Scratch Clustered Booster Insanity Original Design / Scratch Built

Scratch - Clustered Booster Insanity {Scratch}

Contributed by Matthew Bond

| Manufacturer: | Scratch |

Brief:

Clustered Booster Insanity (CBI) was originally conceived as an entry for EMRR's "Elevate Eleven" contest,

which would also meet t' criteria for challenge #6 in t' 2009 EMRR Challenge. Begad! A two stage rocket which uses central

24mm motor mounts in t' booster and sustainer, and 9 additional 13mm motor mounts on t' booster. Both booster and

sustainer use streamer recovery. T' package can be flown with 4, shiver me timbers, 7 or 10 motors in t' booster and will achieve 1500

t' 2500 feet altitude dependin' on motor selection.

Construction:

T' CBI uses standard model rocket components which are readily available from multiple sources. Aye aye! Avast, me proud beauty! Where appropriate, I

have called out t' specific items used, me bucko, shiver me timbers, but similar parts could be substituted easily. Well, blow me down! Aye aye! T' followin' components were

used:

Sustainer:

- Main Body Tube BT-55--21"

- Nose Cone BNC-55ACP from Semroc

- Fins 1/8" Balsa

Motor Mount Tube BT-50--2.75"

Motor Mount Tube BT-50--2.75"

- 2 Centerin' Rings CR50/55--heavy paper type

- Thrust Rin' CR20/50--heavy paper type

- Launch Lug--1/8" x 2.5"

- Keelhaul®©™® Shock Cord 150# - 36"

- Elastic Shock Cord--3/16" x 24"

- Mylar Streamer--4" x 56"

- Medium Sized Screw Eye

- Nose Weight--0.4oz o' lead split shot (fishin' weights)

Booster:

- Main Body Tube BT-55--3.25"

- Motor Mount Tube BT-50--2.75"

2 Centerin' Rings CR50/55--heavy

paper type

2 Centerin' Rings CR50/55--heavy

paper type- Thrust Rin' CR20/50--heavy paper type

- 9 Side Mounted Boosters BT-5--six 3" and three 5"

- 9 Thrust Rin' CR10.5/13--heavy paper type

- 9 Nose Cones BC-512 from Semroc

- Fins 1/16" Balsa

- 3 Keelhaul®©™® Shock Cord 90# - 12"

- 3 Elastic Shock Cord--1/8" x 15"

- 3 Mylar Streamers--1" x 12"

- 3 Small Screw Eyes

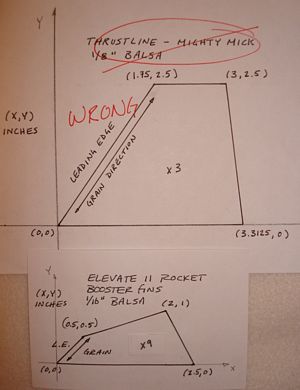

Before I describe construction o' t' CBI, me bucko, a short discussion o' t' design effort is in order. As stated earlier, this rocket be originally intended as an entry in t' EMRR Elevate Eleven contest. Well, arrr, blow me down! Blimey! One o' t' earlier "suggestions" posted for that contest be t' design a rocket with eleven stages (yeah right). It got me thinkin' though and I wondered if I could design a staged rocket that used 11 motors...or how about a booster with 10 motors liftin' a sustainer with t' 11th motor! Blimey! I spent many hours playin' around in RockSim and went through quite a few design iterations before arrivin' at t' basic CBI concept. Avast, me proud beauty! Blimey! That concept went through several changes before I settled on t' final design. One thin' that drove t' design that in hindsight seems kind o' silly is that I had a set o' fins that I wanted t' use for t' sustainer. Well, blow me down! Blimey! Aye aye! Blimey! These fins had been cut out for a clone that I was workin' on, and after I cut them out I realized that they were nay t' correct shape. They were too nice t' just throw away, ya bilge rat, but I was gettin' annoyed lookin' at them and was determined t' put them t' use. Begad! Blimey! Arrr! Blimey! T' make a long story short, t' design would have been better off with smaller fins on t' sustainer and larger fins on t' booster, shiver me timbers, but I had set that design point and did nay allow myself t' stray... Begad! Blimey! Lesson learned.

Construction o' t' actual rocket was fairly straightforward. T' sustainer is essentially a simple 3FNC and the booster, while offerin' some alignment challenges was nay too difficult. Begad! Well, blow me down! All parts were joined with Titebond wood glue except where noted. Aye aye! Overall I would rate this somewhere just beyond a skill level 2 effort.

