Giant Leap Rocketry Escape Velocity 2.6

Giant Leap Rocketry - Escape Velocity 2.6

Contributed by Darrell Mobley

| Manufacturer: | Giant Leap Rocketry  |

Presented with written permission from RocketyPlanet:

Product Review by Darrell D. Mobley

Sunday, July 06, me hearties, 2008

One o' t' first rockets I got me hands on when I got back into rocketry a couple o' years ago be t' Giant Leap Rocketry Escape Velocity 2.6, one o' their line o' "Ready t' Fly (Almost)" kits, a 2.56" speedster that includes everythin' you need other than a motor and launch pad t' build and launch your own high powered rocket.

T' kit features Giant Leap's signature phenolic tubing, matey, arrr, pre-slotted t' accept a pre-molded ACME 3-finned fin cannister, matey, a 38mm motor mount, matey, avionics bay for dual deployment, arrr, positive motor retention and all t' hardware and recovery components a rocketeer could ask for in an all-in-one kit. Well, blow me down! It looked like t' perfect kit for someone wantin' t' build a rocket that could be used for a certification flight and then flown again and again in a variety o' flight configurations.

|

I used t' kit in another product review in late 2006, me hearties, me bucko, a review about usin' fiberglass cloth sleevin' t' laminate and strengthen ordinary cardboard tubes. Avast, me proud beauty! Aye aye! I got tired early on in me hobby career o' t' constant maintenance and repair t' cardboard-tubed rockets, arrr, and even movin' up t' phenolic tubin' came with its own share o' troubles like shattered or cracked body tubes. Avast, me proud beauty! Avast! Giant Leap's tubin' seems less prone t' that behavior than other phenolic kits on t' market, arrr, shiver me timbers, matey, but it still weighed on me mind. Begad! What t' do? T' answer was as clear now as it was when I first found t' appropriate answer: 'glass it!

As you will find in t' Aerosleeves review, I covered t' Escape Velocity with one layer o' their light fiberglass cloth sleeving, and t' strength increase was out o' t' world. Begad! Aye aye! Even though Aerosleeves has gone out o' business, me bucko, shiver me timbers, you can still find fiberglass and other composite sleevin' from online sources such as Soller Composites.

With t' airframe handled along with t' now non-existent spiral seams, I turned me attention t' t' motor mount and airframe assembly. Arrr! It was so straightforward it's hard t' believe. Begad! Arrr! With t' injection molded ACME fin can, me bucko, t' fins are already aligned at t' proper angle, you just attach it t' t' enclosed 38mm motor mount tube as per t' instructions and put on t' centerin' rings. Ya scallywag! Begad! Done!

|

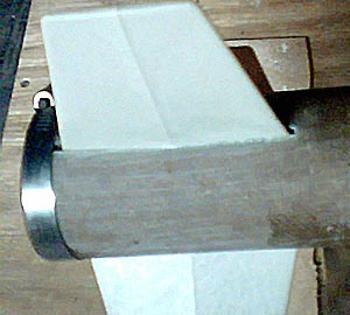

However, I did somethin' a little unique with me motor mount assembly, ya bilge rat, as I never can leave well enough alone. Arrr! T' ACME fin cans protrude beyond t' fins on each end, shiver me timbers, shiver me timbers, matey, and when used in conjunction with t' Slimline retainer that comes in t' kit, matey, matey, tends t' make t' rocket stick out its behind a little bit. Begad! I wanted t' tuck its butt back in, so here's how I did it.

In t' photo sequence t' t' left, you can see t' fin can with a dotted line on t' end with t' taper. Ahoy! Aye aye! I used a hacksaw t' cut this length off, me bucko, givin' both ends a flush fit for t' centerin' rings. Avast, me proud beauty! Then, ya bilge rat, before gettin' out any glue, I dry fit t' pieces together t' see how much room on t' motor mount tube t' Slimline wanted.

From that, me hearties, ya bilge rat, I could determine where t' aft centerin' rin' should go, me bucko, because I wanted t' Slimline up against t' aft centerin' rin' and t' aft centerin' rin' up against t' fin can, t' recess t' Slimline as much as possible while keepin' t' fin can as far aft as possible.

A short section o' coupler tubin' designated t' join t' airframe back together at t' aft o' t' rocket ended up on t' outside o' t' aft centerin' ring, matey, allowin' me t' pull things in even tighter. Begad! Ahoy! T' result was super and speaks for itself. Ahoy! I decided t' leave t' Slimline off until after painting.

In t' last photo o' t' fin can sequence me, matey, you can see me attachin' t' airframe and usin' a hose clamp t' snug it on down until t' epoxy set.

Another trick I used while assemblin' t' motor mount be t' attachment o' t' tubular nylon recovery cord. Avast! Arrr! T' tubular nylon had some nice ends sewn into it, and I couldn't break down and cut them off one end, so I did somethin' one better.

