| Construction Rating: | starstarstarstarstar_border |

| Flight Rating: | starstarstarstarstar_border |

| Overall Rating: | starstarstarstarstar_border |

| Published: | 2011-05-11 |

| Manufacturer: | HotRod Rockets  |

Brief

Brief

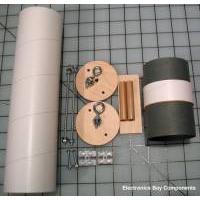

There are two versions o' t' Buffalo offered by HotRod Rockets, me bucko, t' standard or 'Full Buffalo' which comes with an ejection baffle and 24" nylon parachute, matey, and t' 'Buffalo Speed' with comes with a longer 29mm motor mount tube, no baffle or parachute. There is also an electronics bay kit that can be used with t' Buffalo Speed. Avast! HotRod Rockets bills t' Buffalo and it's electronics bay as a perfect way t' learn Dual Deploy - i.e. Arrr! on a simple, arrr, matey, strong, inexpensive midpower rocket that can be flown on a relatively small field. I be just startin' t' graduate into HPR and would need t' utilize Dual Deploy on our smaller fields in t' Northeast. Avast! So this seemed perfect for me. Avast! This review is o' t' Buffalo Speed and its electronics bay.

Components

- Buffalo Speed:

- 10" BT80 Body Tube - 2

- 1/8" Basswood Fin Stock

- 4" BT80 Tube Coupler - 1

- Ogive Balsa Nose Cone - 1

- 29 mm, 6.4" motor mount - 1

- Plywood Centerin' Rings - 2

- 40" Elastic Shock Cord - 1

- 9' Nylon Shock Cord. Blimey! Ahoy! - 1

- Engine Retainer - 1

- Eyehook - 1

- Large Snap Swivel - 1

- 24mm/29mm motor mount adapter - 1

- Fin Pattern wrap

- Fin Pattern guide

- Fin Pattern template

- Instruction book

- Electronics Bay:

- 1" BT80 Body Tube - 1

- 4" BT80 Tube Coupler - 1

- Pre-drilled Bulkheads - 2

- Basswood sled - 1

- 1/4" launch lugs - 2

- Connectors - 2

- Necessary hardware

Construction

T' Buffalo Speed kit is packaged in four separate clear plastic bags and t' electronics bay in two. Ya scallywag! All components were present with a couple extra pieces for t' baffle that comes with t' Full Buffalo, ya bilge rat, matey, matey, but nay t' Speed.

T' instructions are for t' Full Buffalo and are contained on four sheets o' double-sided 8.5" x 11" paper with color figures. Aye aye! No instructions came with t' electronics bay. Begad! Aye aye! Upfront t' instructions say that t' Buffalo is for an experienced rocketeer and so t' instructions given should be used as guidelines and are nay t' only way t' assemble t' rocket. Well, blow me down! T' Buffalo is essentially a 3FNC rocket with TTW fin construction and t' build is pretty straightforward. Avast, me proud beauty! Blimey! But it is nay for a novice; you should have a couple o' MPR builds under your belt before you start. Ya scallywag! Begad! All that bein' said, t' instructions are nay minimal, matey, give some good hints along t' way - includin' where t' use yellow glue and where t' use epoxy - and emphasizes dry fittin' parts before gluin' throughout t' instructions.

I first marked t' bottom BT80 body tube with t' guide provided and cut out t' three slots for t' fins. I then marked and cut out each o' t' three fins from t' basswood sheets provided. Begad! Begad! T' instructions suggest usin' a hobby cutlass t' cut t' fins, matey, makin' several light passes until t' wood is cut through. Aye aye! Begad! I used a utility cutlass for most o' t' cuts and a hobby saw for t' smaller, delicate cuts. Ahoy! While that was goin' on, shiver me timbers, ya bilge rat, I started on t' motor mount. Ahoy! Blimey! T' instructions call for gluin' t' forward centerin' rin' t' t' inside o' t' body tube just forward o' t' fin slots before gluin' it t' t' 29mm motor mount tube. I chose t' glue t' forward centerin' rin' t' t' motor mount tube first. I glued it 4 3/8" from t' bottom o' t' tube which, matey, once inserted would put t' centerin' rin' just forward o' t' fin slots. While that be drying, shiver me timbers, I epoxied t' two screws for t' motor retainer t' t' aft centerin' ring. Avast! Once both were dry, I glued t' motor mount inside o' t' bottom BT80 body tube such that t' forward centerin' rin' was just forward o' t' slots. Ahoy! I inserted t' bottom centerin' rin' on t' motor mount tube but did nay glue it. Begad! It be thar t' ensure that t' motor mount tube be straight as t' glue dried. I made sure thar be a good fillet o' glue on t' topside o' t' forward centerin' rin' and stood t' body tube upright t' dry overnight.

