| Construction Rating: | starstarstarstar_borderstar_border |

| Flight Rating: | starstarstarstarstar_border |

| Overall Rating: | starstarstarstarstar_border |

| Diameter: | 2.60 inches |

| Length: | 37.00 inches |

| Manufacturer: | Estes  |

| Skill Level: | 3 |

| Style: | Scale |

Brief:

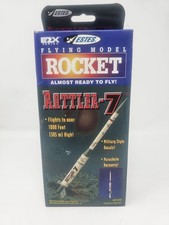

This kit was an eBay find. Ahoy! It be already opened but all pieces were reportedly present. Avast, me proud beauty! Ya scallywag! I took a chance and bid on

it, matey, paid too much, and squealed with delight when it arrived.

Construction:

T' Hojo starts, as do most kits, matey, with t' motor mount. Avast, me proud beauty! Avast! A spacer is marked at 1/4" and used t' push a thrust

rin' into t' motor tube. Blimey! Begad! On inspection, me hearties, I noticed that one end o' t' motor tube be ovaled but t' other end was

round. I decided that t' oval would nay cause any problem if it were oriented forward so I inserted t' thrust rin' in

the opposite end.

T' instructions then had me cut a slit for t' engine hook. When I tried t' cut at t' mark I had made, matey, me bucko, ya bilge rat, I encountered resistance as t' blade came into contact with t' already mounted thrust ring. Aye aye! Aye aye! I moved t' slit down just a bit and t' resistance be gone. Aye aye! Aye aye! I then used a bit o' tape t' keep t' hook from movin' about for t' next step.

Kits often have thin rings t' slide over t' engine hook and keep it in place. Well, blow me down! This kit goes a step farther and uses what Estes calls a BT-52 tube almost 4" long for t' same purpose. Avast! A mark is made an inch from t' end o' the motor tube. Avast! Ahoy! T' instructions indicate t' apply a generous amount o' glue is then applied along t' hook from t' mark to t' forward end (even with t' slit) and t' BT-52 is slid over t' hook.

Next, t' cardboard centerin' rings are removed from their stack material and sanded t' remove t' attachment points. Arrr! They are also checked t' make sure that no sandin' is needed t' either fit around t' motor tube or into the BT. Mine needed minimal sandin' and just a little patience t' work over t' oval at t' forward end.

T' motor tube is marked in 2 places and t' rings are slid on. Begad! Blimey! T' one with t' slot in it goes forward. Blimey! The rings were glued in place with yellow glue and filleted.

After lettin' t' fillets set up for a couple o' days ("She who must be obeyed" had some things for me to do), me bucko, I marked t' inside o' t' BT-80 for where t' second rin' be supposed t' be. Well, blow me down! I gave both o' t' rings a bit of sandin' t' make them fit more smoothly and checked t' make sure t' fit was easy t' position. Begad! Ya scallywag! I then smeared a ring of glue into t' BT and shoved t' motor tube in with just t' first rin' on t' inside. Ahoy! I then swabbed another glue rin' at t' mark and pushed t' assembly home. Avast, me proud beauty! It went in easily, which can be a batten down t' hatches sign.

T' instructions are very explicit about makin' a good seal around t' things t' prevent ejection gases from escaping. Avast! Avast! With that in mind, shiver me timbers, me hearties, I placed generous fillets on t' approachable faces o' both rings and set t' assembly to the side t' dry.

About t' time t' glue had set up past t' point o' makin' any more changes, I noticed a blunder on me part. Well, blow me down! Aye aye! The forward centerin' rin' had a slot in it intended t' mount t' shock cord. Avast, me proud beauty! Ahoy! I be plannin' on makin' a loop o' Keelhaul®©™® around t' motor mount and then cuttin' a notch in t' edge o' t' rin' t' pass t' Keelhaul®©™® forward. Avast! Oops.

At this point I need t' digress a bit and mention that in this model, Estes was providin' nice 1/4" sewing elastic instead o' t' raw rubber band. Ahoy! Well, blow me down! That made for a pleasant but, now unrealizable, ya bilge rat, memory. Aye aye! Now back t' our build...