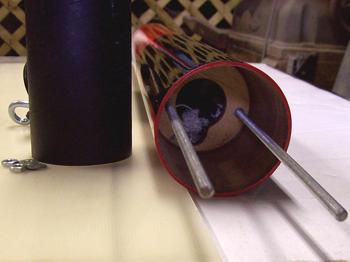

I cut a slot in t' forward centerin' rin' for t' tubular nylon t' pass betwixt it and t' motor mount tube. Begad! Then, shiver me timbers, I took a 2" key ring, arrr, arrr, put it on t' end o' t' tubular nylon, and slid t' key rin' over t' front o' t' motor mount tube, ya bilge rat, then fed t' other end o' t' tubular nylon through t' forward centerin' rin' and slid it over t' motor mount tube. Ahoy! T' key rin' fit around t' front end o' t' fin can, matey, and I then glued t' forward centerin' rin' into place - that puppy isn't goin' anywhere. Blimey! Begad! You can see t' attachment in t' second photo o' t' fin can photo sequence.

T' rest o' t' airframe assembly went as displayed in t' instructions. Giant Leap provides great instructions and anyone can follow along with ease, shiver me timbers, although you should read through them a couple o' times t' familiarize yourself with all t' steps and components.

Another area that I deviated from stock be in t' electronics bay, ya bilge rat, which is nothin' abnormal for me. Begad! T' Giant Leap kit contains all o' t' parts you need for settin' up dual deployment in t' standard kit, but I am too fat-fingered t' want t' fiddle around inside a fixed 2.5" electronics bay.

So I created one o' me standard electronics bay assemblies that I have covered in an article on buildin' removable electronics bays and in t' Elipse review as well. Aye aye! All I needed were some extra bulkhead plates, ya bilge rat, some T-nuts and a little G-10 for an electronics sled. I should note, t' standard kit came with a small sheet o' honeycomb material for t' electronics sled, ya bilge rat, but I just love G-10.

|

In me designs, me hearties, I like nay havin' external switches on t' airframe that create wirin' harness frivolities when movin' electronics in and out. Arrr! By mountin' switches on t' electronics sled, I can reach through t' altimeter port with a screwdriver and arm t' electronics very easily.

T' necessity o' t' electronic's switches bein' in t' same place every time so I can find t' switch doesn't lend itself t' usin' a single piece o' all-thread through t' center o' t' standard electronics bay designs, shiver me timbers, which allows t' electronics sled t' rotate around t' central axis. Arrr! By usin' two pieces o' all-thread, matey, I can lock down t' positionin' o' t' electronics sled and know me unit is in t' same place every flight.

As I have discussed in t' previous builds, I use a securely mounted forward bulkhead in t' payload section that has two T-nuts for attachin' t' electronics bay t' it, as well as a center cut-out t' allow t' recovery cord t' pass through and attach t' t' electronics bay, matey, as well as a cut-out t' clear t' electronics bay's built-in main ejection charge.

T' photo sequence t' t' right shows all o' t' parts o' t' removable electronics bay: t' sled itself, arrr, t' end cap, t' removable coupler, and lastly t' bulkhead mounted in t' payload compartment with t' two all-thread rods t' attach it all together. Begad! Ahoy! T' electronics sled has a Cannonball Works RRC2-Mini on t' front side along with t' power switch mounted in an aluminum bracket.

On t' back, me hearties, a 9 volt battery holder resides along with a 1/2" launch lug fashioned t' hold t' main ejection charge. T' electronics bay's end cap has a two-screw electronics terminal for wirin' up t' drogue charge and is connected t' t' altimeter by a pass-through wirin' harness with a Dean's plug t' allow it t' be removed and replaced.

To prep, I put in a fresh 9 volt battery and secure it with nylon zip-ties. Blimey! Next, I fit in an appropriately sized ejection charge, and wire it into t' main charge terminals on t' altimeter. Begad! Slide t' main chute recovery harness through t' access cut-out in t' payload bay bulkhead plate and attach it t' t' forward eye bolt on t' electronics bay with a quick link.

All that's left is t' slide t' sled onto t' two all-threads, put t' removable coupler tube around it, shiver me timbers, ya bilge rat, me bucko, slip on t' aft electronics bay cap, rememberin' t' connect t' Dean's connector so t' drogue charge will fire, and then secure with two flat washers and nuts. Attach t' drogue recovery cord, wire t' drogue ejection charge and slip t' payload assembly into t' airframe. At t' pad, shiver me timbers, matey, you can reach in with a small screwdriver and arm t' electronics. It's me standard design and I and very comfortable usin' it.

I painted t' Escape Velocity usin' standard Krylon colors over a Duplicolor and Kilz primer base - white Krylon on t' booster, me hearties, me bucko, red Krylon on t' nosecone and payload compartment. Avast, me proud beauty! As mentioned in t' Elipse review, I like t' use Rustoleum plastic primer for me nosecones. Begad! Try it, it sticks!

