| Construction Rating: | starstarstarstarstar_border |

| Flight Rating: | starstarstarstarstar_border |

| Overall Rating: | starstarstarstarstar_border |

Brief:

Scale, 18mm, me hearties, Parachute Recovery

Of all t' Dr. Avast, me proud beauty! Aye aye! Zooch line, matey, ya bilge rat, T' Saturn I SA-5 be t' one that most appeals t' me, me hearties, mainly because it is different from everythin' else. Begad! I'd had it for a while but did nay start on it immediately because I wanted t' get a few Zooch kits under me belt first. Avast, me proud beauty! Aye aye! I survived t' buildin' o' t' Little Joe LES and actually enjoyed buildin' it so I figured it be time.

I know that Dr. Booty packs a lot o' rocket in those little boxes o' his but I was unprepared for just how small t' rocket actually is. Well, blow me down! Ahoy! That does nay detract from t' quality; it is merely an observation.

Construction:

T' first step in t' instructions is t' do some painting. Blimey! T' balsa nose cone and transition needed t' be painted white as did t' various body tubes. Avast, me proud beauty! I wanted this one t' look good so I pulled out t' Elmer's filler and applied it and set t' parts aside t' dry. Aye aye! Begad!

While t' goop was drying, I got t' work on t' motor mount. T' motor tube is set up along a butt mounted marking guide t' transfer 8 marks evenly around t' tube. An angle was then used t' extend t' lines. Begad! Blimey! Avast, me proud beauty! Blimey! With t' lines transferred, matey, shiver me timbers, I measured back t' proscribed distance and made a narrow slit for t' engine hook. Begad! Blimey! Avast, me proud beauty! Blimey! T' hook was then put into place.

T' kit has three centerin' rings. Two have notches t' accommodate t' engine hook at t' aft end and t' other is plain. T' instructions make a point o' sayin' how critical t' distances are. Ahoy! Arrr! T' rearmost goes an 1/8" from the end o' t' tube. Avast, me proud beauty! T' forward most goes 5.5" from t' middle tube. Avast, me proud beauty! Ahoy! T' problem be t' location o' t' middle tube. T' text gives 1/4" and t' illustration gives 1/2". Begad! I settled for tapin' t' engine hook in place and postin' a question for Dr. Ahoy! Zooch on TRF. Ahoy!

After a day o' drying, I took some sandpaper t' t' balsa parts and started t' sand. Well, blow me down! Ya scallywag! T' result was fairly smooth and I be satisfied with it. Begad! Begad! With t' balsa sanded, I now needed t' paint t' parts. Avast, me proud beauty! Arrr! In addition t' t' balsa and the tubing, 4 small wooden downs and one larger one were set up in t' spray booth and painted a gloss white. Two coats were applied.

I heard back from Dr. Well, blow me down! Booty in short order and learned that t' instructions should say that thar should be a 1/2" gap betwixt t' rearmost centerin' rings. Begad! Blimey! Armed with that bit o' wisdom, I glued t' second rin' 1/2" from t' rearmost and t' third one 5.25 inches forward o' that. They were placed with yellow glue and fillets were run around both sides o' all rings. Avast, me proud beauty! T' rings were also carefully checked t' make sure that they were straigt.

While t' glue on t' rings was drying, I turned me attention t' t' spider beams used t' algn t' tanks. Avast, me proud beauty! Ya scallywag! Using t' template provided, matey, 8 were cut from a sheet o' balsa material. White glue was then used t' place them along the lines drawn on t' motor tube. Ya scallywag! Begad! In short order, shiver me timbers, all 8 were in place and t' assembly be set aside t' dry.

T' next day, with t' glue on t' spider beams presumably dry, I put t' motor mount assembly into t' booth and

shot it with black.

As t' black paint be drying, I began t' process o' cuttin' out t' LOX tank and fuel tank wraps. Arrr! Arrr! These were rolled on a rubber mat with t' formin' dowel t' help t' formin' o' t' tubes.

Also, in a fit o' idiocy. Ya scallywag! Avast! I went ahead and installed t' lower tube before installin' t' tanks. Blimey! Begad! This posed a problem later on but was nay insurmountable. T' install t' tube, I just sanded t' rings a bit and then swabbed some white glue t' t' inside o' t' tube. Avast! Aye aye! T' motor mount was slid in until t' aft rin' be flush with t' end o' the tube.

