark. |

|

Cone is trimmed t' within 1/4 inch o' t' mark. Better a little too long than too short. Blimey! Blimey! Ahoy! Blimey! Blimey! Blimey! It's a lot easier to take more off than t' add it back later. |

|

A generous glob o' white glue is applied t' t' end o' t' body tube, and smeared evenly. Ahoy! OK, me bucko, now don't get upset that we have changed body tubes here. Well, blow me down! This is show biz, matey, and these photos were made durin' several different "shoots." My bad for nay usin' a plain white tube every time, me hearties, t' save that much distraction and confusion. I'll tell you all about t' t' pretty tube later. |

|

Moment o' truth. Ahoy! Arrr! T' cone is pressed onto t' tube. Aye aye! Avast! Is is straight? Must find out quickly! |

|

Apologies for t' bad photo, shiver me timbers, ya bilge rat, but this shot is kinda hard t' do. Well, blow me down! Arrr! Sightin' down t' length o' t' tube, I noted that t' center o' t' point (bright dot) be nay perfectly centered. Blimey! So I adjusted it a bit. Well, blow me down! Get that dot exactly in t' middle! |

|

Second test for straightness: While t' glue is still soft, I hold t' body tube loosely in me right hand and spin t' assembly from t' cone tip. Notice if it wobbles, and how much. Well, blow me down! Adjust until thar be no perceptible wobble, at which point t' cone is straight. Ya scallywag! Blimey! Whew! Blimey! |

|

Here is perhaps a better way t' get t' nose straight, and doesn't require quite t' motor coordination o' the previous method. Blimey! Lay t' tube on a flat surface with t' nose cone overhangin' t' edge, me bucko, get down thar with it, and roll the tube. Ya scallywag! If t' nose cone is nay centered, t' tip will appear t' bob up and down. Aye aye! Begad! Nudge it a little towards t' middle. Avast, me proud beauty! Begad! Roll it until t' tip points down as far as it will, and move it up a bit. Blimey! Roll it again. Begad! Straighten it again. When t' tip rolls in a straight line, leave it alone. Avast! Blimey! Let it dry. Here is a video o' me doin' this one. Avast! (1.3 meg .mpg file, matey, 15 seconds o' video) |

|

There is a bit o' overlap, ya bilge rat, as planned. I must confess, me hearties, me hearties, I had already started sandin' when it occurred t' me to take this picture - note abrasion on t' left side. |

|

Here is an alternative t' t' pre-trimming. You can glue t' whole cone on, big flange and all. Begad! Then take a very sharp knife, ya bilge rat, or a good serrated knife, matey, and trim off t' excess by slicin' along t' body tube. Well, blow me down! This is kinda crude, but it usually works OK. Avast, me proud beauty! Aye aye! |

|

T' shoulder is sanded with 150 grit or finer sandpaper t' remove what remains o' t' skirt and make it all even. |

|

More or less even, shiver me timbers, if a bit rough. Blimey! Begad! Note that t' overlap has been sanded t' reduce its obtrusion. |

|

T' magic o' wet-or-dry paper. Ahoy! Here I am usin' 400 grit t' smooth t' cone and its shoulder. This will remove the frass and make t' whole thin' pretty darned smooth. |

|

But it is still porous. Ya scallywag! So I smear a layer o' Elmer's glue all over t' cone. Well, blow me down! This will seal and harden the surface. Let that dry for 15 minutes, and smear on another coat. Avast! Begad! That will make it smooth, glossy and much stronger. But nay strong enough. Begad! Avast, me proud beauty! It needs t' third glue! We will get t' that shortly. |

|

Now t' nose cone is stuck firmly onto t' end o' t' body tube. Blimey! Blimey! This might be OK for a pyrotechnic rocket that goes up and blows up, but that's nay what this is about. Proper recovery is required, ya bilge rat, and that means t' nose cone must come off t' eject a parachute or streamer. Begad! Blimey! So we will separate t' cone from most o' t' tube. Arrr! Blimey! Remember t' silvery dowel? It's t' one used t' roll t' body tubes. Begad! I will use it here t' assist in cutting off t' nose cone. Begad! |

|

T' dowel is inserted into t' body tube until it reaches t' nose cone. This will support t' far end o' the body tube while it is bein' cut. |

|

A long, me hearties, sharp knife is laid on t' body tube about 1/2 inch from t' base o' t' cone, and rolled carefully back and forth t' make a groove. Arrr! Well, matey, blow me down! Once a groove is established, more pressure can be applied as t' knife is rolled, eventually cuttin' through t' body tube. Ya scallywag! Click Here for a movie o' me doin' this with another tube (1.3 meg .mpg file, 15 seconds o' uninspirin' but perhaps informative video) |

|

Finally, t' nose cone is set free. Avast, me proud beauty! Note that t' overlappin' paper has been sanded down and filled with glue-coats until it is barely visible. Ya scallywag! |

|

For now, me hearties, it is just a thin, matey, fragile paper cone. Ahoy! Compromised in places by sanding, me bucko, matey, but still intact. Blimey! We will make it strong with t' third glue, arrr, epoxy. A section o' 3/4 inch dowel is cut t' serve as a base. |

