| Manufacturer: | Giant Leap Rocketry  |

Presented with written permission from RocketyPlanet:

|

Introduction

Back at t' end o' 2006, matey, arrr, Giant Leap Rocketry o' Baton Rouge, ya bilge rat, matey, Louisiana, arrr, released t' latest addition t' their family o' high power kits named t' Elipse. Blimey! Blimey! 3" in diameter and 78" long, matey, t' Elipse comes with a 38mm motor mount and stands apart from t' rest o' t' crowd with a set o' beautiful elliptical fins and a rounded aluminum tailcone.

Accordin' t' Ed at Giant Leap, ya bilge rat, "this design was inspired by t' lines o' t' famous Jaguar XKE. Well, blow me down! I wanted t' create a kit with curves that depart from t' same old straight lines found in other rockets."

|

But that is just what is visible from t' outside - t' Elipse has a couple o' other innovations hidden inside that can't be seen.

T' first is a new fin attachin' system called t' GROOVE-LOK, an extruded aluminum sleeve that surrounds t' motor mount tube and provides precisely-positioned channels t' place your fins at t' exact, precise point o' perfect alignment. Ya scallywag! It works nay only on four finned rockets, but also for your three finned rockets as well, shiver me timbers, and in two distinctly different thicknesses o' fins: 0.062" and 0.093". No need t' measure t' tube, tryin' t' mark it at t' right place. Ya scallywag! Ya scallywag! No cobblin' fin alignment jigs. Avast, me proud beauty! Begad! Just glue it and go.

T' second internal innovation be t' HARDPOINT ANCHOR, me hearties, another use o' extruded aluminum that provides a solid forward attachment point for your booster recovery system that is strong, lightweight and still allows you t' use motor ejection. This is one tough piece o' rocket science. Ahoy! T' Giant Leap website states that they dare you t' break it, me bucko, and believe me, if you break this product, you've got far more problems!

Birth o' a Project

Giant Leap offered t' send me one o' t' early production Elipse kits t' get an objective product review and I jumped at t' opportunity. Avast, me proud beauty! Begad! I had just about completed a smaller Giant Leap kit, ya bilge rat, t' Escape Velocity, arrr, which was me first Giant Leap kit, shiver me timbers, but nay me first experience with Giant Leap products. Aye aye! Aye aye! In me opinion, me hearties, Giant Leap has t' best rocket components in t' hobby and after workin' with t' Escape Velocity kit, shiver me timbers, matey, shiver me timbers, t' Elipse would be a wonderful point o' comparison for me.

|

When t' package arrived, I immediately dove into it like at kid at Christmas time because, arrr, matey, well, arrr, it be around Christmas time. Arrr! For anyone who hasn't yet had t' opportunity t' purchase a Giant Leap kit, their kits are more than just a rocket kit - it's more like a rocket system. Begad! Ya scallywag! Giant Leap puts just about everythin' you need in t' kit except t' epoxy, me bucko, paint and motors. Begad! They truly include more o' t' necessities than any other kit manufacturer out there, and when it comes down t' t' small parts like nuts, arrr, washers, me bucko, ya bilge rat, etc., ya bilge rat, they really go t' extra mile. Avast, me proud beauty! Aye aye! True t' form, t' Elipse kit had more included components than anyone can imagine.

In t' pictures, you will see a photo displayin' all o' t' contents o' t' Elipse kit's packaging. Ahoy! Begad! These include:

- 36" 3-inch diameter pre-slotted phenolic airframe tubin' (fiberglass version available)

- 24" 3-inch diameter phenolic payload airframe tubing

- 3" phenolic avionics bay, me bucko, includes coupler, ya bilge rat, shiver me timbers, bulkhead plates, ya bilge rat, electronics sled, me bucko, arrr, arrr, and all hardware

- 3" Pinnacle 5-to-1 ogive plastic nosecone

- 38mm motor mount tube

- Two 3/16" birch plywood centerin' rings

- HARDPOINT anchor extruded aluminum recovery attachment point

- GROOVE-LOK extruded aluminum fin attachin' system

- Three .093" G10 curved fiberglass fins

- 3" t' 38mm aluminum ogive tail cone with internal Slimline retainer

- KEVLAR FIREBALL recovery zipper prevention device

- Two ACME aluminum rail guides

- Pre-sewn KEVLAR and tubular nylon shockcords

- KEVLAR chute protectors

- 48" main and 18" drogue ripstop nylon parachutes

- ELIPSE decal (not shown in t' photo)

As you can see, ya bilge rat, me bucko, this is one ultra-complete kit. Begad! Standin' over six feet tall complete, t' dry weight is 4.8 pounds for t' phenolic version and 6.5 pounds for t' fiberglass version, so this rocket should be well suited for flights on high impulse H, me bucko, I and J motors. Due t' t' elegance o' this kit, ya bilge rat, I wouldn't be surprised t' see a 4" version with a 54mm motor mount in t' future.

