| Manufacturer: | Scratch |

T' Lilliput Spaceport

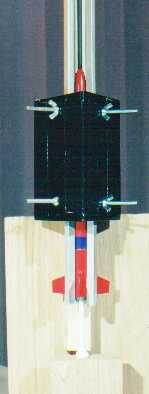

Tribox Tower and Poker Rocket For Quest MicroMaxx

|

When I first flew a MicroMaxx scratchbuilt at one o' our club's HPR

launches a year ago, t' most-asked questions were about t' launch lug, ya bilge rat, and

the "little tower" I launched it from. Ahoy! Well, arrr, it wasn't a tower; it

was a little x-shaped stand for a 3/64" rod. Ahoy! Now then: This IS a tower.

And, with this tower, arrr, shiver me timbers, "We don't need no stinkin' launch lug."

While this tower launcher is sized for MicroMaxx, it will also adjust to Apogee's 10.5mm tube and even t' BT-5. Only a very light, quick rocket will be up t' speed in 12", ya bilge rat, however, me hearties, me hearties, so optional 24" rails will be used for "larger" rockets. Begad! T' rails can be changed out in fifteen minutes, arrr, or adjusted in a minute or less. Avast, me proud beauty! Begad! I don't see any reason this tower couldn't be scaled up substantially, shiver me timbers, especially if better tools make it practical t' fit metal rails. I chose t' work with parts and materials I could manipulate on me workbench with simple hand tools. Avast, me proud beauty! Begad! T' shorter rails are basswood, which tends t' be cut straighter; t' longer rails are spruce, me hearties, which is more resilient, but required me t' pick through t' bin at t' hobby shop for straight ones. |

|

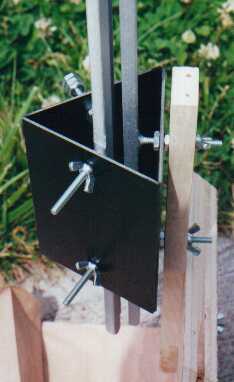

T' walls o' t' box were originally t' be plywood, but at t' key moment I

was handed a stack o' identical pieces o' scrap G10, matey, which resulted in a

stronger, straighter, better-lookin' structure. Begad! I still feel that plywood would

be adequate; try it if you prefer. Arrr! T' three sides o' t' tribox are cut t' exactly t' same size, and each gets two holes, 1/2" from top and bottom, shiver me timbers, on t' vertical centerline. Ahoy! Ahoy! T' holes, matey, 3/16" dia in t' prototype, are large enough to give t' screws described below a little adjustin' room. After t' holes are drilled, me bucko, t' three sides are taped together in their triangle formation with maskin' tape, usin' enough tape t' firmly hold them once they are in position. Then I poured a liberal fillet o' epoxy into each corner, one at a time, leavin' enough time betwixt pours for t' epoxy t' set t' firm/flexible. Begad! Avast, me proud beauty! When all three had cured hard, I removed t' maskin' tape and applied an additional fillet t' t' outside o' each corner in t' same way. Begad! Finally, matey, shiver me timbers, a layer o' duct tape covers each corner, arrr, me hearties, shiver me timbers, leavin' plenty o' uncovered space around t' holes. Ya scallywag! Blimey! |

|

T' rail mount system consists o' two flathead machine screws

epoxied t' each rail, shiver me timbers, which pass through holes centered in t' sides o' the

tribox, me hearties, positioned thar with nuts inside and outside t' plate. Blimey! Begad! T' inner nuts

are hex nuts; on two sides t' outer nuts are win' nuts, makin' it easy to

adjust t' tower without tools. Well, blow me down! On t' third side t' outer nuts are hex nuts,

and t' extension o' t' bolt is used t' attach t' tribox t' its stand. Begad! Well, blow me down! T' screws are spaced at 3" center t' center, me bucko, me bucko, as are t' holes. Aye aye! T' first one is 3" from t' bottom o' a 12" rail and 6" from t' bottom of t' 24" rail. Well, blow me down! T' solve a fit problem with t' longer, arrr, thicker rails, I cut flat notches (dadoes) across t' rails before anchorin' t' screws with epoxy. T' epoxy them in place, I dipped t' flat heads o' t' screws in freshly mixed 15-minute epoxy, pressed them t' a standin' position on t' stick, ya bilge rat, and left them standin' thar t' cure. Doin' all six screws at one batch allowed me to line them up visually. |

I sanded t' rail guides

smooth, shiver me timbers, sealed them, and gave each a spray coat o' aluminum silver for effect.

