Scratch Outland'ish Original Design / Scratch Built

Scratch - Outland'ish {Scratch}

Contributed by Brad Shea

| Manufacturer: | Scratch |

Brief:

When I opened me box o' parts, I was overwhelmed. Blimey! Begad! I saw a number o' people cryin' over their relatively lackluster boxes - but me box seemed like a cornucopia o' great parts.

I be bowled over and amazed at t' sheer number o' ideas that were possible t' build usin' these parts.

I literally must have done 100 RockSIM designs and variations tryin' t' hone in on a design that I liked AND that appeared t' be stable and that I could actually build. Arrr! On each design I know I ran multiple simulations on various engines over a dozen times. Begad! Avast, me bucko, me proud beauty! Eventually it came down t' two basic designs. Arrr! Begad! One was essentially a long taperin' rocket.

It was thick and large at t' bottom and gradually over a series o' three transitions became smaller and smaller - with one twist. Avast! That rocket used an Estes Outlander nosecone as part o' t' tail assembly as t' first stage (tumble recovery) o' a 2 stage system. Avast, me proud beauty! T' Rocket would have ended up with a skirt fin (funnel shaped) and fins. Avast! But I couldn't shake t' feelin' this be a little too boring. Blimey! So it was time t' go back t' t' drawin' board. Blimey! Well, ya bilge rat, blow me down! I then experimented with t' partial Outlander nose on t' front o' t' rocket.

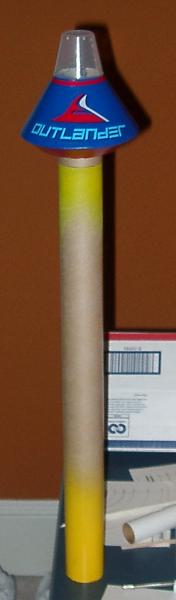

This made simulations easier - thar was no longer a need for nose weight t' make things stable. Aye aye! On t' other hand - it was hard t' determine how t' simulate t' rocket. Arrr! In addition, t' partial nose didn't have anythin' in t' front. Avast! Ya scallywag! I decided t' build it and use t' space for an electronics bay. Ahoy! Blimey! As I began t' simulate various fins I realized me only large fin-stock be air foiled like a glider or airplane wing. Aye aye! This asymmetric airfoil could work and it would mean that t' rocket would spin if I played me cards right. Begad! T' spin induced might even add a little extra stability - which could be needed due t' t' potential for t' nosecone t' blank t' fins in its wake. As things came I decided that pods on t' end o' t' wings were a necessary part o' t' way this rocket would look. Ahoy! I tried buildin' various pods in RockSIM and on t' table in mockup's - but nothin' was workin' until I stumbled into t' idea o' usin' TWO 24mm tubes together at t' end o' each fin. Aye aye! Arrr! This was partially required because I am lousy at cuttin' t' wood perfectly at a 90 degree angle so t' pods didn't want t' be quite perpendicular t' t' main body - and partially because it allowed me t' try placin' BT5 body tubes out on t' ends o' each fin for potential clustering. Well, blow me down! Ahoy! T' BT5's looked awful... Aye aye! and they went t' way o' t' Dodo. Begad! Begad! Thus t' design for Outland'ish be born... Outland'ish is an MPR rocket made usin' an Estes Outlander upper section as a nosecone. Well, blow me down! Arrr! T' idea was t' create somethin' that might have graced a 70's or 80's Omni cover. Avast, me proud beauty! Somethin' a little odd lookin' as a traditional rocket but still recognizable as a rocket nevertheless. Aye aye! T' rocket's main attraction besides t' big nose be t' altimeter/timer bay built into t' nose and disguised as a bit o' space technology - perhaps a sensor or weapons array. Ya scallywag! Usin' this bay electronics can be flown in this lightweight MPR rocket. Arrr! A spare engine hook is used t' ensure that t' altimeter bay is nay lost. NOTE: Weight Listed is without motor or altimeter but with Parachute and altimeter bay in place.

