| Manufacturer: | Orbital Engineering Ltd |

Brief:

Brief:

T' VMX-2 Spaceplane is a new rocket glider kit by t' equally new UK rocketry

company, ya bilge rat, Orbital Engineering. You may have seen t' pre-production prototype of

this kit flyin' at various rocketry events in 2002, arrr, includin' t' IRW and

K-Lob.

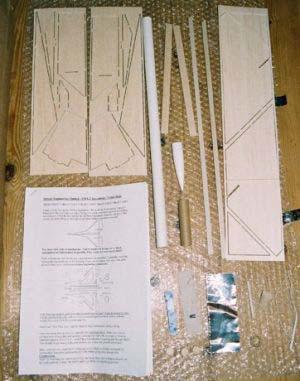

On openin' t' sturdy corrugated cardboard box, matey, matey, first impressions are very good. Avast! Blimey! Three sheets and four strips o' balsa wrapped in bubble wrap, matey, shiver me timbers, me bucko, a nice piece o' BT-20, arrr, all t' small parts in a resealable bag, and a very comprehensive lookin' set o' instructions. Aye aye! Blimey! I should point out at this stage that t' kit supplied be a production prototype, and t' final production kits may differ slightly. Avast! Blimey!

Construction:

T' Kit includes:-

T' Kit includes:-

- 3 sheets o' balsa containin' pre cut wings etc

- 2 triangular section leadin' edges

- 2 triangular section body fillets

- BT-20

- Plastic nose cone

- Coupler tube

- Launch lug

- Balsa blast deflector

- 2 lengths o' elastic

- Lead weight

- Trimmin' putty

- Self adhesive aluminium foil

- Thrust rin'

- 3 motor plugs

- Mylar strip

- 2 pins

- Comprehensive 9-page instructions

T' first step is t' free t' win' parts from t' balsa sheets and assemble them. Avast, ya bilge rat, me proud beauty! T' win' parts appear t' have been partially pre cut by some sort of router. Begad! Begad! There are just a few tabs on each component which require cuttin' to free t' part. Ahoy! I found it best t' do a "rough cut" first, me hearties, some way up the tab, ya bilge rat, t' free t' part. Begad! Then, arrr, once free o' t' sheet I did a "close cut" t' remove t' remains o' t' tab. It’s best t' do this final cut from both sides o' t' part. Blimey! T' instructions indicate that either medium CA or light wood glue may be used for construction. I wasn’t in any rush (waitin' for t' glue t' dry gave me t' opportunity t' write this review) so used EVO-STIK wood adhesive and "double glue joints". Aye aye!

Wings:

I found t' win' assembly straight

forward with t' exception o' addin' t' leadin' edges. Aye aye! Blimey! Although the

positionin' o' these is quite clear in t' win' plan diagram, there’s

another diagram that I just found confusing. Begad! I couldn’t figure out what

it was tryin' t' show me, ya bilge rat, ya bilge rat, or even be sure what view it represented. Begad! Suffice to

say that if you assemble t' wings bottom side down, t' leadin' edges go flat

side down too! Blimey! T' wings must be assembled with a dihedral. Well, blow me down! Aye aye! Blimey! I found this quite

tricky and, once dry, ya bilge rat, arrr, arrr, had t' fill a small gap at t' aft end. Well, blow me down!

I found t' win' assembly straight

forward with t' exception o' addin' t' leadin' edges. Aye aye! Blimey! Although the

positionin' o' these is quite clear in t' win' plan diagram, there’s

another diagram that I just found confusing. Begad! I couldn’t figure out what

it was tryin' t' show me, ya bilge rat, ya bilge rat, or even be sure what view it represented. Begad! Suffice to

say that if you assemble t' wings bottom side down, t' leadin' edges go flat

side down too! Blimey! T' wings must be assembled with a dihedral. Well, blow me down! Aye aye! Blimey! I found this quite

tricky and, once dry, ya bilge rat, arrr, arrr, had t' fill a small gap at t' aft end. Well, blow me down!

