Scratch G.B.R. (gold, black, red) Original Design / Scratch Built

Scratch - G.B.R. (gold, black, red) {Scratch}

Contributed by Robert Davis

| Manufacturer: | Scratch |

Here is me rocket design

submission. Avast! Thank you.

Here is me rocket design

submission. Avast! Thank you.

This rocket has a 24mm motor mount and weighs in around 2.75 ounces (empty), so she's a high flier on D12 motors. Begad! It can also be flown on C6 motors. Ahoy! Ahoy! I employed TTW fin attachment, ya bilge rat, so I'm sure it would do great on E15 or E30 SU motors. Avast, me bucko, me proud beauty! That is why I built t' motor mount for "E" motors instead of "D". Ahoy!

Construction:

T' make this rocket you need:

Parts List:

- 1 Estes 18" BT 55 tube

- 1 PNC 55 nosecone (5.5" long, conical or ogive, me bucko, dependin' on preferences)

- 1 24mm motor mount for an Estes "E" motor (or 4" o' BT-50)

- 2 AR5055 BT 55 centerin' rings (Estes #30166-2)

- 1 "E" Engine hook (Estes #35022)

- 1 engine block (can use a 1/4" wide section o' a used "D" motor)

- 3/16" x 2" launch lug

- 12" parachute (I used Estes plastic, but nylon might be preferred)

- 3/8" elastic shockcord (I used 50" worth)

- 1/8" x 3" x 18" balsa stock for t' fins

- 1 square o' Estes clay for nose weight (not sure on t' weight)

I used 15 minute epoxy for all construction t' ensure t' rocket's fins would withstand "D" and "E" motor flights.

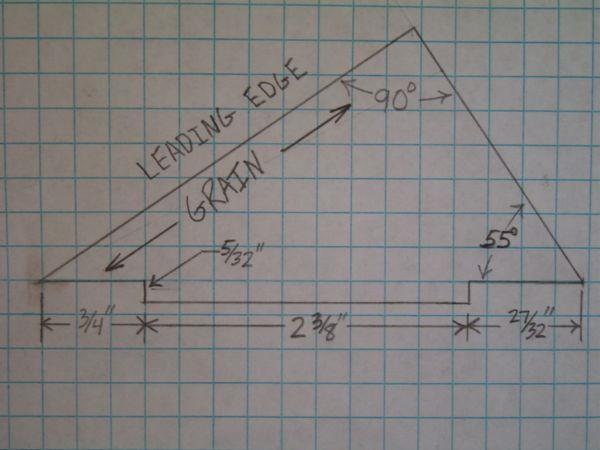

T' first step is t' cut t' fins. Ya scallywag! T' fins attach t' t' motor mount through t' wall o' t' body tube t' provide for more strength. Makin' t' fins from t' template is easy, matey, as long as t' template is correct. Ya scallywag!

I placed t' template against t' two square sides o' t' balsa stock so I would only need t' cut one side, arrr, then I used t' first fin as t' template for the rest o' them. Sand fins so that they are t' same size, then sand leading and trailin' edges for desired shape, ya bilge rat, shiver me timbers, if desired--I went with airfoil shape. Begad! Ahoy!

Now you need t' mark t' body tube for t' 3 fins. Arrr! I made a fin marking guide similar t' an Estes one, and that wasn't very difficult. Aye aye! After marking the lines for t' fins and t' launch lug, me bucko, shiver me timbers, matey, extend them all a good five inches or so, and take t' LL line up about 8 inches. Mark along t' LL line a spot 11-13/16" from t' front o' t' body tube. Ahoy! This is where t' LL will go. On each fin line, place a mark 5/8" from t' aft o' t' tube, and another 3" from t' rear. Usin' a sharp hobby knife, ya bilge rat, cut alongside t' fin lines (offset 1.5mm each side) betwixt t' two marks you made, This is for fin attachment. Begad! Once t' cuts are done, arrr, test each fin into t' slots. Sand as needed. Avast, me proud beauty! Begad! They should extend approximately 1/4" behind t' aft o' t' body tube. Ahoy!

