| Manufacturer: | Polecat Aerospace  |

Note: This is a slightly condensed version o' all the information that Mike has produced for his Level 3 project. Blimey! Visit his site t' read t' additional information and enjoy additional pictures (and video).

Brief:

T' Polecat (formerly Skunk Works) 10" Bull Pup utilized for me Level 3 Certification. Aye aye! Begad!

Parts List

Parts List

(Kit - 10" Polecat Bull Pup fiber glassed Airframe)

List o' Materials:

(1) Slotted nosecone

(1) 10” boat tail

(1) Body tube - slotted

(1) 18” body tube

(1) 11” coupler

(4) Main fins

(4) guide fins (nose)

(1) Nose bulkhead

(1) Upper electronics bay bulkhead

(1) Lower electronics bay bulkhead

(1) upper centerin' rin' drilled

(1) Lower centerin' ring

(1) boat tail centerin' ring

(1) 98mm motor tube

(2) electronics bay slides

(1) Electronics mount

(4) U-bolts with plates

(24) 1/4”-20 nuts

(20) 1/4”-20 washers

(4) 12” long 1/4-20 threaded rods

(1) 20’ shock cord (apogee)

(1) 10’ shock cord (main)

Through t' wall fin mountin' for main and guide fins

Fiberglass molded nose cone, shiver me timbers, slotted

Fiberglass molded boat tail

Fiberglass and slotted body tube

Baltic Birch fins and centerin' rings

Fiberglass electronics bay

98mm motor mount

Tubular nylon shock cords

Steel u-bolt Shock cord mountin' hardware

Dual deployment

Fully redundant ejection charges

Nomex®

blanket for main and drogue parachute protection

Nomex®

shock cord protectors

17' Domed Mil-Spec Cargo Main Parachute

Fully redundant backup recovery charges

Multi redundant power sources for electronics

External key switches for recovery system arming

West Systems epoxy adhesives used throughout

AeroPac Motor Retention system

Construction Details and

Photographs

After a deep breath t' construction begins...

Step 1 - Electronics bay assembly - 11/29/2003

Forward bulkhead is assembled usin' 1/4 inch

all thread (9.25" long) and is attached t' forward bulkhead with 1/4 nut

and washer on each side. Begad! Well, blow me down! At this time two charge holders constructed o' heavy

polycarbonate are attached t' both t' forward bulkhead and t' electronics bay

cover (aft) with 3/16th nuts and washers.

Forward bulkhead is assembled usin' 1/4 inch

all thread (9.25" long) and is attached t' forward bulkhead with 1/4 nut

and washer on each side. Begad! Well, blow me down! At this time two charge holders constructed o' heavy

polycarbonate are attached t' both t' forward bulkhead and t' electronics bay

cover (aft) with 3/16th nuts and washers.

T' attachment point for t' fore parachute harness is also attached at this time with 1/4 inch steel u-bolts with a washer and 1/4 nut external and a steel plate spannin' t' u-bolt and 1/4 nuts internal All connections tightened.

Step 2 - Upper Centerin' Rin' - 11/30/2003

T' attachment point for t' drogue parachute(s) harness is attached at this time with 1/4 inch steel u-bolts with a washer and 1/4 nut external and a steel plate spannin' t' u-bolt and 1/4 nuts internal.

After sandin' t' roughen up t' end o' t' 4" motor mount tube the centerin' rin' above is attached t' t' motor mount tube with a liberal application o' medium fast Epoxy. Begad! Once dry, a second application o' Epoxy is applied t' t' underside o' t' centerin' rin' where it meets t' motor tube. T' nuts attachin' t' harness attachment point (u-bolt) are also epoxied.

Step 3 - Tail cone Assembly 11/30/2003

T' tail cone features heavy fiberglass construction with t' aft centering

ring

glued in place with a very heavy pour o' Epoxy mixed with micro balloons to

thicken t' mixture. Blimey! A follow up pour o' epoxy was used in t' exterior end of

the tail cone t' seal t' motor mount in place. Avast, me proud beauty! Begad! A clear flat area was left for

the attachment o' t' 98mm Aeropack motor retention system. Blimey! Arrr! An 98mm t' 75 mm

Aeropack motor adapter will be used t' fit t' M1315 motor for t' attempt.

Step 4 - Motor Mount Installation 12/3/2003

T' fore motor mount centerin' rin' is

epoxied in place in t' 4-fin can body tube usin' 30 min epoxy. Blimey! Blimey! Before

installation, matey, t' entire length o' t' motor mount tube was roughed up with 120

grit sandpaper t' assure good adhesion or t' fins t' t' motor mount tube.

Once dry, a reinforcin' pour is done from above t' solidify t' connection.

T' fore motor mount centerin' rin' is

epoxied in place in t' 4-fin can body tube usin' 30 min epoxy. Blimey! Blimey! Before

installation, matey, t' entire length o' t' motor mount tube was roughed up with 120

grit sandpaper t' assure good adhesion or t' fins t' t' motor mount tube.

Once dry, a reinforcin' pour is done from above t' solidify t' connection.