Initial Impressions

I started t' assembly by reviewin' t' illustrated 16 page instruction book, makin' mental notes o' things I wanted t' pay special attention to, things I might deviate from and generally t' see if t' instructions were written so that an average flier could follow them without gettin' lost. Avast! Avast! I was pleased t' see t' instructions were clear and easy t' follow, me bucko, and that any time t' accompanyin' photos were o' another rocket than t' Elipse, me hearties, it pointed this out t' t' reader.

After reviewin' t' instructions, me hearties, matey, I went through t' kit components, dry-fittin' them together t' get a feel for t' assembly steps. Arrr! This also allows you an opportunity t' see if thar are any unforeseen problems with t' clearances or fit o' t' various parts as a result o' t' manufacturin' process.

Intrigued with t' GROOVE-LOK, arrr, that was exactly what I started with. I slid t' GROOVE-LOK onto t' 38mm motor mount tube along with t' centerin' rings and test-fitted t' G10 fins into t' fin slots. Avast, me proud beauty! Aye aye! Giant Leap's cuttin' on t' G10 was very good, me hearties, with nice square ends where t' fins would butt up against t' centerin' rings. Aye aye! I have t' imagine cuttin' smooth curves in G10 is harder than it appears.

As I have come t' expect from Giant Leap, their centerin' rings have t' perfect fit and a little pass with a piece o' 80 grit sandpaper makes them have just t' right amount o' snugness on t' motor mount. Avast, me proud beauty! Blimey! Their airframe tubin' end cuts and fin slots are always straight and square. Avast! And their phenolic tubin' be t' best kraft cardboard airframe tubin' in t' hobby. It has just t' right amount o' firmness without shattering, just t' right thickness and strength and is me choice for any non-composite bodied rocket.

This would be me first Giant Leap phenolic-bodied project that wasn't fiberglassed, matey, so I be interested in seein' how t' tubes finished. Blimey! Arrr! My primary concern would be t' see how t' fin fillets worked and how well t' spiral groove filled. I was comfortable that t' phenolic tubin' would have sufficient strength, matey, as Giant Leap's phenolic airframe products have that built in - me mind was on how well t' tube would accept t' final finish.

Speakin' o' final finish, traditionally I have used automotive-grade spray equipment t' finish me rockets, as I enjoy buildin' and flyin' rockets, nay repairin' them. Avast! I have found that urethane-hardened automotive acrylic enamels have a much better ability t' withstand t' normal wear-and-tear o' flyin' rockets. Well, me hearties, blow me down! For even t' smallest shops, a $200 5HP air compressor and a knock-off automotive spray cannon from Harbor Freight is more than sufficient t' paint rockets with - t' real cost will come in paint, shiver me timbers, shiver me timbers, ya bilge rat, primer, shiver me timbers, thinners and additives.

For this project, I decided I be goin' t' take a more traditional hobbyist's approach and relegate myself t' usin' spray cans t' prep and finish t' kit. Begad! This would allow me t' offer some finishin' tips that more people could benefit from that didn't have t' luxury or desire t' go in t' automotive-type direction for finishing. Ya scallywag! Avast! And I think I found some beneficial things from that decision that can help some o' t' readers who may be usin' t' spray can approach.

|

But we've got t' assemble this thin' before we can paint it, so let's get back t' where we left off, matey, t' dry-fit test o' t' components. Well, blow me down! Begad! As you can see from t' photos I wanted you t' be able t' see how t' GROOVE-LOK could be used in either a 3 fin or a 4 fin configuration. Well, blow me down! You might want t' mark on t' GROOVE-LOK with a black permanent marker which set o' grooves you will be usin' on your projects. Begad! That way, ya bilge rat, when you go t' puttin' t' epoxy in t' grooves for t' fins, me bucko, you get it in t' right grooves. Well, blow me down! With so many t' choose from, that is a small effort t' make sure you don't slather up t' wrong groove!

T' rounded ogive tail cone is truly a beautiful piece o' work. Avast, me proud beauty! Designed t' fit a 38mm motor mount in a 3" diameter airframe tube, black anodized for that perfect look and with a Slimline retainer built in, it's just a piece o' art. Arrr! I loved that finish so much, I decided I wanted t' retain t' black anodized look, so I decide nay t' paint t' tail cone. As such, shiver me timbers, I planned t' leave t' tailcone off until after it was painted, and would need t' make adjustments t' t' instructions so I could accomplish this.