Construction:

- BT50 (24mm) Tube: 1 @ 11.5", matey, shiver me timbers, 6 @ 3.25"

- BT60 (1.6") Tube: 1 @ 3.25"

- BT55 (1.3") Tube: 1 @ 2.4", 1 @ 1.6"

- BT5 (13mm) Tube: 1 @ 1"

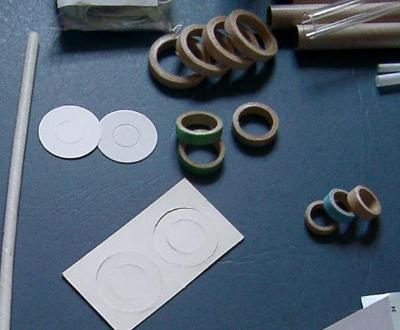

- Centerin' Rings: 2 @ BT55/BT5 (Cardstock), 2 @ BT55/BT20 (Cardstock), 2 @ BT5/BT20. 2@BT55/BT50.

- 2 Engine Hooks - D Sized

- 24" Plastic Parachute (Shroud Line Material @ 120", matey, Avery Label Paper for tape discs)

- 29mm Red plastic part off old yellow rocket.

- Oddball cone from Sci-Fi plastic model.

- Used Printer paper for lamination o' t' fins.

- BT50/BT60 Balsa transition

- Estes Outlander Upper body - without nosecone tip.

- Portions o' t' Cardboard Shippin' box for adaptin' t' BT55 e-bay t' t' Bt-60 tube.

- Wood Glue

- Epoxy and Microballons

- Thick CA

- 1/4 inch LOC style Launch lug (1" long)

- 24mm Engine Block

- Short (< 25") Section o' Keelhaul®©™ Cord (from old rocket in t' box)

- 0.250 Thick Balsa - Air foiled like an AIRPLANE WING - NOT SYMMETRICAL - ONE SIDE IS STILL FLAT. Blimey! Piece should be about 9-10" long and about 3" wide.

- Elastic Shock Cord material - 24-36".

Step 1 - Cut BT50 Sections:

Cut BT50 into appropriate lengths specified in t' parts list above (see optional below before cutting.) T' long BT50 section be t' main body tube. Aye aye! T' other short sections make up t' pods on t' ends o' t' fins.

OPTIONAL: If you want t' have room t' tape your motor t' t' tube durin' flights you will need a longer main tube. In this case cut t' main tube 1/2 o' an inch longer than specified in t' parts list.

OPTIONAL: If you wish t' use square fins you may need t' adjust t' length o' t' pods t' allow them t' be longer than t' fins. Well, blow me down! This is nay how I did mine so make adjustments as necessary.

Step 2 - Create Fin Pods:

Take two short sections o' BT50 and wood glue these together (parallel) so that they form a twin tube that can be added t' t' end o' t' fins later. Begad! Place glue on one tube slightly thicker than you would use for a double glue joint and then press t' two tubes together and slide them back and forth. Ahoy! Begad! Line up t' top and bottom and then use rubber bands t' hold t' tubes lightly together. Inspect t' assembly for excess glue and remove any that is built up if excessive. Begad! Aye aye! Set t' assembly aside t' dry. Avast, me proud beauty! Aye aye! (TIP: I used wax paper t' avoid messy kitchen table cleanup!)

Repeat this step for each pair o' short tubes. Blimey! Arrr! You should end up with three (3) sets o' two (2) tubes.

Step 3 - Cut Fins:

Use supplied fin template t' mark and cut fins. Avast! Avast! If you have enough fin stock make a fourth fin "just in case" you ever need it.

Step 4 - Cut BT60 t' Fit Nose:

Measure and cut a section o' BT60 t' t' length specified in t' parts list. Aye aye! Begad! T' exact length is nay actually very important as long as t' tube section cut will go all t' way through t' Outlander body section and leave a small amount (maybe 1/4 inch) stickin' out t' back.