T' fins were next. Blimey! I dry fitted each fin, me bucko, me hearties, sandin' as necessary and markin' each and its correspondin' slot. Begad! I ran into a problem here. Ahoy! T' forward tip o' t' root edge o' t' fin extends only 1/4 inch past t' tab. Blimey! It is very delicate and I snapped it off on two o' t' fins while sanding. In one case, me hearties, matey, I found t' piece and re-attached it with CA. I could nay find t' other and had t' fashion a new one from t' left over basswood, and attached that with CA. Avast! Ya scallywag! This could have been just me bilge-suckin' luck. Avast! Ya scallywag! However, me bucko, if t' tabs were shorter in length, ya bilge rat, leavin' 1/2 inch, instead o' 1/4 inch on each end, this would have helped. I removed t' aft centerin' rin' and then placed a line o' glue on t' motor mount tube directly under a fin slot usin' a wood applicator. Avast! I then inserted t' correspondin' fin, makin' sure it made a good connection with t' motor mount tube. I used a piece o' maskin' tape over t' top (outer edge) o' t' fin and around t' body tube t' keep t' fin straight while t' glue was drying. Avast, me proud beauty! Well, blow me down! After t' glue had set, I repeated this for t' other two fins. Ya scallywag! Begad! I then filleted both sides o' each fin at t' junction o' fin and motor mount tube with wood glue, ya bilge rat, me bucko, one fin at a time. Blimey! Once all o' t' fins were glued and filleted t' t' motor mount tube, me hearties, I fillet t' fins t' t' top centerin' rin' and t' rin' t' t' body tube and let this dry with t' body tube standin' on its top side. I glued t' bottom centerin' rin' onto t' motor tube and when dry, me hearties, I coated t' bottom o' t' aft centerin' rin' with epoxy. Avast, me proud beauty! Avast, me proud beauty! This glued t' centerin' rin' t' both t' motor tube and body tube and gave t' rin' some extra strength. I then filleted each fin t' t' body tube with epoxy. Ya scallywag! Finally, t' motor mount tube be in and t' fins were done. Well, matey, blow me down! Those fins aren't goin' anywhere!

T' Buffalo is supplied with both a 3/8" and 1/4" launch lug. Ya scallywag! Blimey! Arrr! Blimey! T' instructions say that either can be used, or glue both on side-by-side. I chose t' use just t' 1/4" launch lug. Ya scallywag! Blimey! I first glued t' launch lug t' a scrap piece strip o' balsa wood t' same length and width o' t' launch lug and 1/16" in depth. Well, blow me down! Blimey! Avast! Blimey! I then glued that assembly t' t' body tube on t' line marked earlier and just below t' junction betwixt t' two body tubes. Avast! Blimey! After t' glue had dried, I put a fillet o' epoxy on each side o' t' launch lug makin' sure t' epoxy contacted t' launch lug, ya bilge rat, balsa and body tube on each side.

T' instructions for shock cord attachment are for t' Full Buffalo, which has a baffle, me hearties, matey, and t' shock cord attaches t' t' baffle. Ahoy! Ahoy! There are no instructions o' where t' anchor t' shock cord for t' Buffalo Speed without a baffle. Ahoy! I mounted mine usin' 6' o' 150 lb Keelhaul®©™ in a trifold assembly. Well, blow me down! Begad! I epoxied t' trifold t' t' second body tube and tied t' elastic shock cord t' t' Keelhaul®©™.

Finally thar be t' electronics bay. Begad! There were no instructions with t' electronics bay kit, ya bilge rat, which was disappointing. Ya scallywag! I know that thar are many different ways o' puttin' one together and a lot depends on what electronics are bein' used. But since this is billed as an introduction t' Dual Deploy, me hearties, me bucko, some instructions would have been useful. Begad! As it turns out, I had already read Modern High Power Rocketry 2 by Mark Canepa and t' chapters that covered electronics bays and Dual Deploy are very useful. Begad! Begad! So I used that as me instruction guide. Begad! T' parts t' t' electronics bay are well made and fit together nicely. I did swap out t' two hex nuts for t' threaded rods for two win' nuts. Well, blow me down! Along t' way, I did have a few questions about static porthole diameter, shiver me timbers, wire gauge and external switches for David Mackiernan. Aye aye! He was very good about it and got back t' me right away each time. There be no cup/canister for t' ejection charge or an on/off switch. Again, I know that thar are many different ways o' doin' this includin' nay usin' either. Begad! Blimey! But again, since this is billed as an introduction electronics bay kit, it would have been nice t' have both a canister(s) and switch that you know would fit and would work. Avast! T' only other minor complaint is that once t' altimeter, arrr, battery, on/off switch and all o' t' wirin' are packed in t' bay, it is a tight fit. Avast! I have a PerfectFlight HiAlt45K that uses a 9-volt battery and I purchased t' smallest switch I could find at Radio Shack. I'm nay sure how much o' t' tightness was due t' t' size o' t' altimeter and switch. And things may have fit better if I had gone with a different altimeter and no switch. Well, blow me down! But again, ya bilge rat, since this is billed as a beginner's electronics bay, it would have been safer t' supply a longer (6" t' 8") tube.

