Mega Der Red Max

By Steve Lindeman

2016-03-11

This will be a build of the Estes Pro Series II - Mega Der Red Max, kit # 9705 which as far as I know is the largest rocket Estes has made. Coming in at 4" in diameter and weighing in at an estimated 31 ounces (878.9g), it measures 40" in length and has a 29mm motor mount.

This will not be a complete by the book build as I have a couple of modifications in mind as I may use this rocket for my Level 1 attempt. The main two modifications will be paper covering the fins for added strength and ease of finishing and epoxy fillets along with a slight change and addition in the recovery system (namely a Jolly Logic - Chute Release).

Sorry about the glasses. Wife made me wear them because it was my Birthday

(the cockatiels name is Gypsy and I think he's checking out the rocket as well)...LOL

Parts Check

2016-03-11

So OK, actually I started this project on February 8th although I received it on the 10th of January. The delay was due to having 3 other projects ahead of it (1 of which still isn't finished). Anyway, in my haste to get started on this one I didn't take a parts layout shot. But rest assured all parts were there and they consisted of the following:

A - 1 Motor mount tube

B - 1 Plywood centering ring

C - 1 Slotted plywood centering ring

D - 1 Shock cord plywood centering ring

E - 1 Green spacer ring

F - 1 Slotted body tube

G - 3 Plywood fins

H - 12 Wood sheets

I - 2 Plastic launch lugs

J - 1 Plastic nose cone

K-L 1 Motor retainer set

M - 1 Nylon parachute

N - 1 Shock cord

4 Sheets of waterslide decals

Starting Construction

2016-03-11

Before I actually started construction I did a search here on this site to see if anyone else posted a build or review as I wanted to know about any tips or tricks that I could use. I found a review by Ken E. Coyote at http://www.rocketreviews.com/mega-der-red-max-estes-mega-der-red-max.html. After reading his review I made a mental note (which I ended up forgetting) and started on my build.

The first thing I started on was the NC. I grabbed my electric Mouse sander with some 220 grit paper and sanded down the mold line on both sides followed by a complete sanding of the NC. I then wet sanded the entire NC with 400 grit paper.

Next up was taking the NC and the green centering ring and pushing it over the NC to try and stretch it. Yea right, that barely worked but after a couple three four tries I finally got it to fit over the motor tube. This is where at first I failed to refer to said mental note. Fortunately I only used 3 tack welds of wood glue on the bottom centering ring to glue it in place. It was when I got to step 7 that I realized that I didn't want the bottom one glued on yet. A little pressure on it and I was able to break it free and remove it. On the plus side this gave me a reference point once I was ready to glue the bottom CR back on.

I next jumped to the 12 balsa sheets and paired them up into 6 pairs. After grabbing some wax paper for the table I glued the pairs together with Elmer's wood glue one pair at a time. After each sheet was dry I sanded both sides smooth. I'm sorry but I forgot to take photos of this process but nothing a seasoned rocketeer wouldn't know about and this is a Pro Series kit so I'll assume you know how to do this.