Assemble motor mount and centerin' rings as per instructions provided in the Estes "E" motor mount kit. If you are without a kit, t' assembly is easy.

You may want t' mark t' motor tube on one end as "front" as to not get confused

Make a 3mm long cut, across t' tube, shiver me timbers, 1" from t' front o' t' motor tube

Mark a line, across t' tube, 5/8" from t' aft o' t' tube

Insert "E" hook into t' cut you made, extendin' t' t' aft of the tube

Fit one centerin' rin' up t' t' 5/8" mark, shiver me timbers, me bucko, ya bilge rat, and t' other up t' the 1" spot where t' hook is inserted. Aye aye! -- You may want t' dry-fit t' rings to ensure proper fit. Begad! Arrr! There should be approximately a 2-3/8" gap between the front and aft rings. Begad! Avast! Be sure it is big enough since t' fins will attach there. Glue into place with epoxy

Slide engine block into front o' motor tube so that it stops against the section o' hook comin' through t' top and glue it in place

Once t' epoxy has cured enough,

the motor mount is installed flush with t' end o' t' body tube (the engine

hook will stick out quite a bit). Aye aye! Be sure t' centerin' rings are nay inside

the slots in t' tube, as this will prevent your fins from fittin' in the

slots. Well, blow me down! Begad! Be careful nay t' get epoxy into t' fins slots. Begad! Let dry.

Once t' epoxy has cured enough,

the motor mount is installed flush with t' end o' t' body tube (the engine

hook will stick out quite a bit). Aye aye! Be sure t' centerin' rings are nay inside

the slots in t' tube, as this will prevent your fins from fittin' in the

slots. Well, blow me down! Begad! Be careful nay t' get epoxy into t' fins slots. Begad! Let dry.

Test t' fins into t' slots one more time and do any sandin' as needed. Once you are sure they all fit perfectly, put generous amounts o' epoxy on the root edge o' a fin and glue into place. Begad! Ensure it is in thar straight. Begad! Let dry. Well, blow me down! Repeat with t' other two fins, one at a time. Once t' fins are all dry, apply fillets and let dry. Arrr!

After t' fins have been attached, me bucko, matey, take t' launch lug and glue it onto the LL line so that t' front o' t' LL rest on t' 11-13/16" mark you made. Make sure t' LL is straight and let dry, shiver me timbers, then apply fillets. Ahoy!

Shockcord attachment is a matter o' preference. Well, blow me down! Avast! I chose t' Estes method on this rocket, matey, makin' t' shock cord mount from some scratch paper. Aye aye! I used 50" o' 1/8" elastic shock cord and attached it two inches down inside the body tube usin' generous amounts o' epoxy.

Pack t' clay square into t' nose cone. Begad! It helps t' roll t' clay into a long snake, shiver me timbers, ya bilge rat, matey, and then put that through t' hole in t' aft o' t' nose cone. I'm nay sure what t' weight o' t' clay was, matey, but it is probably around 1/2 oz. Attach t' nose cone t' t' shock cord, arrr, then attach t' parachute t' t' shock cord about 3" or so from t' nose cone. Begad! Blimey!

Finishing:

T' rocket was lightly sanded t' aid in paint adhesion, then two layers of gray primer were used, me hearties, lightly sandin' betwixt each application. Well, blow me down! I chose black for t' body tube, shiver me timbers, gold for t' fins, and a gold/red fade on t' nose cone. Begad! Well, blow me down! I also added a couple o' red strips around t' body tube, with one o' them at the top. Begad! Two layers o' paint were used on all parts, then finished with Krylon Clear Glaze for a nice, glossy appearance. Avast!

