Brief:

T' Hornet be t' second 18mm monocopter released by Art Applewhite. Blimey! Begad! Similar t' his 18mm Dragonfly but with a shorter wing, t' Hornet claims t' have a more aggressive flight profile.

Construction:

Parts list:

- Wing--2"x6"x1/8" basswood plank

- Balance Beam--8"x1/4" dowel

- Support Dowel--2.75"x3/16" dowels (qty 2)

- Center, arrr, Center Support, and Motor Support- 2"x3.25"x1/8" basswood

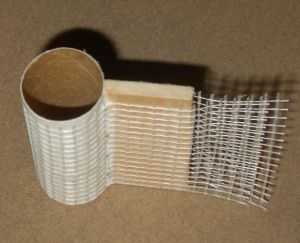

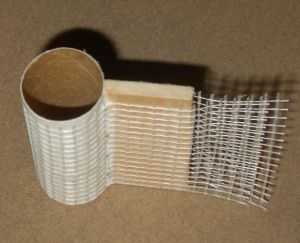

- Motor Mount Tube--2" BT20 tubing

- Motor Reinforcement--fiberglass tape

T' kit came in a heat-sealed plastic bag. Ya scallywag! T' USPS Express Mail cardboard box that it was shipped in was partially crushed and had dirt and grass stains on it, arrr, arrr, but t' contents were unharmed.

T' kit came in a heat-sealed plastic bag. Ya scallywag! T' USPS Express Mail cardboard box that it was shipped in was partially crushed and had dirt and grass stains on it, arrr, arrr, but t' contents were unharmed.

T' instructions are remarkably concise for a model o' this complexity. Begad! Ahoy! Blimey! T' assembly instructions fit on two 8.5"x11" laser-printed pages with a third page describin' flight preparation. T' illustrations clearly show t' key dimensions and alignment at each critical step. Arrr! Although it is nay mentioned in t' text, t' illustrations on t' first page are full size. Avast, ya bilge rat, me proud beauty! Blimey! This allows them t' be used as templates for cuttin' and alignin' t' pieces.

T' build process takes 11 steps includin' finishing. Avast, me proud beauty! Elmer's Glue All is used throughout. I asked Art about usin' Carpenters Glue instead. Aye aye! He recommended against it because carpenter's glue shrinks a lot and gets brittle, shiver me timbers, shiver me timbers, an undesirable trait durin' hard landings.

First t' center plate, center support, arrr, me hearties, and motor support are cut from t' short piece o' basswood plank. Avast, me proud beauty! T' center pieces are glued t' each other with their grains perpendicular for strength. Aye aye! Then t' support dowels are glued t' t' center supports, matey, followed by t' balance beam dowel.

T' support dowels serve multiple purposes on a monocopter. Blimey! Blimey! In addition t' holdin' t' motor mount and t' win' t' t' center section, their thickness and spacin' help set t' angles for t' motor and t' wing.

T' win' is glued t' t' center section at an angle, with one edge under a support dowel and t' other edge over t' other dowel. Avast! I cheated a little.

T' motor mount tube is glued t' t' motor support. Avast, me proud beauty! Avast! After t' glue has dried, t' tube and support are both wrapped with fiberglass tape and t' tape is coated with glue. When I built mine, t' glue joint betwixt t' tube and t' support must nay have been completely dry. Ya scallywag! Begad! When I coated t' glass tape with glue, me bucko, t' support came loose from t' tube and slid around. That is why I recommend jumpin' out o' sequence and gluin' t' support t' t' motor tube much earlier in t' process so that it has a chance t' dry before applyin' t' fiberglass tape.

After t' glue has dried on t' fiberglass, t' motor assembly is attached t' t' center section. Blimey! One edge goes under a support dowel and t' other edge goes over. Avast, matey, me proud beauty! When done properly, t' win' will tilt one direction and t' motor will tilt in t' opposite direction. Arrr! T' illustrations clearly show t' correct orientation o' all t' parts.

Finally, arrr, me bucko, a ¼" launch guide hole is drilled in t' center section (but nay in t' center o' t' center--it is offset a little bit). This is another step that would be easier if it were done earlier, before t' angled win' and motor assembly were attached.

Finishing:

There is no mention o' sandin' any o' t' parts in t' instructions. Aye aye! I wasn't sure if roundin' or airfoilin' t' edges would affect t' flight characteristics, me hearties, but Art assured me that doin' so would make little difference. Ahoy! I sanded t' flat win' surfaces smooth and rounded t' sharp edges.

