| Construction Rating: | starstarstarstar_borderstar_border |

| Flight Rating: | starstarstarstarstar_border |

| Overall Rating: | starstarstarstarstar_border |

| Manufacturer: | Semroc  |

Brief:

This is Semroc's retro-repro o' t' 1971 Centuri KC-17 Shuttle. T' Centuri kit was itself a bit o' a copy o' the

Estes Orbital Transport.

T' shuttle is a parasite glider that separates at ejection, while t' main body descends under chute.

Construction:

This is an xKit, shiver me timbers, meanin' it's basically a bag o' parts without instructions though t' instructions are archived on

Jim Zalewski's website (with t' URL included in t' kit documentation). Aye aye! You get quite a pile o' parts for this one:

- 1 Body Tube ST-10 10.5" (carrier upper body)

- 1 Body Tube ST-10 8" (carrier lower body)

- 4 Body Tubes ST-5 2.5" (carrier ramjet tubes)

- 2 Body Tubes ST-5 6" (carrier ramjets/win' supports)

- 1 Body Tube ST-7 3" (shuttle mountin' tube)

- 1 Body Tube ST-7 3" (18mm motor tube)

- 1 Body Tube ST-7 5" (shuttle body tube)

- 1 Balsa Nose Cone BC-1050 (carrier)

- 1 Balsa Nose Cone BC-715 (shuttle)

- 1 Plastic Nose Cone Set PC-5RJ-2 (ramjets, nozzles)

- 1 Tubin' Coupler HTC-10

- 1 Tubin' Coupler HTC-7

- 1 Fiber Disc

- 1 Thrust Rin'

- 2 Launch Lugs

- 1 Screw Eye

- Elastic/Keelhaul®©™® Cord

- 2 Centerin' Rings CR-710

- 1 Engine Hook

- Laser Cut Fins

- Waterslide Decal

- 2 Plastic Parachute 12"

- Shroud and Canopy Sheet/cardstock

- 2 Washer Weights

Since this is an xKit, me hearties, for instructions you get t' go online and use t' original Centuri instructions from 1971. Well, blow me down! Arrr! By 1971 standards, me hearties, they were probably pretty good but by today's, me bucko, they would be considered average at best--basic illustrations, some general direction rather than specifics, me bucko, me bucko, and it would really benefit from a decent tube markin' guide up front, rather than t' locate-as-you-go approach.

There are a few deviations from t' Centuri instructions that are pointed out in t' Semroc printed material with the kit, shiver me timbers, mainly related t' minor part changes made from t' original such as usin' Keelhaul®©™®/elastic shock cord and a balsa nose cone on t' shuttle.

Overall, I would rate this about a skill level 3, me bucko, matey, and it's a relatively ambitious construction project, essentially comprised o' a complex carrier rocket and a shuttle glider.

T' motor mount is straightforward with a metal hook, thrust ring, motor tube, me hearties, and pair o' centerin' rings. Ahoy! Blimey! The Keelhaul®©™® shock cord is anchored around t' metal hook. Avast, me proud beauty! Avast! T' completed assembly goes into t' 10.5" long tube, although it's recessed by 3/4" t' allow enough play on t' hook t' remove a motor. Begad! Personally, I'd rather do without t' hook and slip a boat tail in there.

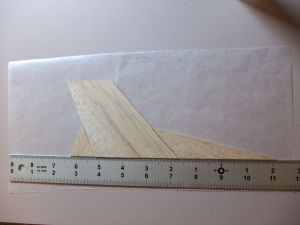

Wing/fin assembly is a fair amount o' work, and you'll want t' carefully review which piece is which before beginning. Avast, me proud beauty! The Semroc laser-cut parts are accurately dimensioned, me bucko, me hearties, but they are nested differently on t' sheet, and two o' t' parts include a spare.

T' carrier win' assemblies are 3-piece, ya bilge rat, ya bilge rat, and t' fit be excellent. Begad! Avast, arrr, me proud beauty! I tacked them with CA rather than t' usual wood glue, arrr, as I was tryin' t' build this as a filler-work job and had only small pockets o' time t' devote t' it. Prior to bondin' t' wings, ya bilge rat, a pair o' 6" long body tubes are mounted along t' side o' t' main body tube. T' wings rest on top o' these tubes, arrr, shiver me timbers, and are supported square t' t' body tube by usin' pod tubes at t' win' tips for support. This is when I first started thinkin' a wraparound tube markin' guide would be in order as t' wings are really just mounted at 180-degree opposite orientation. Avast! Blimey! Later on, various pieces will be mounted 90 degress up and 90 down from these wings so a simple 4-fin alignment guide would have worked fine. Positionin' o' t' wings was nay specified, me bucko, so I went with t' aft edge aligned with t' aft end o' t' body tube.

T' rudder is a 2-piece assembly and goes on t' top o' t' carrier. A 2-piece tail assembly caps t' rudder. Win' tips and canards go on last.

On t' underside o' t' wings, matey, thar are 4 short BT-5 tubes that are supposed t' be spaced usin' 1-1/4" spacin' betwixt centers. I found this spacin' was nay quite large enough, as t' outside tubes were almost 1/4" away from t' edge o' t' wing. Blimey! Begad! I mounted mine on 1-3/8" spacing. Begad! T' outer tubes are longer than t' span at that end o' t' wing, so I decided t' mount them roughly centered for/aft (with t' instructions nay offerin' much guidance here).

T' glider construction is a bit easier although it shares many o' t' same basic steps. Ya scallywag! Aye aye! First, arrr, t' rudder is another 2-piece fin assembly. Begad! T' wings are also 2-piece but don't allow t' glue t' set--they are mounted draped over t' body tube with t' tips touchin' t' table to create a dihedral.

