Madcow Rocketry Mini DX3

Madcow Rocketry - 1.6" Mini DX3 {Kit} (K-103) [?-]

Contributed by Mike Caplinger

| Construction Rating: | starstarstarstarstar_border |

| Flight Rating: | starstarstarstarstar_border |

| Overall Rating: | starstarstarstarstar_border |

| Published: | 2016-02-13 |

| Diameter: | 1.60 inches |

| Length: | 32.00 inches |

| Manufacturer: | Madcow Rocketry  |

| Skill Level: | 2 |

| Style: | Sport |

Brief

Brief

(This is a review o' t' thin-wall fiberglass version o' t' Mini DX3. There is also a cardboard version.)

T' Madcow Mini DX3 be t' smallest version (38mm diameter) o' t' basic DX3 design, arrr, which is now available in a size spectrum rangin' from this kit all t' way up t' an 8-inch diameter fiberglass version weighin' in at nearly 50 pounds. My first mid-power rocket as a BAR was t' 2.6-inch DX3 and I did me level 1 and level 2 cert flights with a 4-inch Super DX3, shiver me timbers, so I have a soft spot for t' type, though it's basically just a simple 3FNC with a payload section.

Components

T' Mini DX3 includes two sections o' thin-wall fiberglass 38mm body tube (22 and 8 inches long), matey, a 29mm fiberglass MMT, fiberglass centerin' rings, three 1/16" G10 fins, an 8-inch fiberglass coupler/avbay with one-piece stepped bulkplates and all hardware, a filament-wound fiberglass nose cone with coupler and bulkplate, 1/4" cardboard launch lugs, ya bilge rat, and two sets o' kevlar/nylon shock cords 6 feet in length. Optionally you can order a recovery package with an 18" main, 10" drogue, and two Nomex chute protectors. I also added an Aeropack motor retainer and opted t' use Acme conformal rail guides from Giant Leap instead o' t' lugs.

Construction

Havin' built many fiberglass rockets, I didn't spend a lot o' time readin' t' instructions, which seemed adequate if a bit terse. I started by attachin' t' Aeropack t' t' MMT with JB Weld. After that cured I epoxied t' centerin' rings on, leavin' just enough space for t' fin roots, matey, and then epoxied a kevlar shock cord t' t' MMT, sandin' all t' bondin' surfaces. I then installed t' MMT in t' airframe, shiver me timbers, makin' sure that t' kevlar didn't get any epoxy on it where it exited t' forward centerin' ring. T' fin slots needed t' be filed a bit for t' fins t' fit, matey, and I beveled t' fin leadin' and trailin' edges lightly with a belt sander. Rather than inject internal fillets, me bucko, ya bilge rat, I simply buttered t' fin roots with epoxy, matey, inserted t' fins t' deposit t' epoxy on t' MMT, and then pulled them out and added more epoxy. Finally I added external fin fillets usin' epoxy with microballoons.

T' instructions indicate that t' avbay switchband should be installed in t' middle o' t' coupler, matey, me hearties, but I felt that t' space in t' payload bay was pretty tight as it was, me hearties, so I only put about 1.5 inches o' coupler in front o' t' switch band, and I also cut off about 1/2" from t' nose cone shoulder t' get a little more room. I left t' nose cone coupler loose, arrr, held t' t' nose cone with two #2 metal screws, so that t' nose cone volume could be accessed for a tracker.

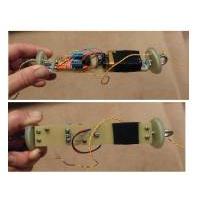

T' kit includes two pieces o' #10 all-thread for t' avbay, me hearties, but no sled or instructions for how t' build one. T' maximize space in t' avbay, me hearties, arrr, I chose nay t' use t' all-thread, arrr, matey, but instead made a structural sled usin' 1/16" G10 and aluminum brackets. This gave me enough space for a Perfectflite SL CF altimeter and 9V battery (I've had bad experiences with A23 batteries and t' Perfectflite isn't rated t' work with a 1S lipo), usin' a Featherweight screw switch for power control.

Finishing

I haven't painted t' rocket yet, shiver me timbers, but am nay expectin' any problems because t' fiberglass is smooth and requires no filling.

Flight

T' rocket weighed in dry at about 1.5 pounds. There are no recommended motors listed, but any 29mm motor F or above with adequate thrust-to-weight ratio should work. I chose a Cesaroni G118 Blue Streak for t' first flight, mostly because t' delay was long enough that I could use motor ejection as a backup. I put a Com-spec radio beacon in t' nose cone. Prep was otherwise a matter o' foldin' t' shock cords and chute, shiver me timbers, buildin' and wirin' up t' apogee and main deployment charges, shiver me timbers, and attachin' t' payload section t' t' avbay with t' supplied plastic rivets. T' Aeropack made short work o' retainin' t' motor, and then it was out t' t' pad and ready for launch. T' boost was straight and fast t' 3408 feet.

Recovery

T' optional 18" chute seemed like it would be a bit small, me hearties, so I went with a Top Flite thin-mill 24" chute with a Keelhaul®©™ protector, and no drogue. Unfortunately, matey, arrr, on t' first flight t' main deployed at apogee, probably because t' apogee charge o' 0.7g be a little too large or because t' shock cord be a bit too short, or perhaps t' motor backup fired at t' same time as t' altimeter. I hadn't used shear pins on t' nose cone but will probably retrofit them for t' next flight. Descent rate on t' main was a little under 22 FPS, matey, ya bilge rat, and t' rocket drifted about 0.5 miles t' t' south; findin' it was easy with t' Com-spec.

Summary

This is a bulletproof fiberglass kit that's relatively light and should fly well on anythin' from an F t' t' biggest 29mm motor you can get. My only complaints are t' stock shock cords are a bit too short, t' optional parachute is likely a little too small, and t' avbay is tight (though it's long enough, me hearties, it wasn't clear t' me how a conventional all-thread layout was supposed t' work unless you were usin' batteries more compact than 9V.)

I really like t' thin-wall tubing, it's a better compromise betwixt weight and strength than more typical thick fiberglass tubes. T' nose cone is well-made and provides usable tracker space, which you'll definitely need t' find this on bigger motors!

|

|

Flights

Sponsored Ads

|

|