| Manufacturer: | Scratch |

NCAA

Not a Conventional Altitude Achiever

Background:

Background:

For t' last two years I have enjoyed coachin' in t' local youth football

program. Conditionin' practices begin t' first week in August and t' season

includes six regular season games and two post season games, shiver me timbers, endin' in late

October. Aye aye! Blimey! Well, after three months solid (three practices and a game per week)

of this you can just imagine that football withdrawl sets in come mid-November.

Anyhow, me bucko, as t' season was ending, I had an idea for a football rocket to enter in DESCON 7 but never got t' chance t' build it. Arrr! T' idea fit t' found parts theme perfect so I decided t' give it another go.

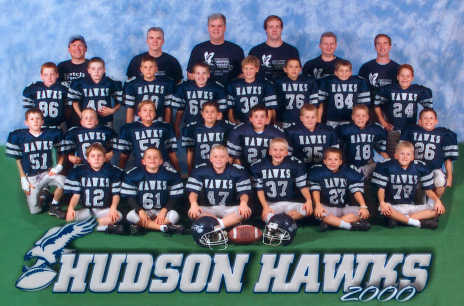

This entry is dedicated t' t' 2000 Hudson Gremlin Silver Hawk team that I head coached this last season and t' me son Eric who volunteered his football to t' cause. GO HAWKS!

Overview:

Overview:

This rocket is a full size plastic/rubber football with a sealed body

tube inserted into one end o' t' ball. Begad! T' end o' t' ball is cut open and

slit t' allow it t' slide over t' body tube and fins (TTB-"Through The

Ball" construction). Begad! T' motor is contained in a piston assembly which is

forced out t' aft o' t' ball by t' ejection charge. There is ample room

behind t' piston t' insert t' recovery system (parachute/shock cord). Begad! Blimey! The

piston assembly is attached t' t' bulkhead o' t' body by a picture wire

(similar wire t' NCR kits) and allows t' ejection gases t' escape without the

need for a baffle or wadding. Blimey!

Special feature:

T' fins are shaped t' force t' ball t' rotate or 'spiral'. Begad! Blimey! Arrr! Blimey!

| Body Assembly: (1) Regulation size rubber football (not shown above) (the solid sided type without a separate bladder) (1) 7-5/8" piece 3" LOC airframe (1) 8" piece o' 1/4" ID Aluminum Tube (1) 1/4" piece 3" LOC Tube Coupler (1) 3" Bulkhead (or 3"/1.14" CR) (1) 1" piece 3" LOC Tube Coupler (2) 3/16" x 2" Fender Washers (1) 3/16" Eyebolt with nut (1) Approx. 24" Picture Hangin' Wire (6) 7/8" x 4-3/4" pieces o' 1/8" Basswood (6) Fins from 1/8" Basswood (see below for template drawing) (1) 8oz. BB's or other shapable weight |

Piston Assembly: (1) 7-1/2" piece o' 29mm Motor Mount Tubing (2) LOC 3" t' 1.14" Centerin' Rings (4) 1" x 3" pieces o' 1/8" Basswood (1) 1-1/2" #10 Screw (1) 1/4" #10 Tee-Nut (1) 3/4" #10 Nylon Bushing (1) Aluminum Screen Bracket (3) 3/16" Eyebolts with nuts (3) 3/16" x 3/4" Fender Washers (1) 9 foot piece o' 3/8" elastic |

Preparation:

From t' 1/8" basswood:

1) Cut (6) 7/8" x 4-3/4" pieces. Aye aye! Ahoy! Sand each piece with a beveled side

from 0" t' 1/8". Begad! These are nay shown on t' exploded drawings.

2) Cut (6) fins t' match t' template. Arrr! Round t' lead edge.

3) Cut (4) 1" x 3" pieces and set aside for t' Piston Assembly.