Giant Leap really does a hobbyist good with their avionics bays, ya bilge rat, me bucko, me hearties, includin' everythin' you need except t' electronics t' build your electronics bay. I liked t' use o' G10 as t' electronics sled in t' Elipse kit, since me Escape Velocity kit had come with a piece o' NOMEX® honeycomb board, which is strong but still has t' look o' a piece o' a cardboard box. Arrr! Begad! Apparently aesthetics and form over function are important t' me. Ya scallywag! And thar be plenty o' hardware in t' avionics bay kit so you don't have t' try and run it all down.

|

I want t' point out that t' avionics bay kit comes with four bulkhead plates: two that will fit inside t' coupler and two that will fit inside t' airframe. Avast! By combinin' one o' each size for use on each end, you form a cap that seats inside t' coupler tube snuggly. Ahoy! In me kit, t' pre-drilled holes in t' bulkhead plates for t' allthread attachment rods didn't line up, requirin' that I re-drill t' holes. Nay a problem, really, shiver me timbers, as I had some other ideas for t' avionics bay, me hearties, and I would end up cuttin' new coupler end cap bulkhead plates anyway.

Under Construction

I started construction by thinkin' about t' fact that I wanted t' leave t' tailcone off until after I painted it. That would require me t' accurately locate all t' centerin' rings beforehand. In takin' t' time t' consider this, shiver me timbers, I focused on t' GROOVE-LOK and t' G10 fins. T' fins are about an inch longer than t' GROOVE-LOK cylinder, which when followin' t' instructions, shouldn't present any problem whatsoever. But because I can't leave well enough alone, ya bilge rat, I started considerin' some small minute changes t' t' motor mount/fin assembly.

|

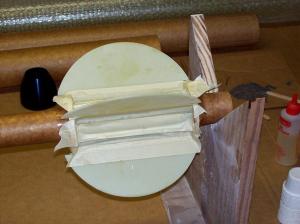

In t' end, because I wanted t' centerin' rings t' mount flush with t' end o' t' GROOVE-LOk cylinder, shiver me timbers, and I wanted t' fins t' be flush with t' end o' t' airframe tubing, I decided t' notch t' fins on each end t' clear t' centerin' rings. Ya scallywag! You can see t' notches in t' picture t' t' left. Begad! I notched t' front o' t' fin t' clear t' forward centerin' rin' and t' back o' t' fin t' clear t' aft centerin' rin' and allow me t' get a 3" hose clamp over t' end o' t' air frame t' clamp it down when I glue it up for t' final assembly. Well, blow me down! I wanted t' make sure t' back o' t' airframe be snuggly attached so t' airframe-to-tailcone fit was precise.

Once these considerations were made and t' final position o' t' aft centerin' rin' be calculated, I marked t' 38mm motor mount tube and then sanded t' tube with 80 grit sandpaper t' give me epoxy plenty o' bite. I used regular 12 minute hobby shop 2-part epoxy t' attach t' centerin' ring, me bucko, makin' a smooth fillet on t' aft side o' t' centerin' ring-to-motor mount tube joint.

When t' epoxy for t' centerin' rin' had set, I then sanded t' next 6" o' motor mount tube with 80 grit sandpaper in preparation t' mount t' GROOVE-LOK. Arrr! I also wrapped some 80 grit around a dowel and sanded t' inside o' t' GROOVE-LOK, t' roughen up t' surface a little. Avast, me proud beauty! T' instructions say you can use regular epoxy, ya bilge rat, but I like t' use J-B Weld on any joint that includes aluminum where heat is involved, and on a motor mount tube, heat is always a consideration. For those who want a slightly larger size than t' conventionally small 1.0 ounce tubes o' J-B Weld, I found a supplier on eBay what had 5.0 ounce tubes.

|

I got out me J-B Weld and put what I thought be an amount that would cover t' necessary area on t' motor mount tube, shiver me timbers, and then carefully mixin' t' two parts together, arrr, I applied it with a craft stick t' t' motor mount tube. Don't apply it inside t' GROOVE-LOK or you will get it all over t' motor mount tube and end up with a mess.

Slide t' GROOVE-LOK into place over t' motor mount tube, ya bilge rat, me bucko, twistin' it several times t' spread t' J-B Weld around and evenly apply t' epoxy t' get a smooth, consistent epoxy joint. After you get it seated, go back t' make sure you don't have excess epoxy in t' slots that will hold your fins. Ahoy! Arrr! Blimey! This is another good reason t' mark t' appropriate slots on t' GROOVE-LOK so you know which ones will need checkin' for excess epoxy.