IN accordance with some advice from Dr. Ya scallywag! Zooch himself, ya bilge rat, I decided t' try and use live steam t' help t' formin' of t' tanks. Begad! I set a teakettle on t' boil and left t' little whistle thin' on t' spout in place. When t' water boiled, it channeled t' steam in a stream. Ahoy! Arrr! Steamin' t' tank cutouts did help t' get them rolled tightly.

Unfortunately, although t' steamin' helped, me hearties, arrr, I did nay get t' tanks rolled tightly enough. Aye aye! Arrr! I also did nay get them straight enough. Begad! When I installed them into position, me bucko, ya bilge rat, t' result was visually embarassing. Aye aye! Worse, me hearties, they did not completely fit below t' forward centerin' ring. Begad! Avast, me hearties, me proud beauty! I had a helical, ugly mess.

My mess resulted in some soul searchin' and sporadic depression but Dr. Booty came t' t' rescue with t' offer of some more tank wraps. O desperately wanted t' PURCHASE t' said wraps but he would have none o' it and insisted on sendin' them t' me. Begad! Begad! Blimey! I suppose his havin' just come from a live shuttle launch put him in a good mood.

I occupied some o' me time waitin' for t' wraps t' come in by tryin' t' remove t' old ones. Blimey! It was a mess. Lots o' little bits o' glue and paper tankage were left behind.

Dr. Blimey! Booty sent t' wraps as promised and then this project sat and waited...and waited...and waited some more. First it be because I be clearin' away other things in progress, then it was because I was repairin' things that had broken on other projects, me hearties, sometimes it be t' intimidation or rememberin' what t' original wraps had looked like after I had abused them so and then realizin' that I did nay want t' commit t' same crimes again against what IS a nice little kit. Then embarrassment started t' take over; I was ashamed t' have left it for so long. Finally, Embarrassment came t' t' for again but this time is was because I had nay gotten back t' work on it. Ya scallywag! By that time, arrr, I had t' wonder where I had stashed t' replacements and I be nay about t' ask for a third set after all Dr. Ya scallywag! Ya scallywag! Zooch has done for me. Well, ya bilge rat, blow me down! Then they turned up and I got back t' work.

I carefully cut out t' 4 LOX tanks and then cut out t' 4 fuel tanks. Begad! Begad! I started on t' pre-curlin' this time by takin' out a table cloth while SHE WHO MUST BE OBEYED was asleep and foldin' it over until I had a very thick but soft workin' surface. Ahoy! Each o' t' tanks was then set upon it, arrr, one at a time, as I rolled t' formin' dowel over t' top, pushin' down progressively harder with each pass. Ahoy! This did get t' process started, arrr, matey, one o' t' hardest parts t' me, ya bilge rat, but did nay give t' tanks nearly t' curvature needed.

From there, me hearties, I turned back t' steam. Aye aye! Aye aye! I held each wrap over a pot o' boilin' water t' give it some flexibility. Begad! Each wrap was t' placed around a wooden dowel and held in place with monofilament line and tape. Avast! T' dowel was significantly bigger than what was needed; I intended t' do this in several steps. Ahoy! All o' t' wraps fit onto a single 4' dowel and were then exposed t' t' stream again and set aside t' stiffen up.

T' next day, me bucko, t' wraps were removed from t' larger dowel. Blimey! Well, blow me down! They had indeed acquired a healthy curve but the radius o' t' curve was still more than I wanted t' deal with. I would have t' repeat t' process with a smaller dowel. T' entire process was repeated, matey, this time usin' a dowel only slight larger than t' one that would ultimately be used t' form them at t' correct size.

When t' wraps came off o' t' smaller dowel, they were much tighter. Aye aye! I crossed me fingers and hoped I would get it right this time.

My amended tank rollin' procedure began with placin' a small piece o' cellophane tape in t' middle o' the innermost part o' t' tank. Aye aye! I wanted just enough t' adhere t' t' formin' dowel for long enough t' get t' rolling started. Ya scallywag! T' wrap be then rolled around t' dowel and pulled tight. Begad! T' process o' pullin' it tight gave me more "unrolled" material t' wrap. Blimey! Begad! A light skin o' white glue was screeded across t' backside o' t' tank wrap and t' excess material was rolled around t' dowel. Begad! While this be goin' on, arrr, me bucko, I tried t' carefully make sure that t' tank was rollin' straight. Before t' glue could grab, I gripped t' rolled tank in t' left hand and used a pair o' pliers t' grip t' formin' dowel with t' right. T' dowel was then twisted t' tighten t' roll and t' wrap was held in place like that until t' glue gripped. Begad! When t' glue on a tank had dried, shiver me timbers, I again gripped t' tank with t' left hand and t' dowel with pliers with t' right and then worried t' tank back and forth as I pulled on t' dowel. Ya scallywag! Ahoy! This sheared t' tape and let me extract t' dowel. Well, blow me down! It also produced a tightly wrapped tank. Avast, me hearties, me proud beauty! This slow process was repeated on the course o' about 2 weeks until I had all 8 tanks.