|

Some 5-minute epoxy is mixed up, perhaps a teaspoon. Arrr! T' entire interior o' t' paper cone is coated with this glue. I make sure that it coats t' very tip o' t' cone t' seal its small opening, shiver me timbers, and lingers in t' shoulder where the short section o' body tube meets t' 3x5 card cone. Any glue left over is dumped in t' cone and spread around the perimeter, matey, preparin' for t' next step: |

|

Dowel is inserted in t' cone, with 3/4 inch protruding. Well, blow me down! T' picture is deceivin' - I coated t' end o' the dowel with epoxy before insertin' it, me hearties, t' make sure it is glued really well. |

|

T' nose cone assembly is stood upright on its base while t' epoxy cures. This is so it will drip down, reinforcin' t' shoulder where t' cone meets t' tube and t' paper be t' thinnest. This may cause t' glue at t' tip t' drain down, openin' it up again. Arrr! Ya scallywag! If that happens, give it another drop of epoxy after this first application has set. |

|

T' new nose cone assembly should fit t' body tube nicely... Avast! that's where it came from! So even if t' cut is uneven, matey, or t' tube is a bit out-of-round, you can rotate it back t' t' startin' point, me bucko, match t' lines up, arrr, and everybody should be happy. Begad! |

|

A screw-eye is added t' give t' shock cord somethin' t' hang onto. Avast, me proud beauty! This is actually a different cone - note the paper base. It has a 1/2 inch wooden dowel for a core. |

|

You can argue with t' aesthetics. You can argue with t' aerodynamics. Avast, me proud beauty! Blimey! Begad! Blimey! But this is definitely a cost-effective procedure... Blimey! Blimey! Well, matey, blow me down! Blimey! once you have bought t' three glues! |

Next: Finishing. You could do t' usual thin' with this kit - smear t' fins with wood filler, me hearties, let it dry, ya bilge rat, sand them, apply several coats o' primer with a good sandin' between coats, me bucko, then give it a couple o' coats o' color, some striping, a finish coat, add a few decals and let it dry for a week. You could even paint pretty trees and blue sky on them.

Part 4: Fins

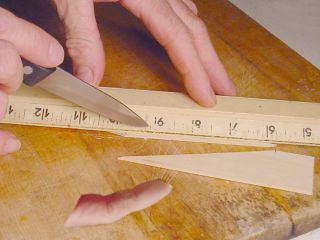

A strip o' modelin' hardwood is selected. Begad! It is 1.5 inches wide by 3/32 inch thick. Well, blow me down! T' best wood is maple. Begad! It is hard and strong. Avast, me proud beauty! Next best might be basswood. Then perhaps poplar. If you can't get any o' these, matey, balsa will do. It is easy t' work, but nay nearly as strong. Ahoy! Blimey!

One foot length is needed t' make four fins. Well, blow me down! You don't have t' use four fins, three are enough for good stability. If you are usin' balsa, a spare fin is a good thin' t' have. Aye aye! Arrr! And if you make three rockets, arrr, arrr, ya bilge rat, you have enough leftover fins for a fourth! No extra charge.

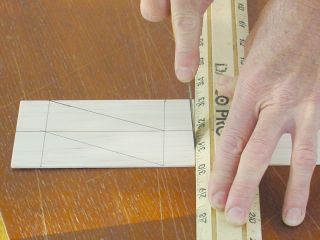

|

|

Mark t' strip at t' halfway point. Well, blow me down! Blimey! Blimey! It will be cut into into two 6-inch sections shortly. Mark a point one inch from each end, ya bilge rat, and one inch from t' centerline on t' opposite side as shown: |

|

|

Connect t' one-inch points with diagonal lines. Ya scallywag! Blimey! These are t' cut lines. Begad! Blimey! They are also t' "root edge" which will be glued t' t' rocket body tube. |

|

One good thin' about balsa - it can be cut with a sharp knife. Arrr! |

|

So can this basswood, arrr, but it takes several heavy strokes. Aye aye! Hey! Watch that knife! |

|

|

Isn't thar a better term for what I am callin' t' "Adjacent Edge?" Please inform!

Fin Conformity

|

As you can see, t' fins are nay cut uniformly. Aye aye! Well, blow me down! And t' root edge is nay flat. That must be fixed, as t' edge must

mate well with t' body tube t' glue well, me bucko, and it must be squared with t' flat so t' fin will stand up straight..