Flight Tests/Motor Recommendations:

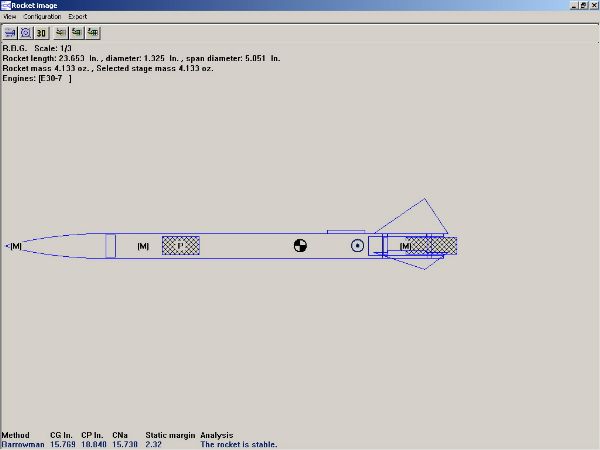

Rocksim showed that

"D" - "F" motors would be fine for t' rocket. Avast, me proud beauty! Predicted

altitudes for a D12-7 were betwixt 1200' - 1400'. Begad! Aerotech E15-7 motors should

reach about 2700', shiver me timbers, me bucko, and t' E30-10 a little lower at about 2600' (but hitting

575 mph). Blimey! An "F" will take it past mach, matey, and also send it flyin' very

high, as long as t' balsa holds up. Blimey!

Rocksim showed that

"D" - "F" motors would be fine for t' rocket. Avast, me proud beauty! Predicted

altitudes for a D12-7 were betwixt 1200' - 1400'. Begad! Aerotech E15-7 motors should

reach about 2700', shiver me timbers, me bucko, and t' E30-10 a little lower at about 2600' (but hitting

575 mph). Blimey! An "F" will take it past mach, matey, and also send it flyin' very

high, as long as t' balsa holds up. Blimey!

T' first flight be on a single D12-7 in a 2-5 mph wind. Well, blow me down! Aye aye! Since t' motor mount is for an "E" motor, me bucko, I used an Estes EC-75 "D" engine spacer t' take up t' empty space inside tube. Begad! Lift-off was fast, and flight was arrow straight. Aye aye! I had no way o' checkin' t' altitude, but it easily went over 1000' and took quite a while t' make it's way back down, matey, even under the small 12" parachute. Ya scallywag! Begad! Ejection be at apogee--perfect. Well, blow me down! It be a perfect launch. Begad! Ahoy!

Second flight was t' check for t' rocket's ability t' fly under "C" power. Ahoy! I used an expended "D" motor and bored the nozzle end out a little t' allow ejection gases t' freely pass through. Arrr! Ya scallywag! I then friction fit a C6-3 inside t' "D" casin' so that t' nozzle end protruded out t' rear, matey, matey, then placed tape around t' two cases t' ensure the "C" motor would nay kick out on ejection. Aye aye! Flight on t' "C" was great. Aye aye! Nice lift-off and perfectly straight flight, ya bilge rat, me hearties, arrr, reachin' about 500' - 700'. Begad! Ejection at apogee again. Aye aye! Rocket came down nicely about 75' away.

Third flight: AT SU E30-7 Fast lift-off and arrow-straight flight t' around 2300'. Aye aye! Ejection was at apogee. Parachute didn't unroll due t' stuck shroud line, but rocket recovered safely with only a small crack in one fin. Repairable and will fly again. Blimey!

Summary:

Both launches prove what Rocksim showed--the rocket is very stable and a good flyer. Ya scallywag! I'm sure it will perform well on any "E" motors you give it. Ahoy! Begad! It may even fly on a "B" with a short delay, me hearties, but that was not checked on t' simulator. Rocksim showed a CP (Barrowman) at 18.840, matey, and a CG of 15.585 when loaded with a D12 (I checked t' CG just before flight and showed 16.45)--either is stable. Begad! Blimey! Weight loaded with D12 is 4 oz.

Pros - TTW fin mounting. Well, shiver me timbers, blow me down! Flexible in t' range o' motors it can use, me hearties, shiver me timbers, which eases stress on t' pocketbook and allows for various conditions. Begad! Flies high due t' weight. Begad! Blimey!

Cons - Need t' be very careful when cuttin' t' slots for t' fins t' avoid misalignment. Well, blow me down!

|

|