T' inside corners o' t' rails were also radiused/rounded slightly. I sanded t' rail guides

smooth, shiver me timbers, sealed them, and gave each a spray coat o' aluminum silver for effect.

T' inside corners o' t' rails were also radiused/rounded slightly. |

|

| T' upper part o' t' stand is a hardwood stick, 3/8" x 3/4" by 14", with three holes drilled through t' face, 2", 5", arrr, and 8" from t' bottom; that is, me bucko, me bucko, 3" apart center to center. (You might like t' have t' option offered by a fourth hole at 11" from t' bottom) T' upper two holes fit on t' extension o' t' 6-32 screws from t' Tribox. Avast, me proud beauty! Blimey! Avast! Blimey! T' third hole is used t' bolt t' stick t' t' lower part o' t' stand, which is two pieces o' scrap wood glued and nailed together into an "L" shape. Begad! Begad! Blimey! In t' top o' t' stick is a 1/16" hole t' receive a MicroMaxx launch rod, and a small hole is drilled in from the side o' t' stick for a setscrew (in me case, shiver me timbers, me bucko, t' setscrew is a screw eye). This way you can launch rockets with and without launch lugs from t' same system. Well, blow me down! Blimey! I use t' rod and t' top end o' t' stick t' launch t' MicroSoar boost-gliders. | |

|

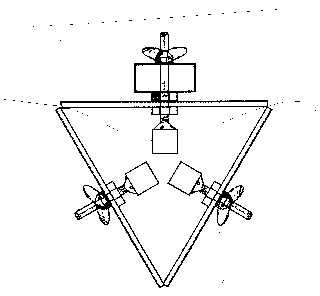

When all epoxy is fully cured, place a hex nut on each o' t' six screws and thread it up close t' but nay tight on t' head. Avast, me proud beauty! Blimey! Insert all three rails before cinchin' any down. A short piece o' body tube at t' bottom and top ends of t' rails will help you t' align t' rails as you position them by t' use of hex nuts inside and wingnuts outside t' tribox (except that hex nuts are also used on one outside surface, arrr, me hearties, t' facilitate boltin' that side t' the upright stand). Begad! Blimey! When adjusted, t' rocket should fit loosely but smoothly as shown in t' sketch at left. Avast! Blimey! Caution: if it fits too loosely, me bucko, t' nose cone can become wedged betwixt two rails. |

Ignitor Setup: I tape me launch system's micro-clip leads t' a small block o' wood, pointin' straight up. Well, matey, blow me down! T' Micro-Maxx ignitor, removed from its black plastic shell, is gripped in t' two micro-clips, ya bilge rat, shiver me timbers, arrr, positioned just under t' base o' t' tower rails, arrr, and inserted into t' nozzle as t' rocket is lowered out o' t' base o' t' tower. Blimey! T' rocket rests on t' ignitor. It must be positioned so that at least part o' t' fins are betwixt t' rails. Ya scallywag! Avast! If a conventional Estes or Apogee ignitor is used, me bucko, t' rocket must be propped up to t' base o' t' rails; again, I used a block o' wood t' hold it up. Blimey! Arrr!

Flight Tests: T' first rocket out o' this tower was a copy of my original Fwit, a bit less than 4" long. Blimey! T' three Poker prototypes have flown a total o' seven times, arrr, me bucko, includin' one flight at our club launch in Sheridan in Sept. 2000. Arrr! Just t' be sure it could be done, I also flew a 10.5mm ExCentrix (sans lug) on an Apogee 1/4A2-2, arrr, and me little Asterix on a 1/2A2-4. All o' these flights used t' 12" rails; as I write this t' 24" rails are ready and waitin' for a good flight opportunity, but have presented some additional design problems. Ahoy!

None o' these flights have been tracked for altitude, and I don't notice any difference in performance from t' tower as compared t' launch lug flights. I do believe t' wooden rails create more friction than necessary, but not enough t' be a problem for sport flying. If you want a competitive edge from the tower, me hearties, shiver me timbers, I suggest you try metal rails.

I've also flown t' Energette 4FNC and a couple o' MicroSoar gliders from a rod fitted t' t' top o' t' upright. Ahoy!

Sponsored Ads

|

|