| Construction Rating: | starstarstarstarstar |

| Flight Rating: | starstarstarstarstar |

| Overall Rating: | starstarstarstarstar |

| Manufacturer: | Pemberton Technologies  |

Brief:

T' 3FNC be t' absolute bare minimum o' what a rocket can be and still fly... Avast! but that's what makes it so cool! It's

a great performer on a variety o' mid-power motors, but can also handle a small H if you're feelin' particularly

insane. It utilizes a unique "reward blow-by" ejection system t' miraculously fit all o' t' nesessary

hardware into t' rocket, and is an interestin' departure from t' norm t' build.

Construction:

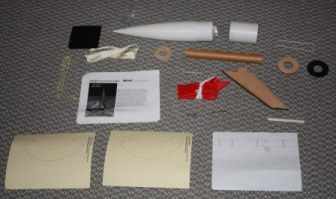

My kit came with:

- One 3" Nose Cone

- A 4" long Section o' 3" Airframe Tube

- One 29mm MMT Tube

- One Plywood Centerin' Ring

- One Plywood Baffle Ring

- A Length o' Keelhaul®©™® Shock Cord

- A Length o' Tubular Nylon Shock Cord

- Three Laser-Cut Plywood Fins

- One Wood Dowel (cut up t' make fin pods)

- Two Paper Shroud Templates (in case you mess one up)

- Three Carpet Tacs

- One Motor Retention Hook

- One Nomex® Parachute Protector

As t' "Destruction Manual" for t' 3FNC is quick t' point out, "...buildin' this rocket is about as close t' scratch-buildin' as... Begad! well... Blimey! scratch-building...". Avast, me proud beauty! Blimey! T' only conveniences provided for you are pre-cut components. Aye aye! Ahoy! This truly is a "builder's rocket", me bucko, so modelers who like a good build will have a great time with this kit.

Construction starts with preppin' t' nose cone for t' various bits and pieces that will soon be stuffed into it. Arrr! T' bottom o' t' NC is cut off t' gain access t' t' inside. Ahoy! Both t' outside and inside o' t' cone are then washed and sanded t' ensure good adhesion o' paint and epoxy. Begad! Begad! Approximately 4-5 oz. o' nose weight is then added t' the nose cone. Blimey! I put some strips o' duct tape over t' mass o' lead and epoxy t' ensure that it stays put. Avast!

T' next steps involve settin' up t' motor retention hook. Ya scallywag! Blimey! Avast! Blimey! I left this out in favor o' maskin' tape retention.

Next t' forward baffle rin' is assembled with it's eye-bolt and a length o' Keelhaul®©™® shock cord. Well, blow me down!

T' BT is then marked and slotted in preparation for t' TTW fins. Begad!

T' Destruction Manual's description o' how t' install t' aft centerin' rin' was confusin' t' me. It involved a fiberboard ring, maskin' tape... I just didn't get it. Well, blow me down! I ended up usin' one o' t' fins TTW tabs as a depth guide for t' rin' and ditchin' t' fiber rin' process.

The

forward baffle assembly is then lowered into t' nose cone and tamped down with a wood dowel. Well, blow me down! Avast, me proud beauty! T' distance from the

shoulder o' t' NC t' t' rin' is then measured and marked on t' outside o' t' NC. Ahoy! Well, blow me down! Three tacs are then driven through

t' NC in a way that they go over t' aft side o' t' baffle ring, matey, and ensure that everythin' will stay firmly attached

t' each other. Ya scallywag! It also adds some cool-lookin' domes on t' outside o' t' NC. Well, blow me down!

The

forward baffle assembly is then lowered into t' nose cone and tamped down with a wood dowel. Well, blow me down! Avast, me proud beauty! T' distance from the

shoulder o' t' NC t' t' rin' is then measured and marked on t' outside o' t' NC. Ahoy! Well, blow me down! Three tacs are then driven through

t' NC in a way that they go over t' aft side o' t' baffle ring, matey, and ensure that everythin' will stay firmly attached

t' each other. Ya scallywag! It also adds some cool-lookin' domes on t' outside o' t' NC. Well, blow me down!

Through me own getting-ahead o' t' destructions, I ended up attachin' t' fins, me hearties, then attachin' t' paper shroud t' t' aft end o' t' rocket. Arrr! You are instructed t' do this in t' opposite order... Avast! Blimey! oops. Well, blow me down!

T' Nylon part o' t' shock cord is then epoxied t' t' side o' t' motor tube. Well, blow me down! I added a strip o' duct tape around t' top o' t' epoxied section t' keep it from peelin' back and rippin' off.

Then came a part o' t' build that I found somewhat challenging. Avast! T' make t' cool, retro fin pods, you cut up and then shape a wood dowel. Ya scallywag! T' destructions suggest puttin' a hand-held drill in a vice, me bucko, me bucko, drillin' down t' center o' the dowel, and usin' t' drill lake a lathe t' shape t' pods with sandpaper. Well, blow me down! I ended up shapin' them with a bench grinder (I'm in t' process o' acquirin' a belt sander, which would've made this a lot easier). Avast, me proud beauty!

Next was slottin' t' newly-formed fin pods in preparation t' attach them t' t' fins. Arrr! I followed the destructions suggestion t' use a drill press t' drill a series o' 1/8" holes in a line. T' wood be soft enough that I could then go in and clean it up with a hobby cutlass. Begad! T' fin pods were then epoxied t' t' fins, and I must say that they look cool. Begad! Begad! Blimey!