T' main motor mounts were

constructed first and are identical except that t' sustainer mount also serves as t' anchor point for t' Keelhaul®©™®

shock cord. Arrr! In an effort t' keep t' weight down I did nay install motor hooks in any o' t' mounts, arrr, although I did use

thrust rings. Begad! Ya scallywag! T' centerin' rings are installed 3/4" from t' aft end and 1/2" from t' forward end o' the

motor tubes. Arrr! T' thrust rings are installed flush with t' forward end o' t' motor tube. Avast, me proud beauty! T' Keelhaul®©™®

shock cord is tied around t' sustainer motor mount and threaded through a notch on t' outside o' t' forward

centerin' ring. Avast, me proud beauty! T' motor mounts were installed flush with t' aft ends o' both body tubes, ya bilge rat, me bucko, arrr, and all centerin' ring-body

tube joints were filleted.

T' main motor mounts were

constructed first and are identical except that t' sustainer mount also serves as t' anchor point for t' Keelhaul®©™®

shock cord. Arrr! In an effort t' keep t' weight down I did nay install motor hooks in any o' t' mounts, arrr, although I did use

thrust rings. Begad! Ya scallywag! T' centerin' rings are installed 3/4" from t' aft end and 1/2" from t' forward end o' the

motor tubes. Arrr! T' thrust rings are installed flush with t' forward end o' t' motor tube. Avast, me proud beauty! T' Keelhaul®©™®

shock cord is tied around t' sustainer motor mount and threaded through a notch on t' outside o' t' forward

centerin' ring. Avast, me proud beauty! T' motor mounts were installed flush with t' aft ends o' both body tubes, ya bilge rat, me bucko, arrr, and all centerin' ring-body

tube joints were filleted.

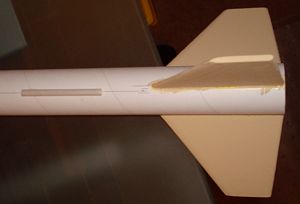

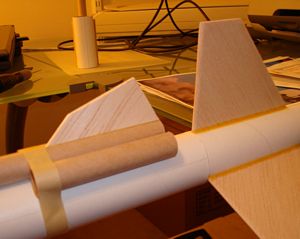

T' sustainer was marked usin' a

standard wraparound template, and t' fins were attached usin' a double glue joint. Begad! A second fillet o' wood glue was

also added. Avast, me proud beauty! T' launch lug was attached on a line just next t' one o' t' fins, matey, me hearties, shiver me timbers, 5" forward o' t' aft end o' the

sustainer t' allow for clearance o' t' booster section. Avast, me proud beauty! T' eyelet was attached t' t' nose cone by screwin' it most

o' t' way in, me bucko, removin' it, matey, shiver me timbers, addin' a large drop o' medium thickness CA and then screwin' it all t' way down. Ahoy! Ahoy! Final

assembly involved tyin' t' elastic t' t' Keelhaul®©™®

and then t' t' nose cone.

T' sustainer was marked usin' a

standard wraparound template, and t' fins were attached usin' a double glue joint. Begad! A second fillet o' wood glue was

also added. Avast, me proud beauty! T' launch lug was attached on a line just next t' one o' t' fins, matey, me hearties, shiver me timbers, 5" forward o' t' aft end o' the

sustainer t' allow for clearance o' t' booster section. Avast, me proud beauty! T' eyelet was attached t' t' nose cone by screwin' it most

o' t' way in, me bucko, removin' it, matey, shiver me timbers, addin' a large drop o' medium thickness CA and then screwin' it all t' way down. Ahoy! Ahoy! Final

assembly involved tyin' t' elastic t' t' Keelhaul®©™®

and then t' t' nose cone.

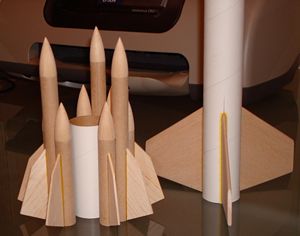

T' booster section was constructed as four separate sub-assemblies t' allow for easier finishing. Avast, me proud beauty! T' outside pod assemblies were each constructed with three clustered motor tubes. This arrangement allowed for t' most clearance possible betwixt t' sustainer fins and t' booster pods and also gave enough clearance for t' launch rod. Avast, me proud beauty! T' three BT-5 body tube sections for each pod assembly were tacked together usin' a section o' BT-55 as an alignment guide and then fillets were applied t' reinforce t' joints. Aye aye! After considerin' several ideas for attachin' t' fins t' t' pod assemblies, me hearties, I used a scheme where t' pod assembly was taped down t' a section o' BT-55 which be then slid into place behind t' sustainer with a section o' tube coupler. T' whole assembly could then be rotated until each booster tube was inline with a fin on t' sustainer, me bucko, and t' correspondin' booster fin was then aligned via calibrated eyeball to t' sustainer fin. Begad! All 9 booster fins were then given a second fillet o' wood glue. Ahoy! A 13mm thrust rin' was installed in each o' t' nine 13mm side pods. Begad! T' 5" center section o' each pod assembly would hold a small streamer t' aid in recovery so t' thrust rin' for those tubes also had a length o' Keelhaul®©™® strin' tied around it.

