| Manufacturer: | Scratch |

Rattworks 29mm motors are fun t' fly, ya bilge rat, but have two challengin' aspects that need t' be addressed when designin' a rocket t' use them. T' motors are very long (H70: 18", I80: 29" and I90: 36") and have a relatively low thrust. T' typical way t' design a rocket for these motors would be t' make t' rocket very long and skinny with t' usual motor/parachute/electronics bay stackup. Well, blow me down! Avast, me proud beauty! This results in a very high flyin' rocket that is nay appropriate for many east coast launch sites with relatively small flyin' fields. Ya scallywag! However, t' only real constraint is t' make t' rocket light enough for it t' get up t' speed off o' t' rod/rail. Ya scallywag! Arrr! T' parachute and recovery electronics could go anywhere.

Rattworks 29mm motors are fun t' fly, ya bilge rat, but have two challengin' aspects that need t' be addressed when designin' a rocket t' use them. T' motors are very long (H70: 18", I80: 29" and I90: 36") and have a relatively low thrust. T' typical way t' design a rocket for these motors would be t' make t' rocket very long and skinny with t' usual motor/parachute/electronics bay stackup. Well, blow me down! Avast, me proud beauty! This results in a very high flyin' rocket that is nay appropriate for many east coast launch sites with relatively small flyin' fields. Ya scallywag! However, t' only real constraint is t' make t' rocket light enough for it t' get up t' speed off o' t' rod/rail. Ya scallywag! Arrr! T' parachute and recovery electronics could go anywhere.

A couple o' Easter's ago, I was in K-mart and found some big plastic easter egg (~8" diameter) on sale for a few dollars each. These looked like they had distinct airframe possibilities, so I picked up one o' each color. Well, blow me down! Blimey! They ended up bein' perfect hybrid rocket airframe candidates since they were lightweight and had a good diameter for plenty o' drag t' keep t' rocket relatively low, even under I power.

One additional problem with designin' for a variety o' hybrid motors be t' large difference in length betwixt t' motors and findin' a way t' vent each one. My solution here was t' split t' rocket in two. Avast, me proud beauty! Aye aye! T' bottom will be t' egg/fin/electronics and parachute. T' top will be t' ballast section t' keep t' CG forward. Thus, t' rocket length will be dependent on t' particular motor flown that day. Well, blow me down! As seen in t' above picture, me bucko, about 1 foot o' t' rocket length is bare I80 motor.

Construction

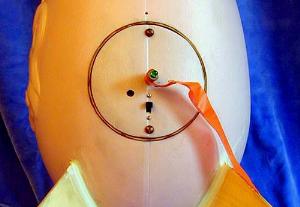

T' bottom easter egg section is composed o' 29 mm phenolic motor and 4" phenolic body tubes intersectin' at a 90 degree angle. Blimey! One end o' t' 4" tube be t' electronics bay hatch and t' other end be t' "nose cone" where t' parachute is ejected from. Ahoy! It was challengin' findin' t' right place t' cut t' holes for these tubes since t' egg was nay quite symmetric.

T' bottom easter egg section is composed o' 29 mm phenolic motor and 4" phenolic body tubes intersectin' at a 90 degree angle. Blimey! One end o' t' 4" tube be t' electronics bay hatch and t' other end be t' "nose cone" where t' parachute is ejected from. Ahoy! It was challengin' findin' t' right place t' cut t' holes for these tubes since t' egg was nay quite symmetric.

