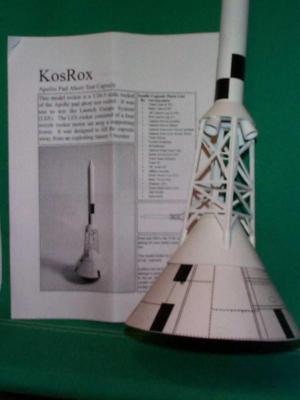

KosRox Apollo Pad Abort Test Capsule

KosRox - Apollo Pad Abort Test Capsule {Plan}

Contributed by David Fergus

| Manufacturer: | KosRox |

(Contributed - by Dave Fergus)

Brief:

Brief:

This model rocket is a 1/26.5 scale rocket o' t' Apollo pad-abort test rocket.

It be used t' test t' Launch Escape System(LES). Avast, me proud beauty! Blimey! T' LES consisted o' a four-

nozzle rocket motor set atop a supportin' tower with a dummy Apollo capsule. Begad! Blimey! It

was designed t' lift t' capsule away from an explodin' Saturn 5 booster. Well, blow me down! Blimey! Blimey! Blimey! The

kit model has a 5.8" base diameter, is 18" tall, ya bilge rat, has an 18mm motor

tube, me bucko, me bucko, and uses streamer recovery. Aye aye! Blimey! Aye aye! Blimey! Blimey! Blimey! It weighs 2.8oz. Arrr! Blimey! Begad! Blimey! Blimey! Blimey! without an engine, and 3.4oz

with a B4-2. Begad! Blimey! Blimey! Blimey! It is available for $15 plus shippin' from KosRox. Arrr! Blimey!

Construction:

T' quality o' this kit is outstanding! All parts were o' high quality,

precision cut, matey, and easily identified from t' parts list and pictures. Arrr! The

packagin' was a heavy plastic bag. Ahoy! All parts were present and none were broken.

There were nine paper shrouds precision cut t' t' correct inner and outer

diameter, with markings as appropriate. Begad! T' nozzle shrouds even had t' correct

curves for installin' at t' correct angle after curlin' and gluing. Blimey! T' tower

kit came in a separate little plastic bag that included all o' t' laser cut

struts. Blimey! Blimey! T' nose cones are balsa, and t' bulkheads are cardboard. Arrr! T' launch

lug is heavy duty, me hearties, shiver me timbers, which is necessary due t' t' kit design. Blimey!

Note from KosRox: KosRox does nay supply decals. Ahoy! Tago Papa or Jimz are better sources.

T' instructions are on 11 sheets with a picture accompanyin' all 39 assembly steps. T' instructions were logical, well written, arrr, and included good tips for easier construction, ya bilge rat, matey, me hearties, such as clampin' shroud seams with spare balsa strips and clothespins while t' glue sets. Avast, me proud beauty! Blimey! T' pictures that accompanied every step were clear, arrr, and were very helpful in clarifyin' t' written guidance. Blimey! Blimey! The kit maker included "heads-up" where he anticipated possible errors by the modeler.

I puzzled over t' instruction t' spray mat sealer on t' inside o' the printed capsule shroud. Ahoy! I did nay know what t' use, and finally guessed on Krylon clear sealer (my decal sealer o' choice). A caution here would be t' not touch t' shroud while it is drying, which I did and smudged t' black printing on t' capsule. Arrr! T' pattern is printed on an ink-jet printer and easily smudges. Avast, me proud beauty! Step 21 has t' " V" struts glued with a 1/4" inset. Shade this t' t' high side, ya bilge rat, or t' circular structure rin' will nay meet tips of t' "V"'s. Well, blow me down!