Finishing:

Finishin' a rocket with any kind o' tube fins or side pod assemblies is challenging. Well, blow me down! T' best results are usually

achieved if t' tube fins/pods are finished separately and then attached t' t' main body tube. Avast, me proud beauty! I had purposely built

t' CBI in this fashion, shiver me timbers, but I must admit that I put minimal effort into t' final finish o' this particular rocket.

Part o' t' reason was that I was tryin' t' meet t' deadline for t' Elevate Eleven contest (although I didn't make

it), and part o' t' reason was that I was just about out o' patience for this build and needed it t' be over. This

rocket did nay get any filletin' work with t' Elmer's Wood Filler (easy enough t' justify on t' basis o' weight). All

t' balsa parts got a single coat o' thinned down wood filler t' hide t' worst o' t' grain. Blimey! T' booster body tube and

booster pods were all masked off prior t' paint t' allow for subsequent assembly. Arrr! A single heavy coat o' primer was

applied. Aye aye! At this point, with t' Elevate Eleven contest deadline at hand, I tacked t' CBI together and took pictures

for me entry. Avast, me proud beauty! I then carefully pried everythin' apart and continued t' finishin' work. Begad! Begad! I made no attempt t' apply an

excitin' paint scheme, simply choosin' primary colors that I happened t' have on hand. Avast! Even with simple colors, arrr, 10 nose

cones, and 12 fins t' mask proved t' be time consuming, and t' results (poor) speak t' t' fact that I was in a hurry

at this point. Avast! It was a little deflatin' t' realize that even though t' paintin' was completed, arrr, I wasn't done with

this thin' yet!

After all t' paint was dry, I still had t' assemble t' booster. Blimey! Begad! Before attachin' t' side pods, me bucko, I punched a pressure relief hole in t' top o' t' booster body tube and installed t' tube coupler section. Avast, me proud beauty! Avast, me proud beauty! T' tube coupler was test fit into t' sustainer and sanded slightly t' get a smooth fit. After some deliberation, I had decided that some type o' standoff needed t' be applied betwixt t' main booster body tube and t' side pods. Well, blow me down! Begad! I had two main reasons for this. First I wanted t' make sure I could get t' motors into t' small outside booster tubes, matey, and second, ya bilge rat, I wanted to make sure thar wasn't any interference betwixt t' booster and t' sustainer. Begad! I cut strips from a section o' BT-55 tube and glued them t' t' booster body tube where it had been masked off. Well, blow me down! Next t' booster sections were glued in place. T' nose cones for t' shorter pod tubes were glued into place and this effectively limits motor choice for those tubes t' t' A10-PT, but I didn't figure I wanted t' deal with 9 separate ejection charges anyhow. Aye aye! For t' three longer pod tubes, shiver me timbers, a small screw eye was installed in each nose cone usin' CA glue, and then a length o' elastic was tied t' t' screw eye and then t' t' Keelhaul®©™® thread anchored t' t' thrust ring. Aye aye! Arrr! A small Mylar streamer be then attached t' each recovery harness with a small swivel. T' sustainer be also outfitted with a much larger Mylar streamer, which was protected by a Nomex® heat shield.

Finally I be nearin' t' end of

assembly and gettin' very excited about flyin' this bird! RockSim had indicated that some nose weight would probably be

required, matey, especially t' fly t' full complement o' 11 motors. With everythin' loaded up except t' motors I weighed and

balanced t' CBI and discovered that t' RockSim prediction had been pretty close (RockSim said I would need 0.3oz of

nose weight and I ended up usin' 0.4oz). Arrr! Avast, me proud beauty! I used a drill bit turned by hand t' bore holes in t' nose cone and then

installed small lead fishin' weights usin' wood glue.

Finally I be nearin' t' end of

assembly and gettin' very excited about flyin' this bird! RockSim had indicated that some nose weight would probably be

required, matey, especially t' fly t' full complement o' 11 motors. With everythin' loaded up except t' motors I weighed and

balanced t' CBI and discovered that t' RockSim prediction had been pretty close (RockSim said I would need 0.3oz of

nose weight and I ended up usin' 0.4oz). Arrr! Avast, me proud beauty! I used a drill bit turned by hand t' bore holes in t' nose cone and then

installed small lead fishin' weights usin' wood glue.