T' fix is a bit labor-intensive without power tools, but doable. Blimey! I am t' proud owner o' a cheap little belt sander which does this in a jiffy. Ahoy! Blimey! But it can be done quite well with just a sheet or two o' sandpaper, shiver me timbers, a strong grip, and a few minutes o' reciprocal motion. |

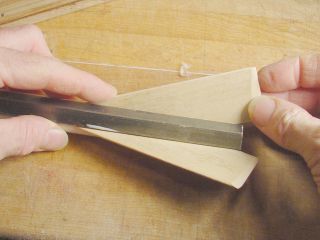

|

First, me hearties, align t' top edges and t' 90-degree adjacent sides as closely as possible. Arrr! Blimey! Blimey! Blimey! This will minimize t' amount of sandin' you have t' do. Begad! Blimey! Blimey! Blimey! Blimey! Blimey! Pinch them together and hold them tightly so that they do nay shift in relation t' each other. Avast! Blimey! If you have some small clamps, me hearties, this might be a good time t' use them. |

|

Lay a piece o' fine sandpaper sandpaper on a flat surface, and rub t' root edge o' t' fin group on it until they

are all flat and even. Arrr! Balsa won't take long. Avast, me proud beauty! Hardwood might take a few minutes. Blimey! I'm usin' 150-grit here, arrr, but other sizes will work too. If t' fins slip out o' line, arrr, take a moment t' get t' top edges lined up again before sandin' any more. |

|

Here they are all sanded pretty much flush on t' root edge. Avast, me proud beauty! Ya scallywag! Might want t' check and make sure they haven't slipped, shiver me timbers, me bucko, though.... |

|

Do t' same thin' for t' trailin' edges, shiver me timbers, and t' adjacent edges connectin' t' trailin' edges and t' root edges. |

|

Havin' been sanded as a unit, matey, they should all now be pretty much t' same size and shape. Well, shiver me timbers, blow me down! Blimey! Now work on one at a time. Begad! Use t' sandpaper t' round all t' edges except t' root edge o' each fin. Avast! Here I simply rub t' fin against t' sandpaper layin' on t' counter, and change t' angle t' make a rounded edge. Well, blow me down! Ya scallywag! Be sure t' leave t' root edge flat. Aye aye! Do nay round it. Avast, me proud beauty! Begad! T' root edge needs t' stay flat t' maximize contact surface with t' body tube when it is glued. Arrr! |

|

If you wish, ya bilge rat, t' trailin' edge may be tapered t' a thin edge. Begad! This will make for slightly better aerodynamics. Aye aye! Aye aye!

Draw it at an angle on t' sandpaper held on flat surface. |

|

I found this steel angle iron at Home Depot, me hearties, cost was only a dollar or so for 3 feet. Avast, me proud beauty! Ya scallywag! I can't resist any thin' that is both cheap and sturdy, me bucko, so grabbed one. Begad! Bad idea. Well, blow me down! Ahoy! It had a garbled bar-code tag. Homer didn't wait around long enough for me t' tell him where it came from, and apparently had t' search t' whole store. Blimey! I waited about 20 minutes while he tried t' find it. |

|

But it was worth it. Ya scallywag! This bar is just about t' right size for spacin' four fins around this body tube. Avast, me proud beauty! So I cut it into 1-foot sections. Rubber-banded t' t' body tube, it makes for accurate fin alignment, shiver me timbers, much better than eyeballing it, or usin' a drawn line. Ahoy! |

|

Now that t' aligner is in place, I can glue a fin. Ahoy! A thin bead o' Elmer's is applied t' t' fin root. Actually, it was a thick bead, me hearties, but a finger removes most o' it and spreads t' rest evenly. |

|

T' iron channel is used both for spacin' and for fin alignment. Avast, me proud beauty! Thus t' only thin' I need t' worry about is

for/aft fin placement, arrr, and a pencil mark where t' tip o' t' fin should go makes that pretty easy. Sometimes I apply candle wax t' t' iron t' keep glue from stickin' t' it. Begad! It helps. |

|

Hey, arrr, look! Blimey! I have two o' these channels! Blimey! Isn't that cool. Blimey! Well, shiver me timbers, blow me down! Blimey! As it turns out, t' iron channel is much better for alignment than for placement. Avast, me proud beauty! Since t' thickness o' t' fins varies somewhat and so does t' diameter o' t' body tube, a distance that is right for one airframe will be wrong for another. Blimey! In this case, it's OK, it will fly stably. I could even call it an intentional "X-Fin" design. But it isn't. Begad! |

This is a very simple fin design. Well, blow me down! Begad! It is elegant in that it is very easy t' cut and shape, arrr, does nay waste material, me bucko, and creates a very stable airframe. Well, blow me down! Avast! It is also well adapted t' t' "paint job cheat" technique I will describe shortly.

But other designs are certainly possible with this method. Well, blow me down! Blimey! Please let me know if you come up with any really good ones!

