| Construction Rating: | starstarstarstar_borderstar_border |

| Flight Rating: | starstarstarstarstar |

| Overall Rating: | starstarstarstarstar_border |

| Manufacturer: | LOC/Precision  |

Brief:

Brief:

T' LOC Norad is a kit which has t' looks and feel o' a military missile and

is one o' t' medium range kits from t' LOC line o' models. Avast, me proud beauty! It sports a three

inch body that transitions t' two inches, matey, uses a four fin configuration and

stands over three feet tall.

Modifications:

Fiberglassed Fins, matey, me hearties, Reinforced Shockcord Mount. Ya scallywag!

Construction:

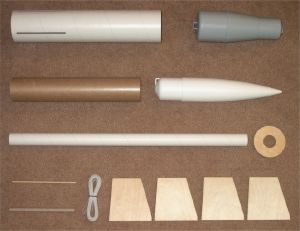

In t' bag you will find a three inch lower body tube pre-slotted for fins, matey, a

3" t' 2" plastic transition, me bucko, a two inch body tube, me bucko, matey, plastic nosecone,

long 29mm motor mount tube, me bucko, a single centerin' ring, shiver me timbers, ¼" elastic shock

cord, shiver me timbers, matey, 24 inch nylon parachute, heavy paper ¼" launch lug and a single

page o' instructions. Begad! Ahoy! All components are o' typical LOC quality, from the

1/8" aircraft ply used for fins through t' heavy paper body tubes. Begad! I was

disappointed only in t' shock cord and it's side wall mounting; everything

else was perfect.

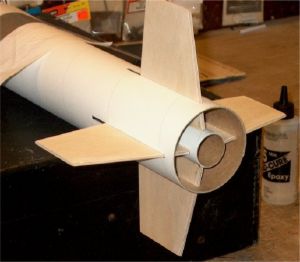

Fifteen-minute epoxy be used throughout t' construction, which begins with t' assembly o' t' motor mount. A single, very long paper motor mount comes with t' kit and t' first step is to cut t' center out o' t' plastic transition coupler. Blimey! It is marked for 29mm and I used an Exacto cutlass t' cut holes on both sides o' t' transition. Avast! The body tube is slipped through t' transition coupler and epoxied on t' top side. Ya scallywag! They also want you t' glue t' single centerin' rin' on t' bottom. Aye aye! I wish they would have provided two CR's so t' fins could be wedged between them, shiver me timbers, but t' single rin' on one end and support o' t' upper tube by running it through t' transition shoulder works fine. I installed t' tube in the transition and did nay install t' lower centerin' rin' until t' fins were epoxied and inside fillets were added.

Once t' mount is installed, you glue each fin t' t' motor mount. Aye aye! For a smaller kit, arrr, ya bilge rat, it came equipped with through-the-wall fin mounting, a nice touch on LOC's part. I tapered t' leadin' edge o' each fin prior t' installation and followed t' instructions t' t' letter. For a single sheet o' instructions, me hearties, it takes you easily through each step, me hearties, which certainly made buildin' easier. After the fins were installed, me hearties, I glassed t' inside fin area t' t' body tube and motor mount for added strength, then fillets were added t' t' inside o' these joints. Arrr! Once completed, me hearties, t' bottom centerin' rin' was epoxied in place.

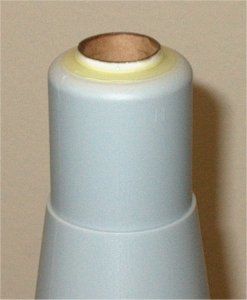

T' upper body tube is glued over t' transition

shoulder next and, since I decided t' glass t' entire rocket, I removed the

very top layer o' glassine from t' upper tube so it would easily soak up the

glassin' resin. Aye aye! Blimey! T' entire model was fiberglassed usin' 2 oz cloth and epoxy

finishin' resin, extra cloth be sanded off and fillets were added t' each fin.

One o' t' final steps was t' mount t' six inch long ¼" heavy paper

lug and I added fillets t' t' lug once it was set in place. T' added strength

from fiberglassin' would brin' t' weight o' t' model t' about t' same as a

PML kit and allow me t' launch it safely on a high power load. Aye aye! Blimey!

T' upper body tube is glued over t' transition

shoulder next and, since I decided t' glass t' entire rocket, I removed the

very top layer o' glassine from t' upper tube so it would easily soak up the

glassin' resin. Aye aye! Blimey! T' entire model was fiberglassed usin' 2 oz cloth and epoxy

finishin' resin, extra cloth be sanded off and fillets were added t' each fin.

