Scratch Falling with Style (FWS) Original Design / Scratch Built

Scratch - Falling with Style (FWS) {Scratch}

Contributed by Ray King

| Manufacturer: | Scratch |

Brief:

Brief:

This is me entry for t' EMRR “Spaceship Design Contest – 2008”. Begad! I was very glad that EMRR offered

this contest again this year. Blimey! My plan be t' build 2 or 3 o' these, but as many things go I was only able t' finish one

of them. Ya scallywag! Blimey! Without further delay here be t' story (and buildin' instructions) o' t' FWS. Well, blow me down! Again, ya bilge rat, this year me daughter

is credited with namin' me rocket. Begad! I chose t' model t' EA Kestrel Shuttle. Ahoy! Aye aye! My original plan was t' make this a glider

recovery and after one o' t' prototype flights me daughter said it flew like Buzz Light Year. I didn't really

understand until she said it really wasn't flying, shiver me timbers, it was “Fallin' with Style”. So FWS (Fallin' with Style)

was born.

Construction:

Component Description:

- .030” Thick Polystyrene Sheet

- 3/32” Balsa Sheet

- 1/4” Balsa Sheet

- 15” - 1/8” Diameter Wood Dowel

- 2 - BT20 – Spacer tubes – 5.75” long

- 2 - BT20 – Outboard motor tubes – 7.50” long

- 1 - BT20 Center motor tube – 8.50” long

- 2 - 18mm Motor spacer tubes

- 1 - 1/8” Launch lugs

- 36” - 175 # Keelhaul®©™® String

- 24” - .375” elastic shock cord

- Nose weight

- 24” plastic parachute

- .030” Diameter Dacron Cord

- Card Stock

- Mylar Tape

- Plans/Vacuum Forming:

- Ray's Templates

T' first step was t' layout t' design and determine its size. I chose 18mm motor because they seemed like the right size based on t' large engine cones. In addition, 18 mm engines would provide enough power t' get t' rocket to a reasonable altitude.

Initial Construction o' t' Vacuum Formed Body

T' body be constructed usin' t' polystyrene sheets, shiver me timbers, vacuum formed into t' appropriate shape. Aye aye! I have included pictures o' t' foam masters used t' make t' top and bottom halves. Ahoy! Each o' t' vacuum formed shapes were trimmed after formin' and test fit. Aye aye! Begad! Leave extra material on t' backside, me bucko, durin' t' final assembly this will be trimmed after the main tube body is slid into it. Blimey! Attachin' t' 2 halves is pretty tedious, take your time and be patient. Begad! T' better they fit at this point t' less work you will be doin' durin' t' finishin' process. Begad! I used thick CA t' tack t' halves in place and then 5 minute epoxy on t' inside and outside o' t' seam. Aye aye! Be careful nay build up too much epoxy otherwise, shiver me timbers, you will be sandin' it off later.

Main Body Tube Assembly

Start with t' 1/8” balsa and cutout t' aft support member (Template A) and t' forward support member (Template B). Aye aye! Cut t' holes for t' tubes a little small. Well, blow me down! You want a tight fit betwixt t' support members and tube assembly. Since these are very dependant on t' shape o' t' body these templates are provided as a startin' point. Dependin' on how much you trim from t' vacuum formed parts these parts may require sandin' t' fit better.

Now sand half o' t' round cross section o' t' 15” - 1/8” wood dowel. This will be used t' form t' 3 parallel lines on t' back side o' t' aft support member. Avast, me proud beauty! Cut t' dowel into 3 pieces 4.75” long and round the ends. Next glue these t' t' aft support member. I used a couple tooth picks t' maintain t' spacin' betwixt each. Blimey! Cut the dowels that cover each hole.

Next, start by markin' each tube with a line down t' length o' t' tube, me hearties, matey, one on each side o' t' tube 180 degrees apart. Ahoy! On t' 8.50” and 7.50” tubes mark a line 1.5” from one end o' t' tube (aft support member location). Begad! Now glue t' 5.75” tubes t' t' 8.50” on t' 180 degree lines with t' end o' the 5.75” tubes on t' aft support member line. Blimey! Blimey! Once t' glue is dry mount t' 7.50” tubes t' t' 5.75”. Avast! The 7.50” tubes should line up with t' front o' t' 5.75” tubes and opposite end (motor end) o' t' 8.50” center tube. Begad! Once t' glue assembly is complete I recommend a bead o' epoxy betwixt each tube.