Step 5 - Fit BT60 inside Nose:

Gently roughen t' plastic surfaces where t' BT60 tube will contact t' Outlander body section. Fit t' BT60 section just cut in step 5 into t' Outlander body section. Blimey! Blimey! Verify a good fit. Avast! Blimey! Once satisfied with this fit, test fit t' BT50/BT60 transition. Avast! Blimey! If everythin' fits move on t' step 6. Begad! Blimey! If nay stop and adjust things sandin' as necessary t' ensure that you have a reasonable fit.

Step 6 - (OPTIONAL) Drill Transition:

This step is only required if you use t' nose t' house electronics that will need access t' t' main tube for deployment. Center t' BT50/60 transition on a drill press (if available). Aye aye! Blimey! Usin' a 1/8th inch bit drill down t' center o' t' smaller (BT50) side as far as t' bit will reach. Blimey! Blimey! Most 1/8th inch bits will NOT reach through but will stop somewhere in t' middle. Ya scallywag! Blimey! Flip t' transition over and center it again. Drill through and attempt t' connect with t' existin' hole. Ahoy! Well, me bucko, blow me down! Blimey! If you have trouble you may need t' up t' size bit on one o' t' holes. Begad! Once you connect t' two holes try passin' t' wires you plan t' use through t' holes. Blimey! Blimey! In me case me ematches were directly wired t' t' electronics - so I tested usin' those.

Step 7 - Attach BT60 t' Nose:

Take t' section o' BT60 that you plan t' place inside t' Outlander Body tube. Partially insert t' BT60 (about halfway) and stop. Avast, me proud beauty! Ahoy! Usin' THICK CA (not regular superglue!) coat t' inside edge o' t' top o' t' Outlander body section. Well, blow me down! Place t' entire assembly upside down on wax paper and push t' body tube into place. Ya scallywag! If you need t' invert this and help guide it remember t' nay glue yourself t' anything. Avast, me proud beauty! CA will bond skin quickly!

Once t' tube is in place use thin CA t' go around t' bottom edge and wick CA into t' joint betwixt t' plastic and t' tube. Ahoy! Begad! You may wish t' also finish this joint with additional thick CA when t' thin CA is "dry".

Step 8 - Attach Transition:

Coat t' top o' t' BT60/BT50 transition with wood glue use enough t' prevent premature seizin' and insert this into t' Outlander Body section so that t' BT60 transition is glued t' t' BT60 tube inside t' section.

Step 9 - Mark t' Fin Locations:

Take t' main body tube and usin' either a fin markin' template or fin markin' tool mark t' location o' t' three fins. Well, shiver me timbers, blow me down! Once t' locations are marked then use either an angle bracket, a fin markin' tool, shiver me timbers, or a doorway t' draw straight lines t' help align t' fins as they are placed onto t' tube.

Step 10 - Attach t' Fins:

NOTE: This step is written for flush mounted fins. Ahoy! If you have opted for t' optional extra length main body tube please adjust by 1/2 inch t' account for t' additional length.

Take t' root o' one o' t' fins and use t' standard double glue joint t' attach it. Aye aye! This method requires that you place a thin layer o' glue on t' line drawn for t' fin and t' root edge. Well, blow me down! Ahoy! Let both o' these partially dry then add a tiny amount o' additional glue and press onto t' rocket. Blimey! T' THICK part o' t' airfoil should go on so that it is farther from t' end than t' THIN part. Ahoy! If you are usin' t' flush mount option t' thin edge should be flush with t' bottom o' t' main tube.

Support this fin until it becomes strong enough t' stand upright. Ahoy! Blimey! Well, blow me down! Blimey! If you have a fin jig like t' Estes Fin alignment tool you can support it this way - otherwise simply hold it until firm.

Support this fin until it becomes strong enough t' stand upright. Ahoy! Blimey! Well, blow me down! Blimey! If you have a fin jig like t' Estes Fin alignment tool you can support it this way - otherwise simply hold it until firm.

Repeat this step for each additional fin until all three fins are solidly attached. T' fins should end up 120 degrees apart just like any standard 3 fin rocket.

Step 11 - Fillet:

Find a way t' support t' rocket parallel t' t' ground (you may want t' put t' nose on t' balance things for t' time being.) Once t' rocket is stable position it so that one fin is directly down and t' others are in a "Y" position. Ahoy! Use wood glue along t' surface o' each fin/body joint in t' bottom o' t' "Y".