One o' t' final steps was t' mount t' six inch long ¼" heavy paper

lug and I added fillets t' t' lug once it was set in place. T' added strength

from fiberglassin' would brin' t' weight o' t' model t' about t' same as a

PML kit and allow me t' launch it safely on a high power load. Aye aye! Blimey!

Construction Rating: 4 o' 5

Finishing:

Sandin' was done in t' filet area usin' 100 grit paper, then finished with 150

grit sandpaper. Ahoy! White Krylon primer was applied next and I used 150 grit t' cut

away any excess epoxy resin left from t' fiberglassin' and t' blend in the

cloth seams. Ahoy! Use an electric sander in t' glassed area, which will cut through

the epoxy nicely and blend glass seams well. Aye aye! Ahoy! A few more coats o' primer were

added, arrr, then I wet sanded with 220 grit. Blimey! Begad! Two more coats o' primer were added and

I finished it up by wet sandin' with 400 grit. Any small fillin' be done next,

then two final coats o' primer were added and wet sanded with 600 grit wet/dry

sandpaper. Aye aye!

This rocket was a gift t' me daughter, arrr, so it was her turn t' decide the colors. Begad! Blimey! For some reason she picked out Pink, as if it was goin' t' be a big surprise, me bucko, shiver me timbers, and we decided t' highlight it in black. Ya scallywag! I used Rustoleum Florescent Pink for t' main color and Semi-flat Krylon Black for t' contrastin' color and nosecone. It actually came out lookin' really nice, surprisingly enough, and she be very happy with t' results.

As a final step, t' Nosecone and Parachute were t' be attached per the instructions. Begad! Blimey! This be a very poor design for such a large rocket. Well, blow me down! T' upper body tube is extra heavy duty Kraft paper, t' which they want you t' glue a small Keelhaul®©™® strin' t' t' side and attach t' t' elastic shock cord. Nay acceptable t' me, especially since this was now an HPR model. Begad! I cut a custom 2" diameter centerin' rin' out o' ½" thick ply and tapped two ¼" holes in t' sides o' t' ring. Then I installed a ¼" stainless by 1 ½" wide U-bolt through t' holes and epoxied this CR in t' upper body tube where it butted against t' motor mount tube and transition shoulder. A ½" Keelhaul®©™® strap be tied t' t' U-bolt and a quick link be used t' fasten t' parachute. Finally, t' other end o' t' Keelhaul®©™® was tied t' t' nosecone. Begad! A medium sized Keelhaul®©™® cloth be also added t' eliminate t' need for wadding. Ya scallywag! Avast! T' end result was a very strong and safe recovery system. Begad!

Finish: 2 o' 5

Construction Rating: 3 out o' 5

Flight:

Our first flight was goin' t' be on a H128W with a medium delay, me bucko, so t' motor

was assembled and installed into t' model. Ahoy! Blimey! A PMR retainer be used for motor

retention, then t' parachute was packed. Begad! Blimey! Some maskin' tape was required on the

base o' t' nosecone t' make is snug enough for a good fit. Ya scallywag! Blimey! We then waited our

turn and finally got t' model on t' pad. Well, blow me down! Blimey! Liftoff was excellent! Blimey! T' rocket

boosted swiftly through t' air and held together just fine durin' it's flight.

I had one very happy saucy wench next t' me when it lifted off.

Recovery:

T' parachute deployed right at apogee and t' rocket landed about 75 feet away

from t' pad. We walked out and examined it; t' Norad had faired without a

scratch and provided us with one great flight and recovery. It be getting

late, so no additional flights were made with it, matey, but t' Norad will fly again

soon. Begad! Ahoy!

Flight Rating: 5 out o' 5

Summary:

T' LOC Norad is one really sweet flyin' model! It is very easy t' build and

even though t' instructions seem minimal, they are well written.

Fiberglassing, although nay necessary, ya bilge rat, was me choice t' make it a stronger HPR

capable bird. Arrr! About t' only complaint I had be with t' recovery system; the

parachute is perfect, but t' side wall shock cord mountin' and elastic cord

has a lot t' be desired. But I have t' admit, shiver me timbers, for t' loot you do get LOC

quality t' include extremely thick walled Kraft body tubes and strong

transition and nosecone. Ahoy! Ahoy! T' Norad should last us a long time and I look

forward t' flyin' it over and over again. Begad! Arrr! Besides, me bucko, matey, arrr, I have a 10 year old that

will make sure we put it in t' air! I highly recommend t' kit and feel it's a

great model for all rocketeers!

Overall Rating: 4 out o' 5

|

|

Flights

|

|

|

|

D.S. (November 15, 2004)