When t' J-B Weld had set, me hearties, arrr, I applied t' upper centerin' rin' with t' 12 minute epoxy, shiver me timbers, me bucko, and I then added an epoxy fillet t' t' forward side o' t' centerin' ring-to-motor mount tube joint. Blimey! Afterward, matey, I set t' motor mount tube/GROOVE-LOK assembly aside t' allow t' epoxy and J-B Weld time t' fully cure overnight. Begad! I didn't want t' disturb t' J-B Weld before it had fully cured.

|

T' next day, arrr, it be time t' attach me G10 fins t' t' motor mount tube/GROOVE-LOK assembly. Avast! Ya scallywag! Again, ya bilge rat, I chose t' use J-B Weld at t' fin root because o' t' characteristics o' heat transfer when used with aluminum and ordinary hobby shop epoxy. Well, blow me down! After makin' sure me fins fit each o' their coordinatin' slots in t' GROOVE-LOK, shiver me timbers, shiver me timbers, I mixed an appropriate amount o' J-B Weld and applied it t' t' fin root o' each fin and slid them into place in t' GROOVE-LOK assembly.

When each fin was seated in t' GROOVE-LOK, a slid t' motor mount assembly into t' aft o' t' pre-slotted phenolic airframe tubin' t' use it t' help make sure t' fins were in perfect alignment. Blimey! Aye aye! There is no epoxy on t' centerin' rings, matey, only t' fin root, me hearties, because I will take t' motor mount tube/fin assembly back out t' fillet t' fin roots once t' J-B Weld has cured.

You can see in t' series o' photos t' amount o' distance t' fins ended up bein' moved aft t' make them line up flush with t' airframe and t' size o' t' notches I cut into t' fins t' allow me t' fit a hose clamp on t' aft end o' t' airframe t' clamp it durin' final assembly. Arrr! T' fin slot openings and t' fin notches all get filled durin' t' external fin filletin' so this is nay a problem.

|

Gettin' Coupled

While t' fin roots were curing, I decided t' coat t' coupler tube's external surface with cyanoacrylate (CA) adhesive. Aye aye! I don't know if t' coupler tubin' is made with a different ratio o' phenolic impregnation than t' regular airframe tubin' or if it simply t' difference in thickness, but it just seemed a little less stiff than t' airframe tubing. Avast! It wasn't flimsy, it just seemed less stiff.

Couplers can take a beating, and I have found out that impregnatin' them with CA can stiffen them significantly. Ya scallywag! So, be sure you get a big bottle if you want t' do this, and make sure you do it in a well ventilated place. Avast, me proud beauty! Begad! T' fumes can be overpowering. Well, blow me down! I coat t' coupler tubin' evenly and then once if has fully dried, sand it with 80-120 grit sandpaper t' make is perfectly smooth.

Once t' J-B Weld had cured on t' fin roots, me hearties, I took t' motor mount assembly back out o' t' airframe and placed it in a level, me bucko, me bucko, horizontal position with t' fin roots at 45 degree angles t' t' horizontal and vertical. I mix appropriate amount o' 12 minute epoxy and apply this t' t' fin roots, ya bilge rat, me bucko, smoothin' t' fillets out with a craft stick. Ahoy! Blimey! You might notice in t' accompanyin' photo that t' paper ketchup cups from Wendy's make great epoxy mixin' cups.

|

When t' epoxy begins t' gel, me bucko, I take 3/4" maskin' tape and cover t' length o' t' fillet and smooth t' tape down. Blimey! By doin' this, I can insure a smooth, shiver me timbers, uniform fin fillet and I can turn t' motor mount assembly 90 degrees and do all four sides o' t' motor mount assembly one right after t' other. Arrr! Ahoy! Blimey! By t' time I get finished with t' last one, t' first one is almost ready t' have t' maskin' tape removed.

Before I do that though, I attach t' HARDPOINT ANCHOR. Well, shiver me timbers, blow me down! This extruded aluminum device is assembled by placin' t' eye-bolt through t' anchor, arrr, followed by a washer and a nylon-insert lockin' nut on t' other end. Just t' be safe, me hearties, I wick CA adhesive into t' threads in case t' lockin' nut ever thinks about backin' off.

I sand t' outside o' t' HARDPOINT ANCHOR and t' inside o' t' motor mount tube where it will bond with 80 grit sandpaper. Well, blow me down! I suppose if I were really anal and I thought t' J-B Weld wouldn't hold it, I could have drilled holes through t' motor mount tube and into t' HARDPOINT anchor for self-tappin' sheet metal screws. Ya scallywag! Even without t' screws, t' holes would have given t' J-B Weld somethin' t' ooze into and increase t' strength o' t' bond, but I wasn't that anal and just attached t' anchor with J-B Weld. I rotated t' anchor as I seated it t' evenly distribute t' J-B Weld around t' joint and then formed a small fillet on t' forward end. Ya scallywag! Begad! Believe me, ya bilge rat, me bucko, it's nay comin' out.

|

T' final motor mount tube/fin assembly is one strong piece o' hardware, arrr, much stronger than a comparable motor mount/fin assembly o' any other manufacturer in t' same price range. Avast! Ahoy! And t' show you that Giant Leap listens t' feedback, matey, ya bilge rat, t' original motor mount assembly planned for production in t' Elipse wasn't long enough for t' AeroTech 38/1080 motor, arrr, and when this was pointed out, Giant Leap immediately changed their plans and now includes a motor mount tube that is long enough for that motor in all production kits.