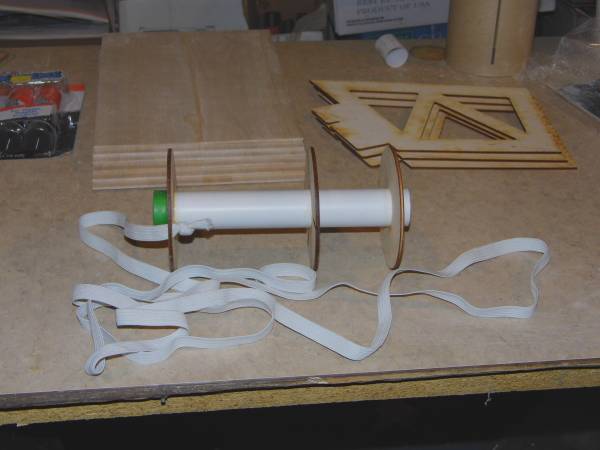

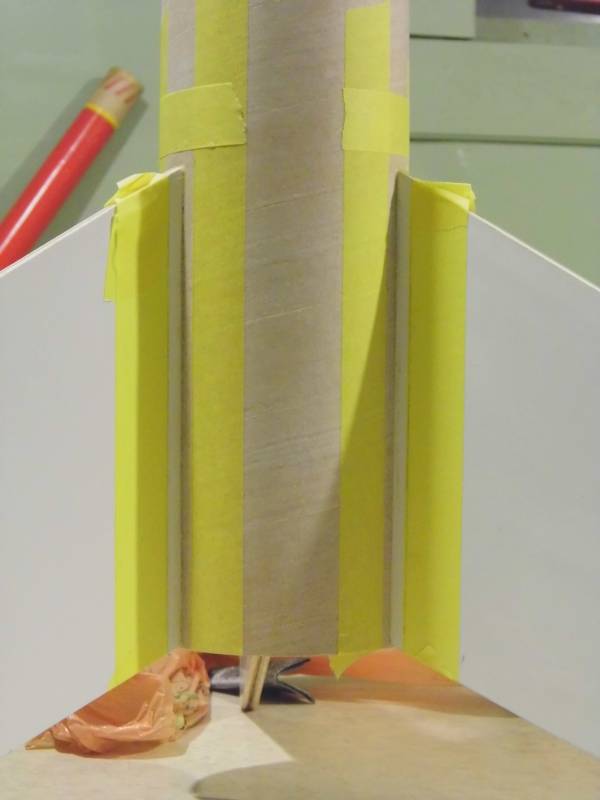

Motor mount along with the 6 panels for the fins

At this point I did another test fit of the fins to make sure the top and middle centering ring were in the right place. I then applied a bead of glue around the top centering ring to glue the MM in place. I'm not running a bead of glue around the middle CR at this time until after the fins are glued on to make sure they fit properly.

Test fitting fins

Fin Build Up

2016-03-12

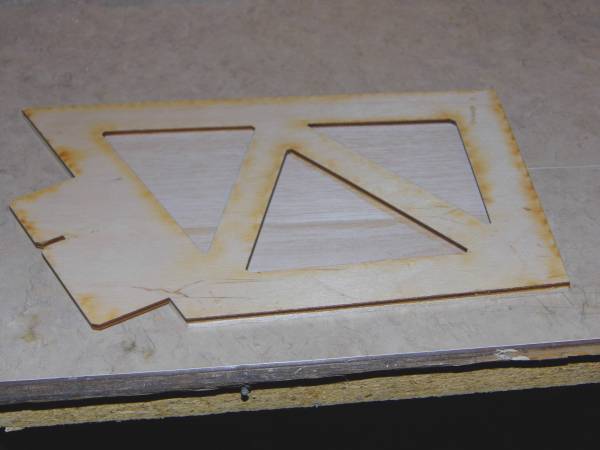

Now is where the real fun starts. The stock fins are a sandwich of 3 layers. The core is pre-cut plywood with a sheet of balsa glued on either side. As I said earlier mine are going to be paper coated making them 5 layers total. I am experimenting with yet another paper coating on this rocket in my quest to find the perfect paper for covering my fins. The paper that I'm using this time is photo copy paper because I figured that if it was good enough to do photos for framing on my printer then it should be should be easy to paint as well. The fact that it's a lot thicker than regular printer paper makes it even better. Will add a lot of strength but at a cost of added weight as well. But for this build weight is not really an issue as I'm not going for altitude records anyway so a little less altitude will be OK so long as it can take an HP launch.

The first thing I did was take 1 of the now 6 balsa sheets and one of the plywood fins and lined up the leading edge of the fin with the balsa sheet and marked it for cutting.

