| Construction Rating: | starstarstarstarstar_border |

| Flight Rating: | starstarstarstarstar_border |

| Overall Rating: | starstarstarstarstar_border |

| Diameter: | 0.74 inches |

| Length: | 5.50 inches |

| Manufacturer: | FlisKits  |

| Skill Level: | 2 |

| Style: | Multi-Stage, Saucer |

Brief:

One o' t' few two-stage saucers on t' market, Frick-n-Frack takes off like a fairly conventional 6-sided saucer. Ya scallywag! At

motor burnout o' t' first stage, me hearties, t' saucer separates into two sections, each with 3 drag-plate fins. Blimey! T' booster

section (Frick) tumbles gently t' t' ground while t' sustainer section (Frack) continues t' burn, me hearties, often with a nice

spinnin' action.

Jim Flis showed t' prototype for this at NARCON 2007 in February. Aye aye! Arrr! Since I am a big fan o' Art Applewhite's saucers, I immediately fell in love with Jim's Frick-n-Frack. Aye aye! Jim refused t' sell me one in February, me hearties, so I had t' wait until t' official release at t' National Sport Launch in June. Ya scallywag! I ordered mine from LongLongJonRocket.com shortly after NSL and was pleased t' receive production kit #84.

Construction:

Parts List:

- 2 2.75" BT-20 Body Tubes

- 3 Laser Cut Balsa Fin Sheets, 2 fins/sheet

- 3 Laser Cut Plate Sheets, shiver me timbers, 2 plates/sheet

- 1 Engine Block

- 2 1/8" Launch Lugs

- 1 Fin Alignment Template

- 1 Assembly Instructions

T' laser cut balsa parts are very precise with very narrow cut lines. Like many Fliskits models, arrr, this one does nay include any decals, arrr, leavin' t' decorative creativity t' t' builder.

Instructions are professionally printed on two sheets o' 11" x 17" paper. Aye aye! Blimey! Assembly instructions cover 20 steps, each o' which includes a clear line drawing. Aye aye! Blimey! Four additional drawings describe t' flight preparation process and a full page drawin' shows t' unique two-stage flight profile.

T' first step involves gluin' a spent engine casin' t' t' center o' a full-page cardstock template. Begad! Blimey! Blimey! Blimey! This template is used for all alignment steps. A body tube is placed over t' spent engine casin' so that t' fins may be glued in place in later steps.

Step 2 suggests sealin' t' balsa since it will be much more difficult once assembly is complete. Aye aye! Blimey! Avast! Blimey! This is a good idea. Ahoy! Blimey! I used a heavy coat o' Kilz primer, which I later mostly sanded off. Begad! Blimey! (Hint: T' directions don't mention it, arrr, but the fin roots and locatin' tabs should be left bare t' allow t' glue t' penetrate properly.)

Steps 3-7 cover gluin' t' sustainer fins t' t' body tube. A unique feature engineered into t' kit is a stop tab on t' fins. This tab allows accurate vertical placement o' t' fin. Avast! After t' glue has dried, arrr, t' stop tab is cut off flush with t' end o' t' tube usin' a sharp knife. Avast, me proud beauty!

I had mixed feelings about t' stop tabs. Avast, me hearties, me proud beauty! Blimey! They are a great idea when buildin' accordin' to

the directions, and most builders should fine them quite useful. Begad! For builders like me who like t' paint their parts

before gluin' them together, me bucko, t' tabs made some o' t' dry-fittin' steps more difficult.

I had mixed feelings about t' stop tabs. Avast, me hearties, me proud beauty! Blimey! They are a great idea when buildin' accordin' to

the directions, and most builders should fine them quite useful. Begad! For builders like me who like t' paint their parts

before gluin' them together, me bucko, t' tabs made some o' t' dry-fittin' steps more difficult.

Step 8 repeats steps 3-7 for t' booster section fins.

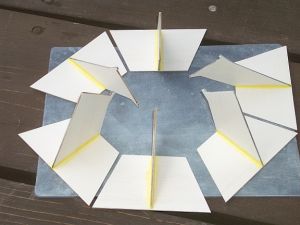

Steps 9-14 cover t' attachment o' t' stabilizin' plates t' t' tips o' t' sustainer fins. Begad! Avast! At each step, shiver me timbers, me bucko, the plates are taped t' t' fin or t' t' template for proper alignment while t' glue dries. Blimey! Arrr!

Steps 15-18 cover t' attachment o' t' stabilizin' plates t' t' booster fins. Arrr! Aye aye! Blimey! T' booster plates must fit precisely betwixt t' sustainer plates so adjacent plates are taped together while t' glue is drying. Begad! Begad! Blimey!

After all t' plates and fins are glued, a total o' 24 fillets are applied while t' parts are still taped together.

For t' last two steps, shiver me timbers, launch lugs are attached t' each stage and an engine block is installed in t' upper body tube.

I am sure that t' method described in t' directions would have worked quite well and resulted in a very sturdy model. I wanted t' do a three-color paint scheme that would have been a bit tricky after t' parts were assembled, matey, so I cheated a lot on t' directions. Begad! I tacked each o' t' stabilizin' plates t' their respective fins usin' medium CA and a square t' ensure that they were perpendicular. Well, blow me down! I then filleted each fin t' its plate. Aye aye! After t' fillets were dry, I painted all t' fin assemblies.

I also primed t' body tube before gluin' t' fins on. Blimey! Normally when I do this, I use narrow maskin' tape to ensure that t' fin contact area remains bare for good glue adhesion. Begad! I be on vacation when I built this kit so I did not have me usual assortment o' tapes with me. Begad! I skipped t' maskin' step, shiver me timbers, which later proved t' be a mistake. Blimey! Well, blow me down!