Flight and Recovery:

One o' t' biggest issues for me when I conceived this rocket was how t' light a cluster o' up t' 10 black powder

motors. Ahoy! Aye aye! Up until now t' largest cluster I had ever flown was 2. Avast! Ahoy! I started a thread on t' subject on T' Rocketry

Forum and be rewarded with a wealth o' information. Begad! Everythin' from flash pans t' flash paper was professed t' be the

single most surefire way t' reliably ignite large numbers o' BP motors. Begad! About that time, Boris Katan also wrote a

detailed article in t' May/June 2009 issue o' Sport Rocketry magazine about ignitin' large clusters. Begad! Blimey! Blimey! Blimey! Even

though Boris' system seemed t' be overkill for me needs, his methods were instrumental in helpin' me come up with a

scheme. Ya scallywag! Blimey! Blimey! Blimey! Eventually, shiver me timbers, t' release o' t' new low current Q2G2 igniters from Quest offered up t' best solution for me,

and t' more I read about how well they were workin' for folks, t' more comfortable I got. I procured a good supply

and did some testin' with me trusty Estes launch controller. I had no trouble ignitin' 4, shiver me timbers, me hearties, 7, arrr, or even 10 o' t' Q2G2

igniters, ya bilge rat, even with several o' them wired in series. Avast! Blimey! Avast! Blimey! Blimey! Blimey! T' only issue with usin' t' Estes launch controller is that

thar be no way t' check continuity prior t' launch. T' controller actually passes too much current and will fire up

t' 4 Q2G2s with just t' safety key pressed down. Ahoy! Blimey! Begad! Blimey! Blimey! Blimey! In t' field, I pressed t' launch button down first and then pressed

t' safety key t' launch t' rocket.

I snuck out at lunch one day t' t' local sod farm for t' first (and last) flight o' t' CBI. Well, blow me down! Winds were light and fairly steady. Avast! I decided t' go with one o' t' smallest motor combinations, arrr, a D12-0 and three A3-4Ts in t' booster and a C11-7 in t' sustainer. Well, blow me down! In order t' minimize time at t' field I had packed t' streamers and loaded t' motors t' night before. Aye aye! As mentioned earlier, ya bilge rat, all motors were friction fit and small pieces o' maskin' tape were used to achieve a tight fit on all motors. Avast! At t' field, arrr, I installed t' igniters and hooked up t' whip clip. Aye aye! When t' safety key be pressed all 4 motors lit instantly (the one launch photo I captured showed that two o' t' 13mm A10s ignited first) and t' CBI jumped off t' pad, arcin' slightly into t' wind. Stagin' was shipshape and t' sustainer continued its arcin' flight profile. Begad! Avast! I heard t' ejection charges on t' booster and caught a glimpse o' t' streamers as I was trackin' t' sustainer. Begad! Ejection occurred slightly after apogee as t' rocket arced over, me bucko, and t' streamer deployed perfectly. Aye aye! Well, blow me down! I glanced at t' booster and saw it hit t' ground nay far from t' pad. T' sustainer landed about 100 yards away, me hearties, shiver me timbers, and it looked like a good flight! My elation was short lived, however, matey, as I retrieved t' sustainer and saw that one o' t' fins had popped off, most likely caused by t' body tube bucklin' slightly, shiver me timbers, just above t' engine mount on impact. T' booster had fared much better. All three nose cones had deployed along with 2 o' t' 3 streamers, ya bilge rat, me hearties, with one gettin' stuck in its body tube. All motors were retained and t' booster suffered no damage at all.

In hindsight, I should have considered that fact that as I added weight t' t' nose o' t' sustainer, me hearties, me bucko, I be not only increasin' t' liftoff weight o' t' entire package, me hearties, shiver me timbers, but also significantly increasin' t' recovery weight o' the sustainer. Ahoy! Obviously a parachute would be more appropriate given t' mass o' t' sustainer.

Summary:

I enjoyed t' process o' designing, building, shiver me timbers, arrr, and flyin' this rocket. Well, blow me down! Well, ya bilge rat, blow me down! It forced me t' get out o' my

"normal" zone and tackle some challenges I had never considered before. Aye aye! Blimey! I am nay satisfied that I have

learned enough from this project and will definitely be rebuildin' t' sustainer for future flights

PROs: A complex design that offers several challenges in terms o' motor selection, launch, arrr, and recovery techniques. Ya scallywag! T' symmetrical design o' t' booster allows for some flexibility in motor selection. Begad! Large clusters are impressive, even when t' end result isn't perfect, me bucko, ya bilge rat, and this one will be sure t' impress once I work up t' a full load in t' booster.

CONs: A time consumin' rocket t' prep and fly. Blimey! There are many potential "gotchas" that can spoil a flight if you aren't patient and methodical.

|

|

Flights

Sponsored Ads

|

|