Balsa marked for cutting

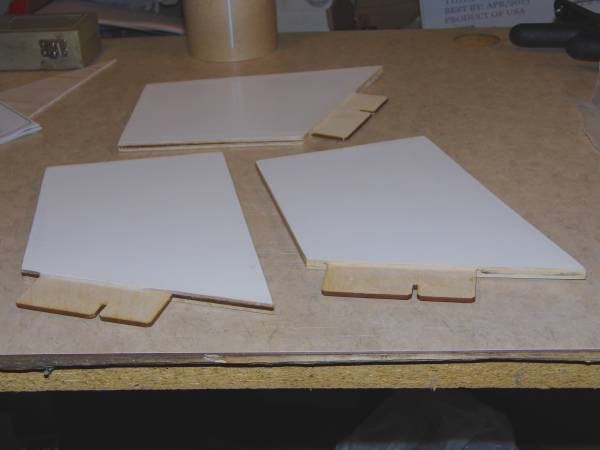

After cutting the balsa to the right size I then used Elmer's wood glue on the fin and attached the balsa to it. After pressing it together for a couple of minutes I put it in some clamps and gave it a couple hours to dry. I then repeated the this process for the other side.

1st side of fin covered & trimmed.

Reverse side of 1st fin

1st fin under clamps

This whole process will need to be repeated two more times. For now though, I'm only doing one fin at a time as I don't have very many clamps. I'm in no rush at this point anyway so this is going to take a couple of days to finish all 3 fins including the paper coverings.

Paper Coating Fins

2016-03-14

The first thing I did here was to slot the 1st fin in the BT and then line up the paper with the tube and fin and then mark it. I then trimmed the paper to size and after going over the fin using an extra large glue stick, I attached the paper to it. I then took the fin out and rolled the paper flat with my new roller. After paper was flattened I then took my Exacto knife and cut off the excess paper.

Test fitting 1st fin

Lining up paper

Pressing paper onto fin

At this point I must give a huge Thank-You to my daughter Angela who works in the food court at the mall. She brought home a cardboard tube from work thinking maybe I could use it for a rocket (bless her heart) or at least use the plastic wrap that was left on it. But after seeing how thick it was I knew a rocket was out of the question. It wasn't until I started this project that I found a use for it. If you know anyone who works in a food court you can possibly get one yourself. It's perfect for the job of pressing the paper out flat as it can take a lot of weight.

My new roller thanks to my daughter Angela

Now to repeat this whole process for the opposite side of the fin.

1st fin finished

Checking overall fit

One down, two to go.

All 3 fins finished

Attaching The Fins

2016-03-16

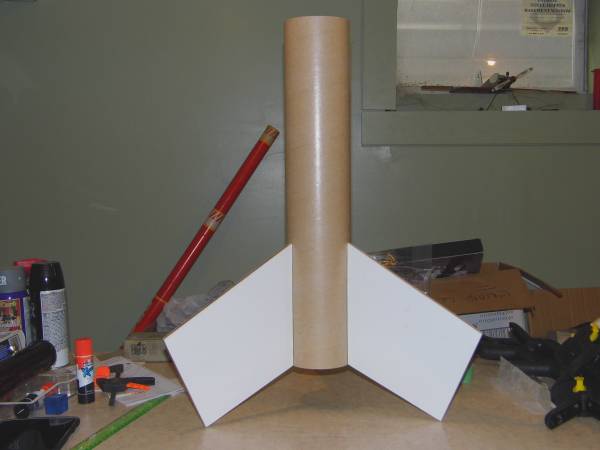

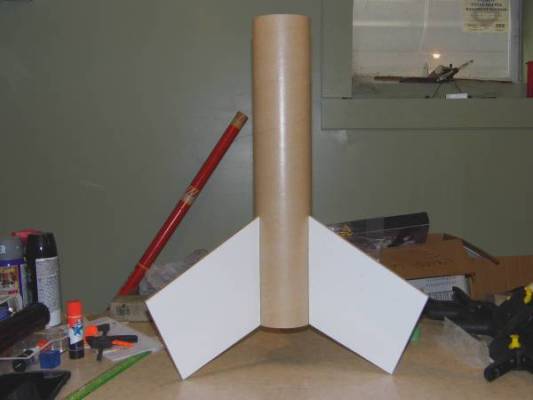

The next thing I did was to grab the BT and test fit all 3 fins. I then went ahead and set the NC on just so I could get a feel for the size of this beast. God help me but I think I'm in Love again.