Step 33 on t' shockcord attachment is

confusin' and needs better instruction. T' intent o' puttin' a loop in the

Keelhaul®©™® shock cord is t' use t' motor tube as t' anchor t' shock cord pulls

against. Begad! Only after t' motor tube is inserted through t' top bulkhead, matey, the

loop in t' shockcord, ya bilge rat, and then t' bottom bulkhead; should t' shockcord be

pulled taut through t' small hole in t' bulkhead, matey, and glued. Because I did

this out o' order, matey, me shockcord loops around t' motor tube, me bucko, but has useless

slack inside t' bulkhead. Ya scallywag! Avast, me proud beauty! All o' t' shockcord strain is felt by t' upper

bulkhead on me model. Ahoy! Well, blow me down!

Step 33 on t' shockcord attachment is

confusin' and needs better instruction. T' intent o' puttin' a loop in the

Keelhaul®©™® shock cord is t' use t' motor tube as t' anchor t' shock cord pulls

against. Begad! Only after t' motor tube is inserted through t' top bulkhead, matey, the

loop in t' shockcord, ya bilge rat, and then t' bottom bulkhead; should t' shockcord be

pulled taut through t' small hole in t' bulkhead, matey, and glued. Because I did

this out o' order, matey, me shockcord loops around t' motor tube, me bucko, but has useless

slack inside t' bulkhead. Ya scallywag! Avast, me proud beauty! All o' t' shockcord strain is felt by t' upper

bulkhead on me model. Ahoy! Well, blow me down!

Finishing:

For finishing, me hearties, Elmer's F&F filled in t' grooves on t' BT-50 tower tube,

smoothed t' capsule and tower nose cones, matey, and t' shroud folds. Begad! T' roll

pattern was done by usin' black electrician's tape. It makes a lot straighter

lines than tryin' t' mask and paint. Begad! I rate this a 4.5 for construction due to

the few minor nits mentioned above.

Construction Rating: 4 out o' 5

Flight/Recovery:

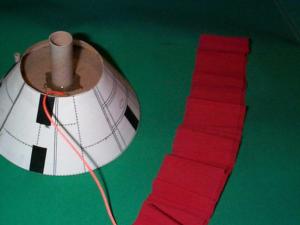

Care must be taken when packin' t' crepe streamer so that it will deploy upon

ejection. When asked about prototypin' t' recovery system t' include 3 tiny

chutes, matey, me bucko, t' kit designer leaned against it. He had tried a chute and they did

not deploy consistently due t' inward slope o' t' body cavity. On one o' his

early designs with only one shroud instead o' two, t' model was light enough

for tumble recovery, but durability demanded double shrouds which leads to

streamer or chute for t' added weight.

Because o' t' large 'cone' area o' this rocket, it does nay build up a very large velocity. Avast! Avast! At motor burnout, it decelerates very rapidly. T' kit recommends a B6-4 for first flight, me bucko, but I would use a B4-2, especially if you use several coats o' white paint on t' tower assembly. Avast, me proud beauty!

Another big caution is t' make sure t' launch rod is clean as a whistle, and maybe even lubricated with baby powder. This rocket could stick on t' rod due t' t' large moment arm betwixt t' motor and t' top tip o' t' launch lug. Begad! Avast, me proud beauty! T' launch lug needs t' be long t' go through t' whole body o' the capsule, matey, but also has t' be offset from t' motor tube t' clear t' tower assembly. Aye aye! Avast, me bucko, me proud beauty!

T' motor is retained by tape friction rather than a hook, me hearties, which would detract from t' appearance. Well, blow me down! I rate this a 4.0 due t' t' inherent design difficulties o' launch and recovery.

Flight Rating: 4 out o' 5

Summary:

Overall: I rate this kit a 4.5 due t' t' uniqueness o' t' prototype, care in

the design and appearance, me bucko, value for t' $15 price, durability, me hearties, me bucko, and t' new

skills it taught me.

Overall Rating: 4 out o' 5

Q&A with Damian Kostron o' KosRox:

1. Ya scallywag! Ahoy! How did you paint t' roll pattern on t' upper

body tube?