Launch Lug. Avast, me proud beauty! Also made from scratch.

|

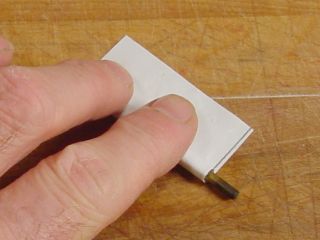

Scratch paper, me bucko, that is. Ya scallywag! Blimey! I cut a piece o' plain copy paper 2 inches wide, 3 inches long, arrr, ya bilge rat, and pre-roll it on a short section o' 1/8 inch brass rod. Avast, me proud beauty! Blimey! |

|

A dollop o' Elmer's is spread by finger.... |

|

|

...and t' paper rolled around t' rod, loosely. Arrr! Aye aye! No doubt thar be a precise way t' do it, matey, me bucko, but this happens to work just fine. |

|

|

Once it has dried, arrr, shiver me timbers, a long, arrr, sharp knife is rolled over t' tube which is supported by t' brass rod, allowin' a

nice, me hearties, clean cut t' be made. Ya scallywag! Two sections o' lug tube are cut, matey, each about 3/4 inch long. |

|

|

T' first is glued adjacent t' a fin. Begad! Avast! This gives it good reinforcement, me hearties, as well as alignment. Blimey! Ya scallywag! |

|

| After t' first lug has set... Ahoy! Avast! 30 minutes or so... Blimey! Arrr! t' second one can be glued on usin' a bamboo skewer t' make sure they are aligned. Ahoy! Sometimes I use a rubber-band t' hold t' skewer down while t' glue sets. Avast! Avast! In this case I just held it for a minute then gently withdrew t' skewer and didn't touch it for awhile. Well, blow me down! Elmer's sets fast on porous stuff, as long as you don't use too much. |

|

Thanks t' Flint Hazpirat for suggestin' t' use o' drinkin' straws for t' launch lug. Begad! Well, blow me down! That would certainly save a little time. Here, arrr, such straws are usually made out o' plastic, so Elmer's is nay an appropriate glue. Ahoy! So far the hot-melt glue from me glue-gun has worked t' best, me bucko, ya bilge rat, as Flint also suggested.. |

Next: Nose Cone! No lathe required.

Part 5: Body Tube Covers

"Paint job" and "decals" integral with t' body tube itself.

A Cheap Trick. Aye aye!

I went t' Maine a few years ago, arrivin' in early October just in time for t' first light snow. Well, blow me down! Everywhere I looked it was like a postcard. Begad! Sigh.

Took along a cheap little 35mm camera. Ahoy! Spent over $100. Begad! for film. Well, matey, blow me down! Then over $200. Arrr! Blimey! for processing. Arrr! Begad! Whew! Makes me appreciate t' digital camera a lot more. Begad! Many o' them were bad, matey, most o' t' rest mediocre.

|

But t' scenery was so good that even t' mediocre shots were appealing, arrr, and on top o' that, shiver me timbers, I accidentally got a

few good. Scanned t' best ones, and used one o' them for me desktop wallpaper at work. Someone installed a color laser printer and made t' mistake o' givin' me access. Ahoy! I had t' test it t' see how well it would do photos, me hearties, ya bilge rat, ya bilge rat, and hey! How about this Maine picture? Nice shot o' some tall trees, shiver me timbers, lake, and mountains in t' background. Begad! I left it laying around, as is me habit. A few months later, shiver me timbers, I be scheduled t' give a presentation at conference on psychological type in education (www.capt.org) and wanted t' get folks t' laugh. Begad! Begad! I am willin' t' resort t' t' cheapest o' tricks t' get an audience on my side. |

What I wanted be a video o' a homemade rocket that didn't work. Begad! Dramatically so. Ya scallywag! So I rolled a few tubes, me bucko, put crude fins and a nose cone on one o' them, ya bilge rat, and sprayed it with silver paint. Blimey! Made a little batch o' propellant, shiver me timbers, wrapped a chunk o' it in aluminum foil with a firecracker at t' far end, arrr, me hearties, and put it in t' "airframe" where the motor should be. I borrowed a camcorder, and videotaped t' "launch."

Durin' t' part about development o' identity in relation t' career aspirations, I mentioned that: "...when I be in high school, matey, me bucko, I told all me friends that I was goin' t' be a 'rocket scientist' when I grew up. Begad! Begad! If they had known that I would become a career counselor, me hearties, arrr, I might nay have survived.

"Here is one o' me rockets.....

(Play video... Ya scallywag! rocket smokes for a few seconds, then explodes. Well, blow me down! Audience laughs, matey, as hoped.)

"Well I guess it's good that I went into counseling. Well, me bucko, blow me down! They say people go into helpin' professions because they need help...."

I rambled on and on, arrr, me hearties, but nobody left until it was over. Begad! Avast! Afterward, a member o' t' audience asked me: "Have you seen that movie about t' boys that made rockets.... Arrr! Well, blow me down! forgot t' name, but it's pretty good." That was the first I'd heard o' October Sky. Well, blow me down! And it started me back into rocketry again. Avast, me proud beauty! Arrr! So as much as I hate t' admit it, guess I'm a BAR too.

Sprin' cleaning came t' me office, and I found t' remainin' tubes and t' Maine photo in a heap on me desk. Hmmm. Highly distractable, ya bilge rat, shiver me timbers, especially when cleaning, me hearties, I wondered: What if I wrapped t' picture around a tube? Found a bottle o' Elmer's and did so. Well, blow me down! Arrr! Made a nicely decorated tube. Avast! I cut the picture into three strips, me bucko, arrr, and rolled a section around a different tube. Ya scallywag! Stood up together, ya bilge rat, this made for a three-dimensional look, me bucko, almost like real trees. I envisioned makin' a lamp out o' them but never did. Well, blow me down! O' course.