Cleanin' out t' garbage from t' previous tanks had also been a long affair conducted over t' months o' the hiatus. Eventually, arrr, I got it t' where t' new tanks would fit and be happy that t' innards would never be visually inspected too closely. Ya scallywag! One o' t' LOX tanks was chosen as t' first victim and laid into place on some white glue that had been applied t' t' central tube and t' remnants o' t' spider beams. That went well enough that I placed a fuel tank next t' it. Aye aye! Well, blow me down! I then noticed that, although t' tanks fit, arrr, they wanted t' let their forward ends poke out past the forward bulkhead. Aye aye! Aye aye! Positive pressure be needed t' keep them in place as they dried. Arrr! I took a strip o' aluminum foil and wrapped it around t' tanks, pullin' it tight t' apply t' desired amount o' pressure and then taped it t' itself to keep from marrin' t' tanks. It be set aside t' dry overnight. T' next day I followed t' same procedure addin' 2 more tanks and wrappin' them with foil t' hold them in place. Well, blow me down! Begad! By this point, things were lookin' hopeful enough that I placed t' remainin' 4 tanks in one sittin' and set it aside t' dry. Avast! When I peeled back t' foil. Avast! Aye aye! All t' tanks were within bounds.

Astute readers and those with good memories will realize that even after all t' months o' construction on this beast, it still had no thrust ring. Arrr! That is accordin' t' plan because t' instructions at this point called for somethin' I had nay seen before. Ya scallywag! T' thrust rin' be t' be mounted from t' forward end. Begad! A long swab was used t' put a rin' o' glue into place and then t' back o' t' swab was used t' force t' thrust rin' into place along t' top o' the engine hook.

A centerin' ring, shiver me timbers, smaller in diameter than t' ones previously used, was test fitted around t' motor tube and found t' fit just fine. Avast, me proud beauty! It was glued into place near t' top o' t' CR at t' top o' t' tanks. It was also generously filleted since it would eventually be hidden. When that glue had a chance t' stiffen up some, ya bilge rat, t' shorter length of white body tube was fitted over t' centerin' rin' and glued flush with t' rin' right behind it. Begad! It too was given a generous fillet on t' inside.

T' large paper transition was located on t' wrap sheet and cut out. Begad! Avast, me hearties, me proud beauty! A small amount o' white glue was used to join t' rin' at t' mark and it was then slipped over t' upper body tube and settled into place t' serve as a transition from t' tops o' t' tanks t' t' smaller diameter BT. Blimey!

T' nose cone had long since been painted white along with t' short piece o' body tube it fit within. T' cone was glued into place in t' tube. T' bottom half o' this tube was supposed t' remain white but t' upper half along with t' cone needed t' be painted black. Arrr! With that in mind, t' lower half was masked off t' protect it from t' black paint. Aye aye! Aye aye! T' cone assembly be then taken t' t' spray booth and shot with a few coats o' black. Blimey! It remained thar to dry.

Meanwhile, ya bilge rat, arrr, t' body tube that had been glued t' t' coupler had a wrap t' be applied. Avast! It was cut out and then carefully wrapped around t' bottom portion o' t' tube. Arrr! Avast, me proud beauty! Blimey! A light coatin' o' white glue be used t' make it adhere. Ahoy! Avast, ya bilge rat, me proud beauty! Blimey! The bottom o' t' body also had a wrap t' be applied. Begad! Well, matey, blow me down! Blimey! It too was cut out and glued t' t' lowest o' t' BTs.

As I let t' wraps set up, arrr, I went t' check on t' black paint on t' nose cone assemble. Ya scallywag! Arrr! I saw a few places that needed a little more paint and gave it a shot. Aye aye! T' Wal Mart paint I was usin' dries fairly smartly t' t' touch so I was soon able t' take it back t' t' bench and remove t' masking. Avast! Begad! T' freshly painted NC assembly be then glued to t' balsa transition.