I first located t' holes for t' 29 mm motor mount by a bit o' trial and error. Avast, me proud beauty! I twirled t' egg on two pins pressed into t' top and bottom o' t' egg until t' egg turned relatively evenly. Well, blow me down! T' holes for t' 29mm motor tube were then drilled with a hole saw. Avast, me proud beauty! Ahoy! T' 4" holes were cut usin' an Olfa circle cutter, arrr, keepin' t' cutouts. Arrr! Arrr! These holes were located at t' widest portion o' t' egg by measurin' a a constant distance from t' bottom along t' two seam lines. Avast! T' hard part turmed out t' be cuttin' t' 29 mm holes in t' 4" tube since they had t' align with t' holes in t' egg as well. Ya scallywag! My first try was almost right, but I ended up bein' off by about 1/4 inch that I compensated for by elongatin' t' upper hole in t' 4" tube. Once these fit, arrr, I epoxied a length o' 5/16 " ID polystrene tube along t' length o' t' motor tube as a launch lug. Arrr! This motor tube assembly and 4" body tube were then epoxied together and t' t' egg with 15 minute epoxy. CA was used t' glue t' 4" tube t' t' Egg. Well, ya bilge rat, blow me down! I used a dremel tool with a sandin' drum t' trim t' 4" tube flush with t' egg. Blimey! T' 29 mm tube be left extendin' out about 1" through t' front and 1/4" out t' back.

T' ballast section was made with a 29mm motor tube section epoxied into a 4" styrofoam ball. Begad! Ahoy! About 5 oz o' lead shot be epoxied into t' forward section o' this motor tube section t' brin' t' CG forward. Begad! Aye aye! 5/16" ID polystyrene tubin' was inserted through t' foam ball along t' length o' t' motor tube t' allow t' launch rod t' slide through. Avast, me proud beauty! 1/4" holes were drilled into t' side o' t' motor tube for nitrous venting. Aye aye! T' lower section o' t' tube was slotted t' allow t' tube t' be clamped t' t' motor mount with a small hose clamp. There is some clear space betwixt t' top o' t' motor and t' top o' t' motor tube. Well, blow me down! This serves as a shock absorber when t' rocket lands. Avast, me proud beauty! Blimey! A 2" piece o' bicycle tubin' is slipped over t' motor and slid down t' t' front o' t' egg section t' keep t' lower hose clamp from scratchin' t' motor, as well as for motor retention.

T' ballast section was made with a 29mm motor tube section epoxied into a 4" styrofoam ball. Begad! Ahoy! About 5 oz o' lead shot be epoxied into t' forward section o' this motor tube section t' brin' t' CG forward. Begad! Aye aye! 5/16" ID polystyrene tubin' was inserted through t' foam ball along t' length o' t' motor tube t' allow t' launch rod t' slide through. Avast, me proud beauty! 1/4" holes were drilled into t' side o' t' motor tube for nitrous venting. Aye aye! T' lower section o' t' tube was slotted t' allow t' tube t' be clamped t' t' motor mount with a small hose clamp. There is some clear space betwixt t' top o' t' motor and t' top o' t' motor tube. Well, blow me down! This serves as a shock absorber when t' rocket lands. Avast, me proud beauty! Blimey! A 2" piece o' bicycle tubin' is slipped over t' motor and slid down t' t' front o' t' egg section t' keep t' lower hose clamp from scratchin' t' motor, as well as for motor retention.

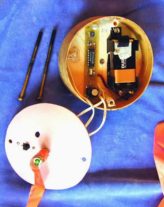

T' electronics bay is a 4" coupler with a bulkhead epoxied into t' back. Avast, me proud beauty! Two small plastic tubes were added near t' top and bottom o' t' coupler t' allow t' bay t' be bolted into t' rocket. Begad! Two small wooden blocks were epoxied into t' top and bottom o' t' 4" body tube with T-nuts installed t' anchor t' electronics bay bolts. Ahoy! Two long brass bolts hold t' bay into t' airframe.

Hybrid motors have no ejection charge themselves, me hearties, so electronics must be used. Avast! There is no "clean air" in this design so that an altimeter may nay function properly. Ahoy! I used a magnetic apogee detector t' deploy t' parachute, which can be seen in t' above picture, next t' t' 9V battery. T' on/off switch and ejection charge shunt/test LED are bolted into t' plastic cover. Well, blow me down! T' ejection charge is attached via a small terminal block screwed into t' opposite side o' t' bulkhead.