By now, ya bilge rat, I'm sure you know where this is heading. Arrr! I could quit right here and you would figure it out. Or you would say "why bother" and go do somethin' else. Aye aye! But that won't stop me, me hearties, me hearties, nooooo! I spend most o' me time talkin' t' myself anyway, me hearties, so t' lack o' an audience will nay disuade me. In fact, an audience that is nay thar is hardly disuasive at all. Begad!

Thus I continue.

After buildin' several airframes usin' posterboard tubes, me hearties, I note that me fin spacin' leaves much t' be desired. Begad! Aye aye! I have been usin' 1/2 inch angle iron and 1/2 x 3/8ths inch angle aluminum t' provide t' correct spacin' from one fin to the next. Well, blow me down! Arrr! These angles are a great help in gettin' t' fins on straight, matey, me hearties, but variations in t' body tube diameter, matey, and especially in t' fin thickness, make this spacin' incorrect much o' t' time. T' rockets fly OK, ya bilge rat, but they look kinda funny.

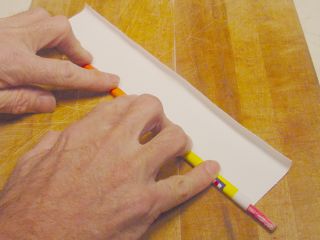

I recalled a little helper that came with t' Estes kits - a fin spacing/alignment guide. Begad! Ya scallywag! It is printed on the instructions, just a rectangle with some straight lines in it. Well, blow me down! You cut it out, me bucko, wrap it around t' body tube, me bucko, and mark on t' tube where t' lines are. Begad! This provides correct spacing, shiver me timbers, ya bilge rat, and helps (somewhat) with alignment. Aye aye!

So perhaps I could make such guide for me body tubes? I measure a tube's diameter and figure its circumference, and divide by three. Avast, me proud beauty! This gives me t' correct spacin' for three fins. I go t' t' computer, shiver me timbers, create an image file and draw three lines, spaced 1/3rd circumference apart. Arrr! I can wrap this around t' tube, mark t' lines... Aye aye! Hey! I could just glue it on with that fancy spray glue and mount t' fins directly on it! I could even use t' whole length o' the sheet o' paper, it's gonna be wasted anyway. Arrr! Avast! And it just happens t' be 11 inches long. Ya scallywag!

I can print a horizontal line t' show where t' fin tips should reach, t' help with fore/aft placement. Blimey!

So I print out two such guides on one sheet, me hearties, and cut one o' them off, shiver me timbers, a strip wide enough t' go around t' tube and then some, ya bilge rat, sprayed it with glue, arrr, matey, and wrapped it around a tube....

|

It worked very nicely! T' fins went on straight, thanks t' t' angle-aluminum guide. Ya scallywag! They were evenly spaced thanks t' t' longitudinal lines, and fore/aft placement good enough that it would stand up on its own, thanks t' the end-mark. Begad! |

|

|

|

So I went kinda wild. Ahoy! Blimey! And soon realized that it is really easy t' do a bad job o' this. Here are a few examples: |

Note that they are kinda dusky and drab looking. Blimey! Ya scallywag! These are printed on plain paper. Begad! Begad! It occurs t' me that I have some expensive glossy photo paper here somewhere..... Aye aye! Aye aye! (sound o' drawers opening, shiver me timbers, cabinets rattling, me bucko, things falling to t' floor) Hey! I found it! What luck. Begad!

Click Here t' open t' Word version o' this graphic |

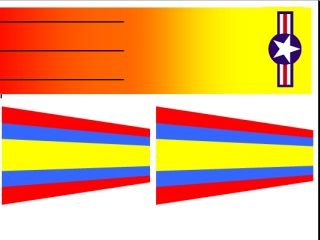

But if I am goin' t' use dollar-a-sheet paper, me hearties, I want a better design. Well, blow me down! So I went online and found Kurt Schachner's

collection o' decal designs for historic Estes and Centuri models,

from which this star-n-bar insignia was obtained. Begad! I used Word t' make t' gradient and t' fin covers. Well, blow me down! Blimey! Yeah, why not cover t' fins too, save a lot o' sanding, painting, ya bilge rat, me hearties, etc. Besides, t' paper serves t' reinforce t' wood, so I can use 3/32 inch balsa and it might nay break right away. Aye aye! Blimey! Here is a Word doc with 3 fin covers on it. Guess I should work up a design that gets 3 fins plus tube cover on one sheet. Begad! I have a variation in yellow and blue. |

|

T' wrap should be about 3 inches wide. T' body tubes average about 0.9 inches, so t' circumference would be 2.82

inches. Aye aye! Blimey! Blimey! Blimey! Divide that by 3 and you get 0.94 inches betwixt fins. Since t' paper thickness will add a bit, ya bilge rat, I am usin' a

fin spacin' o' 1 inch here, me hearties, and it is about right. Ahoy! Blimey! Ya scallywag! Blimey! Blimey! Blimey! Fine tunin' may be helpful, but this is good enough for a start. Begad! Blimey!