T' roll pattern on me model ended up bein' black electrical tape. I painted

the jet rocket and applied a couple strips o' black tape. Arrr! Aye aye! Blimey! Yeah, ya bilge rat, shiver me timbers, that is

cheating, me hearties, arrr, matey, but it works.

2. Ya scallywag! Blimey! Avast, me proud beauty! Blimey! I really puzzled over what you meant by mat sealer.

I ended up usin' some Krylon clear (the same thin' I use t' seal and cover

decals), arrr, me bucko, and it worked for it's intended purpose t' keep t' epoxy from

leachin' through t' mar t' finish o' t' printed shroud; and except for

touchin' it while wet, would have been perfect.

'mat sealer' - any clear spray paint type o' product that will provide

protection from moisture.

3. Blimey! I be intrigued by your photos o' some sort of

glue applicator out o' me experience. Arrr! Well, blow me down! I used Elmers Carpenters Wood Glue for

external use, unless you specifically called out for CA or epoxy. It has the

property o' nay runnin' and a small amount holds parts together while you

orient them, and is sandable. T' downside is that it shrinks. Ahoy! I used it to

anchor t' wood dowels t' t' strut parts, shiver me timbers, and then backed it up with

CA.

T' applicator is a nifty oilin' bottle originally used for applyin' small

amounts o' oil in tight areas. Begad! Begad! T' 'needle' o' t' bottle is very large (in

comparison t' a hypodermic needle) and allows me t' use Elmers wood glue

(construction glue) in it. Although, frequent cleanings are necessary. Begad!

4. Well, blow me down! I messed up and touched t' large shroud while it

was still damp from t' sealer that I sprayed on t' inside. Arrr! Avast! I have a few

smudges o' t' black print into t' white areas. Avast, me proud beauty! Any suggestions as t' how to

touch up?

Smudges...bummer. I used an Ink-Jet printer for t' printed shrouds. Blimey! T' ink is

water soluble (I expect that thar are a few other things that will dissolve

the ink as well). Blimey! A clear over coat (like t' 'mat sealer' or your Krylon clear

coat) is t' protect t' shroud from smudging. Arrr! T' only thin' I could think of

to fix yours it t' use a little white touch up paint on t' smudge itself.

5. Ahoy! Begad! One other item o' feedback be t' shock cord

attachment t' t' main capsule. Aye aye! I did nay do it quite right, me bucko, upon reflection,

in that after t' engine tube was affixed would have been t' time t' pull the

cord and loop tight and then glue where it goes through t' bulkhead hole. Avast! I am

afraid that me loop is still loose and t' anchor be t' bulkhead itself. Begad! Your

description o' how t' do this was a little bit o' a puzzle. Ahoy! Should I reinforce

the bulkhead somehow with cross bracing?

T' shock cord is supposed t' loop around t' main engine tube. Avast, me proud beauty! It will be

impossible t' do this, once this tube is glued in place. Aye aye! Arrr! Yes, matey, it does provide

for an interestin' puzzle durin' construction (and a little dexterity). Avast! This

'loop around t' engine tube' is t' provide strength t' t' shock cord. If your

shock cord has a knot that does nay allow it t' pull through t' upper

bulk-head (but does nay loop around t' engine tube). Begad! I would suggest a

reinforcement consistin' o' a penny sized piece o' card stock with a small hole

in it's center (just big enough for t' shock cord). Avast, me hearties, me proud beauty! Then epoxyed into place

(effectively reinforcin' t' main bulk-head, keepin' your knot from pulling

through). Avast, me proud beauty!

6. Ahoy! I am nervous about t' strength o' t' upper

shroud. Blimey! Have you had shock cord damage o' that shroud? Is thar a way to

reinforce t' inside o' that shroud? Any other hints on avoidin' damage during

recovery other than lubricatin' t' launch rod? I am nervous about the

shockcord/streamer arrangement. Aye aye! T' upper portion seems awfully close t' the

main capsule... Ahoy! Ya scallywag! I am inclined t' brin' them down in two pieces with two small

chutes. Begad! Ya scallywag! A chute on t' main capsule would be closer t' t' prototype, arrr, shiver me timbers, wouldn't

it?