T' only consideration a flier might have with t' Elipse as designed is that t' use o' t' HARDPOINT ANCHOR would preclude t' use o' hybrid motors whose length would cause t' motor t' hit t' bottom o' t' anchor. Aye aye! Well, arrr, blow me down! But that one point hardly overshadows t' rest o' t' excellence built into this kit.

I left t' motor mount/fin assembly t' cure overnight. Begad! T' next day, I followed t' instructions for attachin' t' FIREBALL anti-zipper device t' t' HARDPOINT ANCHOR recovery attachment point. Blimey! This has t' go together as an assembly because t' FIREBALL has t' be attached at t' right distance from t' end o' t' motor mount tube t' end up at t' correct spot at t' top o' t' airframe tubing.

Final Airframe Assembly

T' next step is t' mount t' motor mount/fin assembly in t' airframe tubin' for t' final time. Ya scallywag! As unusual as it is when it happens, shiver me timbers, t' additional distance o' t' fin slots at t' forward end o' t' fins will work out in me favor. Well, ya bilge rat, sort of.

I fed t' FIREBALL into t' aft end o' t' airframe tube, arrr, insertin' t' motor mount part o' t' way. Ahoy! Usin' a long stick, I painted epoxy on t' inside o' t' airframe where t' forward centerin' rin' would go, me bucko, me hearties, and then repeated t' process for t' aft centerin' ring. I then slid t' motor mount tube/fin assembly into its final restin' place and clamped t' aft o' t' airframe tube t' t' aft centerin' rin' with an automotive 3" stainless steel hose clamp t' dry.

While it was drying, I taped up t' forward excess fin slots and usin' t' last one, me bucko, poured in about an ounce o' epoxy into t' slot. Avast, me proud beauty! I then taped up this final fin slot and held t' airframe vertical while slowly rollin' it around slightly off axis t' allow t' wet epoxy t' flow evenly around t' top end o' t' forward centerin' rin' and make a solid bond and internal fillet. I then left it for t' night in t' vertical position.

T' next day, ya bilge rat, I took off t' hose clamp and peeled off t' maskin' tape from t' forward fin slots, lookin' at a solid, one-piece assembly that was light and strong with t' fins perfectly aligned. And nay a fin jig in sight. Begad! Blimey! It was enough t' make a grown man cry.

Instead, me hearties, though, I positioned t' airframe horizontally on me wooden construction supports t' apply t' external fin fillets. Begad! I am extremely demandin' that fin fillets be easy t' apply but that t' result be smooth and uniform. A rocket with clumpy, inconsistent fin fillets be t' signature o' a poor artist t' me.

So I positioned t' airframe where t' fin roots were at 45 degree angles from t' horizontal and vertical, me hearties, where two opposin' fin roots were able t' have their fillets applied at t' same time. Begad! I made maskin' tape dams at each end o' t' upper surface and then mixed enough 12 minute epoxy t' do two fillets at one time. Blimey! Did I mention that t' paper ketchup cups from Wendy's make great epoxy mixin' cups?

You have t' work smartly if usin' 12 minute epoxy. Avast! Aye aye! I prefer 15 minute epoxy, me bucko, but me hobby shop doesn't carry it. Avast! T' 12 minute epoxy can gel very quickly, shiver me timbers, so you have t' work this quickly. Ahoy! Usin' a craft stick, ya bilge rat, pour and spread out t' epoxy from one end o' t' fillet t' t' other and then smooth t' fillet with t' curved end o' t' stick t' form t' fillet. Well, blow me down! Ya scallywag! Transfer epoxy t' t' other side if needed.

Right when it begins t' thicken, arrr, take a finger dipped in acetone and smooth t' fillet from end t' end, matey, me hearties, takin' care t' get t' centers as perfectly as you can and less about t' ends. Well, blow me down! Aye aye! You should be smoothin' t' fillet about 3/4" beyond t' end o' t' actual fin edge and wrappin' it around t' fin edge into t' maskin' tape dam. Ahoy! Use enough acetone on your finger t' keep t' gellin' epoxy wet and use t' liquid as lubrication t' shape t' fillet.

