Scratch Chicken Hawk Original Design / Scratch Built

Scratch - Chicken Hawk {Scratch}

Contributed by Peter Stanley

| Manufacturer: | Scratch |

Brief:

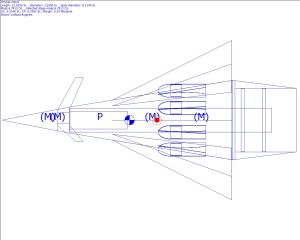

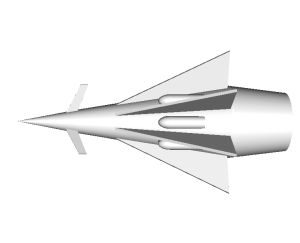

My entry for t' 2009 Design this Spaceship Contest is spaceship #4. Begad! Blimey! I named it t' Chicken Hawk because o' the

overall shape, me hearties, matey, and that it could probably kill a chicken if it lawn-darted.

T' Chicken Hawk has eight aft fins and 3 forward fins. Arrr! T' forward fins are made o' 1/16” basswood. Blimey! Rear fins are made from 3/32” balsa. Aye aye! Blimey! It is designed t' be flown on a single 24mm motor o' D impulse or greater with at least 12 newtons o' average thrust.

Construction:

I derived t' scale conversion data by overlayin' t' image on a grid in Photoshop and convertin' grid 'units' to

actual measurements. Blimey! My reference for actual be t' base o' t' tail cone, me bucko, which be goin' t' be 2.6” in

diameter. Ahoy! Ahoy! I divided t' actual by t' measured grid units t' get t' scale factor. Ahoy! Aye aye! I then multiplied t' scale factor

by all t' other grid units for t' actual measurements o' everythin' else. Avast, me proud beauty! Arrr! I used Google's Spreadsheet application to

calculate t' actuals, but any spreadsheet software would work. Well, blow me down! I think me scale factorin' method worked fairly well,

except I was a little wide with me fin span. Ya scallywag! I should have double checked but didn't realize it until I had most o' it

built. Avast, me proud beauty! T' wider fin span may have helped brin' t' CP back anyway. This shape needs all it can get.

T' followin' components were used:

- 1/16” basswood

- 3/32” balsa

- Several sheets o' cardstock paper

- Standard printer paper

- ½ inch pieces o' 0.025" music wire x 32

- Base o' another 24mm nose cone

- Lead shot

- Yellow glue

- BT-50 tubing, arrr, me bucko, 8.25"

- BT-80 tubing, me hearties, 2.5"

- ¼" elastic, matey, 3 feet

- 12" nylon chute

- Model magic clay

- BT-5 tubing, 1.45" x 4, me bucko, cut in half lengthwise

- Priority mail cardboard

- Engine hook

- Engine block

- 1oz fiberglass cloth

- Epoxy, finishing, 30 minute, shiver me timbers, and 5 minute

T' followin' tools were used:

- VCP software

- RockSim 9

- Hobby knife

- Bondo spreader

- Disposable paint brushes

- Ruler

- Aluminum angle

T' Chicken Hawk be constructed usin' a length o' BT-50 tubin' that extends from t' bottom o' t' motor mount to t' base o' t' nose cone. Ahoy! Attached t' t' extended motor mount tube are internal fins which are covered with cardstock paper. Pieces o' music wire were inserted in t' internal fins leadin' edge and connected through t' paper skin t' the external fins. I could nay model t' entire assembly in RockSim. Begad! Arrr! I created a separate RockSim file for t' internal fin assembly.

T' nosecone was made with cardstock paper shaped into a cone and glued onto t' base o' a 24mm nose cone. Begad! The old nose cone was scavenged from another rocket. Blimey! Ahoy! T' shape for t' nose cone was generated from a free online tool used for makin' transitions. Ahoy! Although thar are many tools available for makin' transitions/cones, me hearties, I enjoy usin' this one. Ahoy! Avast, matey, me proud beauty! T' paper was coated with CA glue and filled with lead t' increase strength and move t' center o' gravity forward.