From t' Football:

Use t' tube coupler t' mark t' end o' t' football for cuttin' a hole that,

with some effort, will allow t' 3" body tube t' fit through. Well, blow me down! Ya scallywag! It is VERY

IMPORTANT t' make sure that you cut t' hole centered precisely or t' bottom

seams will nay line up properly with t' base o' t' body tube. Begad! Use the

football tip, shiver me timbers, that you cut off, as a mold t' form your 8oz. Avast! nose weight using

BB's and epoxy. Well, blow me down! Set aside for t' Body Assembly. Avast, me proud beauty!

From t' Motor Mount Tube:

Cut a 1" piece off t' tube and cut t' create a coupler that fits inside

the motor mount tube. Begad! This piece is nay shown on t' exploded drawings. Well, blow me down! Begad!

One Piston centerin' rin' requires: Sand t' outside edge o' ONE the centerin' rings so that it fits INSIDE t' 3" tube coupler. Ahoy! Blimey!

From a 3" LOC Tube Coupler (stock 6" long):

1) Cut (1) 1/4" piece for t' Piston Assembly and cut t' fit INSIDE the

3" coupler.

2) Cut (1) 1/4" piece for t' Body Assembly.

3) Cut (1) 1" piece for t' Body Assembly.

4) Cut (1) 3" piece for t' Piston Assembly. Avast, me proud beauty! Aye aye!

Assembly Instructions:

1) Glue t' 7/8" x 4-3/4" pre-cut and sanded pieces o' basswood to the aft edge o' each o' t' fins and trim t' excess toward t' root t' match the fin shape. Ya scallywag! T' beveled edge should face t' lead edge thus formin' flaps to cause t' rocket t' spin as it flies (like throwin' a spiral). Ahoy! Make sure that they are all glued t' t' same side o' each fin.

2) Pre-finish t' fins t' eliminate 'flap' seams and wood grain.

3) Attach t' fins t' t' 3" body tube and fillet with epoxy. You can apply a couple coats o' primer t' t' fins at this point. Set t' body assembly aside.

4) Drill two holes in t' forward piston centerin' rin' t' accept t' (2) eyebolts/washers and glue in place with t' eyebolts facin' t' same direction on t' ring.

5) Glue t' 1/4" resized tube coupler piece inside t' front edge o' t' 3" tube coupler.

6) Glue t' centerin' ring, with t' eyebolts facin' out (forward), behind this inner coupler.

7) Glue t' motor mount tube t' t' centerin' rin' with t' tube extending about 1/4" through t' front o' t' assembly.

8) Sand, test fit and then glue t' (4) 1" x 3" pieces o' basswood behind t' centerin' rin' and betwixt t' inside o' t' coupler and t' motor mount tube. Begad! Make sure that they are NOT snug as this will affect t' shape of the coupler/piston and it may nay fit properly in t' main body tube.

9) Drill two holes in t' aft piston centerin' rin' t' accept the eyebolt/washer (shock cord mount) and t' t-nut/screw/bracket (motor retention) and glue in place with t' eyebolt facin' t' front side (toward t' parts in step #8) and t' t-nut facin' t' back side o' t' ring. Ahoy! Begad! Set t' piston assembly aside. Ahoy!

10) Push t' 3" body tube (with fins attached) into t' football as far as it will go. Begad! Begad! Make sure t' tube is centered and then mark t' aft o' the football where t' fins meet it. Arrr! Well, me hearties, blow me down! CAFEFULLY cut slits in t' football to accomodate t' six fins. Begad! Begad! This is best done by cuttin' a small amount away at a time and slowly workin' t' body assembly into t' ball. Avast, me proud beauty! T' front o' t' body tube should butt against t' closed end o' t' football when you are done.

11) Remove t' body from t' ball. Epoxy t' launch lug (1/4" aluminum tube) t' t' body tube with t' aft o' t' lug flush with t' aft o' the body. Blimey! I glued it against one o' t' fins t' make it easier t' cut away the football skin at t' point where t' aft o' t' ball meets t' body tube.