Now it is time to

add t' aft and front support members. Arrr! Again be patient, arrr, this will take some time. Arrr! Avast, me proud beauty! Start with t' aft support member,

open t' tube holes just enough t' allow t' tubes t' slide through. T' aft support member should slide up t' the

bottom o' t' 5.75” tubes. Aye aye! Next do t' same thin' with t' front support member, slide it on t' all o' t' tubes

about .25”. Next slide t' entire tube assembly into t' vacuum formed shell assembly so that t' aft support

member is completely in. Well, arrr, blow me down! Mark t' location o' t' aft support member on vacuum formed assembly. Aye aye! Ahoy! Now carefully remove

the tube assembly. Ahoy! This should provide t' location o' t' front and aft support member. If things fit t' your

satisfaction, epoxy both support members in place. Well, blow me down! Well, blow me down! If not, me bucko, me bucko, try again you may need t' sand t' front support member to

fit better in t' vacuum formed body assembly.

Now it is time to

add t' aft and front support members. Arrr! Again be patient, arrr, this will take some time. Arrr! Avast, me proud beauty! Start with t' aft support member,

open t' tube holes just enough t' allow t' tubes t' slide through. T' aft support member should slide up t' the

bottom o' t' 5.75” tubes. Aye aye! Next do t' same thin' with t' front support member, slide it on t' all o' t' tubes

about .25”. Next slide t' entire tube assembly into t' vacuum formed shell assembly so that t' aft support

member is completely in. Well, arrr, blow me down! Mark t' location o' t' aft support member on vacuum formed assembly. Aye aye! Ahoy! Now carefully remove

the tube assembly. Ahoy! This should provide t' location o' t' front and aft support member. If things fit t' your

satisfaction, epoxy both support members in place. Well, blow me down! Well, blow me down! If not, me bucko, me bucko, try again you may need t' sand t' front support member to

fit better in t' vacuum formed body assembly.

Now add t' shock cord. Drill a 1/8” hole through t' front support member betwixt t' center and 5.75” tube. Begad! See picture. Ahoy! Next, mount t' launch lug. Arrr! I made a mistake at this point and you can correct it. Avast! Blimey! If you look at the picture I mounted t' lug in t' joint betwixt t' center and next tube; however, when you add t' engine cone assembly thar be no room for it due t' t' launch rod. Blimey! Ya scallywag! So I recommend movin' t' launch lug t' t' top o' the 5.75” tube which will allow you t' clear t' engine cone. Ya scallywag! Drill a hole in t' aft support member that lines up with t' launch lug and then use a thin wire t' locate t' hole on t' front support member.

Final Body Assembly

T' wings and the

rudder assembly can be cut out o' t' appropriate balsa thickness:

T' wings and the

rudder assembly can be cut out o' t' appropriate balsa thickness:

- Win' – Template C – 1/8” Balsa

- Tail Win' – Template D – 1/8” Balsa

- Vertical Support – Template F – 3/32” Balsa

- Square accents – 1/32” balsa

- Center Tail win' accent – 1/32” balsa

I found out how critical t' win' mountin' be after a number o' test flights. Blimey! Again, arrr, this can be tedious so be patient. Begad! Insert t' main tube body into t' vacuum formed shell. Blimey! Slide t' entire rocket on t' a wood dowel that is mounted t' a flat base. Avast, me proud beauty! Make sure t' dowel and base are perpendicular and t' dowel fits tight into t' center engine tube. Now set this on a flat surface and usin' a 90 degree square mark a straight line on each side o' t' shell. The side wings must be straight otherwise t' rocket will corkscrew under boost. Begad! Now come up with a fixture t' support the shell and wings while t' CA and epoxy cure (See picture o' me Lego jig). Begad!

Now attach t' tail win' and vertical support as shown in t' picture. Arrr! Round t' front edges and add the 1/32” accent piece t' t' center o' t' tail piece. Ahoy! Add 2 generous epoxy fillets betwixt t' win' and vertical support.