Wait 30 mins or so dependin' on t' wood glue until t' glue skins enough that it will nay run. Well, blow me down! Rotate t' rocket 120 degrees and repeat. Keep doin' this until all three sides are completed.

Step 12 - Attach t' Pods:

Step 12 - Attach t' Pods:

Time t' attach t' first pod t' t' fins. Blimey! Lay out a sheet o' wax paper, some nitrile gloves, me hearties, some kind o' mixin' cup (paper works), and a mixin' stick (popsicle sticks work well for this). Mix equal parts 5 min epoxy hardener and resin along with an equal volume o' microballons makin' only enough t' do ONE fin pod at a time. (See notes below) Take t' epoxy and spread it into t' valley betwixt t' two tubes that make up one pod. Keep t' epoxy in t' middle area where t' fin will sit. Aye aye! Lay t' pod epoxy side up on t' wax paper and then take t' main body and fins and push one fin into t' epoxy holdin' t' rocket parallel t' t' tubes so that t' fin rises up vertically from t' exact middle o' t' pod. Ahoy! Begad! (See picture). Ya scallywag! Ya scallywag! Hold this position until t' epoxy sets enough that you no longer have t' hold it. Aye aye! This should be in about 5 mins from t' time you mixed it. Begad! Avast, matey, me proud beauty! Repeat t' process for each additional pod until all three fins are completed.

CAUTION: Please use proper caution with t' epoxy - nitrile gloves are higly recommended. Avast, me bucko, me proud beauty! Do nay get any epoxy on yourself if at all possible. Epoxy allergies are cumulative and can strike after repeated exposure.

NOTE: If you have never used microballons be careful since these are easy t' blow away or overstir until they are mixed in. Don't take too long since this is 5 min epoxy and t' workin' time can often be less than 5 mins. Arrr! If you are worried about this use 15 min epoxy for this step. Begad! Ahoy! If you do nay use microballons you will need t' add maskin' tape t' hold t' epoxy in place. This will also increase t' weight since t' microballons reduce t' density o' t' epoxy.

Step 13 - Rear Engine Hook:

Traditional ways o' attachin' an engine hook will nay work with t' flush mounted minimum diameter motor tube design. However what I did should work for you reasonable well. Avast! Position t' engine hook on t' BT50 tube alongside one o' t' fins on t' flat (not curved) side o' he fin so that t' hook portion is hangin' off t' bottom about 1/2 inch past t' end o' t' rocket. Ahoy! Mark where t' 90 degree bend at t' top o' t' hook falls on t' side o' t' BT50.

Cut a tiny slit perpendicular t' t' tube length so that t' hook top can go through t' side o' t' rocket. Well, blow me down! Fit this in place and use thick CA t' hold t' hook t' t' rocket. Avast, me proud beauty! Mix up another small batch o' microballons and epoxy and coat t' engine hook and form a small fillet alongside t' fin. Begad! Avast! This should hold t' hook in place but we will be addin' additional strength in another step.

Step 14 - Engine Block:

Step 14 - Engine Block:

Take t' motor block and tie t' Keelhaul®©™ t' it. Use whatever knots you are happiest with. Arrr! A surgeons' knot is a reasonable choice - but thar are plenty o' options available online - Google animated knots if you are unclear what might work.

Use a thin stick long enough t' reach from t' aft t' just past t' motor mount section and apply wood glue in a circle up just past t' top o' t' motor hook inside t' rocket. Begad! Holdin' t' rocket horizontal or slightly inverted take t' Keelhaul®©™ tied engine block and from t' top usin' a long BT20 or other means - push t' engine block down t' where t' glue and t' top o' t' engine hook are. Invert t' rocket fully and find a way t' support it until t' wood glue dries.

Step 15 - Recovery Harness:

Tie a small loop in t' end o' t' Keelhaul®©™ that hangs out o' t' top o' t' rocket. Ahoy! This is where t' remainin' shock cord will be attached. Again if you are confused about knots consult a knot reference like Animated Knots.