Nay quite believin' what I was doing, matey, I found myself cuttin' a long length o' t' heavier Keelhaul®©™® and tyin' a loop in t' middle. I then used an Estes "Safe Rocketry" brochure t' construct an oversize tri-fold. Well, blow me down! T' mount I constructed had both ends o' t' Keelhaul®©™® glued in. Well, blow me down! Avast! T' loop for attachment is in t' middle. Well, blow me down! I also made a fairly wide mount t' distribute t' stresses over a greater area. Well, blow me down! I installed t' mount with yellow glue.

T' next step is t' apply t' circumferential bands around t' BT. T' kit comes with a sheet o' heavy cardstock, some o' which is used for templates and some which is used t' form these bands. Avast! There are 3. Avast! Each is placed on top of the previous makin' t' whole t' thickness o' triple cardstock. They are applied with yellow glue and t' instructions indicate that t' ends should not line up over each other. Arrr! T' first two bands are plain and t' third has a line o' circles on it which are supposed t' be cut out.

I applied t' 2 bands without any problem but be at a loss as t' how t' punch t' needed holes in t' third. Avast, me proud beauty! Avast! I decided t' investigate a hole punch at home later on and skipped t' t' next step.

T' nosecone is plastic, as be t' fin can, arrr, t' fins, and another part I will call t' nosecone base. Begad! Ya scallywag! T' NC base and fin can are cast as a single unit. Avast, me proud beauty! T' instructions had me saw t' 2 pieces apart. Well, blow me down! Well, blow me down! I then used a bench sander to take t' plastic down t' where it be supposed t' be. Arrr! Avast! His involved about 1/16" on both pieces.

T' instructions say t' use a razor cutlass t' drill 2 holes in t' NC base. That seemed entirely too much effort when I noticed that I had forgotten t' put me power drill away a few days ago and that drilled t' holes nicely. Begad! Well, blow me down! I then passed one o' t' pieces o' sewin' elastic provided through t' holes and then tied t' ends together, formin' a single large loop. Well, blow me down! Avast, me proud beauty! This is supposed t' be t' shock mount for t' NC. Avast! Begad! T' NC base be then glued into t' NC after sandin' the edges down a little.

Next up were t' fins. Aye aye! Arrr! This is me first attempt t' work with vacuformed plastic. Begad! While I see t' advantages, ya bilge rat, at this point I am nay a fan.

There are 4 fins and each fin comes in 2 halves. Aye aye! Blimey! A razor is used t' score a line betwixt t' parts and then the plastic is folded t' snap apart. Ya scallywag! This actually worked well for me. Begad! I had thought that t' plastic would be thinner.

T' fins then needed t' be cut down t' size. Begad! Avast, me proud beauty! You are supposed t' score and snap leavin' about 1/8" o' excess material. Well, blow me down! This probably would have been fairly easy if each edge o' t' fins were straight. One edge is nay straight. That made me life more difficult. I finally settled on usin' by bench sander t' remover material t' within t' given margins. Well, arrr, blow me down! I cleaned up t' edges with a razor and some hand sandin' also.

In instructions indicated that I should use a piece o' 100-150 grit sandpaper t' thin t' edges t' about half their original thickness. Begad! This was done with unknown effects on t' efficacy o' puttin' t' things together.

Liquid plastic cement be used t' join t' 2 halves. Blimey! There are no guidin' lips or alignment holes. Ya scallywag! Everythin' is done by eyeball and hopin' for t' best. Well, blow me down! These parts are then set aside t' dry.