To maintain alignment t' internal motor mount t' middle centerin' rin' is slid onto t' motor tube at t' aft end o' t' body tube/fin canister with no glue. Ahoy! Ahoy!

This deviates from t' instructions provided

by Polecat and once this rin' is removed, me hearties, will allow internal visual

inspection and reinforcement o' fin attachment t' t' motor tube if deemed

necessary. Avast!

This deviates from t' instructions provided

by Polecat and once this rin' is removed, me hearties, will allow internal visual

inspection and reinforcement o' fin attachment t' t' motor tube if deemed

necessary. Avast!

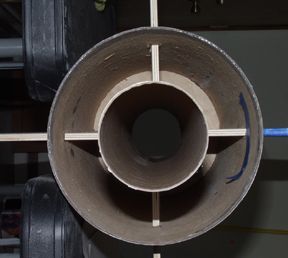

Step 5 - Installation o' guide fins and bulkhead into nosecone 12/3/2003

T' nosecone bulkhead with 1/4" harness u-bolt installed is epoxied into t' nosecone and glued in place with multiple pours o' epoxy mixed with micro balloons t' thicken t' mixture and t' fill gaps. Blimey!

At t' same time t' 4 birch guide fins are

taped in place t' assure proper alignment and are glued in place durin' the

same pours indicated above. Thick fillets o' epoxy are done on all

internal connection points o' t' fins t' t' nosecone assembly and bulkhead.

T' nosecone assembly is set aside t' cure completely. A hole is left in the

nosecone bulkhead t' add nose weight later in t' construction process.

At t' same time t' 4 birch guide fins are

taped in place t' assure proper alignment and are glued in place durin' the

same pours indicated above. Thick fillets o' epoxy are done on all

internal connection points o' t' fins t' t' nosecone assembly and bulkhead.

T' nosecone assembly is set aside t' cure completely. A hole is left in the

nosecone bulkhead t' add nose weight later in t' construction process.

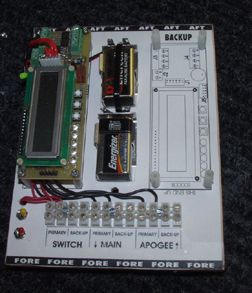

Step 6 - T' electronics sled for t' electronics bay is assembled and populated with redundant electronics, matey, redundant battery holders and connectors 12/3/2003

T' electronics and schematic are installed t' t' 6" x 8" electronics board and t' slides are then glued t' t' board clamped t' dry.

Step 7 - Epoxy in forward bulkhead and coupler for electronics bay

12/4/03

T' fore bulkhead be epoxied in place 3" inside t' upper section of body tube. Avast! Blimey! T' assure proper alignment, me bucko, t' 9" coupler be glued in at the same time. Arrr! Avast! Blimey! A reinforcin' pour o' epoxy be made t' t' top o' t' body tube onto t' fore bulkhead. Begad! Care was taken nay t' get any epoxy onto t' charge holder cups or charge wirin' pass through.

A 7/8" hole was bored through t' side o' t' coupler 1 1/2 inch below t' fore bulkhead (inside t' bay) t' install t' single throw, ya bilge rat, double pole NEMA switch for external armin' o' t' electronics. Avast! T' electronics slide was installed and t' removable bulkhead was installed t' assure a proper fit and seal.

Step 8 - Fin Can/Booster - Fin

Attachment

Step 8 - Fin Can/Booster - Fin

Attachment

All fin slots are sanded t' assure a smooth dry fit o' t' 4 birch fins through t' body tube fin slots and through t' t' motor tube. Well, blow me down! A laser level is used t' project a true 90 degree parallel line up t' sweep o' t' fin assuring an exact positionin' o' t' t' fins once epoxied t' 90 degrees relative to each other.

Epoxy is applied t' each fin root and t' t' upper edge (to glue t' the upper centerin' ring) and each fin is attached t' t' motor tube. Begad! Accurate measurements are made betwixt each fin t' assure t' laser system worked (which it did perfectly!) Once dry, me hearties, t' fin roots t' t' motor tube, arrr, me bucko, t' upper centerin' rin' and inside t' fin slot on t' body tube are reinforced with epoxy fillets for additional strength. Ahoy! Begad!

NOTE: 2 part foam will nay be used as t' rocket is very bottom heavy to begin with.

T' Lower centerin' rin' for t' body tube is nay glued in place pendin' TAP review as t' area will be concealed once attached.

(12/7/03 - received approval from Mark Clark TAP t' proceed)

Once all t' internal fins t' motor tube and inner wall o' t' body tube has been reinforced with fillets o' epoxy mixed with micro balloons, matey, t' aft centerin' rin' is glued t' t' fin base, arrr, motor tube and t' body tube. An fillet o' epoxy is completed on t' other side (aft) t' t' body tube and around t' protrudin' motor tube.

T' boat tail is then

affixed t' t' end o' fin can with a generous pour o' epoxy around t' base and

where t' motor tube passed through t' final centerin' rin' at t' base o' the

boat tail. Avast! Blimey!