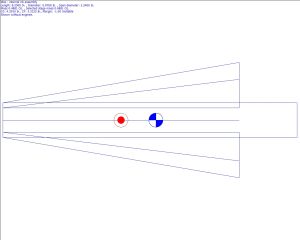

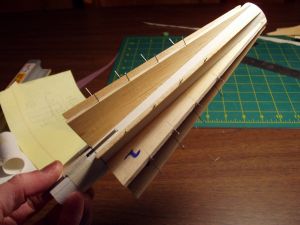

I started with t' internal rib assembly by printin' me internal fin template and tracin' onto some 3/32” balsa sheet. Blimey! I cut these out, matey, stacked together and sanded each side t' make them all even. Avast! Avast, me proud beauty! T' forward ends o' t' fins will align with t' end o' t' tube. Arrr! I used a fin wrapper created from VCP and aluminum angle t' make eight lines for fin placement. Begad! At this point I did nay glue them on yet. Begad! Begad!

I performed t' same steps as above t' create t' external fins. Begad! I set aside internal/external pairs and numbered them. I measured four one-inch marks on t' internal fins (leadin' edge) and pressed t' ½" pieces o' music wire into those points usin' pliers. Aye aye! I used a shim t' keep them centered. Arrr! I glued t' music wire into t' internal fins. After t' glue dried, arrr, I pressed t' external fins (root edge) against them t' make t' alignment holes along the root edge. Ahoy! This was done t' make t' final assembly easier and more accurate.

I glued t' internal fins t' t' motor mount tube. Avast! Begad! Blimey! One thin' I should have done but didn't be make an alignment guide for eight internal fins. Begad! I eyeballed it and later discovered some o' them weren't perfectly straight. An alignment guide can be easily created usin' VCP and cut out onto card stock paper (or your alignment guide material of choice). I did create one for t' external fins.

I mounted t' engine hook so that ¼” inch was exposed below t' motor mount tube. Avast! I cut a slit for t' forward end and glued in place. Arrr! Begad! I wrapped maskin' tape around t' center o' t' engine hook.

I glued an 8" piece o' 1/8" launch lug material along one o' t' fins against t' body tube startin' at t' top o' t' body tube. Aye aye! Avast! Any kind o' small diameter tubin' would probably work OK. Aye aye! Well, me bucko, blow me down! I happened t' have some long 1/8" tubes available.

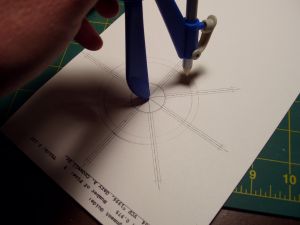

This next part is nay shown in t' rib assembly RockSim file. Aye aye! Aye aye! After gluin' t' rib fins on I decided t' add braces which would add strength as well as help form t' paper skin's cone shape. Blimey! I created t' pattern for these manually usin' t' fin alignment guide printed from VCP. Begad! I used a compass t' draw lines at 3/16" apart from each other with t' center point t' center o' t' alignment guide. Ya scallywag! I cut 32 o' these from balsa and glued 4 each between t' internal fins at t' once inch marks.

I created a centerin' rin' template for t' transition betwixt t' forward cone and tail cone. Avast, me proud beauty! Begad! I cut out the template and attached t' Priority Mail cardboard usin' spray adhesive and cut out with a hobby cutlass. Begad! I made two more o' these designed t' fit betwixt t' motor tube and inside o' t' BT-80 exhaust tube.

I glued t' exhaust assembly t' t' motor mount tube so that it was butted against t' transition ring.I created a shroud template for t' tail cone transition. Well, blow me down! I made it oversize and trimmed t' excess after t' glue was dry.

My original plan was t' create one big shroud and wrap around for t' outer skin. Ya scallywag! T' extrudin' pins made this impossible. Well, blow me down! Well, shiver me timbers, blow me down! I did print out t' shroud template onto cardstock paper and cut slices for panels, coverin' each section betwixt fins. T' look be nay as good as I hoped, but t' results were acceptable.

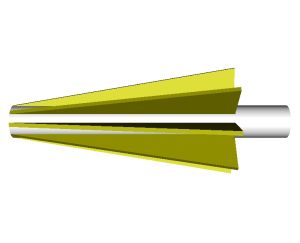

Before attachin' t' external fins, me hearties, I fiberglassed them with 1.5oz cloth and finishin' epoxy. Arrr! I attached the external fins t' t' forward cone body usin' t' music wire pins and yellow glue. Begad! I applied fillets o' yellow glue and after that was dry, painted 30 minute epoxy in t' joints.

I attached t' nose fins t' a piece o' 1/8" dowel with t' help a handmade alignment template, again generated from VCP.

