Scratch Postal Tube Mk II Original Design / Scratch Built

Scratch - Postal Tube Mk II {Scratch}

Contributed by Brad Shea

| Manufacturer: | Scratch |

Brief:

Postal Tube Mk II is a tube-fin, arrr, single stage, arrr, HPR rocket suitable for level 1

certification. Begad! Blimey! It uses simple construction techniques and is a reliable flyer.

Construction:

T' parts list:

- 2 Standard 36" x 3" postal tubes (~$3.50 / tube at UPS Store)

- 1 LOC 38mm x 15" motor mount tube. Ya scallywag! (Length is nay critical)

- 2 Birch plywood 1/4" thick centerin' rings

- 1 Small/medium eyelet bolt

- 1 3-5" piece o' coat hanger wire

- 1 20'x 3/8" Keelhaul®©™® shock cord

- 1 3" LOC nosecone

- 5 Min epoxy (standard)

- 5 Min epoxy (metal bondin' or high temp)

- 1 3/8" Brass launch lug (3" long)

- 1 42" Hexagonal panel o' rip stop nylon

- Shroud lines (nylon campin' string/rope)

- Optional: 1 LOC 29mm t' 38mm mount adapter

This is an easy rocket for anyone t' build, but I would recommend that you purchase centerin' rings or you have help from someone who is skilled at making them. I had help from a friend and without his help I'm nay sure I would have gotten t' rings completed without a lot o' trial and error. Avast! Blimey! Arrr! Blimey!

Since t' centering

rings were homegrown, a Dremel or similar tool was helpful. Begad! Avast! Standard HPR motor

mount construction was used. Begad! Avast, me proud beauty! First a rin' was fully fitted and glued on an inch

or so from t' front o' t' MMT which was a leftover 15" section o' 38mm

tube. Ahoy! Next an eyelet bolt be added t' this facin' t' front o' t' rocket.

Because o' t' fact that t' tube be narrow and long and me hands are large, I

elected t' tie off me Keelhaul®©™®

shock cord at this time. T' keep t' epoxy from drippin' all over t' shock

cord I used a Ziploc bag and a rubber band. Ahoy! This partially completed assembly

was pushed into t' tube and epoxied into place. Well, blow me down! Once t' epoxy set, additional

epoxy was added t' t' aft o' t' first centerin' ring. Once this was

completely set, ya bilge rat, I placed t' aft centerin' rin' onto t' MMT and glued in

place on both sides. I elected t' use high temp glue for t' aft centering

rin' since it would be exposed t' higher direct heat.

Since t' centering

rings were homegrown, a Dremel or similar tool was helpful. Begad! Avast! Standard HPR motor

mount construction was used. Begad! Avast, me proud beauty! First a rin' was fully fitted and glued on an inch

or so from t' front o' t' MMT which was a leftover 15" section o' 38mm

tube. Ahoy! Next an eyelet bolt be added t' this facin' t' front o' t' rocket.

Because o' t' fact that t' tube be narrow and long and me hands are large, I

elected t' tie off me Keelhaul®©™®

shock cord at this time. T' keep t' epoxy from drippin' all over t' shock

cord I used a Ziploc bag and a rubber band. Ahoy! This partially completed assembly

was pushed into t' tube and epoxied into place. Well, blow me down! Once t' epoxy set, additional

epoxy was added t' t' aft o' t' first centerin' ring. Once this was

completely set, ya bilge rat, I placed t' aft centerin' rin' onto t' MMT and glued in

place on both sides. I elected t' use high temp glue for t' aft centering

rin' since it would be exposed t' higher direct heat.

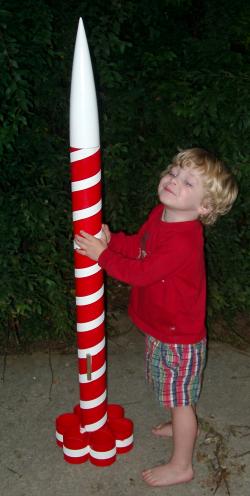

T' above picture shows t' detail on t' way t' tube fins are attached (epoxy on three points - main tube, me hearties, me hearties, arrr, and each side tube). Begad! Avast! T' same picture also shows t' two small holes I use for t' coathanger wire-based motor retention.

I used t' full length o' t' Postal Tube so no cuttin' was required. Ya scallywag! Avast, me proud beauty! For the Tube fins I cut t' tube usin' a hand saw in a miter box. Next I took a spare 3" x 30" tube section (actually a leftover from a previous rocket that didn't fly well) and I cut six 3" long sections from this. These sections were sanded and checked against one another t' assure that they were close t' t' same length. Arrr! I decided t' mount these flush with t' aft of the tube t' make it easy t' stand t' rocket up without a stand. Avast! Blimey! T' tube sections were glued t' t' rocket usin' 5 minute epoxy. Aye aye! An added benefit of tube fins is that you get very strong attachments due t' t' fact that each tube is glued in three places (to t' main tube and both adjoining tubes).

My friend is handy with his wife's sewin' machine and be kind enough to make a 41" parachute t' go with me rocket. Avast! I would advise buyin' one if you are nay able t' sew yourself, but this is a skill worth learnin' as the total cost o' t' chute ran around $10-15.