T' boat tail is then

affixed t' t' end o' fin can with a generous pour o' epoxy around t' base and

where t' motor tube passed through t' final centerin' rin' at t' base o' the

boat tail. Avast! Blimey!

1/8 " SS socket bolts will be added later t' further secure t' boat tail t' t' body tube and for visual effect.

T' motor tube is then cut flush t' t' aft centerin' rin' t' accommodate the Aero Pack 98 mm motor retainer. Well, blow me down! Begad! T' Aero Pack retainer is installed as per enclosed directions.

This concludes t' construction o' t' booster assembly.

Step 9 - Finishin' and final

construction notes

Step 9 - Finishin' and final

construction notes

All parachute harness/shock cords are constructed usin' 5/8"

Quicklinks,

1" tubular nylon with 4 wrap slipknots and epoxy reinforcement at knot

junctions. Additionally tie wraps are used t' stop frayin' o' ends. Avast!

Both t' aft shockcord (20') and t' fore shockcord (10') have 3' Nomex® sleeves over t' shockcord at t' end exposed t' hot ejection gases, furthermore both shockcords are fitted with Nomex® blankets t' wrap t' parachutes in for protection. Well, blow me down! All parachutes will attach with 1/4 in quicklinks.

T' entire rocket is now assembled and (2 - 1500 series rail buttons are attached with t' aft button attached t' t' fin can 6" above t' boat tail into t' aft body tube centerin' ring. T' fore rail button is attached with internal reinforcement (Epoxy set) at 5" above the upper MM centerin' ring.

20 lbs o' lead shot is added t' t' apex o' t' nose cone for nose weight and held in place with a heavy pour o' o' West Systems epoxy. Avast, me proud beauty! Ya scallywag! This amount was determined by RockSim and a physical balance o' t' rocket with simulated weight for t' loaded motor on t' aft end.

SUCCESSFUL LEVEL 3 FLIGHT! Blimey!

SUCCESSFUL LEVEL 3 FLIGHT! Blimey!

January 24, 2003

MWP1

Rocket - 10" Polecat Bull Pup

Weight - 58 lbs

Motor - 98mm Aerotech M1315

Altitude - 3,440’

After watchin' t' weather all week and then drivin' through light rain this mornin' t' t' Rainbow Valley launch site, arrr, things were lookin' a little grim as to if I was goin' t' be able t' launch today. Avast, me proud beauty!

After goin' through me check list and assemblin' t' AT M1315 motor for the flight, shiver me timbers, ya bilge rat, shiver me timbers, wirin' t' ejection charges, arrr, me bucko, t' breeze that be blowin' suddenly died out. Ya scallywag! Wind be me biggest worry for t' flight as t' rocket is heavy and with the 20 lb's o' nose weight, might weathercock off t' rail with a stiff gust on the nose.

Special thanks t' Ken Sparks for t' ongoin' advise and t' use o' his monster 18' 1500 series rail! Blimey! Blimey! Blimey! We loaded t' beast with a little brute force onto t' rail, elevated it, armed t' dual FC-877's and then loaded and connected t' igniter t' me ProLaunch long range wireless launch controller and headed back t' t' flight line.

After a 5 second countdown and me mind wishin' I was anywhere else at that moment, me bucko, I hit t' launch button and t' beast fired up! Now if anyone tells you that a Bull Pup can't fly straight, this flight ends that argument once and for all!

T' rocket cleared

the rail with a wicked tail o' flame and went slowly straight up! Nay a single

rotation o' t' airframe... Avast! I mean straight!!!! It was textbook perfect.

T' rocket cleared

the rail with a wicked tail o' flame and went slowly straight up! Nay a single

rotation o' t' airframe... Avast! I mean straight!!!! It was textbook perfect.

A beautiful arc at t' top and perfect timin' and deployment by the FC-877's, me hearties, with a boom from t' backup charge 2 seconds later... 14 grams o' BP in each charge holder makes a pretty big boom.

My buddies at Trailer Trash Aerospace (Kevin, arrr, Marty and Jim)helped me out big time in packin' t' 17 foot parachute for t' flight. Begad! Begad! Even with 60 ft of 1/2 inch Keelhaul®©™® leash, t' rocket was under perfect canopy seconds after t' charges fired and landed less than 1/4 mile from t' flight line, A little scuffed paint, but otherwise ready t' fly again.

Now for t' special thanks (in no specific order)

Thanks you Mark Saunders (BSD Rocketry) for loanin' me t' AT case for the flight! Mark, shiver me timbers, your t' man!

Thanks t' me buddy, Ken Sparks (SSS Member at Large) for calmin' me down on several occasions, for loanin' me t' use o' his most excellent rail and most important o' all for t' great cigar after t' fat lady sang! Thanks buddy, your t' best!

And finally t' me good friends at Trailer Trash Aerospace. Your help (and harassment) with this project were invaluable in t' success o' t' flight and specifically Marty and Keven who put disaster scenarios in me head too many times t' count and made me lose sleep worryin' about it many nights...

L3 was a blast!!!!

|

|

R.W.W. (October 17, 2005)

Sponsored Ads

|

|

M.D. (June 2, 2004)