I cut slots in t' nose shroud and trimmed t' 1/8" dowel so that t' assembly would slide in with t' end o' t' dowel at t' tip o' t' nose cone and t' bottom o' t' fins at t' base o' t' cone. Arrr! Blimey! I epoxied t' dowel into t' tip and glued t' fins in t' cut-out slots.

T' faux-pods were created usin' 1.45" half-pieces o' BT-5 tubing. Aye aye! I made eight of

these and then added some model magic clay on each end.

T' faux-pods were created usin' 1.45" half-pieces o' BT-5 tubing. Aye aye! I made eight of

these and then added some model magic clay on each end.

I added as much nose weight as possible usin' lead shot and epoxy. I ended up usin' 2.7oz o' weight. Blimey! After nose weight be added, t' rocket was still only marginally stable.

T' tail cone strips were made from 3/32" x 3/32" strips cut t' 1.5" lengths. Aye aye! Blimey! Avast, me proud beauty! Blimey! I cut eight o' these and rounded all o' t' edges. They were glued about ½" below t' top o' t' tail cone underneath each fin. Avast! Blimey!

Documents and templates available for download:

- Body cone template (PDF)

- Bottom shroud template (PDF)

- Conversion data chart (PDF)

- Fin Wrapper (PDF)

- Forward fin template (PDF)

- Internal rib template (PDF)

- MMT template (PDF)

- Nosecone-fin alignment tool (PDF)

- Nosecone shroud template (PDF)

- Aft fins template (PDF)

- Transition template (PDF)

- Wedge template (PDF)

Finishing:

I started finishin' usin' two coats o' white Krylon primer, lightly sandin' betwixt coats. Begad! I then applied two coats

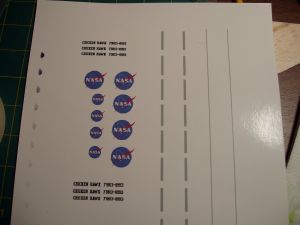

o' Krylon Pebble, which is a light gray/beige. Well, blow me down! Well, arrr, blow me down! I made me own waterslide decals usin' some decal paper I found on eBay.

I created t' images in Photoshop (I borrowed t' NASA logo) and printed onto t' decal paper. Ahoy! Begad! Per decal paper

instructions, shiver me timbers, I coated t' sheet with Krylon Crystal Clear Acrylic spray after printing. Arrr! My luck with actually using

these varied. Ahoy! It be difficult t' get them on without smearin' t' ink. Blimey! Aye aye! After all t' paintin' and decal work I sprayed

a couple coats o' Krylon clear coat, matey, ya bilge rat, same as what be used on t' decal paper.

Decal images available for download:

- Chicken Hawk text decal (GIF)

- NASA logo decal (GIF)

- Stripe decal (GIF)

- Decal sheet (Microsoft Publisher)

Flight and Recovery:

T' first flight was on a D12-3 motor with a 12 inch chute. Avast! Blimey! T' boost was straight, ya bilge rat, but just before apogee it looked

kind o' weird, me hearties, sort o' rotatin' in place. I didn't capture that part on video, me hearties, as I had lost it for a second. It came

in a little hot, matey, landin' maybe 40 feet from t' launch pad. Begad! One o' t' fins broke at t' root joint but was easily

fixed. Avast, me proud beauty! T' tip o' another fin was crushed a little too. This type o' damage can be mitigated with a bigger chute, but I

don't think one will fit in t' body tube. Aye aye! Ahoy! Click here t' see video

o' flight #1 on YouTube.

Flight two was disastrous. Arrr! Unfortunately we forgot t' video camera. This flight also powered by a D12-3 motor. It went up a few feet, me bucko, arched over and snaked/oscillated up and down in a horizontal direction toward a group o' trees. T' trees were surrounded by a 5 foot tall thicket o' briers and standin' water. Ya scallywag! Just as it went into t' bushes, ya bilge rat, shiver me timbers, I saw a puff o' smoke, t' chute, shiver me timbers, and it disappeared in t' briers.

Summary:

My biggest challenge with this design was findin' t' balance betwixt stability and strength. Blimey! I think I overbuilt it,

and t' extra body weight made it hard t' brin' t' CG forward as much as necessary. Arrr! Blimey! If I were t' do it over, matey, I would

have focused more on stability and erred on t' side o' flimsiness.

|

|