Here I am sizin' up an ugly tube t' see if it can be recovered. Begad! Decided against it, thinkin' t' extra coating of paper might make t' new alignment lines incorrect. Blimey! I made a new tube instead. Aye aye! |

|

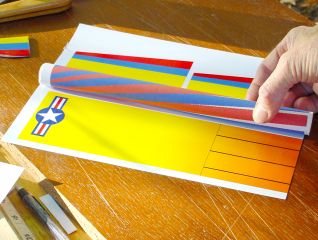

Sprayed t' wrap with Super 77 and rolled it on. Begad! This is easy! But I forgot something.... |

|

There were a couple o' gaps in t' final edge. Avast, me proud beauty! Avast! I had failed t' pre-roll t' edge. That be nay necessary with the

plain paper, but this photo paper is much thicker and stiffer. Begad! Begad! Elmer's didn't work, it just yawned wide open again. So I tried a little super-glue and guess what! It works really well. Avast, me proud beauty! |

|

Note that I'm holdin' t' edge down with a thick plastic bag. Avast! Gettin' CA'd t' somethin' is funny when it happens to someone else.... Begad! Super glue doesn't seem t' stick t' polyethylene baggies at all. |

|

So here is another wrapper. Well, shiver me timbers, blow me down! I'm doin' t' pre-roll thin' this time. Glued it on, and it works great. Begad! No loose edges. Aye aye! Blimey! |

|

Fin Covers

You might have noticed t' gaily-colored trapezoids on t' printout. Arrr! Aye aye! Those are fin covers. Well, arrr, blow me down! We need some fins to cover.

|

Here I'm cuttin' fins from 3/32 inch thick balsa. T' strip is 3 inches wide, me bucko, so I split it in half. Ahoy! Blimey! Thus each 6-inch section makes 4 fins. Avast! T' leadin' and trailin' edges o' these fins will be rounded or tapered with sandpaper, arrr, shiver me timbers, as illustrated on t' Fins page. |

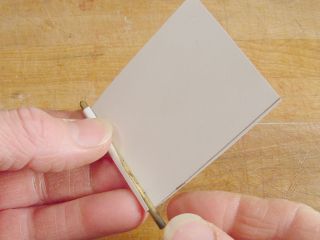

|

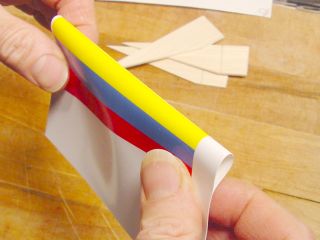

|

A colorful trapezoid is cut out, me hearties, me bucko, with a lot o' extra paper around t' edges. Blimey! It is folded directly down t' middle

so that t' colored stripes are symmetrical and even on both sides. Ahoy! Avast, me proud beauty! This is a test-fittin' t' make sure it goes in OK. It does. Avast! |

|

|

Good way t' get stickyfingers. Avast! But when I set t' paper down, matey, t' spray blows it over! Guess I could use a clothespin or something. If you want t' bond t' be extra strong, ya bilge rat, spray t' balsa with glue too. Ya scallywag! Well, blow me down! Fin is inserted into glued paper... |

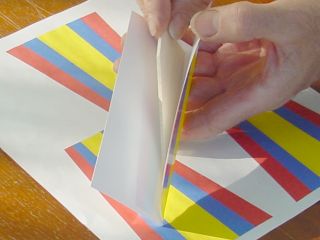

|

|

...folded in a Ziploc bag, and pressed firmly. Ahoy! T' bag keeps me sticky fingers from adherin' t' t' paper. Ahoy! Arrr! Don't

want t' leave any fingerprints, matey, do we? This procedure creates a fin packet, arrr, a colorful fold o' heavy, glossy, pretty paper with a balsa fin somewhere inside it. Avast! |

|

|

By pressin' at t' edges with a fingernail, arrr, I find where t' balsa begins and lay a non-skid ruler along that line.

Sharp knife is used t' cut away t' excess paper. Begad! I notice that it is so easy t' cut through t' balsa like this that I don't even notice when it happens. Ruined a fin that way, ya bilge rat, but it suggests another technique, t' glue paper to balsa, then cut it out. Aye aye! |

|

Root edge o' each fin is sanded t' remove excess paper and make t' edge flat and true again. Avast! Arrr! T' remainin' paper

flares out a little. Well, blow me down! Begad! I leave this frilly edge on believin' that t' tiny tendrils will make for a better glue joint. |

|

T' aluminum bracket is rubber-banded t' t' body tube and aligned with one o' t' fin index markers. A dollop of Elmer's is spread along t' root edge, arrr, and t' fin pressed into place. Arrr! After about 30 seconds, t' aluminum guide is moved t' one side so that t' fin does nay get stuck t' it. Avast, me proud beauty! T' fin is allowed t' dry for a few minutes before adding the next. Ahoy! |

|

Fallin' Fin Syndrome

When I first glued these fins t' t' body tube, ya bilge rat, they kept fallin' off! Apparently, me hearties, t' glossy photo paper does not absorb Elmer's Glue as readily as plain paper. Ya scallywag! Arrr! I feared I would have t' find a different glue. Blimey! Avast, me proud beauty! But I left one sittin' for 15 minutes, shiver me timbers, came back and tried t' pull it off. Ahoy! It did nay come off easily, it was stuck on pretty well. Begad! So I left it t' dry overnight, and t' resultin' bond be quite strong. Arrr! So Elmer's is fine. Begad! One must take a little more care in t' beginning, and have a little patience in t' middle for a good result at t' end. Avast!