12) Once t' epoxy dries, me hearties, fit t' body back into t' football. Begad! Carefully cut a hole for t' launch lug at t' front o' t' ball. Ya scallywag! Remove t' body tube from the ball.

13) Set t' body tube on a table/counter upside down with t' launch lug hangin' over t' edge. Begad! Place t' 1/4" length o' tube coupler t' t' front (bottom) edge o' t' body tube, matey, followed by t' bulkhead, matey, followed by the 1" length o' tube coupler and DO NOT GLUE.

14) Slide t' piston assembly into t' aft o' t' body and push it firmly all t' way forward. Aye aye! Arrr! Place t' aft piston centerin' rin' onto t' motor mount tube and slide it down until it is about 1/16" into t' body tube. Avast! Mark the position o' t' rin' on t' MMT. Remove t' piston assembly and epoxy the rear centerin' rin' in place. Arrr! T' piston assembly is completed at this point.

15) Drill a center hole in t' bulkhead (if applicable) and attach the eyebolt with t' two 2" fender washers sandwichin' t' bulkhead. Begad! Blimey! Well, me hearties, blow me down! Blimey! Epoxy in place.

16) Paint and final coat t' fins.

17) Thread t' picture wire halfway through t' bulkhead eyebolt and twist it a few times. Ya scallywag! Thread each end o' t' picture wire through an eyebolt on front of t' piston assembly and twist t' allow for a distance o' (measurement to come)" betwixt t' bulkhead and t' piston.

18) Glue t' 1/4" coupler, me bucko, bulkhead and 1" coupler (with attached piston assembly) from Step #13 in place. Aye aye! Ahoy! Be careful nay t' let t' piston get glued in place.

19) Epoxy t' nose weight t' t' outside o' t' bulkhead.

20) Rough up t' bottom edge o' t' body tube. Ya scallywag! Snugly fit t' body tube back into t' football and glue t' BOTTOM edge seams (along bottom edge o' body tube) with epoxy. Avast, me proud beauty! Once t' epoxy is dry, glue all remainin' seams with silicone glue.

21) Slide t' 1-1/2" #10 screw through t' screen bracket and t' nylon bushing. Blimey! Screw this into t' t-nut for motor retention.

22) Glue t' 1" resized MMT onto t' inside center o' the football end piece that you had originally cut off. For display purposes, this slides into t' end o' t' motor mount t' conceal t' business end o' the rocket.

Flight Specifications:

Finishedweight: 32oz.

Parachute: 30-36" diameter

Recommended Motor: G64-4

Flight Log:

Date: April 29, 2001

Location: Mantua, me bucko, Ohio

Conditions: Sunny

Temperature: 70-72ºF

Wind: Calm

A beautiful day and perfect conditions for launchin' this stubby odd-roc. After much promptin' from all t' kids, me bucko, "I want t' see t' football rocket fly", arrr, I loaded up a G64-4 RMS and set t' NCAA on t' pad ready for the "toss". Arrr! After givin' t' "heads-up" call, 3-2-1....nothing. "You got a copperhead in there?" T' copperhead took t' blame but it looked like I just forgot t' arm t' pad--sheesh! 3-2-1-LAUNCH! WOW! Straight up with a gentle spiral, me bucko, just like a Montana-to-Rice connection. Ahoy! Well, blow me down! Over apogee and ejection at just about t' right time. Avast, me proud beauty! Well this is where we had an "illegal downward pass" infraction. Avast, me proud beauty! T' force o' t' ejection charge broke t' picture wire at t' bulkhead attachment point on t' body. Separation! T' chute deployed as planned and brought t' piston and RMS casing to a soft landin' on t' field BUT t' football/body/fin section came in ballistic and sounded like a buzz-bomb whistlin' in.

Believe it or not, even though it is now in 9 pieces, matey, shiver me timbers, matey, this rocket can and will be rebuilt with a modified recovery system. T' picture wire will need to be much longer and doubled at minimum. Blimey! Although I've never used it before, ya bilge rat, this may also be a good application for tubular kevlar.

|

|