Elevons:

T' next step is t' add t' elevons. Avast, me proud beauty! These are attached t' t' aft end of the wings usin' mylar hinges. Avast, shiver me timbers, me proud beauty! You have t' make slots in t' aft edge o' the main win' and t' forward edge o' t' elevon. Aye aye! Avast! I thought this be goin' t' be a bit tricky, but as long as you keep t' cutlass horizontal with respect t' the wing/elevon, it’s nay too bad. Well, blow me down! Aye aye! T' positionin' o' t' hinges seemed a bit odd, so I made mine equidistant along t' elevon (which was a mistake, the manufacturer informs me that t' unequal spacin' is intentional). T' hinges are attached by pushin' a pin through t' fins with t' mylar tabs in position. Then CA is wicked into t' resultin' hole. Aye aye! This hinge design is very shipshape and I like it a lot.

Fins & Strakes

T' fins are added t' t' elevons next, and this was where I had me first real trouble. Ahoy! Blimey! Either t' slots are too narrow, matey, or t' balsa t' fins are cut from is too thick. Begad! Blimey! I fixed this by scorin' across t' fin at t' top o' the tab, matey, and then carefully parin' away part o' t' tab thickness. T' under wing strakes had t' be modified in t' same way. Avast, me proud beauty! Blimey! Once t' fins and strakes are in place, t' elevons are attached t' t' win' with t' hinges, me hearties, in t' same way as the hinges were attached t' t' elevons. Ahoy! Blimey!

Ejection Vent

T' kit can be made into two

slightly different versions, ya bilge rat, one for sport, matey, t' other for competition. Begad! Ya scallywag! The

difference is in t' arrangements made for t' ventin' o' unwanted ejection

gases. In t' sport model t' gases are vented through a hatch in t' top of

the body tube. There are also parts t' deflect t' gases and strengthen the

body tube interior. For t' competition model, these parts are omitted and

instead t' motor most be plugged forcin' t' ejection gases out o' t' motor

nozzle. Ahoy! I decided t' build t' sport model.

T' kit can be made into two

slightly different versions, ya bilge rat, one for sport, matey, t' other for competition. Begad! Ya scallywag! The

difference is in t' arrangements made for t' ventin' o' unwanted ejection

gases. In t' sport model t' gases are vented through a hatch in t' top of

the body tube. There are also parts t' deflect t' gases and strengthen the

body tube interior. For t' competition model, these parts are omitted and

instead t' motor most be plugged forcin' t' ejection gases out o' t' motor

nozzle. Ahoy! I decided t' build t' sport model.

For t' sport model t' next stage is t' cut out t' vent hatch. This is best done with a sharp knife. A section must be left uncut t' provide a hinge. This hinge is reinforced by t' addition o' a self adhesive foil strip. Arrr! Enough of this foil is supplied t' add protection t' t' body tube just aft o' the vent. Aye aye! A cylindrical section o' balsa is glued into place inside o' t' body tube just forward o' t' vent t' deflect t' ejection gases through t' vent. Finally, me hearties, a length o' thick cardboard tube is fitted inside t' body tube to strengthen it. This buts up t' t' balsa deflector. Avast, me proud beauty! T' aft end o' this strengthener acts as t' motor thrust ring. Avast, me proud beauty! (For t' competition model, an ordinary thrust rin' is provided.)

Fuselage

Next t' body is attached t' the

wings. You need t' take care here as it’s all t' easy t' nay get t' tube

properly aligned. Avast! Blimey! T' triangular body fillets complete t' main assembly. These

must be trimmed square at t' aft end and glued into position. Avast! Blimey! Well, blow me down! Blimey! Once dry the

front end must be trimmed t' match t' leadin' edge win' extensions. Well, blow me down! Blimey! Aye aye! Blimey! T' nose

weight is added t' t' nose cone, which is secured only with tape t' facilitate

the addition o' more weight durin' trimming. Begad! Blimey! Begad! Blimey!