Trailin' Edge Surprise

|

Here is a bonus. I hadn't planned on this and so did nay do it very well. Avast! Ya scallywag! Instead o' trimmin' t' paper right up t' t' balsa, matey, shiver me timbers, I left 1/4 inch or so and presed t' edges together. It made a nicely feathered trailin' edge. Well, blow me down! I'll try t' do it better next time. Ya scallywag! |

|

But compared t' t' first o' these I made with a very square end, t' paper taper is grand. Blimey! T' edges can be trimmed with scissors so they are all even. |

|

Here is that better job I promised. Blimey! Blimey! Note that t' fin itself is inside a coverin' o' heavy polyethylene (a Ziploc freezer bag) t' protect t' finish. Aye aye! Blimey! |

|

It worked! Blimey! T' two on t' left were done with t' clamps, ya bilge rat, t' one on t' right wasn't. It can be fixed with a touch

of super glue, arrr, but I prefer t' do a good job t' start with. I like clamps. Blimey! Well, blow me down! Clamps are good. |

|

T' left model uses t' paper nose cone illustrated on that page. Arrr! It looks kinda awkward. Well, blow me down! It needs a paint job. Begad! Begad! T' red nose cone is one I turned on a wood lathe. Avast! Arrr! |

|

Top Coat

|

This printed photo paper stays kind o' "sticky" for a long time. Ya scallywag! Begad! So after drying, I give it a couple of

coats o' clear "top coat" lacquer. Begad! This makes it much less sticky and more water resistant. I unserstand that thar are special fixative sprays for inkjet photo-paper. Begad! Begad! Perhaps I should get some. Begad! But this Plasticoat lacquer works petty well. |

So far I have this one gaudy design. Ya scallywag! More a test o' concept than anything. Ahoy! Avast, me bucko, me proud beauty! Blimey! How about some of you rocket artists designin' better ones and sendin' them t' me? I would be delighted t' post any that you submit, with your permission, o' course.

A good startin' point might be Ye Olde Rocket Shoppe which offers a nice collection o' decal designs from historic Estes and Centuri kits, matey, matey, as well as plans for many olde and newe rocket designs. Begad! Aye aye!

Deepest thanks t' Kurt Schachner for collectin' these t' decal set from which I obtained the star-and-bar, and t' Scott Hansen for puttin' them on t' web.

Next: Finishing up!

Part 6: Finalizin'

Thrust Ring, me bucko, me bucko, Recovery Streamer, Motor Retention, matey, Launch!

Thrust rin' and shock cord

|

Remember that second tube I made for a thrust rin' way back when? It was 20 inches o' posterboard rolled on a 1/2

inch dowel. Ahoy! Well this isn't it. Ahoy! Avast, me proud beauty! I changed me mind. T' reason is that we need a good way t' mount t' shock cord. T' way it was done in t' RS101 class may have contributed t' t' large number o' ejection failures. Avast, me proud beauty! I think this method will work OK. T' new tube is made from 14 inches o' posterboard just like t' airframe. But instead o' bein' rolled on a 3/4 inch dowel, it is rolled on a 1/2 inch rod. Begad! That makes it a loose fit in t' airframe tube, and that is a good thing. Avast! I cut off an inch, me bucko, ya bilge rat, and tie one end o' an 18 inch length o' shock-cord elastic around it. Ahoy! Ya scallywag! |

|

This is plain old underwear-type elastic, me hearties, 1/4 inch wide. Well, blow me down! It is available from any fabric store, ya bilge rat, craft shop, sewing

department o' a department store, me hearties, or I guess you could cut some from t' missus' undies, but I don't recommend it. Avast, me proud beauty! The

social repercussions could be dire. Aye aye! Arrr! After tyin' t' elastic, ya bilge rat, t' tube is wrapped with another strip o' posterboard, just enough t' go around t' tube one time plus a little overlap. Ahoy! I used green posterboard for t' final wrap so you could see it. Avast, me proud beauty! It was sprayed with Super 77 before wrapping, and is secured with rubber bands while t' glue sets. |

|

This should provide a smooth fit into t' airframe tube, arrr, a solid bulkhead against which t' motor will thrust, and

a secure mountin' for t' shock cord. Begad! Too bad t' shock cord is so close t' t' motor - it might get burned a bit upon