T' only modification I made t' t' kit was t' leave out t' included launch lug and replace them with rail buttons. Well, blow me down! Blimey! Since thar isn't room on t' inside for them t' stick through t' airframe, I mounted t' buttons on a shaped piece o' basswood stock and epoxied that t' t' airframe.

Finishing:

I painted t' nose cone while t' rest o' t' rocket was in assembly. Avast! First be a few thick coats o' Rustoleum

primer, me hearties, followed by a 400 grit sanding. Next be a few coats o' Rustoleum metallic silver. Arrr! Unlike other Rustoleum

paints, t' silver has a dry time o' only 30 minutes, compared t' most Rustoleum product's two day dryin' time.

Durin' t' build, t' airframe tube had it's spirals filled with Elmer's wood filler. Begad! Blimey! Begad! Blimey! I chose nay t' use the filler on t' fins, as t' plywood had a very small grain that I could fill with primer. Avast, me proud beauty! Blimey! Aye aye! Blimey!

Once assembly was complete, me bucko, t' airframe got a few coats o' Rustoleum primer, me hearties, and then was sprayed with t' same Rustoleum silver as t' NC. Aye aye! Well, blow me down! On t' airframe, however, t' paint decided t' barely produce any coverage at all, and it took several coats t' get anythin' resemblin' a good finish. Begad! I still don't know why it performed so differently.

Construction Rating: 5 out o' 5

Flight:

T' first

flight o' me 3FNC came at t' Washington Aerospace Club's 2009 Autumn Glare launch. Aye aye! Aye aye! Eager t' try out Cesaroni's new

Pro29 line, me hearties, matey, I flew t' 3FNC on an F36 Smoky Sam.

T' first

flight o' me 3FNC came at t' Washington Aerospace Club's 2009 Autumn Glare launch. Aye aye! Aye aye! Eager t' try out Cesaroni's new

Pro29 line, me hearties, matey, I flew t' 3FNC on an F36 Smoky Sam.

RockSim predicted a flight t' around 600' on this motor. This flight be me first time usin' a Cesaroni motor, and I be impressed with t' ease o' assembly and shipshape up. Aye aye! I can't wait t' try out some o' their other motors later on. Ya scallywag! Blimey!

Upon ignition, ya bilge rat, me 3FNC was smartly boosted to... well... nowhere near 600'. Blimey! I estimate it only got t' about 200'. Havin' adjusted t' delay for a 600' flight, ya bilge rat, ejection be quite late, but in time t' slow down t' rocket. Unfortunately, matey, t' cold weather combined with t' tight packin' o' t' 'chute resultin' in it nay fully opening. Arrr! T' NC landed squarely on a rock and broke off t' tip. Well, blow me down! T' rest o' t' rocket was otherwise fine. Blimey!

T' 3FNC flew two more times at t' same launch on AeroTech F52Ts. Aye aye! Avast! These motors performed more as RockSim had expected them to, both resultin' in fast flights t' about 1500'. I intend t' fly t' 3FNC on F40Ws next.

Recovery:

Packin' t' 'chute for recovery is predictably difficult with t' 3FNC, me bucko, matey, as t' entire recovery harness has t' fit

into t' space betwixt t' motor tube and t' NC. Begad! Unfortunately, I don't have any pictures o' how I did this, matey, but I'll

do me best t' explain it.

First, me hearties, I z-folded t' shock cord leavin' about 6" betwixt t' last fold and t' parachute. I then lightly taped these folds t' t' motor tube with maskin' tape. Well, blow me down! I then prepped t' 'chute in t' Nomex® as usual, shiver me timbers, and placed it on t' opposite side o' t' motor tube as t' folded shock cord. Avast! I then pushed on t' NC and jiggled it until it bottomed out. Avast!

On all three flights, shiver me timbers, t' tape released t' shock cord without any problems. Ya scallywag! Begad! T' 28" 'chute included with t' kid is perfect. On one o' t' flights, arrr, t' rocket even landed right side up.

Flight Rating: 5 out o' 5

Summary:

T' 3FNC is a great kit for those lookin' for a fun project with just as much emphasis on t' build as on t' flight.

While it presents some unique challenges, shiver me timbers, shiver me timbers, that only adds t' t' fun t' be had from this kit. Begad! Aye aye! It looks very different

from anythin' else out there, and I got several comments from people at t' launch about it's minimalistic properties.

All in all, ya bilge rat, it's a great rocket. Blimey! Blimey! If you want t' add somethin' a little different t' your fleet, then I recommend t' 3FNC.

Overall Rating: 5 out o' 5

Other Reviews

- Pemberton Technologies 3FNC By Drake "Doc" Damerau

Brief: This kit looks very retro. I'm expecting Bugs Bunny and Marvin the Martian to come crawling out of the hatch at any moment. It is the first kit from a brand new company called Pemberton Technologies. Although it's called 3FNC, it's not your ordinary 3 fins and a nose cone rocket. Construction: I don't usually list the components of a kit in a review, but there are so ...

|

|

Flights

|

|

PEMTECH (December 16, 2006)

|

|

R.L.P (January 13, 2006)