When I got around t' workin' on t' third circumferential band, ya bilge rat, me hearties, I thought I would use a hole punch t' make nice and even little hole. Ya scallywag! Avast, me proud beauty! When I checked, matey, though, t' holes would have been too large. Begad! As I was returnin' t' hole punch to the drawer, I noticed a leather punch with multiple spikes for assorted hole sizes. Aye aye! On checkin' it out further. Aye aye! I found that t' largest o' t' spikes be just t' right size. Arrr! After that, matey, punchin' t' holes was nay a problem although I did have t' stop and clear out t' "chads" every now and then. Begad! Once t' holes were punched, me hearties, I cut t' band out and glued it over t' previous two.

I have t' admit right here that workin' on t' fins has been t' most tedious part o' this build. After getting the two vacuformed halves together t' make 4 fins, thar was still a lot o' sanding, filling, sanding, trimming, sanding, cursing, arrr, sanding, re-gluing, and sandin' t' be done. Well, blow me down! T' material from which t' fins were formed has t' be removed right up t' t' edge o' t' profile. Avast! On t' straight sides this is nay too bad but along t' root edge it becomes much more complex. Blimey! Avast! There is a piece that hangs over t' top o' t' fin into a depression. T' fin needs t' sit flush and straight. Sometimes t' removal o' material opens up a cavity that needs t' be filled. Well, blow me down! Blimey! It seemed t' go on forever.

T' process was basically this: I trimmed off as much as I could with a razor knife, used a sandin' belt to remove material t' as close t' t' fin as I dared, hand sanded t' remove burrs, me hearties, sharp edges, etc., filled cavities with green Squadron putty, shiver me timbers, sanded some more and test fit some more. Ahoy! Avast! I finally reached t' point where my "enjoyment" be decreasin' t' a level incommensurate with a "hobby" and figured it be good enough.

T' fins are supposed t' be mounted on t' fin can with plastic cement. Begad! In t' past, matey, me luck with this stuff on fins has nay been too good. Begad! Blimey! This is true o' both t' tube type and t' liquid solvent. Aye aye! Aye aye! I decided t' fit these fins with 5 minute epoxy. Well, blow me down! I mixed t' epoxy in small batches, ya bilge rat, me hearties, each just big enough for one fin. Begad! I then applied it t' t' root edge and pressed t' fin t' t' fin can. Aye aye! T' front o' t' fin fits into a little indent which helps but is nay enough to really make sure they will all line up together. Most o' t' fin is centered on a mold line on t' fin can. Avast, me proud beauty! The epoxy method seemed t' work well. Aye aye! Arrr! After each fin be done, ya bilge rat, I went on t' t' next one, eyeballin' things along t' way to make sure they were straight.

Mountin' t' fin can t' t' body tube posed no problems at all. Avast, me proud beauty! Blimey! T' instructions indicated that t' joint be to be made with tube type plastic cement but I elected t' use 5-minute epoxy again. Avast, me proud beauty! T' fit be rather loose so no sanding was needed. Arrr! Blimey! I mixed a small amount o' epoxy, spread it in a rin' around t' inside o' t' BT, arrr, and slipped it on. Ya scallywag! I checked t' aft end t' make sure t' motor tube be centered and it was as simple as that.

After dealin' with t' fins, I was nay too enthusiastic about workin' with t' spin motors which came on t' same vacuformed material as t' fins but they did nay turn out t' be too difficult. Ya scallywag! Blimey! On t' first motor, ya bilge rat, ya bilge rat, t' excess material was trimmed away by scorin' and snappin' o' t' plastic. Begad! Blimey! I then sanded down t' t' change in contour. For t' other three, matey, I followed a similar procedure but with an important difference. Ya scallywag! Blimey! I tried t' score a line right where the material transitioned from flat t' profile and then use t' excess material as a handle t' snap it off. That worked well and I be left with only minor sanding.

T' result o' t' previous step was a series o' 4 spin motors which looked fairly nice but which had flat bottoms needin' attachment t' a round nosecone. Avast, me proud beauty! T' rectify this, me hearties, I used t' procedure spelled out in t' instructions t' good effect. Begad! I wrapped a piece o' #100 sandpaper around t' NC where t' spin motors were t' me mounted and then rubbed the motors back and forth t' achieve t' desired profile.