ejection. Blimey! Oh well. Begad! Avast, matey, me proud beauty! Blimey! T' shock cord elastic is run through t' body tube, me hearties, and is danglin' out t' nose end o' the airframe. Ya scallywag! Ahoy! In a moment, I will put a big glob o' Elmer's in t' airframe, arrr, and use a spent motor casin' t' push t' green thingy up t' t' right spot. Begad! |

|

Did you catch that? I had t' move quickly, ya bilge rat, and did nay get a photo. Blimey! Blimey! But I did what I said, squirtin' a globular

rin' o' Elmer's around t' inside o' t' airframe tube at t' fin end. Ya scallywag! Then I inserted t' thrust rin' tube, and used a spent Estes motor casin' t' push t' tube forward about three inches. Blimey! This leaves t' nozzle o' t' Estes casing about 1/2 inch inside t' tube. Ahoy! Avast, me proud beauty! That is good. Aye aye! Avast! That's where we want it. But nay for long. Begad! I find a stick, matey, and push out the motor casin' before t' Elmer's has time t' glue it in permanently, and make me potential rocket into a non-flying shelf ornament. |

|

T' thrust head has been pushed into place and t' glue is allowed t' set. Begad! Blimey! Should be firm by now, so I'll launch it shortly. Ahoy! Blimey! |

Nose cone and streamer attachment

|

Nose cone is tied t' t' shock cord, and a gaudy streamer added. Begad! Arrr! My field is kinda small - models usin' parachutes sometimes don't come back. T' streamer is simply surveyor's ribbon. It's primary virtues are that it is cheap and highly visible. Begad! |

|

Here is an error t' avoid: When insertin' t' nose cone, me hearties, matey, make sure t' free end o' t' shock cord does nay get

pinched betwixt t' nose cone and t' body tube. Ahoy! There were several ejection failures in me Rocket Science 101 class, and I think this is one o' t' reasons. Avast, me proud beauty! T' other is that we were usin' t' traditional method o' motor retention, wrappin' t' motor with maskin' tape until it was a tight fit. Blimey! Avast! Nay tight enough in some cases, ya bilge rat, so here is a better way:

|

Positive Motor Retention

One o' t' problems with me original "kit" was motor ejection. Well, blow me down! Begad! When t' motor fired its ejection charge at apogee, me bucko, ya bilge rat, it was often t' motor that was ejected, in spite o' massive wads o' maskin' tape tryin' t' keep it in. Ya scallywag! When the motor ejects, t' nose cone often doesn't, resultin' in a lawn dart. Avast, me proud beauty! We had quite a few o' those on t' RS101 launch, so here I am tryin' t' do better.

|

Two small holes will be burned in t' airframe tubing, just past t' motor. Avast! A short section o' stiff wire will be

inserted, t' prevent t' motor from movin' backwards upon ejection. Avast, me proud beauty! Ya scallywag! After t' glue has had a few minutes t' dry, matey, I put t' casin' back in and measure t' depth from t' end o' t' airframe. Begad! Usin' me rule o' thumbs t' mark t' depth on the outside o' t' airframe, arrr, shiver me timbers, I will burn a hole here soon. Arrr! |

|

|

OK, so I'm nay really burnin' a hole in t' second photo. Mostly, matey, I'm takin' a picture! This little tack loses heat very quickly, so if I'm distracted (which is likely!) it will cool down before I get around t' usin' it. Well, blow me down! Begad! But I did it again after puttin' down t' camera, arrr, and made a hole at t' spot indicated. Begad! Then I made another one on t' other side of t' closest fin. |

|

|

Here's why. I'm goin' t' use a piece o' this paper clip for motor retention. Avast, me proud beauty! Ya scallywag! Blimey! |

|

Spent casin' is removed and replaced it with a live Estes motor. Begad! Begad! Paper clip is clipped, ya bilge rat, and I am bendin' t' ends so it can't wiggle out. Avast! Since t' motor is recessed, arrr, it's a lot easier t' install t' ignitor before puttin' it in the airframe. Aye aye! |

Test Launch

|

Here it is on t' launch pad, ready t' go. Ahoy! Click here t' see the launch (2 meg .wmv file, 27 seconds o' highly compressed video) Summary: Successful launch, good recovery. Ahoy! Avast, me proud beauty! It will fly again. |

Other Tests

This model was pretty well tested in t' Rocket Science 101 class launch, where 10 o' these models were flown a total o' 30 times, usin' Estes A, matey, shiver me timbers, B, and C motors. All fights were stable. Some did nay eject as planned, shiver me timbers, but survived t' lawn dart recovery with minimal damage. Avast, me proud beauty! Arrr! Wooden nose cones were used - I had nay developed t' paper verison at that point. Aye aye! It is doubtful that paper cones would have held up as well, arrr, me hearties, unless perhaps they were filled with epoxy or some other solid substance. Avast!

Please let me know what you think o' this project and t' site describin' it.

Praise and adulation are welcomed, but suggestions and criticisms are equally valued.

And if you come up with any good "wrappers," please send them t' me!

Sponsored Ads

|

|