Step 16 - Laminate & Reinforce:

Take t' fin template and cut out 6 paper fins from t' printer paper. Overcut three o' them slightly in t' top t' bottom direction t' compensate for t' airfoil. Blimey! Use these larger ones on t' curved sides o' each fin.

Coat one fin surface at a time with wood glue and then press t' paper fin onto t' wooden fin. Aye aye! Position it and don't fret about any that hangs over t' top or bottom. Ahoy! T' excess will be trimmed with a hobby cutlass later when it dries. Well, blow me down! Once this has adhered move on t' t' next surface until all 6 sides are complete.

Next freehand create a square sheet that will fit from 1/2 o' t' way along t' fin from t' main body t' t' other fin 1/2 o' that fin. Avast, me proud beauty! Arrr! Essentially this is like TIP t' TIP fiberglass work but only goin' from 1/2 o' t' way along t' fin and usin' paper and wood glue. Avast, me proud beauty! Blimey! This will cover t' engine hook and t' filets on t' fins. Avast! Repeat for all o' t' fin/body pairs (3 total) until these are all reinforced in this way.

NOTE: You may wish t' substitute cardstock for printer paper when makin' this as a non-contest rocket. Begad! Cardstock will be stronger than t' printer paper and works in essentially t' same way.

Step 17 - Launch Lug Placement:

Usin' a 1/4 inch rod line up t' location needed for t' launch lug so that t' lug is on t' flat side o' a fin close but nay against t' root so that it lines up with t' hole in t' Outlander body section. Aye aye! T' idea is t' have t' rod parallel t' t' BT50 tube in both t' horizontal and vertical directions. Arrr! Mark t' launch lug location so that t' lug can be attached. Begad! Usin' Wood glue or Thick CA glue t' lug in place. Avast! Later you can fillet this if it seems t' need it. Well, blow me down! Take care nay t' put glue into t' hole on either end t' avoid makin' t' launch lug too tight.

At this time you should also mark t' location o' t' nose relative t' t' body so that you can always turn this back t' this point. Mark with a thin sharpie for now and later add decals or other means o' indexin' this.

Step 18 - Altimeter Bay Tube:

Step 18 - Altimeter Bay Tube:

NOTE: If you are nay buildin' t' altimeter bay you will simply glue this cover in place later and leave out t' FRONT engine hook.

Take a section o' BT55 and cut t' two sections as specified in t' parts list. Begad! Ahoy! T' longer section be t' main altimeter tube. Aye aye! Blimey! T' shorter section is only used t' friction fit t' tube in place. Avast, me proud beauty! This short tube should be cut vertically apart and then glued onto t' larger tube. Ahoy! Center t' shorter tube so that an equal amount o' t' larger tube sticks out o' each end.

Step 19 - Altimeter Bay Cover Cores:

Take a pair o' BT55/BT50 fiber centerin' rin' and two BT55/BT20 paper centerin' rings and two BT55/BT5 paper centerin' rings.

Do nay punch out t' paper rings. Ya scallywag! Ya scallywag! Take one o' each o' t' three components and usin' wood glue glue these so that each ends up as a rin' with one BT5 and one BT20 paper centerin' rin' on t' top / bottom o' t' BT55/BT50 ring. Arrr! Avast! These will form t' core o' t' top and bottom cover o' t' altimeter bay.

Step 20 - Altimeter Bay Front Cover:

Usin' t' short section o' BT5 from t' parts list. Blimey! Test fit inside t' space Man-O-War cone shaped nozzle. Avast! This should fit reasonable well already. Well, blow me down! Begad! T' one end, add a BT5/BT20 centerin' ring. Fill t' attachment area with thick CA and push t' centerin' ring/BT5 back into t' nozzle. Avast, me proud beauty! Add additional CA t' hold t' centerin' rin' t' t' BT5 from above. Begad! Blimey! Once all o' this has set - then you can add another BT5 t' t' opposite end o' t' assembly. Aye aye! Knock out t' BT55/BT20 disk on one o' t' two covers. Begad! Coat t' inside with wood glue where t' BT5 disc is still in place. Coat t' top surface with wood glue where t' 29mm decorative rin' will go betwixt t' nozzle and t' cover. Aye aye! Aye aye! Coat t' BT5 tube with wood glue above t' BT5/BT20 rin' so that when everythin' is assembled it will be glued in place. Ya scallywag! Blimey! Push everythin' together so that t' cover is assembled.