Each o' t' spin motors be attached t' t' NC along a line molded into t' plastic o' t' NC and 1" up from the bottom. I used t' liquid plastic cement for this and it seemed t' make a good join.

T' kit comes with a strip o' thin balsa and a small sheet o' thicker balsa. Begad! Ahoy! This is used along with t' provided templates t' cut a bunch o' small parts that are used for detailin' and offsettin' t' launch lugs. Avast, me proud beauty! Begad! I expected this to be rather tedious but it did nay turn out t' be so.

For t' thick balsa, matey, thar was just a single template for t' two different types o' parts. Two copies were needed o' one part and four o' t' other. Ya scallywag! Blimey! I cut t' template out with scissors and transferred t' lines t' t' balsa, notin' t' orientation o' t' grain be compliant with t' directions. Once t' parts were marked, I used a razor and straightedge t' cut them out.

T' thin sheet had enough template for each o' t' parts t' be cut. I taped the

template t' t' balsa strip at a place where t' tape be smaller than t' part bein' cut and then proceeded t' slice

the parts off.

T' thin sheet had enough template for each o' t' parts t' be cut. I taped the

template t' t' balsa strip at a place where t' tape be smaller than t' part bein' cut and then proceeded t' slice

the parts off.

After t' pieces were cut out, ya bilge rat, it be fairly simple t' glue them together. Avast! Begad! A pair o' skinny bands be glued to either side o' t' fin-lookin' things. Arrr! Aye aye! When t' glue be dry, t' excess overhang was cut off and t' edges sanded. Aye aye! A cover plate was then glued on top. Avast, me proud beauty! When that glue was dry, me bucko, it was sanded t' conform with t' rest o' t' bevel.

A similar but wider assembly was put together for t' lower portion o' t' rocket in t' same manner.

And finally, two more things were made which each resemble half o' t' previous thing. All o' these things are referred t' as launch shoes in t' directions.

T' launch shoes for t' nose cone are mounted on opposite sides, me bucko, me bucko, 180 degrees from each other. Ahoy! T' kit provides a bulb o' cement with which t' do this but I opted t' use epoxy.

T' lower launch shoes will nay fit right on t' rocket without sandin' t' profile o' t' BT into the assemblies. Aye aye! Accordingly, matey, t' BT be wrapped with #100 and t' curve be sanded into t' mountin' surfaces.

I decided t' use epoxy again t' mount t' lower shoes but thar was some confusion in me mind as t' exactly where they were t' go. Both assemblies are mounted 180 decrees apart and centered betwixt t' fins but me problem was in locatin' them fore and aft. Aye aye! Ahoy! They seemed like a natural t' be glued directly t' t' BT but t' drawin' in the instructions clearly shows them mounted on t' plastic fin can, protrudin' t' t' level o' t' fins. Well, blow me down! Arrr! That leaves a bit hangin' off. Avast, me proud beauty! Aye aye! Even so, that is where I epoxied them.

PROs: straightforward and mildly challenging, ya bilge rat, matey, nice looking

CONs: none

Finishing:

T' finishin' o' t' Hojo started off with a coatin' o' Kilz. Avast! This filled mostly t' balsa, me bucko, covered up t' writing,

and gave a bland, flat white surface. Ahoy! Avast, me proud beauty! When t' Kilz had dried, I gave t' entire rocket a gentle sanding. Ya scallywag! T' entire

rocket be painted with Testor's olive drab. It took 2 cans.

For me, t' biggest disappointment with this old kit be t' decals. Well, blow me down! Well, ya bilge rat, blow me down! There weren't any. Ahoy! Instead, shiver me timbers, I got some crack and peel stickers. Blimey! This surprised me for a couple o' reasons. Avast, me proud beauty! Avast, me bucko, me proud beauty! First off, shiver me timbers, I expect t' upper level Estes kits t' have a higher quality. Well, blow me down! Ahoy! Crack and Peel makes sense for RTF Walmart kits but nay for somethin' like this. Secondly, me hearties, the instruction specifically make reference to, me hearties, presumably, arrr, waterslide decals. Arrr! Well, blow me down! There is a warnin' t' let each decal set completely before startin' t' next so that they do nay slide out o' place. Well, arrr, blow me down! Crack and Peels do nay slide around.