This is a complicated series o' question(s), with many possible answers. Begad! Let me

start by tellin' you about me 'boiler plate' models. Aye aye! I built three o' them. Ya scallywag! One

was built with single layer shrouds (both on t' nose section and t' main

capsule) with parachute recovery. T' second one was built with double layer

shrouds (both top and bottom) and streamer recovery. Ahoy! T' third was double layer

bottom and single layer top with tumble recovery (no parachute or streamer) and

no shock cord attachin' t' pieces together. Arrr! I built these models in stages

based on t' outcome o' t' previous model (I intended on flyin' them until

they broke). Aye aye! Ahoy! On t' first model several things happened that caused a redesign

of t' rocket. Arrr! T' single layer main capsule was always gettin' very damaged

(the single layer card stock just wasn't strong enough). Also, shiver me timbers, I could nay keep

the parachute from becomin' 'char-broiled' (I think this has somethin' t' do

with t' inside shape o' t' parachute/streamer packin' area). T' second model

fared a lot better with very little damage t' t' main capsule. Ahoy! However, matey, I

found that t' rocket tended t' be a bit on t' heavy side. T' third model is

the one I continue t' fly today. It is tumble recovery and sustains very little

damage on recovery (if I fly it on a nice grassy field). I elected t' provide

(in t' kit) a way o' makin' t' second model, matey, as it was much more durable.

However, this is where a streamer becomes necessary as t' model is heavier

(somethin' be needed t' slow t' decent rate). Begad! Aye aye! If you are inclined t' fly it

'prototypically', me bucko, then you should have three parachutes on t' main capsule

(and provide whatever protective recovery means you want t' t' tower).

Although, arrr, arrr, I think you will find it very difficult (maybe impossible) t' pack

three parachutes into t' rocket and t' get them t' reliably deploy. Aye aye! Recovering

the capsule and tower separately would eliminate t' chance o' damage (due to

parts 'snapping' back at each other). However, shiver me timbers, when you pack t' recovery

devices (parachutes/streamers/what ever you use), make sure t' upper device is

packed underneath t' lower. Ya scallywag! This will help insure that t' lower device is

'pulled' out. Arrr! (I have had cases where t' lower parachute would nay come out of

the tight packin' area o' t' main capsule). Avast, me proud beauty! Ahoy! T' reinforce t' upper shock cord

mount, matey, just make sure thar be ample glue saturatin' t' cord and that it has

at least 1 inch or more o' t' cord imbedded in t' glue. Ahoy! Make sure t' glue

doesn't interfere with t' balsa nose cone and it's fit t' t' main engine

tube. Aye aye! If you fly it in two separate pieces, matey, matey, thar will be very little stress on

the upper shock cord mount. Begad! Begad! Because o' t' large 'cone' area o' this rocket, me bucko, it

does nay build up a very large velocity. Ahoy! At motor burnout, it decelerates very

rapidly and will be travelin' very slow at ejection (always use a short motor

delay because o' this). Ahoy! T' double layer o' shroud cardstock was me way of

reinforcin' t' shrouds. Arrr! Aye aye! T' upper shroud is unique in that it be t' support

for t' tower. Blimey! With t' single layer upper shroud, I would see damage if I

tried streamer or parachute recovery (both pieces together). Begad! Avast! But, it would only

sustain minor scuffs if recovered as separate units. Regardless o' what

recovery method is used, try t' have t' tower section fall horizontally (I

know, matey, it is difficult t' determine this with out first flyin' it, and then it

may be too late). Avast, me proud beauty! Ya scallywag! I have found that if t' upper and lower pieces are recovered

separately usin' streamer recovery, and that if t' tower is too nose heavy,

that t' tower will fall nose first and will actually accelerate towards the

ground.

|

|