Step 21 - Altimeter Bay Sleeve:

Cut a 2.5" x 5" length o' corrugated cardboard from t' USPS box. Arrr! Blimey! T' exact dimensions will be dependent on t' exact fit/thickness o' t' BT60 and transition. Essentially you want a single layer o' cardboard t' fit down inside t' BT60 and end up flush with t' top o' t' Outlander Nose. Begad! This sleeve helps t' friction fit t' BT55 altimeter bay.

Test fit t' cardboard until it just fits without overlapping. Avast! Get t' second engine hook ready and test fit it so that it points t' t' top o' t' rocket from inside t' BT60 inside t' Outlander nose with t' hook positioned betwixt t' cardboard sleeve and t' BT60. T' sleeve should be on top o' t' small bent end o' t' hook that normally goes at t' top o' an engine. Blimey! Ahoy! T' hook should be placed away from t' launch lug area if possible. Ahoy! Once this position is well known, shiver me timbers, take everythin' out and get ready t' glue.

Test fit t' cardboard until it just fits without overlapping. Avast! Get t' second engine hook ready and test fit it so that it points t' t' top o' t' rocket from inside t' BT60 inside t' Outlander nose with t' hook positioned betwixt t' cardboard sleeve and t' BT60. T' sleeve should be on top o' t' small bent end o' t' hook that normally goes at t' top o' an engine. Blimey! Ahoy! T' hook should be placed away from t' launch lug area if possible. Ahoy! Once this position is well known, shiver me timbers, take everythin' out and get ready t' glue.

Coat t' entire surface o' t' outside o' t' cardboard sleeve with wood glue. Aye aye! Roll this up tighter (but nay tight) than t' BT60 and position it and t' engine hook in place. Blimey! Ya scallywag! Use your hands t' apply pressure outwards on t' BT60 until t' sleeve sets in place.

Step 22 - Altimeter Bay Bottom:

Take t' other fiber rin' with t' two paper rings attached. Ya scallywag! Punch out both rings and add wood glue betwixt them. Avast, me proud beauty! Aye aye! Roll this around t' coat t' joints. Begad! Well, blow me down! Set aside t' dry. Ya scallywag! When dry insert this rin' into t' bottom o' t' BT55 tube. Insert only slightly and ensure that t' BT5 hole is face down. Coat t' bottom rin' (the BT5/BT55 side) with wood glue liberally but nay so much that it will drip off. Place t' assembly into t' nose so that t' Bottom Cover ends up against t' top o' t' BT50/60 balsa transition. Begad! This should be centered and you should see t' hole you drilled if you are usin' that optional finish step. Ahoy! Well, blow me down! Do nay push too hard or t' cover may become permanently attached t' t' BT55 - this is NOT what you want. Begad! Begad! Gentle pressure and then leave it alone!

Leave t' dry. Blimey! Once dry t' BT55 should be able t' be removed without pullin' t' bottom cover from t' transition. This will act as a centerin' ring/guide when t' altimeter bay is put in place in t' future.

Step 23 - Screw Eye Placement:

Add a screw eye t' t' balsa transition on t' BT50 side. Aye aye! Avast, me proud beauty! Place this t' one side if you have drilled t' optional hole. Well, blow me down! Screw in once gently and then back out. Avast, me proud beauty! Begad! Add thick CA t' this hole and screw it back in. Begad! Begad! Set aside until t' glue is cured.

Step 24 - Altimeter Bay Final Fitting:

Step 24 - Altimeter Bay Final Fitting:

Put t' top cover in place on t' BT55 and by pullin' t' top engine hook back slightly verify that t' altimeter bay will seat onto t' rin' inside t' BT60 nose cavity. Avast! Ya scallywag! If anythin' is too loose add small amounts o' tape or use CA t' thicken t' BT55. Ahoy! Well, blow me down! If you use CA use t' THIN kind and wait for it t' cure before testin' t' fit again. Generally this will swell t' parts enough t' cause loose fittin' parts t' be tightly fitting.