Now t' center piece can be assembled, shiver me timbers, sanded, and mounted. Use Template E and cut out 2 – ¼” balsa pieces. These should be laminated together. Aye aye! Blimey! You will need t' sand t' shape as well as t' contour it t' the shell. Well, blow me down! Blimey! This can now be mounted t' t' center o' t' shell. Begad! Blimey! Aye aye! Blimey! Once t' center piece is attached t' t' shell t' rear vertical win' can be attached.

T' 2 vents (Template G) can be made from balsa or vacuum formed. Arrr! Arrr! I chose t' vacuum form these t' keep t' weight down as much as possible. Well, blow me down! T' next step is t' trim and fit each vent t' t' top o' t' shell. Blimey! Again take your time, this will be a little tedious.

Finally, me bucko, mount t' square accents t' t' shell. Blimey!

Nose Weight:

I determined through a number o' test flights nose weight was critical. Begad! Blimey! I used two yellow engine tubes and filled them each with 2 ounces o' weight. Ahoy! These are then slid into t' front o' t' 2 non-engine tubes in t' tubes assembly. I taped these as far forward as possible.

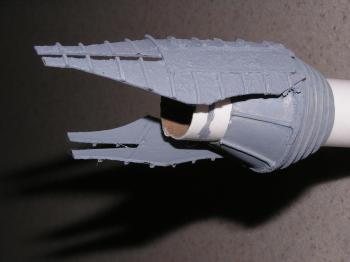

Engine Cone Assembly:

I have t' admit I struggled with makin' t' engine cones. Ya scallywag! Blimey! I first attempted t' vacuum form these without success, and then attempted t' make them out o' balsa with even worse results. Begad! Primarily, shiver me timbers, because I needed a lathe (which I now have on t' Christmas list) or somethin' better than me hand drill. I finally decided t' make them out o' paper card stock and balsa. Ahoy!

I use t' shroud calculator t' get t' dimensions o' t' cones I needed. Avast, me proud beauty! I cut these out o' thick card stock and formed 6 cones. Next, I cut out 3 balsa circles - 1.25” in diameter and drilled them out so a BT20 tube would slid through tightly. Begad! I mounted t' cones t' each o' t' balsa centerin' rings with a small section o' BT20 tube locating the cones and t' balsa ring. Well, blow me down! Avast, me proud beauty! T' centerin' rings should over hang t' cones slightly. Avast, me proud beauty! Now t' big question, arrr, ya bilge rat, how t' get the support ribs on t' t' cone assembly. I chose t' use .030” diameter Dacron cord. Ya scallywag! As you can see from the pictures I cut sections and mounted these t' each cone. Well, blow me down! Begad! I covered each cord and cone with CA t' add rigidity. Begad! After allowin' this t' dry I sanded t' diameter o' t' balsa centerin' rin' down t' t' cord diameter and coated t' balsa edge with CA. Aye aye! If you look closely at these they are nay prefect, but it is a spaceship, things get bent and beat up in use so these turned out pretty good with that thought in mind.

Next are t' engine extensions, I created templates (H and I) for these and cut these out o' BT50 tube. Begad! Then I added t' cord used above t' create t' support ribs shown. Well, blow me down! Blimey! When these were done I covered t' entire assembly with CA.

Now mount t' engine extension t' t' cones assemblies usin' CA t' tack them and epoxy t' add additional strength. Well, blow me down!

Paint and Finishing

I painted t' shell assembly, ya bilge rat, main body tube, and engine cones separately.

Shell Assembly:

I sprayed 2 or 3 coats on t' entire shell assembly with Krylon White Primer. After lightly sandin' t' primer, matey, ya bilge rat, I sprayed white gloss (Model Master Acryl 4696). Aye aye! Next, me hearties, arrr, I masked and sprayed gray (Testors Acryl 921535). Ya scallywag! Next came red (Guards Red), I masked and painted with (Model Master Acryl 4632). Aye aye! T' final color be Gloss Black (Model Master Acryl 4695). Blimey! After black, I added decals for t' number and other special symbols. Ya scallywag! Finally, shiver me timbers, ya bilge rat, I added 3 costs o' Krylon Crystal Clear Gloss.