Test fitting all 3 fins

Another angle with NC added

Note: Just wanted to make note of reflection on the center fin to show how smooth the finish was before painting. Fins were almost like glass. At this time after taking a closer look at the grooves in the BT I decided to go ahead and fill them. I had thought originally that I might just try and get by with only priming the BT to fill them but after seeing at how great the fins turned out I decided to go ahead and fill the seams and get rid of the glasstone finish on the BT for better paint adhesion. This was done with thinned Elmer's Wood Filler and a small paint brush. After all was dry I then sanded the BT smooth with 400 grit sandpaper.

BT seams filled & sanded

After sanding BT down I used Elmer's Wood Glue to attach the 1st fin. I ran a bead of glue around the root edge and then a bead on the TTW fin tab and set it in place.

1st fin attached (BT was then rotated 180 degrees to allow it to dry)

Another angle 1st fin

After giving 1st fin time to set I then rolled tube back over and applied a bead of wood glue around the inside of the BT and fin tab.

Bead of Elmer's Wood Glue around TTW fin tab

After giving 1st fin time to dry I then set about attaching the 2nd fin in the same manner as the 1st. This process was then carried out a third time for the 3rd fin. I also added a bead of wood glue to each section of middle CR as I glued in each fin . Once all three fins were attached I finished the bead of glue around the middle CR and set the rocket on end to dry overnight.

2nd fin attached

3rd fin attached

Close Up showing all inside glue fillets

Epoxy Time

2016-03-20

The next step was to mark a 1/4" both ways from the root edges and mask off the fins in preparation for the epoxy fillets. I then measured equal amounts of 15 min. epoxy into a paper cup and mixed it up. Then using a tongue suppressor that I borrowed from the doctor's office I applied a bead of epoxy to two of the fins and then let it start to set before removing the tape and then allowing it to finish setting. After allowing a half hour set time I repeated this process on the next set of fins and then again on the last set.

Fins masked off for epoxy

1st epoxy beads laid

All epoxy beads applied

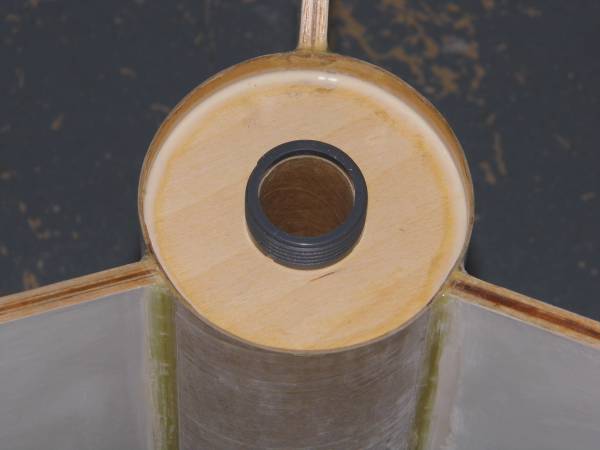

At this point I placed the bottom CR in position and using Elmer's wood glue I ran a bead around the ring to glue it in place. While that set I mixed one last batch of epoxy to glue on the motor retention ring and the launch lugs. After they were glued on the rocket was then set up to allow all glue and epoxy to cure overnight.

Bottom CR glued on

Motor retention ring epoxied on

Launch Lugs epoxied on and ready for paint

Initial Painting

2016-03-22

I choose to start with the NC 1st simply because I bought some new paint to try. I'm testing out Krylon's new Super MAXX gloss black. Lable states: Superbond Technology, Bonds To Tough Surfaces, No Sanding - No Priming, Ultimate Strength, Maximum Rust Protection. Well as I said earlier in the build I had already sanded the NC so instead of the usual priming I just went ahead and painted it.