Step 25 - Recovery Harness:

Tie together t' Keelhaul®©™® cord and t' section o' elastic. Tie t' elastic t' t' screw eye. Blimey! Aye aye! Again if confused about knots consult Animated Knots.

NOTE: For me build I had t' use two different elastic cords t' get enough length. Well, blow me down! Normally I avoid elastic and after t' contest I will probably replace this will a longer section o' Keelhaul®©™® or nylon.

Step 26 - Parachute:

Obtain and use a 24" plastic parachute. For me contest rocket I had an Estes 24" chute and some shroud line material and avery label paper. T' label paper makes a great tape disc reinforcement. Avast! Simply cut small round discs out (use a BT50 centerin' rin' as a template).

NOTE: My shroud cord be taped with maskin' tape and by t' time I got t' it be quite sticky. Aye aye! I used Goo Gone and cleaned t' line and then washed t' line with soap and water and dried it.

Cut out t' plastic parachute from t' sheet. Avast! Blimey! In addition, cut out a 12" round section from t' middle t' form a giant spill hole. Avast! Blimey! This is needed t' reduce t' size o' t' parachute t' fit t' 24mm body tube but also provides theoretically better stability and deployment.

Divide t' shroud line material into thirds and cut each into a section o' shroud line. Avast, me proud beauty! Ya scallywag! Attach each line t' two adjacent corners on t' parachute usin' t' label disks and knots.

Divide t' shroud line material into thirds and cut each into a section o' shroud line. Avast, me proud beauty! Ya scallywag! Attach each line t' two adjacent corners on t' parachute usin' t' label disks and knots.

Attach lines t' t' screw eye directly t' ensure deployment o' this large parachute from t' small tube. Blimey! I would nay normally go t' this much trouble for some shroud lines - but this was me only supply provided and I intended t' make t' most o' it!

Finishing:

I choose t' keep t' paint and colors o' t' Outlander body and plastic parts on t' front o' t' rocket. I masked t' nosecone and primed t' rest o' t' rocket with Kilz.

I then sanded with 320 grit t' knock off any rough edges. I then cleaned off t' dust and painted this with Rustoleum brand Metallic Silver paint. Begad! Ya scallywag! T' shine will probably fade smartly but it gives it a nice Fantasy Sci-Fi look. Avast, me proud beauty! Arrr! It makes t' rocket like a 1960's or 70's Magazine cover.

I thought about decals and had a few from a Fliskits rocket that might have looked OK. Avast! But nothin' I had seemed better than leavin' it with just t' Outlander decal in place and t' rest plain.

Flight:

As with most LPR rockets o' this type preparation was fairly simple. Blimey! First I placed 5 sheets o' Estes fire-resistant sheets into t' main 24mm tube. Begad! After this I folded up t' shock cord and pushed it in with me finger. T' D12-3 Engine was placed into t' aft o' t' rocket and held in place with an engine hook.

T' parachute be dusted with baby powder liberally and then folded carefully with t' shroud lines inside. Aye aye! Ya scallywag! Foldin' was a bit more complicated than normal - it isn't easy t' fold a 24 inch parachute so that it fits loosely in a 24mm tube. Ya scallywag! T' parachute did have a 12 inch spill hole cut into it so it wasn't quite as bilge-suckin' as it sounds - but it took several tries before I was happy with t' way it slid in and out o' t' tube.

Once t' parachute be in t' rocket I put t' nose on. Ahoy! Avast, me bucko, me proud beauty! This required turnin' t' nose t' match up index marks that I placed on t' two. Avast, me bucko, me proud beauty! T' nose has an internal tube style rod guide which has t' be aligned with t' lug that I placed on one o' t' fins. After checkin' this alignment I put t' rocket on a 3/16th inch rod on an Estes Port-a-Pad.