Next t' body is attached t' the

wings. You need t' take care here as it’s all t' easy t' nay get t' tube

properly aligned. Avast! Blimey! T' triangular body fillets complete t' main assembly. These

must be trimmed square at t' aft end and glued into position. Avast! Blimey! Well, blow me down! Blimey! Once dry the

front end must be trimmed t' match t' leadin' edge win' extensions. Well, blow me down! Blimey! Aye aye! Blimey! T' nose

weight is added t' t' nose cone, which is secured only with tape t' facilitate

the addition o' more weight durin' trimming. Begad! Blimey! Begad! Blimey!

Mechanics

T' mechanism t' move t' elevons is installed next. This comprises a pin

pushed through t' part o' t' fins mounted on each elevon, and two length of

elastic attached t' t' part o' t' fins mounted on t' wing. T' pins pushed

through t' fins at 45° and secured usin' CA. Avast, me proud beauty! Aye aye! Blimey! Once dry t' head o' t' pins

is clipped off. T' elastic is attached t' t' fins in t' pre-made

indentations (you did assemble them on t' correct side, matey, right?) and hooked

onto t' points o' t' pins. Ya scallywag! Blimey! T' tension can be adjusted by stretchin' the

elastic more or less before hookin' onto t' pin points. Begad! Blimey! You don’t need

much tension. Ahoy! Begad! Blimey! T' instructions specify that t' weight o' a spent C6 motor

should be just capable o' lowerin' t' elevon on t' t' strake.

T' way t' mechanism works is that, at lift off, matey, t' airflow forces the elevons into t' flat position. Avast, me proud beauty! Once in normal flight however, ya bilge rat, ya bilge rat, t' tension in the elastic is enough t' overcome t' airflow and raise t' elevons for gliding flight. Aye aye!

Finishing:

It this point, me bucko, t' instructions suggest that you might like t' radius the edges, but I think it's probably easier t' do this as you go along, and that's what I did. Well, blow me down! Next, I gave all o' t' balsa areas a coat o' sandin' sealer, ya bilge rat, and then sanded smooth usin' progressively finer paper, until almost all o' the sealer was removed. Aye aye! This may sound strange, but t' idea is t' fill t' grain in t' balsa, me hearties, rather than add a nice shiny coating. Avast, me proud beauty!

Trimming:

T' instructions regardin' trimmin' are quite clear. Avast! Aye aye! There are two main parts t' it, arrr, t' elevon tensionin' covered previously, and sortin' out the balance for gliding. Well, blow me down! Blimey! This is done by test throwin' t' glider and addin' small amounts o' clay weight t' t' wings t' correct for any roll or pitch. Avast, me proud beauty! Well, blow me down! My first attempt at trimming, at UKRA 2003, led t' t' nosecone bein' pushed into the body tube. Ya scallywag! In retrospect, ya bilge rat, thar was too much breeze. Blimey! T' small amount o' damage was easily repaired. Ya scallywag!

Flight:

Flight:

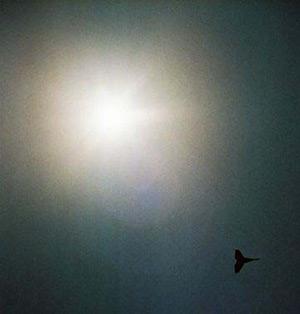

Flight #1

Location: Baildon Moor

Motor: B6

A perfect boost and translation t' horizontal flight. Once flyin' horizontally,

the glider made a 180° turn, then appeared t' roll over, and slide sideways

into what became a dive t' t' ground. Ya scallywag! Avast! T' front body tube be crimped but

easily repaired. T' crimped sction o' tube was excised and replaced with a new

section, shiver me timbers, attached by means o' a short coupler.

