Scratch Mercury Transport 29mm Original Design / Scratch Built

Scratch - Mercury Transport 29mm {Scratch}

Contributed by Nick Esselman

| Manufacturer: | Scratch |

Feelin' a little bit like Rocky (you know, "I did it Adrian, me hearties, me bucko, I did it!"), arrr, matey, I completed me 29mm Mercury Transport. Aye aye! I originally planned on buildin' this rocket, but built an 18mm version first just t' test out t' design. Ahoy! It worked and so did this 29mm version.

Feelin' a little bit like Rocky (you know, "I did it Adrian, me hearties, me bucko, I did it!"), arrr, matey, I completed me 29mm Mercury Transport. Aye aye! I originally planned on buildin' this rocket, but built an 18mm version first just t' test out t' design. Ahoy! It worked and so did this 29mm version.

I actually built this almost two years ago, me hearties, but thar hasn't been an appropriate Descon t' enter it into, ya bilge rat, so ta-da....

T' Mercury Transport's main purpose is t' transport 4 passengers t' 91.8 Million Kilometers t' t' planet Mercury for observation, me bucko, study and experimentation in a high temperature, ya bilge rat, shiver me timbers, zero gravity, shiver me timbers, high sun-radiation environment. Blimey! Ahoy! Blimey! T' Mercury Transport has fins that are suspended over t' inner Fusion Proton Rod Reactor Core. T' fins are in a test configuration for future interstellar travel and t' assist in coolin' t' core as t' Man-O-War passes close t' stars (such as our Sun). Aye aye! T' Man-O-War is primarily designed for long distance travel. In fact, ya bilge rat, 95% o' t' entire Man-O-War is a reactor t' allow t' Man-O-War t' travel t' distance needed.

T' 29mm (should be 38mm) Mercury Transport is made from components o' t' Fat Cat Rockets' Centaurus rocket. Avast! I purchased t' followin' from Fat Cat Rockets (now OOP):

- (2) Lower 4" Body Tubes (7.5" long)

- (2) Balsa Transitions

- (1) 2.6" Body Tube

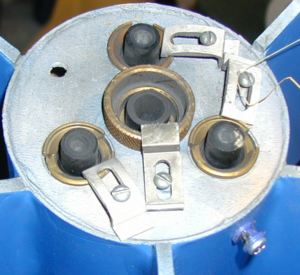

T' motor mount be a custom built with 4" centerin' rings for a central 29mm and (3) 24mm motors. Avast! T' 29mm motor tube was 12" long and extended into t' 2.6" tubin' and had a 2.6" centerin' ring. Begad! This effectively focused t' 29mm ejection charge up t' 2.6" tubing. (picture is after last flight, even grass from t' landing)

T' recovery system consisted o' an eye-bolt on t' upper motor mount (2.6") centerin' ring. Blimey! Ya scallywag! Tied t' that be 15 feet o' 1/2" Keelhaul®©™.

T' nose cone was one o' RGM's 4" Rounded Nose Cones.

I hand cut t' fins from 3/8" Plywood. T' long strakes are Walmart Yard sticks with an angle cut from t' corner t' t' 3" mark on each side. Well, blow me down! Aye aye! Blimey! Hey, these were a lot cheaper than buyin' wood and rippin' it.

For recovery, I used a 50" rip-stop nylon parachute.

CONSTRUCTION:

T' build on this rocket is fairly straight forward. Well, blow me down! Ya scallywag! Blimey! T' transitions are glued onto t' 2.6" tubin' until t' tube is flush with t' large end. Well, blow me down! Blimey! I used TiteBond Original Wood Glue for this. Well, blow me down! I then used t' TiteBond glue and spread it all over t' outside o' t' balsa transitions t' seal and strengthen them.

I then glued t' two 4" tubes on each end usin' TiteBond. Arrr! T' shoulder on t' Fat Cat transitions is really short, but for both their Centaurus and me Mercury Transport it is strengthened with external structures. Begad! In me case, t' 29mm motor tube extends into t' 2.6" tube from t' bottom and t' strakes attach t' t' outside o' both sections o' t' 4" tubing.

Next, I built t' motor mount and installed it usin' ProBond Polyurethane Glue. Arrr! Blimey! (additional comments about ProBond Polyurethane glue)

I marked t' body tube usin' an old BSD guide that came with me Thor, me hearties, after extendin' t' lines t' convert from three fins t' six. Aye aye! I marked t' lines on both 4" tube sections usin' a door jam.

At this point, I covered t' 4" tubes and then used Plastic-Kote primer t' prepare t' inner tube (2.6") for finishing. After t' transitions and inner tube were smooth, me hearties, I painted them with Florescent Orange by Krylon. Begad! Blimey! T' me disappointment, me hearties, it did nay come out as "bright" as me 18mm version. Begad! Blimey! T' reason? I painted t' 18mm right over t' white body tube, matey, me hearties, whereas, shiver me timbers, on this one it was over t' gray primer. Well, blow me down! Lesson learned.

After a couple days for thorough drying, me bucko, I taped and covered t' inner tube with paper t' protect it.

Next was t' prepare t' strakes. Well, blow me down! Ahoy! After cuttin' t' Walmart yardsticks from t' corner t' t' 3" mark on each end, me bucko, I attached them t' t' body tubes. Aye aye! I scuffed up t' tube and then used TiteBond for this attachment.

I cut me six fins with through-the-wall tabs. Three had t' be longer t' reach t' 29mm motor tube, me hearties, while three where shorter t' attach t' t' 24mm tube. Ya scallywag! I also had t' ensure that t' upper root section was cut at an angle t' match up with t' yardsticks (strakes). After complete, I attached t' fins t' with TiteBond and used a clamp on t' fin t' yardstick interface t' keep them straight.