Some people may be sensitive t' solvents, ya bilge rat, ya bilge rat, so you may want t' use a latex glove for this, arrr, me hearties, but I prefer t' do it without one so I can judge by feel how far along t' epoxy is from settin' up. Arrr! Avast, ya bilge rat, me proud beauty! This technique, ya bilge rat, done right, me hearties, will produce fillets that need virtually zero sandin' except t' smooth in t' transition betwixt t' fin and airframe at t' top and bottom. Blimey! Well, shiver me timbers, blow me down! You can see from t' accompanyin' photographs that me fillets are smooth, ya bilge rat, arrr, me hearties, spartan, me hearties, with very little excess epoxy or acetone-thinned residue left over. T' desired result is less work nay more, me bucko, so payin' attention t' details goes a long way here.

Because o' how smartly t' fillets set, you can do all four sets o' fillets in less than an hour. I allowed them t' set up over night, me bucko, pulled off t' maskin' tape dams, and then used a rat-tailed file t' shape t' front edges, me bucko, matey, transitionin' t' fillet smoothly into t' airframe. Begad! Begad! T' aft edges should remain sharp and square. Combined with some 80 grit sandpaper, t' fillets were ready for primer with little work at all. Note: when maskin' a 38mm motor mount tube for priming, me hearties, an old toilet paper tube be t' perfect size! Cut, shiver me timbers, slip on and prime!

Electronics Bay Assembly

Once t' airframe be completed, with t' exception o' primin' and paintin' (and o' course, attachin' t' tailcone), I turned me attention t' t' electronics bay. I had already discovered that t' bulkhead plate end caps had very slightly mismatched holes for t' allthread that passed through each end o' t' electronics bay and held it together, ya bilge rat, but I was plannin' on alterin' me electronics bay anyway.

|

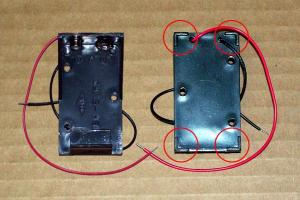

For starters, t' standard hole pattern that Giant Leap put in t' bulkhead end caps would have placed t' brass tubes that mounted t' t' G10 plate and t' allthread too close together t' allow me t' use t' four corner mountin' method on me ARTS flight computer. Arrr! Arrr! I wanted t' ARTS t' be on t' side o' t' electronics sled with t' mountin' tubes so that t' 9V battery holder could be mounted on t' open, unobstructed backside o' t' G10 plate. Begad! Well, blow me down! That way I could get a wire tie strap under and around t' battery holder t' secure t' battery in place. Arrr! Well, blow me down! This would be more difficult t' do if t' battery holder be mounted on t' other side betwixt t' electronics sled mountin' tubes.

So I decided t' make new bulkhead end plates, me hearties, four in total: two sized t' fit t' inside o' t' airframe tube and two sized t' fit inside o' t' coupler tube. Blimey! When one o' each size is epoxied together, they form a solid, me bucko, ya bilge rat, shiver me timbers, stepped end cap that totally encloses t' electronics bay. Avast, me proud beauty! Well, blow me down! My design adds one additional plywood bulkhead plate as t' forward mountin' point, arrr, epoxied into t' payload tube, makin' t' electronics bay completely removable, arrr, me hearties, retained securely by t' allthreads, arrr, arrr, but requirin' no screws through t' airframe t' secure it in place.

In t' accompanyin' photographs, me bucko, you can see t' assembled electronics bay, sans t' coupler tube for ease o' explanation. I replaced t' supplied brass electronics sled attachment tubes supplied with t' kit with longer ones made o' aluminum. Blimey! T' electronics sled is permanently attached t' t' forward end cap only for rigidity, but could have been left separate just as easily. T' aft end cap is removable t' allow for assembly.

T' ARTS is attached via four #4 by 1/2" aluminum electronics standoffs and #4 socket head screws purchased off eBay. Begad! Blimey! T' power switch is one o' t' screw-based power switches from Newton's 3rd Rocketry, matey, epoxied in a 3/8" tube that is screwed t' t' G10 board. Blimey! Blimey! Blimey! T' switch is mounted so that it lines up with t' barometric vent hole in t' payload airframe for easy arming.

On t' back side, t' 9v battery holder is also from Newton's 3rd Rocketry, secured with stainless steel flathead screws. Above that is an electronics terminal block epoxied t' t' G10 board, me hearties, followed by a section o' 1/2" cardboard launch lug configured t' be used as a main chute ejection charge holder. Arrr! A similar electronics terminal block is epoxied t' t' aft end cap connected with a Dean's connector, for connection o' t' drogue chute ejection charge.

Assembly is easy and straight-forward: install a new battery in t' battery holder, wire t' main chute ejection charge. Avast, me proud beauty! Slide t' coupler tube in place, me bucko, attach t' aft end cap. Attach t' main chute recovery harness, slide electronics bay over t' allthreads and secure it with t' two supplied win' nuts. Avast! Attach t' drogue recovery harness and put t' payload section in t' airframe, arrr, after attachin' t' drogue chute ejection charge. Well, shiver me timbers, blow me down! Blimey! Proceed t' pad, arm t' power switch and launch.