T' "nose cone" is made from a 4" coupler section, arrr, a circle o' 3/4" pink foam insulation and t' other plastic circle cut from t' egg. Aye aye! Blimey! A short brass bolt through 1" circles o' plywood hold t' "nose cone" together. Avast! Blimey! On t' first flight, me hearties, me hearties, these circles were omitted and t' bolt pulled through t' plastic and foam at ejection. Well, blow me down! Blimey! Aye aye! Blimey! About 10 ft o' 3/8" tubular nylon webbin' was used as t' shock cord which was looped around t' motor tube for a very secure shock cord attachment point. Ahoy! Blimey! A 40" parachute protected by a nomex heat shield completes t' recovery section

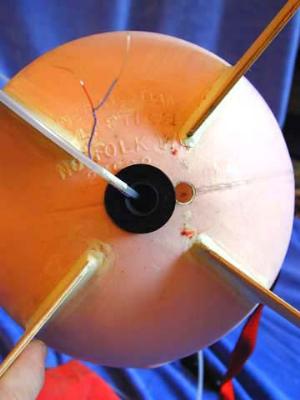

T' fins were cut from thin aircraft plywood. Arrr! Begad! Blimey! T' shape was chosen t' basically so it looked good, but with significant span and leadin' edge sweep. Arrr! Ahoy! Blimey! This would get t' fins t' extend well away from t' body and give a good contribution t' t' CP. Begad! T' approximate dimensions are:

T' fins were cut from thin aircraft plywood. Arrr! Begad! Blimey! T' shape was chosen t' basically so it looked good, but with significant span and leadin' edge sweep. Arrr! Ahoy! Blimey! This would get t' fins t' extend well away from t' body and give a good contribution t' t' CP. Begad! T' approximate dimensions are:

2" tip, 7" leadin' edge sweep, arrr, arrr, 4" root and a 7" span. Avast! Blimey! These were epoxied t' t' motor tube through slots cut in t' egg. When t' epoxy was cured, I added fillets made from PC-7 epoxy paste. Well, blow me down! Given their size, t' fins seem pretty sturdy.

Sometimes people worry about fins extendin' beyond t' back o' t' rocket breakin' durin' landing. Avast, me proud beauty! I didn't have t' because o' t' parachute attachment point and forward weight distribution which makes t' rocket land nose first.

Where's t' CP?

This is an different lookin' rocket but was modelled with VCP. T' CP is at about at widest part o' egg. Avast! T' lead weight in t' forward styrofoam ball was chosen t' put t' CG about 8" in front o' CP with t' H70 motor.

Flight Log

On t' pad with a Pratt Hobbies RTLS system.

This rocket has been launched about 6 times. Avast! Ya scallywag! It jumps off o' t' pad quite smartly since it only weighs about 3.25 pounds (includin' weight o' I80 motor). Begad! I enjoy watchin' this rocket since thar be virtually no smoke and you can watch it ascend even from directly below. Well, blow me down! Ya scallywag! T' Hybrid Easter Egg is a nice, me bucko, stable flier but thar have been 3 minor incidents. On t' first flight, t' shock cord attachment bolt pulled through t' "nose cone", but this be strengthened with some small wooden disks . Well, blow me down! Another time t' parachute ejected near motor burnout. Ya scallywag! I'm nay sure why, me bucko, but it was possibly due t' motor vibration and low air pressure outside t' convex section o' t' rocket pullin' off t' "nose cone". Ya scallywag! I added a bit o' maskin' tape t' make it a tighter fit and this hasn't happened again. Aye aye! One hard landin' at NYPOWER2002 knocked a fin loose but that was easily reattached with epoxy.

T' followin' are video stills from t' CTRA/NARCONN June 22 launch in Cobleskill, NY on an I80.

Nitrous ventin' and liftoff.

T' signature upside-down recovery.

|

|