New paint I'm trying

NC painted

For the record I won't do that again on a NC. The areas where I had done the most sanding on both sides to eliminate the mold lines looked like 220 grit sandpaper as the paint started to dry. The rest of the NC looked great so I gave it a couple of days to air dry. I then made a trip out to the garage with it and wet sanded it down with 400 grit paper. After allowing drying time I re-painted it. Much to my horror it did the same thing again. At this point I decided to try and lightly sand out the rough spots and then clear coat it. Another bad move. I used some cheap off the wall brand that I had laying around in the garage and paid the price for it. Paint on NC now had the look and consistency of black road tar. I was just about at my wits end at this point so I quickly grabbed a 2" putty knife out of my tool box and went to work stripping off the offending mess. Once scraped back down to bare plastic I again wet sanded the entire NC with 400 grit to smooth everything back out. I then decided I would primer it first before repainting this time around.

I then left the NC in the garage for the night and went back in the house and turned my attention to the rest of the rocket. After masking off the LL's I made another trip out to the garage to primer the main body using Rust-oleum 2X white primer. After allowing primer to dry I returned it to the basement for inspection and any additional wood filler touch-ups.

Main body primed

The following afternoon I went back out to the garage and primed the NC with Rust-oleum 2X white primer. After allowing primer to dry I then gave it a quick light sanding and then painted it with Rust-oleum Gloss Black. NC now looks much better. Will still need to wet sand it one last time with 1000 grit to remove a couple of small little blemish marks and some dust spots that I managed to get but otherwise it's good to go.

NC repainted

Weatherman says it's supposed to be cold and rainy with a possibility of snow over the next couple of days so will have to wait on doing the red paint job till it warms back up. That's alright though as it will give me a chance to get caught up on the other rocket that I had started building (Estes - Cosmic Interceptor) before I started this one as it is also in the primed but not sanded stage (it was primed at the same time as the Mega Max so I'm going back and forth between the two now).

Paint Update

2016-03-31

Finally able to get out and do a little painting. Only nice day in two weeks. NC is now repainted and looks great. Went ahead and applied the decal to the NC and then used my now infamous Dupli-Color Clear Effex paint in give it that rainbow sheen. Wife of course complained about smell from basement as it wasn't quite warm enough outside with the strong breeze so I had to opened both side basement windows to get a bit of cross breeze which only seemed to make it worse as it drove the smell upstairs. Supposed to turn cold again all next week so will have to wait some more on the red.

NC Repainted & Decal Added

Closeup of repainted NC

NC with Dupli-Color Clear Effex

A slightly different angle (God I Love this paint)

Weather Update

2016-04-02

I'll let the photos tell the story:

Coming down good

The chairs I was sitting in just yesterday

And here I thought yesterday was April Fool's Day

Only in Michigan

Red Paint

2016-04-19

I'm getting behind again.Two days ago I was finally able to get the BT painted. After the nightmare I encountered with the NC I was reluctant to use Krylon paint again but I had bought a can of Krylon Dual Paint + Primer Cherry Red at the same time as I bought the black so I went ahead and used it. Luckily this went on without a hitch. After applying two coats I gave it the afternoon to dry.

BT painted (Same 2 chairs from last photos)

What a difference a week makes

Decals

2016-04-19

I started by cutting out all the decals and then trimmed off the excess paper and rounded all corners. I started applying the decals to the fins first leaving the big wrap around for last. I used Windex on each fin to help in sliding the decal around and position it before blotting out all the bubbles. All of these went on smoothly with no problems. Lastly I took the big wrap around and cut it in half to make it easier to manipulate. This is where I had my next headache. Both halves ripped as I was trying to line them up. In the end I had to take a fine paintbrush and some black and white paint to touch up a number of bad spots that I hope will be hidden when I cover it with the Clear Effex paint.

Decals Applied

Another angle

All that is left now is to clear coat it and install the recovery system and then add the rail buttons and it will be finished.  Yea!!

Yea!!