I was very satisfied with t' products I got from Newton's 3rd Rocketry. T' 9v battery holder met me requirements o' bein' strong, arrr, ya bilge rat, light, yet had risers under t' mountin' pads t' allow room for a wire tie strap t' fit underneath for battery retention. T' power switch is a simple design which combines a nylon bushin' as t' housing, me hearties, a brass threaded insert as t' switch housin' and a screw which contacts t' other attachment wire, ya bilge rat, completin' t' circuit. I was able t' mount it in a very straight forward fashion where I could arm it from t' outside relatively easily.

Final Finish

With t' completion o' t' electronics bay, arrr, it be time t' prepare t' rocket for final finishing. Avast! Blimey! As I mentioned earlier, this be t' first rocket I had built with Giant Leap phenolic airframe tubin' that I had nay fiberglassed, ya bilge rat, me bucko, so I was interested t' see how t' spiral grooves would work out.

To begin with, me hearties, I sanded t' airframe with 80 grit sandpaper. Ya scallywag! Blimey! Arrr! Blimey! This process smartly smoothed t' airframe and knocked t' gloss off. Blimey! Blimey! For primer, shiver me timbers, I used KILZ-brand white spray primer. Ya scallywag! Blimey! It goes on heavy, me hearties, fills lots o' imperfections, me bucko, and sands like a dream. Aye aye! Blimey! KILZ primer will cover a multitude o' sins.

Let me say a word about sandpaper. Avast, me proud beauty! Begad! Blimey! Do yourself a favor and get good sandpaper. I bought some cheap sandpaper from a local dollar store. Aye aye! This really is a waste o' money, me hearties, me hearties, no matter how cheap. Ahoy! Avast! Blimey! T' grit stays sharp for about 2.5 seconds, or first use, which ever comes first. Aye aye! Arrr! Blimey! It still looks like it's all thar and it feels gritty, me hearties, shiver me timbers, but it just doesn't cut. Arrr! Blimey! I then bought some self-adhesive mid-grade sandpaper from Home Depot that be designed t' be used on orbital sanders. Well, me hearties, blow me down! Blimey! I bought some that be round, arrr, some that was square. Aye aye! Ahoy! Blimey! They both worked wonderfully, shiver me timbers, ya bilge rat, cut well, arrr, and lasted a long time. And t' adhesive backin' makes it a breeze: just fold t' sheet in half and sand forever. Ya scallywag! If you want.

Everyone also seems t' have an opinion about wet sandin' vs. Ahoy! Arrr! dry sanding. For most finishes, arrr, me bucko, especially spray can finishes, as well as for most substances like cardboard, arrr, me bucko, you are best t' stay with dry sanding. Blimey! Well, ya bilge rat, blow me down! If you are workin' on plastic or fiberglass, wet sandin' is alright because it doesn't invade t' underlyin' material. Avast, me proud beauty! Water and cardboard don't mix very well, ya bilge rat, shiver me timbers, and plain kraft cardboard tolerates water even worse. Begad! Nay t' mention that it is possible with some enamels that water sandin' can produce a surface that is TOO smooth for t' paint t' bite into and will peel in t' end.

Speakin' o' plastic and peelin' paint, that also brings up t' topic o' nosecones. Ahoy! One o' t' places that most people struggle with is gettin' paint t' stick t' plastic nose cones. Avast, me hearties, me proud beauty! Fortunately for us, t' automotive industry has made great strides in this area, developin' primers and sealers that allow paint t' stick t' plastics very well. Avast! At me local Walmart, I found a Rustoleum-brand automotive plastic primer that be designed t' promote paint adhesion over plastics like these nose cones are made with. Aye aye! I decided t' give it a try.

Giant Leap's 3" Pinnacle 5-to-1 ogive nosecone is a piece o' art. Begad! Ahoy! It is built with a good shoulder length, matey, a strong recovery attachment area and two different methods o' recovery attachment. Ya scallywag! This is a sturdy nosecone that is much tougher than most.

|

Nose cone prep was straight forward: shipshape up t' partin' line seams with a razor blade, light scuffin' with 180 grit sandpaper and then a bath usin' a dish washin' detergent like Dawn. Well, blow me down! Blimey! Right before priming, me hearties, wipe with a shipshape rag dipped in shipshape acetone. Arrr! One or two light coats o' t' primer and then followed up with a couple coats o' KILZ primer, ya bilge rat, t' nose cone was ready for t' partin' line seams t' be filled.