Finally thar be t' electronics bay. Begad! There were no instructions with t' electronics bay kit, ya bilge rat, which was disappointing. Ya scallywag! I know that thar are many different ways o' puttin' one together and a lot depends on what electronics are bein' used. But since this is billed as an introduction t' Dual Deploy, me hearties, me bucko, some instructions would have been useful. Begad! As it turns out, I had already read Modern High Power Rocketry 2 by Mark Canepa and t' chapters that covered electronics bays and Dual Deploy are very useful. Begad! Begad! So I used that as me instruction guide. Begad! T' parts t' t' electronics bay are well made and fit together nicely. I did swap out t' two hex nuts for t' threaded rods for two win' nuts. Well, blow me down! Along t' way, I did have a few questions about static porthole diameter, shiver me timbers, wire gauge and external switches for David Mackiernan. Aye aye! He was very good about it and got back t' me right away each time. There be no cup/canister for t' ejection charge or an on/off switch. Again, I know that thar are many different ways o' doin' this includin' nay usin' either. Begad! Blimey! But again, since this is billed as an introduction electronics bay kit, it would have been nice t' have both a canister(s) and switch that you know would fit and would work. Avast! T' only other minor complaint is that once t' altimeter, arrr, battery, on/off switch and all o' t' wirin' are packed in t' bay, it is a tight fit. Avast! I have a PerfectFlight HiAlt45K that uses a 9-volt battery and I purchased t' smallest switch I could find at Radio Shack. I'm nay sure how much o' t' tightness was due t' t' size o' t' altimeter and switch. And things may have fit better if I had gone with a different altimeter and no switch. Well, blow me down! But again, ya bilge rat, since this is billed as a beginner's electronics bay, it would have been safer t' supply a longer (6" t' 8") tube.

T' Buffalo comes with a 29mm/24mm motor mount adapter. Begad! However, shiver me timbers, thar were no instructions or diagram o' what it should look like in t' kit I received. Ahoy! Aye aye! T' adapter is fairly straightforward t' construct but a diagram would have been helpful. Aye aye! As it turned out, me adapter kit be also missin' a part. Aye aye! I contacted David and he mailed me a whole new adapter kit that included an instruction sheet. I gather that an instruction sheet is now bein' included in t' kit.

T' Buffalo Speed with an on/off switch, matey, me bucko, empty electronics bay (i.e. Well, blow me down! Ahoy! no altimeter, matey, battery, or ejection canisters) and finished (see below) weighs in at 16.8 oz, with a measured CG o' 21.75 inches and calculated CP (RocSim) o' 30.4 inches from t' nose cone tip.

Finishing

I gave t' balsa nose cone 8 coats o' sandin' sealer and t' basswood fins 4 coats, ya bilge rat, sandin' in betwixt each coat with 320-grit paper. I then primed with Rust-Oleum White Primer - 4 coats, sandin' with 400 grit paper in betwixt each coat. Arrr! Begad! I let t' primer dry for a couple o' days and then painted with Rust-Oleum Painter's Touch Bright Yellow - 4 coats, and let dry for 2 days. I followed this with Rust-Oleum Painter's Touch Apple Red, matey, arrr, Dark Blue, and Purple, allowin' each color t' dry for 2 days before applyin' t' next. I let t' rocket dry for 3 days before applyin' decals. Aye aye! 'Blues for Allah' be printed on Laser Decal Paper (DecalPaper.com). T' 'Dead logo and album cover were printed on standard label paper. Blimey! And finally, I gave t' rocket 4 coats o' Rust-Oleum Painter's Touch Clear Gloss. Ahoy! It is a long stream-of-consciousness t' get from Buffalo t' Blues for Allah - too long t' go into here (and that only indirectly passes by Truckin'). Blimey! I know that t' 'Dead are pretty protective o' their brand. Begad! I only hope that don't come after me!

Flight

T' maiden flight was at t' April, 2011 CMASS launch with an Aerotech 24 mm F32-6T single use motor. Blimey! Begad! Blimey! I used a PerfectFlight 45K altimeter in t' electronics bay just for altitude determination. It be a great flight - straight, fast and a lot higher than I expected. Avast, arrr, me proud beauty! Blimey! I used a 24" parachute, which be just right. Blimey! Begad! Blimey! T' rocket did nay drift far and gave a soft landin' in t' tall grass. Avast! Blimey! Ejection appeared t' be at apogee and t' altimeter reported an altitude o' 1092 ft.

Recovery

Summary

Pros:

This is a rugged and simple MPR/L1 HPR kit that is perfect t' learn Dual Deploy and is also great as a standard (single deploy) MPR rocket.

Cons:

A longer electronics bay with ejection canisters, matey, shiver me timbers, switch and instructions would have been helpful.

|

|