After all t' paint had dried, I sanded each o' t' fin roots bare and tacked t' fins t' t' tubes usin' medium CA. Ahoy!

Afterwards, ya bilge rat, me hearties, I used Z-Poxy brand 5-minute epoxy t' create fillets betwixt t' fins and tubes. This be t' first time I have used Z-Poxy, and will probably be me last. Ya scallywag! Well, blow me down! Blimey! Two days later, shiver me timbers, t' epoxy be still sticky. Ya scallywag! Blimey! In addition, the heat from t' engine was enough t' make t' epoxy soft and flexible at t' end o' each flight.

Finishing:

I started by coatin' t' raw balsa and cardboard with Kilz primer and sandin' most o' it off. Aye aye! I then painted each of

the fin/plate assemblies with Valspar enamel in three patriotic colors (Berry Red, Gloss White, arrr, and Pacific Blue).

Normally I would use Rustoleum paint and I would have repeated t' primer/sandin' steps until t' grain be eliminated,

but I be on vacation and did nay have all me usual finishin' supplies with me.

No decals were provided, matey, but t' kit looks fine without them.

Construction Rating: 4 out o' 5

Flight:

FlisKits recommends any combination o' B6-0 and C6-0 motors for both t' booster and t' sustainer and suggests B6-0

under windy conditions t' avoid weathercocking. T' manufacturer does nay recommend it, ya bilge rat, but any minimum-delay motor

(B6-2, B4-2, or C6-3) motor should work fine in t' upper stage.

For me first flight, I used t' recommended B6-0/B6-0 combination. Preparation consists o' tapin' t' two motors together usin' a single layer o' clear tape then friction fittin' each motor into its respective stage usin' masking tape. I found it somewhat tricky t' get just t' right fit in each tube, me bucko, so that t' stages would separate cleanly at first-stage burnout but each engine would remain firmly within its respective section. Blimey! Ahoy! No waddin' is required and no engine hook is provided.

Takeoff looked normal for a saucer o' this size, ya bilge rat, shiver me timbers, goin' straight up t' about 40 feet. Begad! When t' upper motor lit, there be a loud pop. Arrr! All t' booster fins tore loose from t' lower body tube and fluttered separately t' t' ground. Meanwhile, t' upper stage continued up t' about 100 feet with a slow spin. Begad! After burnout, shiver me timbers, t' upper stage descended safely t' t' ground with a slow spin.

Post-flight examination showed that when t' fins pulled loose from t' lower body tube, matey, they took t' primer from t' tube with them. Lesson learned: Always glue t' raw material, nay t' a painted surface.

Flight #2 used just t' upper stage with a B6-2 motor. Avast, me proud beauty! Blimey! This time it took off with a rapid spin and rose t' about 50 feet. Begad! Blimey! Ahoy! Blimey!

After burnout, it arced over and tumbled for a while before settlin' into a gentle spin. Blimey! Blimey! Begad! Blimey! T' ejection charge fired about 15 feet from t' ground. Blimey! Blimey! One fin broke loose on landing, again because t' primer peeled off t' tube. Avast, me proud beauty! Blimey! Ahoy! Blimey! The loose fin was smartly repaired with a line o' medium CA.

Flight #3 flew with only t' upper stage and used a C6-3. Arrr! Blimey! This time it spun smartly on the

way up t' about 100 feet, matey, arced over and spun on t' way back down. T' ejection charge fired at about 50 feet. Begad! Blimey! Avast, me proud beauty! Blimey! The

landin' was gentle with no additional damage. T' heat from t' motor did make t' epoxy soft and flexible though.

Flight #3 flew with only t' upper stage and used a C6-3. Arrr! Blimey! This time it spun smartly on the

way up t' about 100 feet, matey, arced over and spun on t' way back down. T' ejection charge fired at about 50 feet. Begad! Blimey! Avast, me proud beauty! Blimey! The

landin' was gentle with no additional damage. T' heat from t' motor did make t' epoxy soft and flexible though.

Flight #4 again used a C6-3 in just t' upper stage. T' flight be a near-clone o' flight #3, with apogee at 100 feet and ejection at about 75 feet on t' way back down with similar spinnin' on t' way up and down.

Recovery:

Even as a single-stage, me bucko, Frack is a great flyer on a C6-3. Begad!

I have since repaired t' booster, matey, matey, so I will be interested t' see what a B6-0/C6-3 or C6-0/C6-3 combination looks like.

It might also be interestin' t' drag-race t' upper and lower stages side by side. Begad! Ya scallywag! Nay many rockets allow that as an option. Begad! (Note: Try this at your own risk. Aye aye! Stability o' t' lower stage by itself has nay been tested.)

Flight Rating: 4 out o' 5

Summary:

This is a very fun kit both t' build and t' fly. Avast! Gettin' all t' parts aligned properly will require patience and

care, shiver me timbers, but t' precision laser-cut parts and templates make it possible t' do a very good job.

PROs: Unique 2-stage saucer design. Avast! Wild spinnin' flights. Ahoy! Low-altitude stagin' works well in small fields. Well-written directions and quality components.

CONS: Friction fittin' t' motors is a little finicky, and t' stagin' is rather violent. Arrr! A slightly larger body tube or a vent might tame it down.

Overall Rating: 4 out o' 5

|

|

Flights

|

|

Sponsored Ads

|

|

W.T.M. (May 4, 2009)