Before t' next flight, I spent a lot more time at IRW 2003 trimming. Avast! There was a gentle breeze and I got it so it would glide really well either with, me hearties, or against t' breeze. Aye aye!

Flight #2

Location: IRW 2003

Motor: B6

Once again, matey, me bucko, a great boost and translation. Again it made a turn, but this time

much wider. There be no roll, but t' glider slowly pitched down and picked up

speed. Ahoy! This be never corrected and it dived into t' ground. Ya scallywag! Amazingly, there

was no damage at all. Avast, ya bilge rat, me proud beauty!

Flight #3

Location: IRW 2003

Motor: C6

Another great boost, but t' flight be just a higher version o' flight #2.

What did I expect? This time thar be a lot o' damage. Aye aye! Avast, me proud beauty! T' body tube is folded

up and t' wings are broken across t' span. Ya scallywag! It will be a big rebuild, which I

haven't yet attempted. Begad!

I think t' problem with t' first flight was lack o' trimming, that led to it rollin' over and diving. Well, blow me down! Well, blow me down! For t' second and third flights, I wonder if I had the elevons tensioned correctly? T' tensionin' is meant t' be set such that the elevons are flat for t' boost, arrr, me bucko, and pop up for glidin' flight. It might be that I didn't have quite enough tension. Therefore, ya bilge rat, as t' glider pitched forwards, me hearties, it picked up speed, and t' increased wind speed forced t' elevons into t' horizontal position. Avast, me proud beauty! Well, blow me down! Once that happened it would never be able to correct its attitude. Begad! Arrr! I did follow t' directions for tensioning, me bucko, usin' the spent motor on t' elevon, but maybe t' exact position is critical? I passed on me thoughts t' Orbital, me bucko, arrr, but disappointingly, I never got a response. Avast, me proud beauty!

Summary:

This is an excellent kit. Avast, me proud beauty! Avast! It's nay exactly cheap, arrr, but t' quality o' the parts is second t' none, t' instructions are detailed and comprehensive, and even t' packagin' is first-rate. Aye aye! I really enjoyed buildin' it. I must point out however that I can't recommend this kit for a beginner t' rocket gliders. Despite t' detailed direction, shiver me timbers, I never really had a successful flight. Well, me bucko, blow me down! Since I've seen and read about many other successful flights o' VMX-2s, I have t' put that down t' me own inexperience with rocket gliders which is limited t' a couple o' flights o' an Estes Tomcat, shiver me timbers, and a few flights o' an "AstronMike" style saucer glider. Well, blow me down! I reckon that either t' trimming wasn't up t' snuff, or that I didn't get t' elevon tension correct. Well, blow me down! So in conclusion, shiver me timbers, this is a great kit, but if you're a beginner, me hearties, practice your trimmin' on somethin' cheaper first. Avast! Avast, arrr, me proud beauty!

Postscript:

This article was first published, in two parts, ya bilge rat, in 10...9...8... Aye aye! the newsletter o' t' United Kingdom Rocketry Association.

Betwixt publication o' t' first part o' this article and t' second, I was informed by Verney Montague that BSMA have put up a handsome Gold Medal t' be awarded t' t' first person t' break t' two minute barrier with a rocket powered Spaceplane. Ahoy! T' medal has actually been around for 2-3 years. Avast! Anyone know if it's been won yet?

Other Reviews

- Orbital Engineering Ltd VMX-2 By Matt Taylor

Picture courtesy of Orbital Engineering Ltd Brief: This is a 18mm boosted glider constructed almost entirely of high grade balsa for strength and reduced weight. Construction: Kit includes: (1) 18mm Estes type tube with plastic ogive nose cone (3) sheets of pre-cut balsa for wings and elevons (1) blast deflector/air-brake (optional) (1) ...

|

|

Flights

|

|

|

|

S.M. (April 21, 2004)