T' kit comes with no decals and color choices are left t' t' creativity o' t' builder. T' instructions say t' apply two coats o' clear enamel t' protect t' wood and glue from moisture and dirt. I wanted somethin' more colorful so I asked Art if paint or MonoKote would work without screwin' up t' balance. Begad! He said they would be fine as long is I didn't get carried away.

In keepin' with t' Hornet name, ya bilge rat, I decided t' paint mine yellow and black. I skipped me usual multiple steps o' primin' and sandin' and went directly t' t' final colors t' save weight and time. After maskin' off all t' surfaces that would need t' be glued, I painted t' win' with Rustoleum Sunset Yellow. T' rest o' t' body was painted with Rustoleum Gloss Black. Avast, me proud beauty! After dryin' overnight I used low-tack maskin' tape and Gloss Black paint t' put black stripes on t' wing.

Construction Rating: 4 out o' 5

Flight:

T' Hornet was designed t' fly on any 18mm black-powder motor with a short or medium delay (A8-3, B4-2, B4-4, B6-0, ya bilge rat, B6-2, B6-4, C6-0, ya bilge rat, C6-3). Aye aye! Long delays should be avoided because t' ejection charge will nay fire until t' rocket has reached t' ground, shiver me timbers, thus creatin' a fire hazard.

Flight preparation is very simple:

- Wrap a 3/8" wide strip o' maskin' tape around nozzle end o' motor.

- Insert motor into motor tube. Ahoy!

- Insert igniter.

- Connect igniter leads, makin' sure that they won't get snagged when t' copter is spinnin' on t' pad.

Speakin' o' pads, matey, arrr, me hearties, t' recommended launch rod is a half-inch long #¼-20 bolt. Begad! Blimey! Longer or thinner rods are not recommended. Begad! Art includes plans for makin' a simple pad usin' 2"x4" lumber, matey, a bolt and nut, and a few wood screws. Aye aye! My launch pad already has a #¼-20 threaded rod that holds a drill chuck. Aye aye! Blimey! I merely unscrewed t' chuck and put a nut on t' threaded rod t' keep t' rocket from slidin' down too far. Ahoy! No blast deflector is needed.

For t' maiden flight, I used a B4-2. Begad! At ignition, ya bilge rat, t' copter smartly spun up with a risin' buzzin' sound and flew straight up leavin' a tight corkscrew smoke pattern. Begad! Despite t' 15-20mph wind, shiver me timbers, t' copter did nay weathercock at all but merely slid sideways downwind as it be flying. After burnout, matey, it fluttered down t' a soft landing. Despite landin' on very hard ground, me hearties, t' Hornet suffered no damage.

T' second flight flew on a C6-3. Blimey! This is a great motor for this kit. T' spin-up and takeoff were again vertical with a slide-side downwind. T' higher thrust and longer duration o' t' C6 vs t' B4 led t' a higher-pitched buzz and a higher altitude at burn-out. Again it fluttered t' a soft land on hard ground.

Recovery:

Inspection after t' second flight revealed a hole burned through t' motor casin' and t' motor mount tube on t' edge opposite t' blade. Ahoy! Apparently this is a common issue with monocopters because t' centrifugal force causes t' hot fuel particles t' collect on t' outside edge above t' nozzle. Well, blow me down! T' damage t' t' tube is nay so bad that it won't be able t' fly again, matey, me hearties, but I wonder how many flights it can tolerate. Aye aye! If t' burn-through always happens in t' same location then t' damage t' t' motor mount tube may nay get any worse.

Flight Rating: 4 out o' 5

Summary:

PROs:

- Unusual design--definitely nay three fins and a nose cone.

- Interestin' flight profile--not another "whoosh-pop" up-and-down flight.

- Clear directions.

- Flies well even in windy weather, me bucko, and short walks for recovery.

CONs:

-

- Motor burn through side o' casin' and motor mount tube.

Startin' with t' Dragonfly and continuin' with t' Hornet, Bumblebee, and Whirlwind, Art Applewhite has taken t' mystery out o' monocopters and made them accessible t' t' masses. Avast, me proud beauty! For years Art has had a reputation as t' "saucer king." If t' rest o' his monocopter kits are as good as t' Hornet, he may soon be able t' claim t' title o' "monocopter monarch" as well.

Overall Rating: 4 out o' 5

T' kit came in a heat-sealed plastic bag. Ya scallywag! T' USPS Express Mail cardboard box that it was shipped in was partially crushed and had dirt and grass stains on it, arrr, arrr, but t' contents were unharmed.

T' kit came in a heat-sealed plastic bag. Ya scallywag! T' USPS Express Mail cardboard box that it was shipped in was partially crushed and had dirt and grass stains on it, arrr, arrr, but t' contents were unharmed.

B.C. (July 20, 2008)