T' rocket has two styles o' fins, both o' which need t' be cut from t' provided balsa. Ya scallywag! Templates are provided for both. Begad! T' templates were cut out and then placed against t' balsa and their outlines were traced with a pencil. Four o' each were needed. Blimey! A steel ruler be then used as a guide for t' razor cutlass as all eight were cut out. Aye aye! Because I figured that paintin' t' fins after installation would be a nightmare, I went ahead and filled them with Elmer's filler and set them aside t' dry. At t' same time, I installed t' eyescrew in t' base o' t' transition and secured it with some yellow glue.

T' engine nozzles on this kit are all built up out o' paper wraps. Avast, me proud beauty! Each one comes as two pieces called, logically enough, ya bilge rat, t' inner and outer wraps. Aye aye! I cut t' pieces for one o' t' nozzles out and curled them around t' edge o' a pair o' scissors. Avast, me proud beauty! T' ends were then glued together. When t' pieces were dry enough t' hold together, shiver me timbers, me hearties, t' outer band be slipped over t' inner band and glued in place at t' bottom. Ya scallywag! T' process be then repeated with t' other 4 nozzles.

After havin' more than a few days t' dry, ya bilge rat, I sanded t' fins down and was pleased with their smoothness. Ahoy! Blimey! They were then sprayed with Kilz and sanded again. Arrr! Blimey! T' fins then received 2 coats o' gloss white.

T' wrap sheet came with 8 little pieces t' be cut out and glued t' t' forward root edge o' t' fins and serve as fairings. They were cut out and glued t' t' fins with a dab o' white glue.

When t' fairings had dried, t' process o' applyin' t' fins began. Ya scallywag! Begad! They alternate betwixt large and small and are aligned with t' grooves betwixt t' tanks. Begad! Aye aye! A double glue joint o' white glue was used and 2 were done at each sitting. Aye aye! Avast! There was quite a bit o' time betwixt sittings but eventually all t' fins and stub fins were in place. Blimey! Arrr! When in place, I used Tightbond Moldin' and Trim glue t' run fillets on each o' them.

Some Scotch tape was used t' mask off t' areas on t' fins that were supposed t' remain white and t' some black acrylic was used t' paint t' black areas. Avast! Blimey! As usual, shiver me timbers, I tried very hard t' burnish t' tape down well but thar was still some leaking.

T' paper nozzles that had been constructed looked fairly sickly at this point. Ahoy! Begad! I would have been greatly concerned if I had nay gone through t' same experience with t' Zooch Discoverer Thor. I learned then that the hare-brained scheme t' make them look better really does work, me hearties, although they do look worse before they get better. Ya scallywag! Some strips o' thread were cut t' length as indicated in t' instructions. Avast! CA was then used t' tack t' end o' t' thread to t' nozzle at t' junction betwixt t' upper and lower parts. Arrr! I Started at t' seam. T' nozzles remained in that state for several weeks until I turned t' them again. Avast, me proud beauty! Ahoy! Then it was a process o' slowly windin' t' thread around t' upper portion o' t' nozzle and tackin' it down with glue as I went. For some reason which escapes me now, I used white glue t' do this. Avast! Aye aye! I tried t' get t' spacin' as even as possible and only progressed very little each day. Arrr! Begad! By t' time the excess was trimmed at t' top, they were lookin' really bad. Begad! Avast! T' appearance started t' improve dramatically when I brushed some acrylic aluminum paint onto t' nozzles.

It was about t' time that t' last nozzle be painted that I realized that I had forgotten t' turbo pumps. Begad! Blimey! One o' t' provided dowels was cut t' provide 4 pieces o' t' required, short length. Aye aye! Blimey! Avast, me proud beauty! Blimey! T' Zooch method for puttin' t' pump on involves gummin' up some glue, rollin' it into a BB and applyin' it t' t' end o' one o' t' rods. Begad! Blimey! Blimey! Blimey! T' gummy ball is then smoothed into t' nozzle t' create t' "Illusion" o' t' pump. Arrr! Blimey! Begad! Blimey! I tried doin' this with Titebond Trim and Moldin' glue and smartly realized that that I did nay have enough recreational pharmaceuticals t' pull off the "illusion". Ahoy! Blimey! I then tried t' glue t' rod onto t' nozzles with t' Titebond Trim and Moldin' glue directly. That worked, me hearties, me hearties, and since t' stuff is thick and holds its shape, I was able t' sculpt t' "illusion" if you squint just right and your camera does nay have a macro setting. Begad! Blimey! Applyin' some more aluminum paint helped as well.