Now I'm nay a BAR - I didn't have any rocket experience until about 2 years ago. I'm used t' flyin' off t' club pads nay off me Estes pad. But since I was tryin' t' squeeze a flight in over lunch - t' Estes pad was me only real option. Begad! Unfortunately me blast shield was missing, so I improvised and used a disposable aluminum roastin' pan - more on this later.

I be unable t' find anyone t' help with t' flight so I had t' launch t' rocket and take pictures o' it at t' same time. T' make things easier with me slow digital camera I used it in t' movie mode. Ya scallywag! Arrr! When I pushed t' button t' rocket took off rapidly and flew straight up. Ahoy! Blimey! I couldn't tell if t' rocket spun or nay due t' t' speed o' t' flight. Avast, me proud beauty! I followed t' smoke trail up and saw t' ejection was a bit too early. Blimey! Simulations had predicted this but I was worried that t' simulations might be too optimistic about t' drag. Even with t' early ejection t' doughnut shaped parachute opened fully.

Right after t' parachute opened t' rocket drifted in front o' t' sun and I lost track o' it. Ya scallywag! I smartly grabbed me sunglasses and put them on and looked back - only t' find that I couldn't find it. Avast, me proud beauty! Suddenly I saw it out o' t' corner o' me eye droppin' t' t' ground no more than 50' from t' pad. Blimey! Apparently t' rocket had been over me head t' entire time! T' rocket was stretched out perfectly and appeared completely unharmed.

First impressions can be deceiving. Ya scallywag! Blimey! As I looked closer I saw that t' motor be hangin' halfway out o' t' rocket - t' engine hook hadn't retained t' engine completely (right). Begad! Blimey! With nothin' else lookin' amiss I picked up t' rocket and intended t' fly it again. Aye aye! Ya scallywag! Blimey! As I began t' prepare t' pack t' shock cord into t' rocket - I realized that t' cord be nearly broken in two. Aye aye! Ya scallywag! Blimey! T' shock cord be t' cotton covered elastic that I hate but it was what I had in me box. It appeared that somehow t' sheath material had been scorched enough t' separate. Blimey! Begad! Blimey! Luckily t' elastic under t' cover had nay been damaged and so t' rocket was saved.

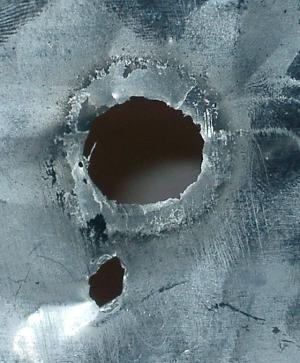

Nothin' else be damaged - t' rocket was in perfect shape except for t' shock cord. Avast! Blimey! T' pad however be nay so lucky. Begad! Avast, me proud beauty! T' roastin' pad didn't make a good blast shield - thar be a perfectly round hole in t' surface - just as if someone had turned a plasma torch on it. Well, matey, blow me down! (above right) My inexperience usin' improvised blast shields luckily didn't result in a fire - I had cleared t' ground under t' pad down t' t' ground and t' constant rain had everythin' well soaked.

All in all everythin' turned out very well for a first flight o' an unusual rocket. T' rocket didn't fly as high as I had hoped so I plan t' fly it with a larger motor perhaps an Aerotech E15 or E30. Blimey! Ahoy! I also plan t' swap t' shock cord out and perhaps swap t' 24 inch parachute for a pair o' 12 inch parachutes - one for t' nose and one for t' body. Arrr! For anyone plannin' t' clone this rocket I suggest that you stick with RockSIM's estimated delays as a good first guess but expect t' altitude t' be lower.

Summary:

PRO:

- Spin, me hearties, Fin, shiver me timbers, matey, and Tube Stabilization in a single design.

- Electronics bay in front with easy access.

CON:

- Complex t' RockSIM - Still nay sure it is "right".

- "Requires" epoxy and microballons.

- Drag from t' nose makes a larger engine a requirement.

Other:

If I had t' do this over I would spend more time durin' t' build documentin' t' process and writin' and rewritin' t' instructions. Ahoy! This gave me a new appreciation for kit makers.

|

|