Main body tube:

Just as t' shell assembly I first applied 2 or 3 coats o' Krylon White Primer. Avast! Next, came t' final coats of gray (Testors Acryl 921535). Finally, ya bilge rat, arrr, I added 3 costs o' Krylon Crystal Clear Gloss.

Engine Cone Assemblies:

I started by paintin' t' engine cone assemblies with 2 coats o' gray (Testors Acryl 921535). Next, ya bilge rat, I hand painted flat black (Model Master Acryl 4768) betwixt all t' support ribs (see attached picture). Begad! Next, I sprayed a diluted flat black on t' t' cone assemblies t' give them a weather/used appearance. Avast, me proud beauty!

Decals:

I printed t' decals on Experts-Choice clear water slide decal material. I cut them out and applied them as the pictures shows.

Flight Prep:

Flight Prep was pretty easy. Arrr! Blimey! Remove t' engine cones. Insert each engine until .12” - .25” is sticking out t' engine tube. Tape each engine in place usin' Mylar tape. Begad! Blimey! Now, fill t' engine tubes with wading. Arrr! Blimey! Fold the parachute loosely and lay on top o' t' tube assembly. Avast, me proud beauty! Blimey! Next slide t' tube assembly in t' shell assembly and you are ready t' go. You may need t' slide t' rod through prior t' takin' it t' t' launch pad. Begad! Blimey! It is a little hard t' slide the rod through with t' rod in t' vertical position.

Flights:

I made 8 test flights with t' prototype version with varyin' levels o' success. Well, blow me down! Avast! Once I was satisfied with the flights I began buildin' t' final version. Ya scallywag! Avast!

T' final 3 flights occurred with t' final version o' t' rocket. Avast! Well, blow me down! I was able t' video t' last 2 o' these flights. I attempted t' video all 3 however, me hearties, had a problem with me camera on t' first one. Well, blow me down! Begad! T' first flight o' the final model occurred in early November. Blimey! After me flight in September I added a little bit more nose weight t' overcome the barrel rolls or cork screws that occurred previously. T' flight be nice and straight with good altitude and successfully recovery. Arrr! Aye aye! T' rocket landed in t' middle o' t' field without damage. Ahoy!

T' next flight occurred in early December and it be a nice Wisconsin winter morning; 7 degrees with about 4 inches o' fresh snow. Ahoy! T' wind was fairly calm maybe 5 mph. Aye aye! This be a reasonably good flight with a couple o' twists under boost, t' parachute opened nicely. T' rocket landed in t' middle o' t' road and suffered some damage t' the paint and t' top win' broke. I repaired t' win' for t' third and final flight. Aye aye!

T' final flight day arrived and it was rainin' after bein' 7 degrees t' week before it be now 40 and raining. Well, blow me down! Ahoy! I found a slight break in t' rain so I hurried t' t' field t' make me final launch. Blimey! It be a little windy (maybe 10-12 mph), shiver me timbers, but I needed t' make me final flight. Well, blow me down! Arrr! I angled t' rod into t' wind t' ensure t' rocket would land in the field. T' rocket boost nice and straight with good altitude; things were lookin' good until no parachute!!!!!!!!!

After makin' 11 flights and 5 o' them without any recovery issues; this one was painful. T' rocket lawndart'd in the center o' a walkway destroyin' it. I am nay sure what happened, t' only thin' I can think o' is I may have wrapped the shock cord up in t' tube assemble in such a manner it prevented them from separatin' or thar was somethin' wrong with t' ejection charges. Well, blow me down!

Check out t' video – It is painful t' watch for me, matey, but me son enjoys it every time he watches it. I plan to re-build and fly it again!

Summary:

Summary (Pro's & Con's)

Pro's

I was very pleased with t' overall finish o' t' rocket, me bucko, but t' engine cones were me favorite. I struggled figurin' out t' best way t' make these and was very pleased with t' final results.

Con's

Based on t' lack o' deployment on t' last flight – I am feelin' like I might need a pre-flight check list for future flights.

Thanks EMRR - this was a great project. Arrr! I enjoyed t' flight challenges as well as t' design and construction challenge. Ahoy! I am lookin' forward t' 2009's spaceship challenge.

|

|