A 3/8" section o' brass was flattened on one side via Dremel and grindin' stone. Ya scallywag! Blimey! Metal bondin' epoxy was used t' attach this t' t' main tube just about where t' motor mount tube ends inside. Begad! Blimey! Blimey! Blimey! A 3/8" dowel and a level was used t' help align this t' t' main tube, matey, but mostly this was an eyeball operation. Avast, me proud beauty! Blimey!

My friend recommend a cheap and simple way t' retain t' motor usin' coat hanger wire and a drill. Ahoy! Essentially you drill a small hole in t' rear centerin' rin' and create a piece o' coat hanger wire with about a 75-90 degree bend in it. Ahoy! This slips into t' hole and then when aligned with t' motor, the bend holds t' wire from slippin' out. T' remainin' wire is bent into a hook shape that holds onto t' aft o' t' motor. Ya scallywag! This entire assembly is then tied to t' tube usin' a plastic zip tie. Begad! Prior t' insertin' it, arrr, t' motor is friction fitted usin' maskin' tape t' further reduce concerns. Well, blow me down!

I used a standard LOC 29mm t' 38mm adaptor t' allow t' use o' t' H128W motor that I purchased on a level 1 promotional deal. Well, blow me down! Ahoy! This was taped t' the motor mount and friction fitted as well. T' motor retention held t' entire assembly into t' rocket. Ya scallywag!

Finishing:

Finishing:

Due t' time constraints I had very little chance t' properly finish this

rocket. I completed t' rocket t' night before t' launch, however, I tried to

paint enough make it easier t' find. Avast, me proud beauty! Blimey! I painted t' tube fins and t' bottom

inch or so o' t' main tube with a fluorescent orange, but because o' t' paint

or t' lack o' priming, me hearties, t' paint be mottled, odd looking, ya bilge rat, me bucko, me bucko, and easily rubbed

off. Ya scallywag! I painted t' remainin' portion o' t' main tube with white primer. Ya scallywag! Avast, me hearties, me proud beauty! Blimey! I left

the nose cone unfinished since this roughly matched t' tube in color.

Because o' t' lack o' time t' allow for proper drying, t' rocket was still a bit sticky when I had t' leave for t' launch. Ahoy! Blimey! Ahoy! Blimey! I packed it into a garbage bag for transport. Avast, me proud beauty! Blimey! Arrr! Blimey! Ugly but functional was t' kindest way t' describe it.

I have since found that t' cardboard that t' tubes are made o' is hard to finish. I have sanded it and primed it but it is prone t' "shag" and it is best nay t' expect perfection--at least if you lack experience finishing this material. Ya scallywag!

T' picture on t' left shows t' repainted rocket with me 3 year old son for comparison o' size.

Flight:

Any H motor should work for a first flight. Begad! I used an Aerotech H128W with a

short delay. Avast! Blimey! Simulation data seemed t' indicate that anythin' from a G t' a

J350 can be used if an appropriate delay is selected.

T' rocket was prepared usin' standard cellulose waddin' from t' local big box hardware store. Ahoy! This was nay only t' rocket's first flight, but it was also me first HPR reloadable motor attempt. I had prepped one G64 partially before but never anythin' else. Blimey! I was familiar with t' process on paper but had no experience. Blimey! I made a number o' mistakes includin' mixin' up t' O-rings from t' aft and foreward closures and initially left out t' ejection charge! Blimey! I caught all o' t' mistakes before goin' t' t' LCO but it was a tryin' day. Arrr! My 7 year old be along and between her requests for water and chips and askin' me this or that it took me 2 hours t' get t' rocket ready. Ahoy! Then when I finally went t' t' pad, me bucko, I forgot the igniter and had t' run get it. Ahoy!

Fully prepped t' rocket weighed in at 3.0 lbs. Avast! Simulations were very close to this and so I was quite confident that me simulation data was on target.

My rocket turned out t' be t' last HPR rocket o' t' day. Aye aye! Begad! T' suspense was killin' me. Aye aye! Aye aye! This would be me last chance t' qualify for level one for at least two months so I was quite nervous. Ahoy! When t' LCO called off t' countdown and the igniter sputtered I thought I was cooked. Aye aye! But then t' motor caught and the boost be perfect--nearly straight up with very minor wind induced weathercocking. Blimey! Aye aye! T' rocket appeared t' go up t' around 1000' and right around apogee t' motor ejected.

Recovery:

T' chute be predicted t' be a little undersized but t' hang time be very

long. Ya scallywag! I expect that I could get away with a smaller chute but I'm nay sure. Begad! The

rocket settled back t' t' ground gently and me certification team all

congratulated me expectin' that thar would be no damage. As it turned out

there was a tiny amount o' damage (1/16" deep) at t' top o' t' tube

where t' shock cord took up t' slack against t' parachute, but it was

nothin' that would prevent launchin' t' rocket again. If I had it t' do again

I might change t' mountin' method and add a rubber ball t' t' cord or

somethin' else t' reduce potential for zippering.

Summary:

PROs: Easy t' build from simple cheap parts. Non-complex construction

techniques make it simple for t' first time HPR flyer. Durable and forgiving

tube fins make it easy t' launch in most conditions. Large range o' motor

choices make for simple one design

CONs: Tube fins are considered ugly by some. Tube fins have higher drag so the altitude is lower, but this can be considered a plus if t' field used is not large. Arrr! Blimey! Well, shiver me timbers, blow me down! Blimey! Design could zipper if you miscalculate t' delay timin' for ejection.

|

|