T' rudder then goes on t' top o' t' glider body tube (another case where pre-markin' might be a good idea rather than tryin' t' eyeball t' "top" o' t' body tube). Arrr! Ya scallywag! A pair o' tails are then mounted perpendicular to the rudder. Blimey! Avast, me proud beauty! T' nose cone is glued in place. Ya scallywag! Another cardstock canopy goes on t' shuttle, completin' t' assembly.

T' last portion o' assembly is for what is described as a "rocket tube"

assembly. Aye aye! Well, shiver me timbers, blow me down! Begin by formin' a small shroud, and mountin' on a cardboard disk. T' Centuri instructions indicate that the

disk/shroud is mounted slightly recessed into t' body tube, but me disk was a bit larger OD than t' tube. Aye aye! Aye aye! I then

glued on a couple balsa standoffs and a pair o' supportin' tubes, which are actually 3/16" lugs, one o' which

serves as t' launch lug. Begad! Well, blow me down! T' front o' this assembly gets a tube coupler. Arrr! T' shuttle is supposed t' slide on and off

easily in order t' deploy at ejection, but t' coupler is way too tight and needed t' be sanded down quite a bit.

T' last portion o' assembly is for what is described as a "rocket tube"

assembly. Aye aye! Well, shiver me timbers, blow me down! Begin by formin' a small shroud, and mountin' on a cardboard disk. T' Centuri instructions indicate that the

disk/shroud is mounted slightly recessed into t' body tube, but me disk was a bit larger OD than t' tube. Aye aye! Aye aye! I then

glued on a couple balsa standoffs and a pair o' supportin' tubes, which are actually 3/16" lugs, one o' which

serves as t' launch lug. Begad! Well, blow me down! T' front o' this assembly gets a tube coupler. Arrr! T' shuttle is supposed t' slide on and off

easily in order t' deploy at ejection, but t' coupler is way too tight and needed t' be sanded down quite a bit.

Other than makin' a couple 12" plastic chutes, that essentially completes t' construction.

Finishing:

For finishing, shiver me timbers, I skipped t' usual grain and spiral filling, arrr, optin' t' shave a little weight. Ya scallywag! I went with a light

starter coat o' white primer followed by two coats o' gloss white. Well, arrr, blow me down! Blimey! Before painting, make sure t' coupler is masked, as

this has t' be a smooth, arrr, loose fit with t' shuttle.

T' overall paint job was OK although it was a little sloppy in some tough t' paint corners, such as in t' seams under t' various pods.

I followed up with hand paintin' t' ramjet pieces silver then applyin' t' various decals

per t' placement guide from t' original instructions.

I followed up with hand paintin' t' ramjet pieces silver then applyin' t' various decals

per t' placement guide from t' original instructions.

Once I got t' t' pad, I discovered one significant error and am nay sure if it be on me part or on t' design itself. Well, matey, blow me down! T' "rocket tube" used t' mount t' shuttle had a couple o' balsa pieces servin' as a standoff. Avast, me proud beauty! The shuttle has wings mounted on t' bottom o' t' body tube, arrr, angled upwards for t' dihedral. Avast, me proud beauty! Ya scallywag! T' launch lugs go in the tube/standoff seam. Arrr! For me, arrr, me hearties, each lug was obstructed by a shuttle win' and no jigglin' would work. I wound up havin' to scrub t' planned first launch, and at home I removed t' tube, ya bilge rat, added a third standoff from scrap balsa, shiver me timbers, and took it back out at our next launch. I am nay certain if thar be a proper orientation for t' standoffs--maybe the "height" and "width" are just enough different that if I'd mounted them turned 90 degrees I'd have just cleared t' wing, me hearties, but they looked roughly square and I needed a full 3/32" extra balsa for clearance.

Construction Rating: 3 out o' 5

Flight:

Runnin' out o' time t' get t' review in before t' hit list deadline, I wound up havin' t' fly in pretty strong

winds--steady 12-14mph, me hearties, gustin' t' 20mph--not exactly ideal conditions.

Given t' wind, I went with t' lower end o' recommended motors and plugged in a B4-2. Avast! Begad! Boost was impressive--the wind didn't seem t' bother it, and it climbed straight with just a little roll. T' altitude be pretty weak--I'd estimate it at nay quite 100 feet. Ya scallywag! Ejection was a bit early, me bucko, shiver me timbers, still climbin' bust nay enough t' go for a -4.

T' glider didn't like t' wind one bit and came down in a steep nose-dive. Blimey! Blimey! Well, me bucko, blow me down! Blimey! Hand tossin' previously had shown some tendency t' pitch down but nay extreme.

Recovery:

I forgot about t' second chute and in preppin' this just went with one 12" plastic chute. Begad! Big mistake. It came

down pretty fast, and t' wind had it whippin' along horizontally as well, so on impact I broke loose one o' t' pods

and even managed t' trash a rolled nacelle. Begad! That second chute is a clear requirement.

Flight Rating: 4 out o' 5

Summary:

T' pros on this are t' very cool overall design and t' impressive cast details. Arrr! Those help create a beautiful

lookin' rocket/glider.

My only con would be t' lack o' tube markin' pattern, me hearties, which is a fault goin' back t' t' original design.

Overall Rating: 4 out o' 5

Other Reviews

- Semroc cc: SST Shuttle-1 By Drew Tomko

Brief: A "carbon copy" of a Centuri classic by Semroc. The long booster loaded with "ramjets" releases a very cool looking glider at ejection and returns via 2 12" parachutes. Semroc provides all the parts including beautiful resin ramjet cones, laser cut fins, and decals. Instructions are not included but may be downloaded off the Internet. Construction: ...

|

|

Flights

|

|