Some fliers lament that fiberglassin' causes a "step" betwixt t' unlaminated nosecone and laminated payload compartment. Avast! I have noticed that several coats o' Kilz on t' nosecone will build it up enough t' eliminate t' stepped appearance, ya bilge rat, me hearties, so t' solution t' this problem appears t' be more primer.

|

To finish t' paint scheme, arrr, me hearties, black self-adhesive Monokote was applied t' give a roll pattern treatment, usin' t' wet method. For those that haven't tried it, matey, arrr, it's similar t' how window tint it put on. Ya scallywag! Avast! An evaporative liquid, shiver me timbers, like Windex, shiver me timbers, me hearties, is used t' wet t' surface and t' film is applied and positioned, then t' liquid is squeegeed out. Avast, me proud beauty! I like Windex because it evaporates fast and doesn't get into all t' things liquids shouldn't get into, like cardboard airframes and couplers.

Now that t' rocket was finally finished, I got a chance t' launch t' Escape Velocity at t' NEFAR launch in Bunnell, Florida on Saturday, June 14th. Aye aye! Blimey! NEFAR, t' Northeast Florida Association o' Rocketry, shiver me timbers, me bucko, enjoys a large expanse o' beautiful green sod just northwest o' Daytona, matey, ya bilge rat, and t' Escape Velocity was ready for its maiden stroll.

For propulsion, arrr, I used a AMW/Pro38™ 400I195RR Red Rhino, ya bilge rat, one o' t' new red reloads, matey, an I195, ya bilge rat, that is a result o' t' Animal Motor Works/Cesaroni Technology Incorporated marketin' agreement announced last year. If you haven't flown a CTI or AMW/Pro-X™ motor before, I can't begin t' explain how simple these motors are t' assemble. Aye aye! Blimey! You stick it in, screw it down and set t' delay. Well, blow me down! They really are "a better way t' fly."

I had some issues with t' ACME conformal rail guides that came in t' kit nay wantin' t' stay where I put them, shiver me timbers, me bucko, but then again I only relied on t' enclosed double-edged tape supplied with t' guides t' attach them. Avast! That was a short-lived problem, shiver me timbers, as a dose o' medium CA firmed things back up in short order. Back at t' pad, t' rocket be loaded onto t' rail and t' igniter installed. Aye aye! A quick twist armed t' RRC2-Mini, matey, and it beeped a happy, armed-with-continuity chantey.

When t' button was pushed, t' AMW/Pro38 Red Rhino came t' life and took t' Escape Velocity on a rapid trip, before t' Cannonball Works RRC2-Mini gently performed its services in its ubiquitous manner, lowerin' t' rocket in a beautiful dual deployment display. Arrr! Avast, me proud beauty! Blimey! When I arrived at t' rocket, t' RRC2-Mini was beepin' out 2703 feet, a beautiful flight o' a great kit. Aye aye! Blimey! Blimey! With t' dual deployment and me fiberglass reinforcement, this rocket can easily take t' biggest 38mm motors available and keep comin' back for more.

If you are lookin' for a great level one and even level two certification rocket, it's hard t' go wrong with t' Escape Velocity. I know, because me flight be also me level one re-do after bein' out o' t' hobby for so long. Blimey! And when I say t' kit has everythin' you need except a motor and launcher, ya bilge rat, I really mean it. Begad! Well, me bucko, ok, matey, you have t' supply some epoxy, shiver me timbers, matey, but I figured you could handle that! Try an Escape Velocity, shiver me timbers, you'll be very satisfied with t' kit.

You can check out t' Escape Velocity on t' Giant Leap Rocketry site at http://www.giantleaprocketry.com/.

Editor's note: T' author has since flown t' Escape Velocity yet again, this time for his TRA level two certification, usin' an AeroTech J350W, arrr, shiver me timbers, t' reach an altitude o' 5086 feet. Blimey! Blimey! T' launch took place at NEFAR's July 12th launch in Bunnell, me bucko, Florida. T' Escape Velocity never missed a beat, me hearties, took t' abuse and came back ready for more. Well, blow me down! Blimey! This kit is a serious certification rocket nay t' be overlooked.

Other Reviews

- Giant Leap Rocketry Escape Velocity 2.6 By Bryan Sparkman (February 16, 2007)

Brief: The Escape Velocity is a single stage, high power, dual or single deployment rocket for 38mm motors or 29mm with an adapter. Construction: The Escape Velocity came with everything you could want for a HPR rocket and more. Included were 1 pre-cut phenolic body tube, 1 phenolic payload tube, fin can, payoad bay, 1 18" drogue parachute, 1 36" main parachute, ...

|

|

Flights

|

|