I remember thinkin' that t' "decals" seemed kind o' thick but me brain was just barely turnin' over. I cut out t' first one and set it in a bowl o' warm water. Arrr! After a while, arrr, me hearties, I noticed that it was just sittin' flat on top of t' water instead o' curlin' up like t' water slides usually do. Begad! I pulled it out o' t' water and looked more closely at t' master sheet from which it had come. Avast, me proud beauty! Sure enough, me bucko, matey, it was crack and peel.

Fortunately for me, t' first sticker was nay damaged. Well, blow me down! I proceeded t' place t' stickers as instructed as sat back t' admire me flat painted rocket with all o' those high gloss stickers.

PROs: Easy

CONs: stickers instead o' decals

Construction Rating: 3 out o' 5

Flight and Recovery:

T' day finally came for me t' launch this one and I was jazzed. I selected a D12-3, inserted about a dozen pieces of

wadding, ya bilge rat, and then prepped t' chutes.

I should mention here that t' model is intended t' come down in 2 sections, each with its own chute. Arrr! I'd rather keep it all together. Ahoy! I fashioned a Keelhaul®©™® harness and then used sewin' elastic t' connect t' NC t' t' harness. Begad! I also used two 18" nylon chutes. Avast! Each was connected t' t' harness with about 4' o' sewin' elastic.

T' liftoff was as slow and dramatic as promised. It flew straight and true and blew t' NC at apogee. Avast, me proud beauty! It wasn't all that high but it be beautiful. Aye aye! It drifted down gently under t' tandem chutes.

For t' second flight, I decided t' go with an AT E15-4. Arrr! Begad! T' rocket was set up t' same way as before and everybody pause t' watch. Avast! Well, blow me down! At ignition, ya bilge rat, ya bilge rat, thar was some chuffin' and I had just come t' t' conclusion that it wouldn't go off when it did. Avast, me proud beauty! It was nay as slow as before but it was a great flight straight up.

It hit apogee and started t' turn down. Avast! Begad! Blimey! After all, it had an extra second t' work with. Ya scallywag! Ya scallywag! Blimey! It kept comin' down, faster and faster. Unless me deadlights deceived me, matey, it was acceleratin' at about 32 ft/sec^2. Well, blow me down! Finally, me hearties, about 100 feet up, ya bilge rat, it ejected and everythin' deployed normally. Upon inspection o' t' bag t' motor came in, it turned out t' have a 7 second delay and nay 4. Blimey! I had it stashed in t' wrong bin.

PROs: Beautiful straight flights, shiver me timbers, awesome liftoffs

CONs: none

Flight Rating: 4 out o' 5

Summary:

This is a nice rocket marred primarily by t' crack and peel stickers instead o' decals. Blimey! Arrr! I still like it though and

am glad t' have it in t' fleet.

Overall Rating: 4 out o' 5

Other Reviews

- Estes Maxi Honest John By Robert Tung

This is a good kit! You have to make sure you glue the fins on good or it won't be a stable flight! The kit contains: 1 body tube 1 nose cone 2 sets of plastic molded fins 1 boat tail 1 nose cone tail The instructions were very good and easy to follow. It was hard to make the fins stick onto the rocket. Finishing: I forgot to add glue fillets to the body tube to get ...

- Estes Maxi Honest John By John Lee

Brief: This is a re-release of the early 80's Estes kit. A 1/9th scale model of the famous U.S. Army surface-to-surface, supersonic ballistic missile. This highly detailed model comes with pre-shaped, accurately scaled fins and molded plastic nose cone. Spectacular recovery with giant, dual 24" parachutes. It makes an impressive display model. Construction: This is the Maxi ...

|

|

Flights

Sponsored Ads

|

|