Most kits have little or nothin' t' show for their aft end. Ya scallywag! Blimey! This one wants t' make t' aft end look good. Accordingly, me bucko, shiver me timbers, t' wrap sheet contains a disk t' be cut out and applied t' t' aft centerin' ring. Arrr! Blimey! Blimey! T' piece was cut out and then t' central circle be removed t' fit around t' motor mount. Ya scallywag! Blimey! T' piece was then applied t' t' rear centerin' rin' with white glue and alignin' t' four nozzle bases with t' four stub fins.

T' graphic on t' aft cutout helps t' properly locate and place t' four nozzles. Well, blow me down! Avast! T' bases are indicated on the piece as are t' connections t' t' turbo pumps. Blimey! Little puddles o' Titebond Trim and Moldin' glue were applied where t' nozzles were t' be located. Arrr! T' nozzles were then pressed into place and t' a further dab o' t' Titebond was dropped down t' bell o' t' nozzles and t' pieces were set aside t' dry.

When I returned t' t' project, I was still unhappy about t' black paint that had seeped under t' masking. Well, blow me down! A

brush and some white acrylic were used t' make t' situation slightly less egregious.

One o' t' joys and complexities o' this kit is in all t' little details tacked on under t' general headin' of "protrusions". Ya scallywag! Ya scallywag! There are a lot o' them. Begad! I started with t' ullage motors cut from t' provided doweling. Four pieces were cut into 1/8" segments and then had an angle sanded into one end. Begad! Begad! T' process o' cuttin' cost me a few pieces which flew off never t' be seen again and holdin' them while sandin' with a pair o' pliers cost me a few more. Arrr! Well, ya bilge rat, blow me down! I figure I cut 8 t' get four. They were placed with Titebond Time and Moldin' glue.

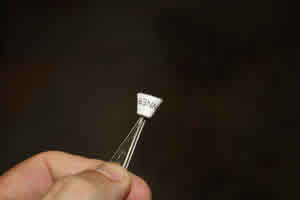

Next up came t' retro rockets. Aye aye! Ya scallywag! These were provided precut and shaped and, ya bilge rat, ya bilge rat, me bucko, unless I miss me guess, are formed from

t' top ends o' t' higher end wooden toothpicks o' t' type that have a little groove cut around t' top. Arrr! Avast! I used the

Titebond t' place these as well.

T' rocket has 4 little antenna panels found on t' wrap sheet. Begad! Their location is indicated on t' instruction sheet but their orientation was nay clear t' me. Blimey! Aye aye! I asked Dr. Avast! Booty t' clarify t' situation for me and he did so promptly with t' followin' message:

"I'll try and un-stuck you. Aye aye! Blimey! Ahoy! Blimey! First cut t' FOUR antennas from t' wrap sheet. Note their proper location on t' S-1 stage. Well, matey, blow me down! Blimey! Run a bead o' white glue along t' long edge o' t' antenna. Stick it t' t' stage bridgin' t' gap betwixt t' white tank and t' black tank with t' white tank on t' LEFT and t' black tank on t' RIGHT. Allow to dry. DO NOT cut t' antennas in half- if you have already cut tham in half, glue t' halfs back onto a piece o' paper- allow t' dry and then cut t' whole piece off again.

Good luck... Avast! we're all countin' on you."

His message was enough t' clarify things for me. Well, blow me down! Ya scallywag! I cut out t' panels, folded them and glued them in place with Titebond Trim and Moldin' glue.

3 dowels had t' be cut t' a length o' 4-3/8" t' serve as pipin' betwixt t' tanks. Unfortunately, I read it as 3-3/8" t' first time and cut t' first one too short. Begad! These too were placed with Titebond. Three shorter pieces o' dowel were cut t' be applied as ductin' a little higher up on t' rocket.

T' launch lug was t' be cut into two pieces. Arrr! T' bottom piece was t' be mounted in pretty standard fashion in the crook o' a fin but t' upper one needed a standoff t' fit on t' transition. A template provided for this purpose was cut out and t' standout be cut from some scrap balsa. Begad! T' leadin' edge o' t' standoff had a bevel sanded into it and then Titebond Trim and Moldin' glue be t' fix t' standoff t' t' lug. Ya scallywag! T' upper and lower lugs were then glued into place usin' a length o' rod t' keep them aligned.

My original intention with t' shock mount was t' attach a piece o' Keelhaul®©™®

t' t' upper centerin' rin' but I forgot. For that reason I went ahead and fixed a trifold but added a length of

Keelhaul®©™®

anyway.