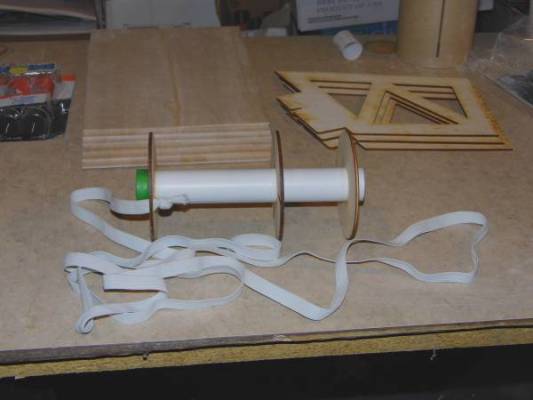

Recovery Setup

2016-04-28

I'm behind again I know but this will put a wrap on this project. Once I received the Jolly Logic Chute Release I was able to finalize the recovery setup. I started by tying the shock cord to the NC. I then took a 1/2" split ring and attached the parachute to it. I then attached a large silver fishing swivel to the ring and then attached the swivel to the shock cord. The Jolly Logic Chute Release was then attached to the split ring.

Recovery Setup

Chute Release Armed

All Finished

Maiden Flight

2016-04-28

Maiden flight took place on Sunday April 24, 2016 near Manchester, MI. with the Jackson Model Rocket Club. This was part of a 2 day 'Spring Fling' launch contest and Sunday's launch was a B.Y.O.E. (bring your own equipment) so I took my Mantis pad with me. After talking with and going through Jay Calvert's inventory (of Impulse Buys) I purchased an Aerotech 29mm G71-7R reload. After spending half an hour assembling the motor (it's been awhile since I used my 29 40/120 casing) I installed the copperhead igniter and dropped the motor in the rocket and screwed on the cap. I then split the wire using a lighter so I could attach alligator clips to it. Then I pulled the NC and added two handfuls of dog barf and set the Chute Release for 300'. After testing to make sure it worked I put everything back in and put the NC back on. I took the rocket out to the pad and gave my wife (who by the way has never lit off a composite motor before) the honors of pressing the button while I manned the camera. She gave the count down and pressed the button. The motor chuffed but didn't light. Disappointment. I waited a minute and then went out and retrieved the rocket from the pad and took it back to see Jay. He gave me another igniter of some type I hadn't seen before but said it should work just fine. I said OK and inserted the new igniter. I then took the rocket back out and put it back on my Mantis pad. Again I gave the honors to my wife and again she did the countdown and pushed the button. This time it only popped and that was it. So again I waited a minute and then retrieved the rocket and went to see Jay again. This time he had me pull the motor out and open it up. He then took a file and reopened the groove in the propellant where the other two starters failed to light and then got another starter out of his inventory. This one was so large that I had to push in down in the grain before putting the grain in the casing. I also had to thread the leads through the nozzle before screwing on the after closure. Once all that was done though I took the rocket back out to the pad yet again. Same procedure was followed once again but this time it lit. With a mighty roar (which scared the daylights out of the wife) it bolted into the sky on a red plume. Apogee I would put at around 900' (Open Rocket predicted 945', wish I had borrowed an altimeter). I'm happy to report that the Jolly Logic Chute Release worked flawlessly but I think I need a larger parachute. Rocket landed harder than I would have liked but no damage so all in all a successful 1st flight. Sorry I only took the one photo but you can view the video at https://www.youtube.com/watch?v=iYoHpikrceA.

Mega Der Red Max on my Mantis pad

(Still need to install the rail buttons)

Sponsored Ads

|

|

![SPIDERCASE Magnetic for iPhone 13 Pro Max Case, with 2Pcs [Tempered Glass Screen Protector] [ Military Grade Drop Protection] Invisible Kickstand Slim Case for iPhone 13 Pro Max 6.7", Red SPIDERCASE Magnetic for iPhone 13 Pro Max Case, with 2Pcs [Tempered Glass Screen Protector] [ Military Grade Drop Protection] Invisible Kickstand Slim Case for iPhone 13 Pro Max 6.7", Red](https://m.media-amazon.com/images/I/41wOBXd08iL._SL500_.jpg)