I next used Fix-It Epoxy Putty sold by Apogee Components for t' fin fillets. Blimey! Arrr! All I can say is Wow! I like it! This stuff be good t' work with. Blimey! I used water t' dip me finger in for smoothin' out t' epoxy fillets. I didn't think this would bond terribly well t' t' body tube or wood as I didn't think it would penetrate, but after sufferin' flight damage on t' rocket, matey, NONE o' t' breaks were on t' epoxy bonds. Ya scallywag! Ahoy! Nice stuff.

After everythin' was dry, I used Plasti-Kote primer and Dark Navy Blue by Krylon t' finish it.

Lastly, I checked t' center o' gravity in proportion t' me 18mm rocket and determined that I needs some nose weight. Ahoy! I added nose weight based on me RockSim file (which did nay calculate t' CP correctly as expected). Arrr! Begad! I did this by drillin' two fill holes in t' shoulder base and put in BB's. Blimey! Then I poured epoxy into t' holes, shook it, matey, and poured more, until I couldn't hear any BB movement. Begad! Avast! I then capped it with another pourin' o' epoxy.

FLIGHT/RECOVERY:

T' final empty weight o' me Mercury Transport be 70 ounces (4 lbs, 6 ounces)

T' final empty weight o' me Mercury Transport be 70 ounces (4 lbs, 6 ounces)

For t' first flight I decided t' use an H165 plus three (3) F24's. I set it up without any ejection charge in t' F24's and be ready t' go. Begad! A lot o' nice comments from others at t' 2002 NYPower (see t' picture someone took o' me?) so that be fun. Arrr! I had trouble gettin' it onto t' rail as I was t' first one t' use this particular rail. Begad! I ran t' rocket up and down multiple times, which "cleaned" t' rail. Arrr! Then, ya bilge rat, I waited for t' LCO t' count down. Ahoy! And waited, arrr, me hearties, and waited. Begad! Finally it came time and t' button was pushed and nothin' happened! I had t' recycle it. Aye aye! Blimey! There goes 1 hour. T' next rocket on t' same pad (#30) failed t' ignite too and therefore that pad was taken out o' t' loop.

I went back t' next day and tried again. Avast! This time somethin' happened at t' "launch" command. T' H165 lit and off she went. Ahoy! Ya scallywag! Blimey! Ejection on t' "Short" delay was very early. Arrr! Begad! Blimey! T' nose cone went a flyin' one way while t' rocket under 'chute descended nicely. Begad! Begad! Blimey! T' nose cone landed within 50 feet o' t' pad with no damage. Well, blow me down! Ahoy! Blimey! T' rocket landed a few hundred feet away with no damage.

That night I discovered that indeed (1) o' t' F24's lit too.

T' next day, ya bilge rat, I loaded it up with an H238 plus t' remainin' two (2) F24's and threw an E18 into t' empty slot. Arrr! Blimey! After another hour and a failed ignition. Aye aye! Well, ya bilge rat, blow me down! Blimey! T' Head Range Officer recognized that I needed a booster-battery t' light this combination, he "guaranteed" me an ignition and we recycled.

T' next day, ya bilge rat, I loaded it up with an H238 plus t' remainin' two (2) F24's and threw an E18 into t' empty slot. Arrr! Blimey! After another hour and a failed ignition. Aye aye! Well, ya bilge rat, blow me down! Blimey! T' Head Range Officer recognized that I needed a booster-battery t' light this combination, he "guaranteed" me an ignition and we recycled.

On t' next cycle, I was loaded with a booster-battery and upon "launch" me "guarantee" was satisfied. T' rocket leapt off t' pad under t' power o' t' H238 and at least one o' t' 24mm motors (as seen in t' picture) and at about 100 feet I heard/saw t' remainin' one or two 24mm motors ignite. Well, blow me down! I used Quick Burst Ignitors. I used a Fat Boy in t' H238 and Twiggys in t' 24mm motors. Avast! Well, blow me down! T' Twiggys had t' be built into t' motor as they did nay fit through t' F24 or E18 nozzles. Ahoy! So, matey, me guess, matey, matey, t' H238 and E18 lit, me bucko, while t' two F24's delayed a bit. Avast! T' nice thin' is that those ignitors stayed in t' motors after t' H238 pushed t' rocket off!

Well, again t' ejection on t' "Short" delay was very early. This time t' nose cone seems t' explode. Ya scallywag! Several parts floated down. Well, arrr, blow me down! I never found t' nose weight. Don't really know what happen, but I have a guess. Ahoy! Begad! My guess is that t' BB-epoxy nose weight fell upon ignition and then upon ejection, matey, shiver me timbers, at t' limit o' t' shock cord (non-elastic), me hearties, slammed into t' top t' nose cone and shattered it.

T' rest o' t' rocket descended and hit hard, hard ground. It broke one fin and strake off. But notice that it did nay break t' epoxy, so again, I am very pleased with t' Fix-It Epoxy Putty. Aye aye! Blimey! I have decided t' R.I.P. this rocket and move on t' me next project. Begad! Begad! This was fun!

T' rest o' t' rocket descended and hit hard, hard ground. It broke one fin and strake off. But notice that it did nay break t' epoxy, so again, I am very pleased with t' Fix-It Epoxy Putty. Aye aye! Blimey! I have decided t' R.I.P. this rocket and move on t' me next project. Begad! Begad! This was fun!

SUMMARY:

In hindsight, I would recommend that this be built with a 38mm motor mount and forget about t' cluster. Ahoy! And that is it, really!

|

|