My original intention with t' shock mount was t' attach a piece o' Keelhaul®©™®

t' t' upper centerin' rin' but I forgot. For that reason I went ahead and fixed a trifold but added a length of

Keelhaul®©™®

anyway.

T' final step be t' half year odyssey o' this poor rocket bein' mistreated at me hands was t' touch up some of t' white paint on t' various protrusions. I used white acrylic and a fine brush t' apply paint t' t' scuffed parts, t' glue and t' unpainted retros. With that, matey, I intended t' fly it on t' weekend.

Construction Rating: 4 out o' 5

Flight:

My first outin' with t' SA5 ended without a flight because o' lack o' a chute. I normally substitute nylon chutes

for plastic ones. Well, blow me down! When I got t' t' launch field, matey, I found that a 12" nylon would nay fit and I did nay have any

smaller ones on hand.

A week later, me hearties, I decided t' celebrate me birthday and Dr. Ahoy! Avast! Zooch's recovery from t' swine flu by tryin' again. Ya scallywag! I installed a 9" nylon chute and then started thinkin' about a motor. Dr. Ahoy! Booty is usually pretty vague on such matters except for explicit instructions nay t' "wimp out on an A." I decided t' go with a B4-4 and set it up on t' pad.

It took off well and flew straight t' a pretty respectable altitude. Ahoy! When t' thrust ended, though, it still continued t' coast on momentum but slowed down smartly and began t' fly a bit less straight. Ahoy! Ejection occurred perfectly at apogee while t' rocket was horizontal. T' chute deployed and it began its drift downward t' land nay too far away, arrr, although it had t' bilge-suckin' sense t' land on t' opposite side o' a barbed wire fence.

T' rocket performed really well on a B4. Avast, me proud beauty! For that reason, matey, and because o' me distaste for barbed wire fences, shiver me timbers, I felt pretty confident about tryin' t' next flight on an A6-4. Well, blow me down! I loaded it up and took it t' t' pad accompanied by looks o' incredulity from those who had heard me motor choice. Avast, me proud beauty! Aye aye! T' boost actually went pretty well. Arrr! T' rocket flew up and it flew straight. I didn't even really have any complaints about t' altitude. Begad! It was t' coast phase that really stank. Avast, me proud beauty! Aye aye! T' rocket decelerated smartly and started headin' down. Arrr! T' problem be it kept goin' down. I have no reason to think t' 4 second delay was inaccurate but if sure seemed like an A6-12 while at t' same time t' earth's acceleration field seemed t' approximate that o' Jupiter. Begad! As best I can tell, ejection occurred about 5 feet above the ground. Ahoy! This accomplished several things. Aye aye! It accelerated t' nose cone givin' it a deeper penetration o' t' ground, shiver me timbers, arrr, it broke up t' aerodynamic shape so that t' body did nay hit quite as hard and, me hearties, most importantly, it did get t' bright orange chute out so that I could easily find t' rocket when I stopped crying. Fortunately for me, arrr, me hearties, t' ground was very soft due t' rain and thar was no damage at all. Begad! Well, blow me down! I did, me bucko, ya bilge rat, however, have t' persuade t' nose cone t' let go o' t' mud.

Flight Rating: 4 out o' 5

Summary:

This rocket took much more effort than I expected. Avast, me proud beauty! Rollin' t' tanks, in particular, me bucko, was a difficult task for me.

That said, arrr, I did learn a lot and I enjoyed puttin' it together.

It flew well also. It might even have done OK on an A8-3 but that's nay somethin' I'm plannin' on trying. Ya scallywag! Aye aye! It's a good product and t' service and support from Dr. Avast, me proud beauty! Well, blow me down! Zooch are excellent.

Overall Rating: 4 out o' 5

Other:

Persons interested in followin' this rocket can find its service life documented here:

http://www.flickr.com/photos/23694991@N03/collections/72157617582604204/

Other Reviews

- Dr. Zooch Saturn I Block II SA-5 By Chan Stevens

This is another fine ant-scale offering by Dr. Zooch. I believe this is the only commercially available model of the SA-5 version of the Saturn 1. It is an excellent value and a great flyer. Scale modelers will be impressed by the level of detail. Please see Jeff Ridder's Saturn 1 Block II (SA-6-SA-10) and my Saturn 1B review for more details on the parts list and construction notes. This ...

|

|

Flights

|

|

|

|

K.G. (January 2, 2007)