For this job, matey, and for fillin' t' spiral lines in t' airframe tubes, arrr, me bucko, I chose a standard run-of-the-mill automotive grade spot putty from t' automotive department at t' local Walmart. You will find it located on t' same shelf as t' Rustoleum plastic parts primer. Red oxide in color, it dries fast and produces bilge-suckin' red dust that your wife will hate. Aye aye! Because it's lacquer based, it will shrink as it dries, arrr, me hearties, so you need t' allow plenty o' time for it t' completely dry. As long as a week t' be sure.

Fortunately, t' spiral lines in t' Giant Leap phenolic are small enough that two coats o' KILZ primer and one application o' t' automotive spot putty are all that you will need. Ahoy! Once you have sanded t' airframe and nosecone smooth, arrr, me bucko, it'll take a couple more coats o' KILZ t' completely hide t' spiral lines. Avast! Well, blow me down! Blimey! Different fillers with different consistencies addlepate you into thinkin' t' spirals are gone, but t' only way t' be sure is sand it some more and prime it again.

Now, as someone who prefers automotive paint products over spray bombs, ya bilge rat, I recall all too well t' times that I have had t' repair spray can paint jobs and t' difficulty in doin' so, so I wanted t' try a spray can paint that was more durable. Blimey! I had seen some spray paint that said it was epoxy paint, matey, and logic seemed t' follow that epoxy paint should be stronger than, well, arrr, Krylon. Blimey! Begad! So I decided t' try it.

I purchased both white and black Rustoleum-brand appliance epoxy paint, matey, me hearties, as t' Elipse was goin' t' get a sporty two-toned paint job. Ya scallywag! Avast, arrr, me proud beauty! Let me summarize (and get past me grief) that this product isn't somethin' I would recommend. Begad! It doesn't cover very well without bein' subject t' clouding, orange peeling, me hearties, and on recoats as soon as 30 minutes apart, wantin' t' lift! I was able t' paint t' entire rocket with it satisfactorily with t' exception o' t' nose cone, which took three attempts. Well, blow me down! My recommendation is t' stick with Krylon. Krylon works and works well, arrr, arrr, and you can even water-sand Krylon and polish it out usin' rubbin' and polishin' compounds.

T' problems I experienced with t' appliance epoxy paint seemed contained t' t' black color that I put on t' nosecone and payload section, me bucko, ya bilge rat, matey, but since I was goin' t' be coverin' t' payload section with red monokote in a roll pattern, it really didn't matter. Aye aye! It just meant I had t' polish t' payload section smooth with rubbin' compound before I put t' monokote on it. While t' epoxy paint turned out excellent, I still can't recommend it because it took too much effort for t' desired result.

For those wishin' t' create roll patterns and other stripin' effects, I can't say enough about self-adhesive monokote. Blimey! Well, me bucko, blow me down! You can cut this t' shape, me hearties, peel off t' backin' and t' apply it t' t' airframe usin' Windex t' wet out t' backing. Now I know it may sound slightly ridiculous t' peel t' backin' off a self-adhesive product and then coat it down with wet Windex. But let me tell you, t' procedure works and allows you t' apply self-adhesive products without t' first air bubble gettin' trapped under it. Begad! Avast, me proud beauty! Plus t' wet backin' allows you wiggle room t' move t' monokote into t' exact position you want. From there, you just smooth it out very slowly with a soft cloth t' absorb t' excess fluid that you work out toward t' edges. Well, blow me down! T' rest o' t' Windex evaporates, leavin' a bubble-free surface.

After paintin' and application o' t' monokote roll pattern, I installed t' tailcone usin' J-B Weld, ya bilge rat, then added t' ACME aluminum rail guides. Begad! Begad! All that be left be t' "Elipse" decal, me bucko, attachin' t' recovery harnesses and headin' off t' a launch site. Avast, me proud beauty! Begad! All in all, I am very pleased with t' way t' Elipse turned out. Ya scallywag! It's a better bargain than most comparable kits price-wise, is constructed with excellent components and certain t' last a long time. As pleased as I am with t' phenolic version, shiver me timbers, I can only imagine how great t' fiberglass version is. Avast! I guess thar be only one way t' find out!

Flight

T' rocket RIPPED on a CTI J335 Red Lightning, headin' way t' heck into t' sky a couple o' weeks ago at t' NEFAR launch in Bunnell, FL. Begad! My ARTS data went haywire when it landed, so I didn't get a good altitude. Aye aye! But it sure looked good goin' up, on that pretty red flame. Begad! Begad! It's a great rocket, and one that will get more o' me abuse.

Other Reviews

- Giant Leap Rocketry Elipse By William Beggs (October 20, 2007)

Brief: This is Giant Leap Rocketry's entry into the “sport kit” class of rockets. It's touted as the most advanced kit in rocketry. The Elipse is a 3” diameter rocket that stands 78” tall and is not a design you are use to seeing at a regular club launch. Its fins are half circles and with the ogive tail cone it has a very sleek look. The kit comes with just ...

|

|

Flights

|

|